ASTM D350-96

(Test Method)Standard Test Methods for Flexible Treated Sleeving Used for Electrical Insulation

Standard Test Methods for Flexible Treated Sleeving Used for Electrical Insulation

SCOPE

1.1 These test methods cover procedures for testing electrical insulating sleeving comprising a flexible tubular product made from a woven textile fibre base, such as cotton, rayon, nylon, or glass, thereafter impregnated, or coated, or impregnated and coated, with a suitable dielectric material.

1.2 The procedures appear in the following sections:ProceduresSectionsBrittleness Temperature18 to 22 Compatibility of Sleeving with Magnet Wire Insulation45 to 59 Conditioning6Dielectric Breakdown Voltage12 to 17 Dielectric Breakdown Voltage After Short-Time Aging29 to 33 Dimensions7 to 11 Effect of Push-Back After Heat Aging73 to 78 Flammability22 to 28 Hydrolytic Stability 66 to 72 Oil Resistance34 to 37 Selection of Test Material5Solvent Resistance 60 to 55Thermal Endurance38 to 44

1.3 The values stated in inch-pound units, except for C, are to be regarded as the standard. The values in parentheses are provided for information only.

1.4 This is a fire-test-response standard. See Sections through , which are the procedures for flammability tests.

1.5 These test methods can be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions, but should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment which take into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 45.2 and 63.1.1 .Note 1—This standard resembles IEC 60684-2, Specification for Flexible Insulating Sleeving-Part 2 Methods of Test, in a number of ways, but is not consistently similar throughout. The data obtained using either standard may not be technically equivalent.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 350 – 96 An American National Standard

Standard Test Methods for

Flexible Treated Sleeving Used for Electrical Insulation

This standard is issued under the fixed designation D 350; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope statements, see 45.2 and 63.1.1.

1.1 These test methods cover procedures for testing electri-

2. Referenced Documents

cal insulating sleeving comprising a flexible tubular product

2.1 ASTM Standards:

made from a woven textile fibre base, such as cotton, rayon,

D 149 Test Method for Dielectric Breakdown Voltage and

nylon, or glass, thereafter impregnated, or coated, or impreg-

Dielectric Strength of Solid Electrical Insulating Materials

nated and coated, with a suitable dielectric material.

at Commercial Power Frequencies

1.2 The procedures appear in the following sections:

D 374 Test Methods for Thickness of Solid Electrical Insu-

Procedures Sections

lation

Brittleness Temperature 18 to 21

D 471 Test Method for Rubber Property—Effect of Liq-

Compatibility of Sleeving with Magnet Wire Insulation 45 to 59 3

uids

Conditioning 6

D 618 Practice for Conditioning Plastics and Electrical

Dielectric Breakdown Voltage 12 to 17

Dielectric Breakdown Voltage After Short-Time Aging 29 to 33

Insulating Materials for Testing

Dimensions 7 to 11

D 746 Test Method for Brittleness Temperature of Plastics

Effect of Push-Back After Heat Aging 73 to 78

and Elastomers by Impact

Flammability 22 to 28

Hydrolytic Stability 66 to 72

D 876 Test Methods for Nonrigid Vinyl Chloride Polymer

Oil Resistance 34 to 37

Tubing Used for Electrical Insulation

Selection of Test Material 5

D 2307 Test Method for Relative Thermal Endurance of

Solvent Resistance 60 to 65

Thermal Endurance 38 to 44

Film-Insulated Round Magnet Wire

D 3487 Specification for Mineral Insulating Oil Used in

1.3 The values stated in inch-pound units, except for° C, are

Electrical Apparatus

to be regarded as the standard. The values in parentheses are

D 3636 Practice for Sampling and Judging Quality of Solid

provided for information only.

Electrical Insulating Materials

1.4 This is a fire-test-response standard. See Sections 22

D 5423 Specification for Forced-Convection Laboratory

through 28, which are the procedures for flammability tests.

Ovens for Evaluation of Electrical Insulation

1.5 These test methods can be used to measure and describe

E 145 Specification for Gravity-Convection and Forced-

the properties of materials, products, or assemblies in response

Ventilation Ovens

to heat and flame under controlled laboratory conditions, but

2.2 IEEE Standard:

should not be used to describe or appraise the fire hazard or fire

IEEE 101 Guide for the Statistical Analysis of Thermal Life

risk of materials, products, or assemblies under actual fire

Test Data

conditions. However, results of this test may be used as

elements of a fire risk assessment which take into account all

3. Terminology

of the factors which are pertinent to an assessment of the fire

3.1 Descriptions of Terms Specific to This Standard:

hazard of a particular end use.

