ASTM D5628-06

(Test Method)Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimens by Means of a Falling Dart (Tup or Falling Mass)

Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimens by Means of a Falling Dart (Tup or Falling Mass)

SCOPE

1.1 This test method covers the determination of the threshold value of impact-failure energy required to crack or break flat, rigid plastic specimens under various specified conditions of impact of a free-falling dart (tup), based on testing many specimens.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 8.

Note 1 - This test method and ISO 6603-1 are technically equivalent only when the test conditions and specimen geometry required for Geometry FE and the Bruceton Staircase method of calculation are used.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5628 – 06

Standard Test Method for

Impact Resistance of Flat, Rigid Plastic Specimens by

1

Means of a Falling Dart (Tup or Falling Mass)

This standard is issued under the fixed designation D5628; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* D4000 Classification System for Specifying Plastic Mate-

rials

1.1 This test method covers the determination of the thresh-

D6779 Classification System for Polyamide Molding and

old value of impact-failure energy required to crack or break

Extrusion Materials (PA)

flat, rigid plastic specimens under various specified conditions

E177 Practice for Use of the Terms Precision and Bias in

of impact of a free-falling dart (tup), based on testing many

ASTM Test Methods

specimens.

E691 Practice for Conducting an Interlaboratory Study to

1.2 The values stated in SI units are to be regarded as the

Determine the Precision of a Test Method

standard. The values in parentheses are for information only.

3

2.2 ISO Standards:

1.3 This standard does not purport to address all of the

ISO 291 Standard Atmospheres for Conditioning and Test-

safety concerns, if any, associated with its use. It is the

ing

responsibility of the user of this standard to establish appro-

ISO 6603-1 Plastics—Determination of Multiaxial Impact

priate safety and health practices and determine the applica-

Behavior of Rigid Plastics—Part 1: Falling Dart Method

bility of regulatory limitations prior to use. Specific hazard

statements are given in Section 8.

3. Terminology

NOTE 1—This test method and ISO6603-1 are technically equivalent

3.1 Definitions:

only when the test conditions and specimen geometry required for

3.1.1 For definitions of plastic terms used in this test

Geometry FE and the Bruceton Staircase method of calculation are used.

method, see Terminologies D883 and D1600.

3.2 Definitions of Terms Specific to This Standard:

2. Referenced Documents

2 3.2.1 failure (of test specimen)—the presence of any crack

2.1 ASTM Standards:

or split, created by the impact of the falling tup, that can be

D374 Test Methods for Thickness of Solid Electrical Insu-

seen by the naked eye under normal laboratory lighting

lation

conditions.

D618 Practice for Conditioning Plastics for Testing

3.2.2 mean-failure energy (mean-impact resistance)—the

D883 Terminology Relating to Plastics

energy required to produce 50% failures, equal to the product

D1600 Terminology for Abbreviated Terms Relating to

of the constant drop height and the mean-failure mass, or, to

Plastics

the product of the constant mass and the mean-failure height.

D1709 Test Methods for Impact Resistance of Plastic Film

3.2.3 mean-failure height (impact-failure height)—the

by the Free-Falling Dart Method

height at which a standard mass, when dropped on test

D2444 Test Method for Determination of the Impact Re-

specimens, will cause 50% failures.

sistance ofThermoplastic Pipe and Fittings by Means of a

Tup (Falling Weight)

NOTE 2—Cracks usually start at the surface opposite the one that is

struck. Occasionally incipient cracking in glass-reinforced products, for

D3763 Test Method for High Speed Puncture Properties of

example, is difficult to differentiate from the reinforcing fibers. In such

Plastics Using Load and Displacement Sensors

cases, a penetrating dye can confirm the onset of crack formation.

3.2.4 mean-failure mass (impact-failure mass)—themassof

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

the dart (tup) that, when dropped on the test specimens from a

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

standard height, will cause 50% failures.

Current edition approved Sept. 1, 2006. Published October 2006. Originally

e1

approved in 1994. Last previous edition approved in 2001 as D5628-96(2001) .

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5628–06

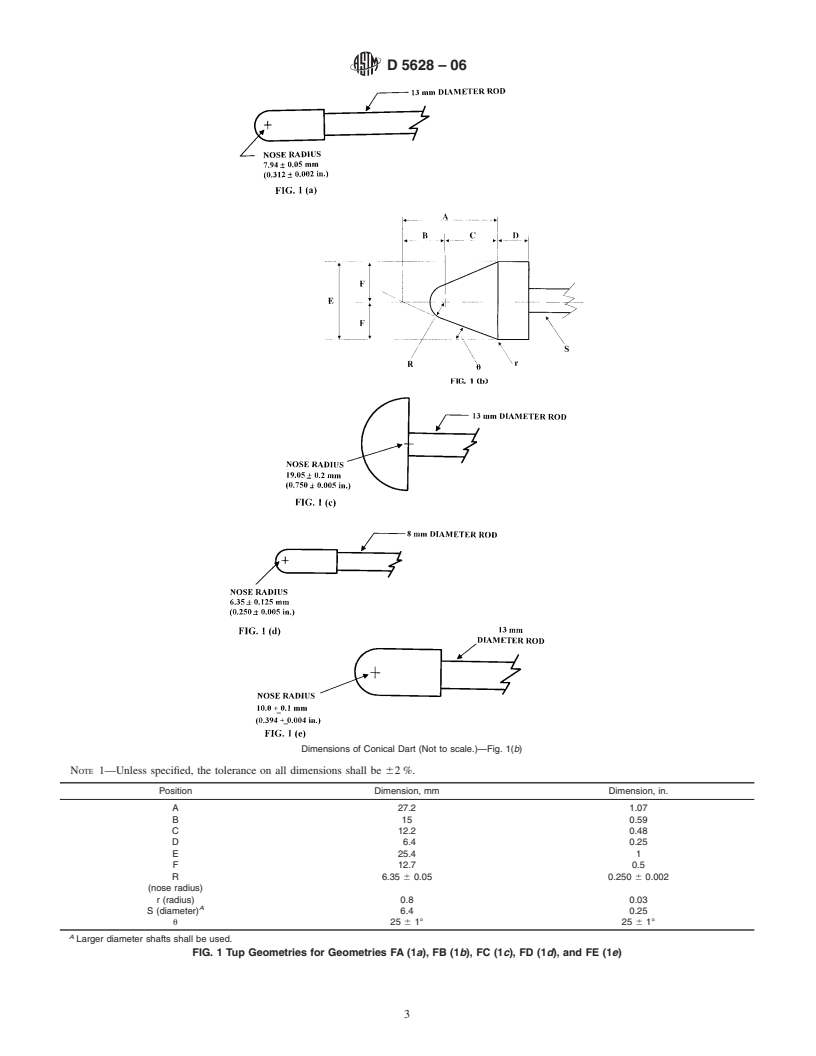

3.2.5 tup—a dart with a hemispherical nose. See 7.2 and been used in specifications for extruded sheeting.Alimitation

Fig. 1. of this geometry is that considerable material is r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.