ASTM D5762-02

(Test Method)Standard Test Method for Nitrogen in Petroleum and Petroleum Products by Boat-Inlet Chemiluminescence

Standard Test Method for Nitrogen in Petroleum and Petroleum Products by Boat-Inlet Chemiluminescence

SCOPE

1.1 This test method covers the determination of nitrogen in liquid hydrocarbons, including petroleum process streams and lubricating oils in the concentration range from 40 to 10 000 μg/g nitrogen. For light hydrocarbons containing less than 100 μg/g nitrogen, Test Method D 4629 can be more appropriate.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 6, 7.1, 8.2, and 8.2.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 5762 – 02

Standard Test Method for

Nitrogen in Petroleum and Petroleum Products by Boat-Inlet

1

Chemiluminescence

This standard is issued under the fixed designation D 5762; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * by a photomultiplier tube, and the resulting signal is a measure

of the nitrogen contained in the sample.

1.1 This test method covers the determination of nitrogen in

liquid hydrocarbons, including petroleum process streams and

4. Significance and Use

lubricating oils in the concentration range from 40 to 10 000

4.1 Many nitrogen compounds can contaminate refinery

µg/g nitrogen. For light hydrocarbons containing less than 100

catalysts.They tend to be the most difficult class of compounds

µg/g nitrogen, Test Method D 4629 can be more appropriate.

to hydrogenate, so the nitrogen content remaining in the

1.2 The values stated in SI units are to be regarded as the

product of a hydrotreator is a measure of the effectiveness of

standard. The values given in parentheses are for information

the hydrotreating process. In lubricating oils the concentration

only.

of nitrogen is a measure of the presence of nitrogen containing

1.3 This standard does not purport to address all of the

additives. This test method is intended for use in plant control

safety concerns, if any, associated with its use. It is the

and in research.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Apparatus

bility of regulatory limitations prior to use. Specific hazard

5.1 Boat Inlet System, capable of being sealed to the inlet of

statements are given in Section 6, 7.1, 8.2, and 8.2.2.

the combustion tube and swept with inert gas. The boats are

2. Referenced Documents fabricated from platinum or quartz. To aid quantitative liquid

injection,addasmallpieceofquartzwooltotheboat.Theboat

2.1 ASTM Standards:

drive mechanism should be able to fully insert the boat into the

D 4052 Test Method for Density and Relative Density of

2 furnace tube inlet section. A drive mechanism that advances

Liquids by Digital Density Meter

and withdraws the sample boat into and out of the furnace at a

D 4057 Practice for Manual Sampling of Petroleum and

2 controlled and repeatable rate is required.

Petroleum Products

5.2 Chemiluminescence Detector, capable of measuring

D 4177 Practice for Automatic Sampling of Petroleum and

2 light emitted from the reaction between nitric oxide and ozone,

Petroleum Products

and containing a variable attenuation amplifier, integrator, and

D 4629 Test Method for Trace Nitrogen in Liquid Petro-

readout.

leum Hydrocarbons by Syringe/Inlet Oxidative Combus-

2

tion and Chemiluminescence Detection

NOTE 1—Detectors designed to maintain the chemiluminescence reac-

tion cell at reduced pressure are acceptable for use and were included in

3. Summary of Test Method

the instruments used to determine the precision of this test method.

3.1 A hydrocarbon sample is placed on a sample boat at

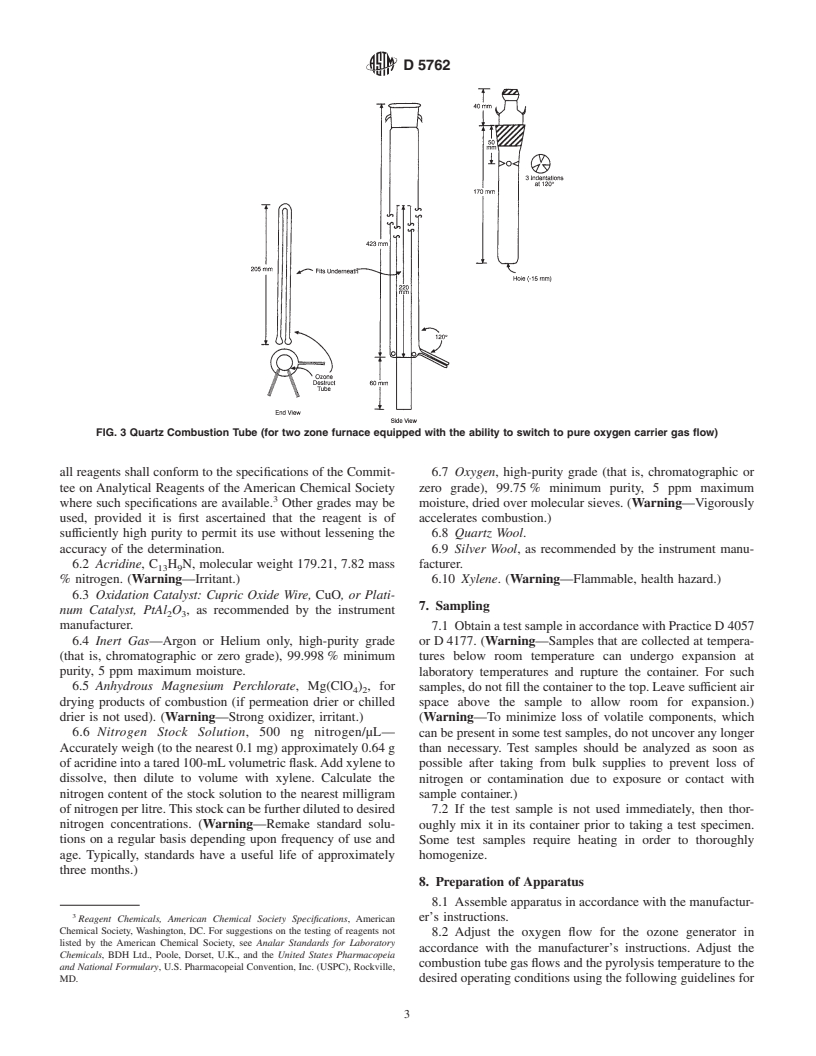

5.3 Combustion Tube, fabricated from quartz. The inlet end

room temperature. The sample and boat are advanced into a

of the tube shall be large enough to accept the sample boat and

high-temperature combustion tube where the nitrogen is oxi-

to have side arms for introduction of oxygen and inert gas.The

dized to nitric oxide (NO) in an oxygen atmosphere. The NO

construction is such that the carrier gases sweep the inlet zone

contacts ozone and is converted to excited nitrogen dioxide

transporting all of the volatilized sample into a high-

(NO ). The light emitted as the excited NO decays is detected

2 2

temperature oxidation zone. The oxidation section should be

large enough to ensure complete oxidation of the sample.

Combustion tubes recommended for the two furnaces in 5.5.1

1

and 5.5.2 are described in 5.3.1 and 5.3.2. Other configurations

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

are acceptable if precision and bias are not degraded.

D02.03 on Elemental Analysis.

5.3.1 Quartz combustion tube for use with the single-zone

Current edition approved April 10, 2002. Published June 2002. Originally

furnace is illustrated in Fig. 1. A water-jacket around the inlet

published as D 5762 – 95. Last previous edition D 5762 – 01.

2

Annual Book of ASTM Standards, Vol 05.02. section can be used to cool the boat prior to sample injection.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.