ASTM F2980-13

(Test Method)Standard Test Method for Analysis of Heavy Metals in Glass by Field Portable X-Ray Fluorescence (XRF)

Standard Test Method for Analysis of Heavy Metals in Glass by Field Portable X-Ray Fluorescence (XRF)

SIGNIFICANCE AND USE

5.1 Waste glass is currently recycled into various consumer products. This test method has been developed as a tool for evaluation of heavy metals in glass to satisfy reporting requirements for maximum allowable content for some applications.

5.2 The ranges within which this test method is quantitative are given in Table 1.

5.3 For amounts of the analyte elements outside the ranges in Table 1, this test method provides screening results. That is, it provides an unambiguous indication that each element can be described as present in an amount greater than the scope upper limit or that the amount of the element can be described as less than the scope lower limit with a high degree of confidence.Note 2—In general, when a quantitative result is obtained, the analyst can make a clear decision as to whether a material is suitable for the intended purpose. When the contents of elements of interest are outside the quantitative range, the analyst can still make a decision whether the amount is too high or whether additional analyses are required.

5.4 These methods can be applied to glass beads, plate glass, float glass, fiber glass, or ground glass. This test method has been validated for the ranges of matrix compositions that are summarized in Table 2.

5.5 Detection limits, sensitivity, and element ranges will vary with matrices, detector type, and other instrument conditions and parameters.

5.6 All analytes are determined as the element and reported as such. These include all elements listed in Table 1. This test method may be applicable to other glass matrices, additional elements, and wider concentration ranges provided the laboratory is able to validate the broadened scope of this test method.

SCOPE

1.1 This test method covers field portable X-ray fluorescence (XRF) spectrometric procedures for analyses of arsenic and lead in glass compositions using field portable energy dispersive XRF spectrometers.

1.2 The mass fraction range of arsenic within which this test method is quantitative is given in Table 1. Scope limits were determined from the interlaboratory study results using the approach given in Practice E1601.

1.3 The mass fraction range for which lead was tested is given in Table 1. However, lead results cannot be considered quantitative on the basis of single-sample results because the precision performance is not good enough to allow laboratories to compare results in a quantitative manner.Note 1—The performance of this test method was evaluated using results based on single-sample determinations from specimens composed of glass beads. One laboratory has determined that performance can be significantly improved by basing reported results on the mean of determinations from multiple samples to overcome inherent heterogeneity of elements in glass beads, especially the element lead. Additional information is provided in Section 17 on Precision and Bias.

1.3.1 To obtain quantitative performance, lead results must consist of the average of four or more determinations.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Some specific hazards statements are given in Section 7 on Hazards.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2980 − 13

Standard Test Method for

Analysis of Heavy Metals in Glass by Field Portable X-Ray

Fluorescence (XRF)

This standard is issued under the fixed designation F2980; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers field portable X-ray fluores-

2.1 ASTM Standards:

cence (XRF) spectrometric procedures for analyses of arsenic

D75/D75M Practice for Sampling Aggregates

and lead in glass compositions using field portable energy

D6299 Practice for Applying Statistical Quality Assurance

dispersive XRF spectrometers.

and Control Charting Techniques to Evaluate Analytical

Measurement System Performance

1.2 Themassfractionrangeofarsenicwithinwhichthistest

E29 Practice for Using Significant Digits in Test Data to

method is quantitative is given in Table 1. Scope limits were

Determine Conformance with Specifications

determined from the interlaboratory study results using the

E135 Terminology Relating to Analytical Chemistry for

approach given in Practice E1601.

Metals, Ores, and Related Materials

1.3 The mass fraction range for which lead was tested is

E177 Practice for Use of the Terms Precision and Bias in

given in Table 1. However, lead results cannot be considered

ASTM Test Methods

quantitative on the basis of single-sample results because the

E691 Practice for Conducting an Interlaboratory Study to

precisionperformanceisnotgoodenoughtoallowlaboratories

Determine the Precision of a Test Method

to compare results in a quantitative manner.

E1361 Guide for Correction of Interelement Effects in

X-Ray Spectrometric Analysis

NOTE 1—The performance of this test method was evaluated using

results based on single-sample determinations from specimens composed

E1601 Practice for Conducting an Interlaboratory Study to

of glass beads. One laboratory has determined that performance can be

Evaluate the Performance of an Analytical Method

significantly improved by basing reported results on the mean of deter-

E1621 Guide for ElementalAnalysis by Wavelength Disper-

minations from multiple samples to overcome inherent heterogeneity of

sive X-Ray Fluorescence Spectrometry

elements in glass beads, especially the element lead. Additional informa-

tion is provided in Section 17 on Precision and Bias.