3.1.1 flammability—a measure of the rate of travel of a

1.6 This standard does not purport to address all of the

flame down a specimen when ignited and held in a vertical

safety concerns, if any, associated with its use. It is the

position.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific hazard

Annual Book of ASTM Standards, Vol 10.01.

Annual Book of ASTM Standards, Vol 09.01.

Annual Book of ASTM Standards, Vol 08.01.

1 5

These test methods are under the jurisdiction of ASTM Committee D-9 on Annual Book of ASTM Standards, Vol 10.03.

Electrical and Electronic Insulating Materials and are the direct responsibility of Annual Book of ASTM Standards, Vol 10.02.

Subcommittee D09.07 on Flexible and Rigid Insulating Materials. Annual Book of ASTM Standards, Vol 14.02.

Current edition approved March 10, 1996. Published May 1996. Last previous Available from the Institute of Electrical and Electronics Engineers, Inc., 345

edition D 350 – 91. E. 47th St., New York, NY, 10017.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 350

3.1.2 size—a numerical designation which indicates that the sphere of 50 6 5 % relative humidity and 23 6 2°C (73.4 6

inside diameter of the sleeving lies within the limits prescribed 3.6°F) shall be used in conducting all tests and for conditioning

in Table 1. specimens for a period of at least 18 h prior to testing.

3.1.3 wall thickness—one half the difference between the 6.2 In the case of dielectric breakdown voltage tests after

outside diameter of the sleeving mounted on a loosely fitting humidity conditioning, specimens shall be conditioned for 96 h

gage rod and the diameter of the gage rod when measured in in an atmosphere of 93 6 3 % relative humidity and 23 6 2°C

accordance with 9.2. (73.4 6 3.6°F) before testing. If a conditioning cabinet is used,

specimens shall be tested for dielectric breakdown voltage

4. Apparatus and Materials

within 1 min after removal from the cabinet.

4.1 Ovens used in these test methods shall meet the require-

6.3 For details regarding conditioning, refer to Practice

ments of Specification D 5423.

D 618.

5. Selection of Test Material DIMENSIONS

5.1 In the case of sleeving on spools or in coils, not less than

7. Apparatus

three turns of the product shall be removed before the selection

7.1 Gage Rods—Standard gage rods shall be made of steel

of material from which test specimens are to be prepared.

and shall have smooth surfaces and rounded edges. One rod is

5.2 In the case of sleeving offered in cut lengths, test

required for each of the maximum and minimum diameters

specimens shall not be prepared from material closer than 1 in.

shown in Table 1 for each size. Each rod shall be within

(25 mm) from each end.

60.005 in. (66.012 mm) of the values shown in Table 1.

5.3 Specimens for test shall not show obvious defects unless

8. Test Specimens

the purpose of the test is to determine the effect of such defects.

5.4 Specimens shall be prepared from samples selected in

8.1 Five test specimens of at least 7 in. (180 mm) in length

accordance with Practice D 3636. The sampling plan and

shall be cut from material obtained in accordance with Section

acceptance quality level shall be as agreed upon between the

5.

user and the producer.

9. Procedure

6. Conditioning

9.1 Inside Diameter—Pass the minimum gage rod for the

size sleeving under test into the specimen for a distance of 5 in.

