ASTM D1708-06a

(Test Method)Standard Test Method for Tensile Properties of Plastics by Use of Microtensile Specimens

Standard Test Method for Tensile Properties of Plastics by Use of Microtensile Specimens

SCOPE

1.1 This test method covers certain material specifications for which a history of data has been obtained using the standard microtensile specimen. The specimen geometry has been changed to be equivalent to that of ISO 12086-2:1955. In general, this test method is superseded for general use by either Test Methods D 882 or Test Method D 638. The very small Type V specimen in Test Method D 638 is the recommended specimen when limited amounts of material are available.

1.2 This test method covers the determination of the comparative tensile strength and elongation properties of plastics in the form of standard microtensile test specimens when tested under defined conditions of pretreatment, temperature, humidity, and testing machine speed. It can be used for specimens of any thickness up to 3.2 mm [1/8 in.], including thin films.

1.3 This test method cannot be used for the determination of modulus of elasticity. For the determination of modulus, see Test Method D 638 or Test Methods D 882.

1.4 Test data obtained by this test method are relevant and appropriate for use in engineering design.

1.5 The values stated in SI units are to be regarded as standard. The values given in brackets are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

There is no equivalent or similar ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D1708–06a

Standard Test Method for

Tensile Properties of Plastics by Use of Microtensile

1

Specimens

This standard is issued under the fixed designation D1708; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* D638 Test Method for Tensile Properties of Plastics

D882 Test Method for Tensile Properties of Thin Plastic

1.1 This test method covers certain material specifications

Sheeting

forwhichahistoryofdatahasbeenobtainedusingthestandard

D883 Terminology Relating to Plastics

microtensile specimen. The specimen geometry has been

D4000 Classification System for Specifying Plastic Materi-

changed to be equivalent to that of ISO 12086-2:1955. In

als

general,thistestmethodissupersededforgeneralusebyeither

E691 Practice for Conducting an Interlaboratory Study to

TestMethodsD882orTestMethodD638.TheverysmallType

Determine the Precision of a Test Method

V specimen in Test Method D638 is the recommended speci-

2.2 ISO Standard:

men when limited amounts of material are available.

ISO 12086-2:1995 Plastics—Fluoropolymer Dispersion,

1.2 This test method covers the determination of the com-

Moulding, and Extrusion Materials—Part 2 Preparation of

parativetensilestrengthandelongationpropertiesofplasticsin

3

Test Specimens and Determination of Properties

the form of standard microtensile test specimens when tested

under defined conditions of pretreatment, temperature, humid-

3. Terminology

ity, and testing machine speed. It can be used for specimens of

3.1 Definitions: Definitions of terms applying to this test

1

any thickness up to 3.2 mm [ ⁄8 in.], including thin films.

method appear in Terminology D883 and Test Method D638,

1.3 Thistestmethodcannotbeusedforthedeterminationof

Annex A2.

modulus of elasticity. For the determination of modulus, see

Test Method D638 or Test Methods D882.

4. Significance and Use

1.4 Test data obtained by this test method are relevant and

4.1 This test method provides data for quality control and

appropriate for use in engineering design.

acceptance or rejection under specifications.

1.5 The values stated in SI units are to be regarded as

4.2 Before proceeding with this test method, reference

standard.Thevaluesgiveninbracketsareforinformationonly.

should be made to the ASTM specification of the material

1.6 This standard does not purport to address all of the

being tested. Any test specimen preparation, conditioning,

safety concerns, if any, associated with its use. It is the

dimensions, or testing parameters, or combination thereof,

responsibility of the user of this standard to establish appro-

covered in the materials specification shall take precedence

priate safety and health practices and determine the applica-

over those mentioned in this test method. If there are no

bility of regulatory limitations prior to use.

material specifications, then the default conditions herein

NOTE 1—There is no equivalent or similar ISO standard.

apply. Table 1 of Classification System D4000 lists theASTM

materials standards that currently exist.

2. Referenced Documents

2

2.1 ASTM Standards: 5. Apparatus

D618 Practice for Conditioning Plastics for Testing

5.1 The apparatus shall be as specified in Test Method

D638, with the following exceptions:

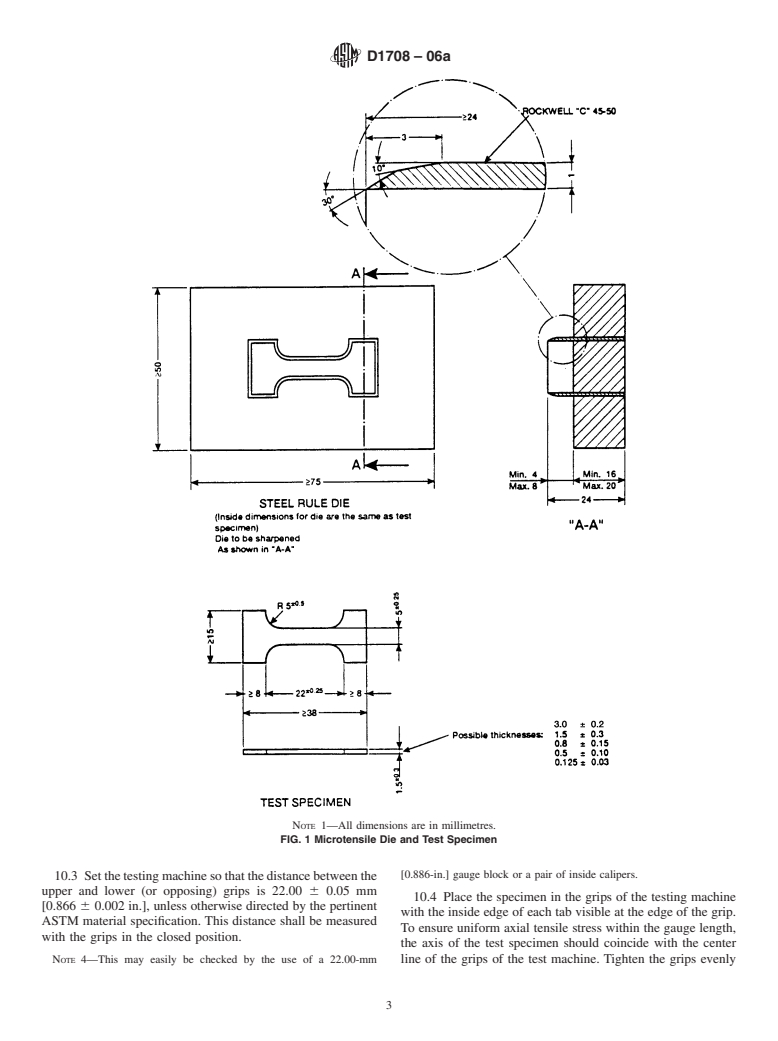

5.1.1 Grips—Serrated grips faces should be used with care,

1

since yielding or tearing at the grips may interfere with

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

measurement of elongation even when the specimen breaks in

Current edition approved Nov. 1, 2006. Published November 2006. Originally

the reduced section. Grips with rubber coated faces are

approved in 1959. Last previous edition approved in 2006 as D1708 - 06. DOI:

recommended for thin specimens. Care should be taken when

10.1520/D1708-06A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute, 25 W. 43rd St., 4th

the ASTM website. Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1708–06a

TABLE 1 Tensile Strength at Break for Seven Laboratories and Shims

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.