F2576 Terminology Relating to Declarable Substances in

Materials

1.3.1 To obtain quantitative performance, lead results must

consist of the average of four or more determinations.

2.2 ANSI Standard:

N43.2 Radiation Safety for X-Ray Diffraction and Fluores-

1.4 The values stated in SI units are to be regarded as

cence Analysis Equipment

standard. No other units of measurement are included in this

standard.

2.3 AASHTO Standard:

TP-97-11 Test Method for Glass Beads used in Pavement

1.5 This standard does not purport to address all of the

Markings

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Some specific 2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

hazards statements are given in Section 7 on Hazards. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This test method is under the jurisdiction of ASTM Committee F40 on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Declarable Substances in Materials and is the direct responsibility of Subcommittee 4th Floor, New York, NY 10036, http://www.ansi.org.

F40.01 on Test Methods. Available from American Association of State Highway and Transportation

Current edition approved Feb. 15, 2013. Published March 2013. DOI: 10.1520/ Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

F2980-13. http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2980 − 13

TABLE 1 Scope Ranges for Quantitative Results

convenient laboratory use. The two measurement options are

Element Scope Lower Limit (mg/ Scope Upper Limit (mg/ discussed throughout this test method.

kg) kg)

Arsenic 240 2000

5. Significance and Use

Lead 120 500

5.1 Waste glass is currently recycled into various consumer

products. This test method has been developed as a tool for

evaluation of heavy metals in glass to satisfy reporting require-

3. Terminology

ments for maximum allowable content for some applications.

3.1 Definitions—Definitions of terms applying to X-ray

5.2 The ranges within which this test method is quantitative

fluorescence (XRF) and declarable substances appear in Ter- are given in Table 1.

minologies E135 and F2576, respectively.

5.3 For amounts of the analyte elements outside the ranges

3.2 Compton-matrix correction, n—measured intensity of

in Table 1, this test method provides screening results. That is,

Comptonorincoherentscatteredradiationmaybeuseddirectly

itprovidesanunambiguousindicationthateachelementcanbe

to compensate for matrix effects or indirectly for the determi-

described as present in an amount greater than the scope upper

nationoftheeffectivemassabsorptioncoefficienttocorrectfor

limit or that the amount of the element can be described as less

matrix effects.

than the scope lower limit with a high degree of confidence.

NOTE 2—In general, when a quantitative result is obtained, the analyst

3.2.1 Discussion—The compensation for matrix effects is

can make a clear decision as to whether a material is suitable for the

based on a combination of sample preparation and experimen-

intended purpose. When the contents of elements of interest are outside

tal intensity data. the quantitative range, the analyst can still make a decision whether the

amount is too high or whether additional analyses are required.

3.3 Compton scatter, n—inelastic scattering of an X-ray

photon through its interaction with the bound electrons of an

5.4 These methods can be applied to glass beads, plate

atom.

glass, float glass, fiber glass, or ground glass. This test method

has been validated for the ranges of matrix compositions that

3.3.1 Discussion—This process is also referred to as inco-

are summarized in Table 2.

herent scatter.

5.5 Detection limits, sensitivity, and element ranges will

3.4 fundamental parameters, FP, model, n—model for cali-

bration of X-ray fluorescence response, including the correc- vary with matrices, detector type, and other instrument condi-

tions and parameters.

tion of matrix effects, based on the theory describing the

physical processes of the interactions of X-rays with matter.

5.6 All analytes are determined as the element and reported

3.5 Acronyms: as such. These include all elements listed in Table 1. This test

method may be applicable to other glass matrices, additional

3.5.1 EDXRF—Energy dispersive X-ray fluorescence

elements, and wider concentration ranges provided the labora-

3.5.2 QC—Quality control

tory is able to validate the broadened scope of this test method.

3.5.3 XRF—X-ray fluorescence

6. Interferences

4. Summary of Test Method

6.1 Spectral Interferences—These can occur for some ele-

4.1 Portablehandheldinstrumentsareusedtomeasureglass

ments as a result of partial or total line overlaps. These line

spheres, ground glass, cullet, fiberglass, and sheet glass for

overlaps can result from scattered characteristic lines from the

their contents of arsenic and lead. Samples of sheet glass can

targetoftheX-raytubeorbyX-rayfluorescencefromatomsin

be measured directly. Samples that are not in sheet form are

the specimen. Spectral interference can also be the result of

measured as is or after pulverizing to an appropriate particle

escape peaks from the solid-state detector. See Guide E1621

size.

for a full discussion of models used to correct for these effects.