6.1 Unless otherwise specified, a standard laboratory atmo-

(127 mm) without expanding the wall of the sleeving. If the rod

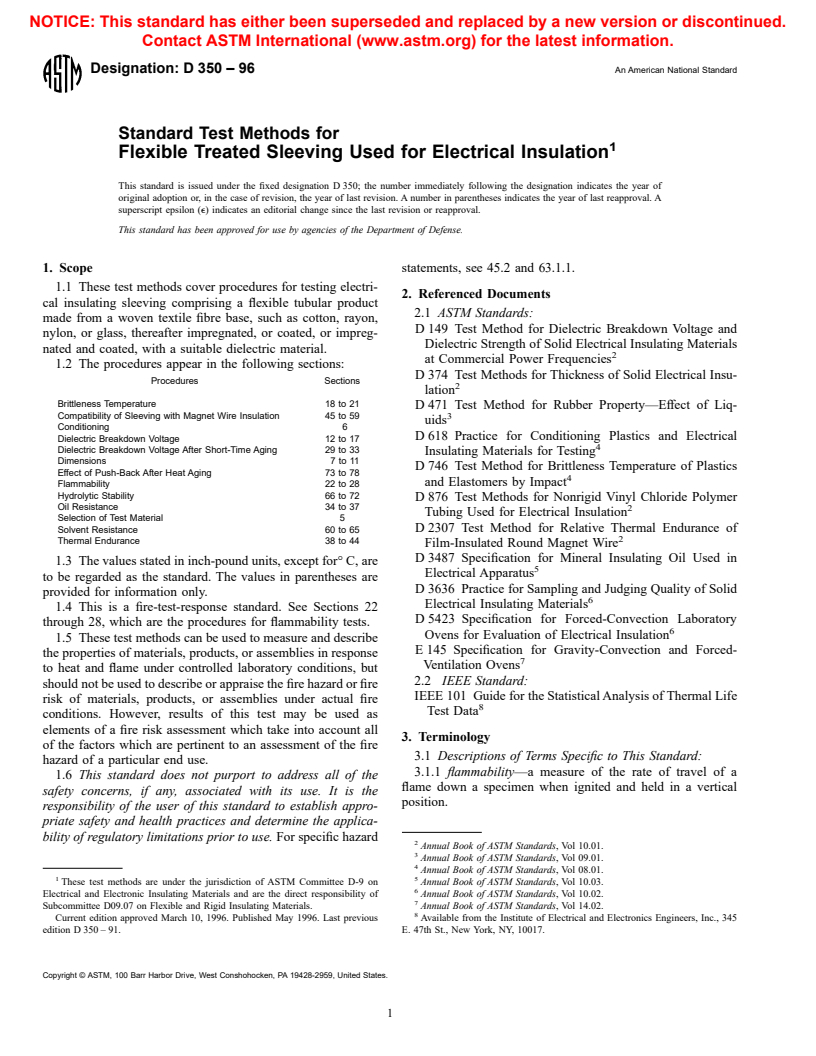

TABLE 1 ASTM Standard Sizes for Flexible Sleeving

has a snug fit, then consider the specimen as having an inside

Inside Diameter, in. (mm)

diameter equal to the diameter of the rod. If the minimum gage

Size

rod fits loosely, insert the maximum gage rod into the speci-

Max Min

men. If the maximum gage rod passes freely into the specimen

1 in. 1.036 (26.3) 1.000 (25.4)

⁄8 in. 0.911 (23.1) 0.875 (22.2) for a distance of 5 in. with a snug fit, or if it expands the wall

⁄4 in. 0.786 (20.0) 0.750 (19.1)

of the specimen, then consider the sleeving to be of that size

⁄8 in. 0.655 (16.6) 0.625 (15.9)

which falls within the limits of the maximum and minimum

⁄2 in. 0.524 (13.3) 0.500 (12.7)

inside diameters as represented by the gage rods.

⁄16 in. 0.462 (11.7) 0.438 (11.1)

9.2 Wall Thickness—Insert in the specimen the largest

⁄8 in. 0.399 (10.1) 0.375 (9.5)

standard gage rod that will pass freely into the sleeving. Apply

No. 0 0.347 (8.8) 0.325 (8.3)

a micrometer over the specimen and make thickness measure-

No. 1 0.311 (7.9) 0.289 (7.3)

ments as specified in Method C of Test Methods D 374 except

No. 2 0.278 (7.1) 0.258 (6.6)

that the force on the pressor foot shall be 3 oz (85 g). Obtain

No. 3 0.249 (6.3) 0.229 (5.8)

No. 4 0.224 (5.7) 0.204 (5.2)

the average of five thickness readings taking the micrometer

readings at approximately 90° intervals about the circumfer-

No. 5 0.198 (5.0) 0.182 (4.6)

ence of the specimen and spaced lineally approximately 0.25

No. 6 0.178 (4.5) 0.162 (4.1)

No. 7 0.158 (4.0) 0.144 (3.7)

in. (6 mm). Methods A and B of Test Methods D 374 can be

No. 8 0.141 (3.6) 0.129 (3.3)

used as alternative methods where agreed upon between the

manufacturer and purchaser. Compute wall thickness as half

No. 9 0.124 (3.1) 0.114 (2.9)

No. 10 0.112 (2.8) 0.102 (2.6)

the distance between the outside diameter of the mounted

No. 11 0.101 (2.6) 0.091 (2.31)

sleeving and the diameter of the gage rod.