4.2 The samples of glass spheres or powders may be placed

In this particular case, the most obvious line overlap is the

into disposable cups with a polymer film supporting the glass.

overlap of As K-L (As Kα ; 10.53 keV) on Pb L -M (Pb

2,3 1,2 3 5

The filled cup is measured from below through the polymer

Lα ;10.55keV)andviceversa.Theenergydifferencebetween

film.

these two lines is about 0.02 keV, which cannot be resolved

with the detectors used. The emission lines of these two

4.3 The glass specimen may be analyzed in situ by using a

elements will appear as a single peak. However, both As and

handheldspectrometerpositionedincontactwithsheetglassor

Pb have alternative lines that can be used for analysis. For Pb,

the contents of a larger container, for example, a bulk shipping

container.

4.4 The handheld XRF may be used while the operator is

TABLE 2 Matrix Components and Ranges

holding the unit or by being mounted in a stand for safer, more

Oxide Scope Lower Limit, % Scope Upper Limit, %

SiO 58 80

Al O 110

2 3

Andermann, G. and Kemp, J. W., “Scattered X-rays as Internal Standards in

NaO3 15

X-Ray Spectroscopy,” Analytical Chemistry, Vol 20, No. 8, 1958.

CaO 6 20

The algorithm used for the procedure is usually implemented in the instrument MgO 1 5

manufacturer’s software. Third-party software is available and may be used.

F2980 − 13

the use of the doublet Pb L -M ,N (Pb Lβ ; 12.61 keV) is 7.1.3 Signal conditioning and data-handling electronics in-

2,3 4 5 1,2

highly recommended. This line has virtually the same sensi- clude the functions of X-ray counting and peak processing.

tivity as the Pb L -M line. For As, the As K-M (As Kβ ;

3 5 2,3 1,3

7.2 The following spectrometer features and accessories are

11.72 keV) can be used; its sensitivity is about 20 % of the

optional.

more intenseAs K-L line. It is possible to determine the net

2,3

7.2.1 Beam Filters—used to make the excitation more

intensity of Pb L -M based on the intensity of Pb L -M ,N

3 5 2,3 4 5

selective and reduce background count rates.

(this implies determining a proportionality factor between the

7.2.2 Drift Correction Monitor(s)—Because of instability of

two lines on specimens with no or varying amounts of As).

the measurement system, the sensitivity and background of the

This can then be used to calculate the intensity of As K-L .

2,3

spectrometer may drift with time. Drift correction monitors

6.2 In EDXRF, the possibility exists that two photons are may be used to correct for this drift. The optimum drift

seen and treated as a single one by the counting electronics. correction monitor specimens are permanent materials that are

When that happens, they appear as a single photon with an stable with time and repeated exposure to X-rays.

energy corresponding to the sum of the energies of the

7.3 Reference Materials:

individual photons. This phenomenon is called the sum-peak.

7.3.1 Purchased certified reference materials, and

For this effect to be significant, the total count rate must be

7.3.2 In-house reference materials that were analyzed by at

high; and (at least) one element must be present at a relatively

least two independent methods.

high level; and the element concerned must have a high yield.

7.4 Consumables:

In the current method, the presence of e.g. iron at high levels

7.4.1 Disposable latex or nitrile gloves,

could lead to a sum-peak of 2 Fe K-L3 (6.4 keV) photons, with

7.4.2 Methanol or isopropyl alcohol,

an energy of about 12.6- 12.8 keV - this corresponds to the

7.4.3 Deionized water,

energy of Pb L -M ,N . The software provided by the

2,3 4 5

7.4.4 XRF sample cups,

manufacturer must correct for this effect; otherwise the inten-

7.4.5 Lint-free wipes, and

sity (and thus the contents) of Pb L -M ,N is overestimated.

2,3 4 5

7.4.6 Polymer film, including, but not limited to polyimide,

6.3 Matrix Interferences—Some of the X-rays generated

polyester, and polypropylene.

within the sample will interact with atoms in the matrix. As a

result of such interactions, the emitted intensity of the analyte

8. Hazards

depends on the amount of the analyte in the sample and, to a

8.1 Safety practices shall conform to applicable local, state,

lesser, but measurable degree, on the amounts of other ele-

and national regulations. For example, personal monitoring

ments. The magnitude of such matrix interferences is most

devices and periodic radiation surveys may be required.

pronounced for elements that are present in high concentra-

8.2 Dust Mask—When this test method is performed on

tions. Several mathematical models, such as the fundamental

powder samples, it may be advisable to use a dust mask.

parameter model, exist for the correction of such effects; see

Guide E1361 for a full discussion. Typically, these matrix

8.3 Gloves—The use of powder-free polymer gloves is

correction models require that the net intensities are free from

recommended to prevent contamination of sample surfaces by

line overlap effects. In practice, the approach chosen depends

body oils and other substances.

upon the manufacturer.