No. 12 0.091 (2.31) 0.081 (2.06)

10. Report

No. 13 0.082 (2.08) 0.072 (1.83)

No. 14 0.074 (1.88) 0.064 (1.63)

10.1 Report the following information:

No. 15 0.067 (1.70) 0.057 (1.45)

10.1.1 Identification of the sleeving,

No. 16 0.061 (1.55) 0.051 (1.30)

10.1.2 Method of measurement if other than Method C,

No. 17 0.054 (1.37) 0.045 (1.14)

10.1.3 Size of sleeving, and

No. 18 0.049 (1.24) 0.040 (1.02)

10.1.4 Wall thickness.

No. 20 0.039 (0.99) 0.032 (0.81)

No. 22 0.032 (0.81) 0.025 (0.64)

11. Precision and Bias

No. 24 0.027 (0.69) 0.020 (0.51)

11.1 Precision—The overall estimates of the precision

D 350

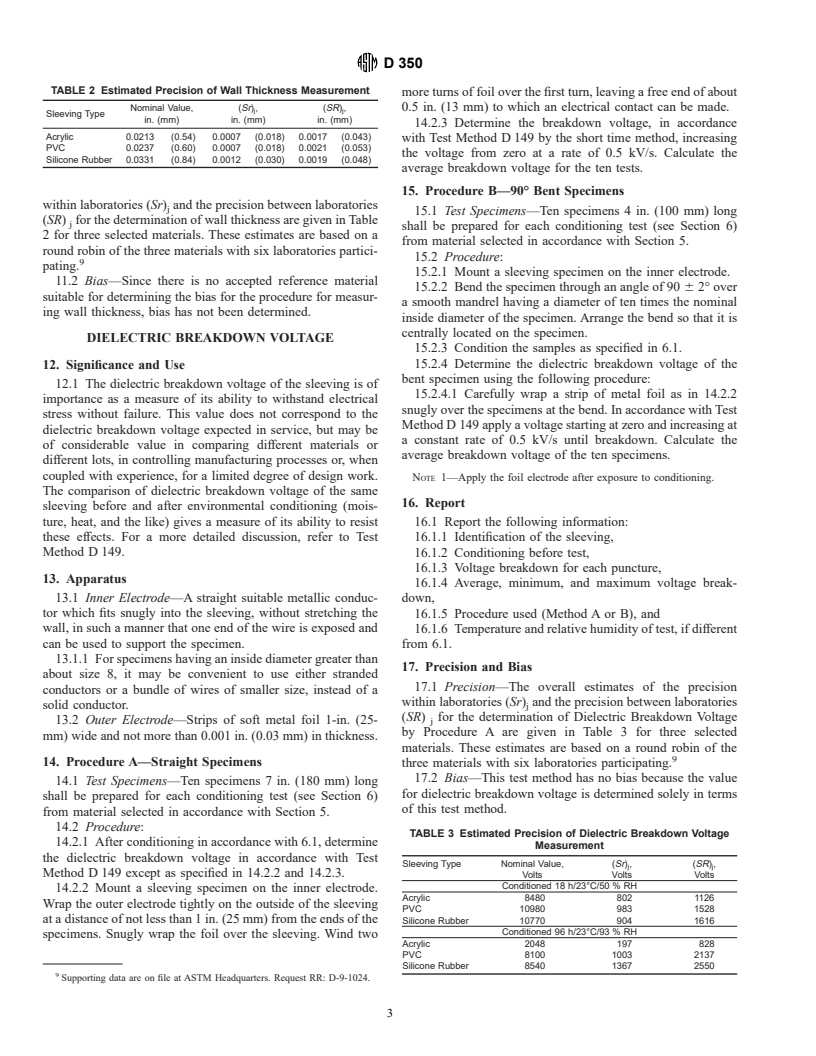

TABLE 2 Estimated Precision of Wall Thickness Measurement

more turns of foil over the first turn, leaving a free end of about

Nominal Value, (Sr) , (SR) , 0.5 in. (13 mm) to which an electrical contact can be made.

j j

Sleeving Type

in. (mm) in. (mm) in. (mm)

14.2.3 Determine the breakdown voltage, in accordance

Acrylic 0.0213 (0.54) 0.0007 (0.018) 0.0017 (0.043)

with Test Method D 149 by the short time method, increasing

PVC 0.0237 (0.60) 0.0007 (0.018) 0.0021 (0.053)

the voltage from zero at a rate of 0.5 kV/s. Calculate the

Silicone Rubber 0.0331 (0.84) 0.0012 (0.030) 0.0019 (0.048)

average breakdown voltage for the ten tests.