9. Sampling

6.4 Float glass is heterogeneous because one side is coated

9.1 Usersshoulddevelopplanstodetermineifthemeasured

with tin. Differential absorption can bias the results.

specimens are representative of a larger quantity of material.

7. Apparatus

Refer to AASHTO TP-97-11 or Practice D75/D75M for

7.1 EDXRF Spectrometer—designed for X-ray fluorescence examples of sampling procedures for quantities greater than 45

kg.

analysis with energy dispersive selection of radiation. Any

EDXRF spectrometer can be used if its design incorporates the

9.2 For laboratories having small quantities of material,

following features.

three replicate measurements may be taken to obtain informa-

7.1.1 Source of X-Ray Excitation—capable of exciting the

tiononhomogeneity.Iftherangeofthreeresultsisgreaterthan

recommended lines, typically an X-ray tube. The recom-

the repeatability limit of this standard test method, there may

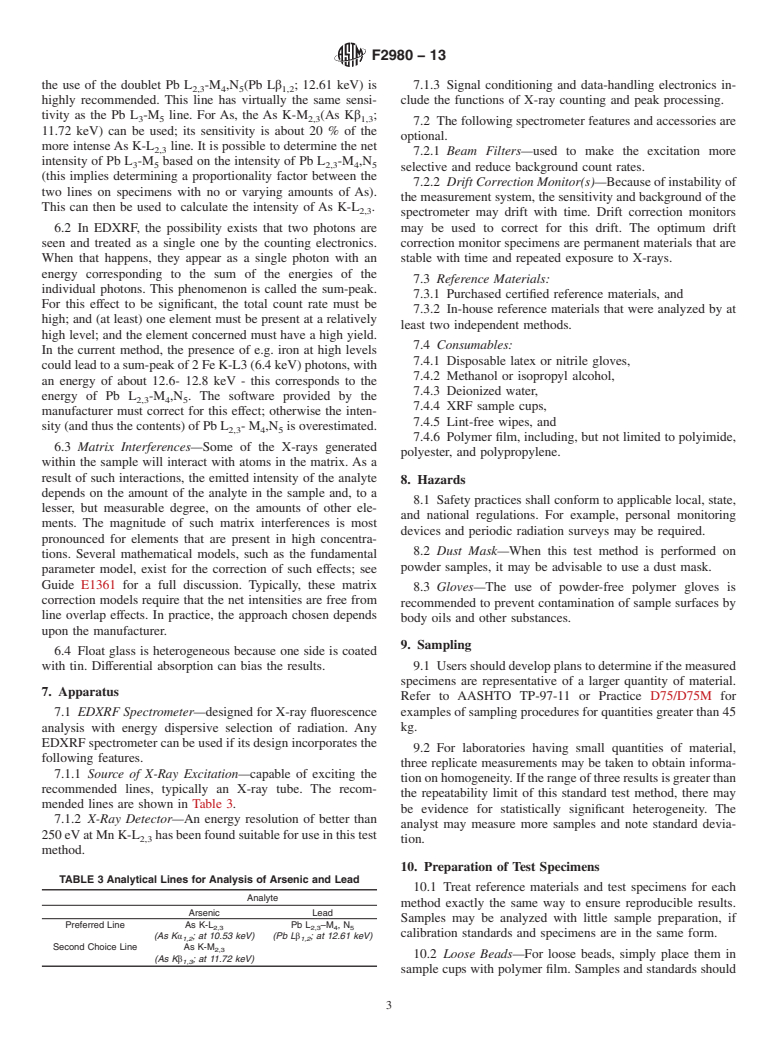

mended lines are shown in Table 3.

be evidence for statistically significant heterogeneity. The

7.1.2 X-Ray Detector—An energy resolution of better than

analyst may measure more samples and note standard devia-

250eVatMnK-L hasbeenfoundsuitableforuseinthistest

2,3

tion.

method.

10. Preparation of Test Specimens

TABLE 3 Analytical Lines for Analysis of Arsenic and Lead

10.1 Treat reference materials and test specimens for each

Analyte

method exactly the same way to ensure reproducible results.

Arsenic Lead

Samples may be analyzed wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.