15. Procedure B—90° Bent Specimens

within laboratories (Sr) and the precision between laboratories

j

15.1 Test Specimens—Ten specimens 4 in. (100 mm) long

(SR) for the determination of wall thickness are given in Table

j

shall be prepared for each conditioning test (see Section 6)

2 for three selected materials. These estimates are based on a

from material selected in accordance with Section 5.

round robin of the three materials with six laboratories partici-

15.2 Procedure:

pating.

15.2.1 Mount a sleeving specimen on the inner electrode.

11.2 Bias—Since there is no accepted reference material

15.2.2 Bend the specimen through an angle of 90 6 2° over

suitable for determining the bias for the procedure for measur-

a smooth mandrel having a diameter of ten times the nominal

ing wall thickness, bias has not been determined.

inside diameter of the specimen. Arrange the bend so that it is

centrally located on the specimen.

DIELECTRIC BREAKDOWN VOLTAGE

15.2.3 Condition the samples as specified in 6.1.

15.2.4 Determine the dielectric breakdown voltage of the

12. Significance and Use

bent specimen using the following procedure:

12.1 The dielectric breakdown voltage of the sleeving is of

15.2.4.1 Carefully wrap a strip of metal foil as in 14.2.2

importance as a measure of its ability to withstand electrical

snugly over the specimens at the bend. In accordance with Test

stress without failure. This value does not correspond to the

Method D 149 apply a voltage starting at zero and increasing at

dielectric breakdown voltage expected in service, but may be

a constant rate of 0.5 kV/s until breakdown. Calculate the

of considerable value in comparing different materials or

average breakdown voltage of the ten specimens.

different lots, in controlling manufacturing processes or, when

coupled with experience, for a limited degree of design work.

NOTE 1—Apply the foil electrode after exposure to conditioning.

The comparison of dielectric breakdown voltage of the same

16. Report

sleeving before and after environmental conditioning (mois-

ture, heat, and the like) gives a measure of its ability to resist 16.1 Report the following information:

these effects. For a more detailed discussion, refer to Test 16.1.1 Identification of the sleeving,

Method D 149. 16.1.2 Conditioning before test,

16.1.3 Voltage breakdown for each puncture,

13. Apparatus

16.1.4 Average, minimum, and maximum voltage break-

13.1 Inner Electrode—A straight suitable metallic conduc- down,

tor which fits snugly into the sleeving, without stretching the

16.1.5 Procedure used (Method A or B), and

wall, in such a manner that one end of the wire is exposed and 16.1.6 Temperature and relative humidity of test, if different

can be used to support the specimen.

from 6.1.

13.1.1 For specimens having an inside diameter greater than

17. Precision and Bias

about size 8, it may be convenient to use either stranded

17.1 Precision—The overall estimates of the precision

conductors or a bundle of wires of smaller size, instead of a

within laboratories (Sr) and the precision between laboratories

solid conductor. j

(SR) for the determination of Dielectric Breakdown Voltage

13.2 Outer Electrode—Strips of soft metal foil 1-in. (25- j

by Procedure A are given in Table 3 for three selected

mm) wide and not more than 0.001 in. (0.03 mm) in thickness.

materials. These estimates are based on a round robin of the

14. Procedure A—Straight Specimens

three materials with six laboratories participating.

17.2 Bias—This test method has no bias because the value

14.1 Test Specimens—Ten specimens 7 in. (180 mm) long

for dielectric breakdown voltage is determined solely in terms

shall be prepared for each conditioning test (see Section 6)

of this test method.

from material selected in accordance with Section 5.

14.2 Procedure:

TABLE 3 Estimated Precision of Dielectric Breakdown Voltage

14.2.1 After conditioning in accordance with 6.1, determine

Measurement

the dielectric breakdown voltage in accordance with Test

Sleeving Type Nominal Value, (Sr) , (SR) ,

j j

Method D 149 except as specified in 14.2.2 and 14.2.3.

Volts Volts Volts

Conditioned 18 h/23°C/50 % RH

14.2.2 Mount a sleeving specimen on the inner electrode.

Acrylic 8480 802 1126

Wrap the outer electrode tightly on the outside of the sleeving

PVC 10980 983 1528

at a distance of not less than 1 in. (25 mm) from the ends of the Silicone Rubber 10770 904 1616

Conditioned 96 h/23°C/93 %

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.