ASTM D2442-75(2007)

(Specification)Standard Specification for Alumina Ceramics for Electrical and Electronic Applications

Standard Specification for Alumina Ceramics for Electrical and Electronic Applications

SCOPE

1.1 This specification covers the requirements for fabricated alumina parts suitable for electronic and electrical applications and ceramic-to-metal seals as used in electron devices. This standard specifies limits and methods of test for electrical, mechanical, thermal, and general properties of the bodies used for these fabricated parts, regardless of part geometry.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2442 – 75 (Reapproved 2007)

Standard Specification for

Alumina Ceramics for Electrical and Electronic

1

Applications

This standard is issued under the fixed designation D2442; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope at Commercial Power Frequencies

D150 Test Methods for AC Loss Characteristics and Per-

1.1 Thisspecificationcoverstherequirementsforfabricated

mittivity (Dielectric Constant) of Solid Electrical Insula-

alumina parts suitable for electronic and electrical applications

tion

and ceramic-to-metal seals as used in electron devices. This

D257 Test Methods for DC Resistance or Conductance of

standard specifies limits and methods of test for electrical,

Insulating Materials

mechanical, thermal, and general properties of the bodies used

D618 Practice for Conditioning Plastics for Testing

for these fabricated parts, regardless of part geometry.

D1711 Terminology Relating to Electrical Insulation

1.2 The values stated in SI units are to be regarded as the

D1829 Test Method for Electrical Resistance of Ceramic

standard. The values given in parentheses are for information

3

Materials at Elevated Temperatures

only.

D2149 Test Method for Permittivity (Dielectric Constant)

2. Referenced Documents And Dissipation Factor Of Solid Dielectrics At Frequen-

2

cies To 10 MHz And Temperatures To 500°C

2.1 ASTM Standards:

D2520 Test Methods for Complex Permittivity (Dielectric

C20 TestMethodsforApparentPorosity,WaterAbsorption,

Constant) of Solid Electrical Insulating Materials at Mi-

Apparent Specific Gravity, and Bulk Density of Burned

crowave Frequencies and Temperatures to 1650°C

Refractory Brick and Shapes by Boiling Water

E6 TerminologyRelatingtoMethodsofMechanicalTesting

C108 Symbols for Heat Transmission

E12 Terminology Relating to Density and Specific Gravity

C242 Terminology of Ceramic Whitewares and Related

3

of Solids, Liquids, and Gases

Products

E122 Practice for Calculating Sample Size to Estimate,

C408 Test Method for Thermal Conductivity of Whiteware

With Specified Precision, the Average for a Characteristic

Ceramics

of a Lot or Process

C573 MethodsforChemicalAnalysisofFireclayandHigh-

3

E165 PracticeforLiquidPenetrantExaminationforGeneral

Alumina Refractories

Industry

C623 Test Method for Young’s Modulus, Shear Modulus,

E228 Test Method for Linear Thermal Expansion of Solid

and Poisson’s Ratio for Glass and Glass-Ceramics by

Materials With a Push-Rod Dilatometer

Resonance

F19 Test Method for Tension and Vacuum Testing Metal-

D116 Test Methods for Vitrified Ceramic Materials for

lized Ceramic Seals

Electrical Applications

F77 Test Method for Electrical Resistance of Ceramic

D149 Test Method for Dielectric Breakdown Voltage and

3

Materials at Elevated Temperatures

Dielectric Strength of Solid Electrical Insulating Materials

F109 Terminology Relating to Surface Imperfections on

Ceramics

F134 Test Methods for Determining Hermeticity of Elec-

1

This specification is under the jurisdiction of Committee C21 on Ceramic

tron Devices with a Helium Mass Spectrometer Leak

Whitewares and Related Products and is the direct responsibility of Subcommittee

3

C21.03 on Methods for Whitewares and Environmental Concerns. Detector

This specification also includes material and suggestions provided by ASTM

F417 Test Method for Flexural Strength (Modulus of Rup-

Committee D09 on Electrical and Electronic Insulating Materials.

3

ture) of Electronic-Grade Ceramics

Current edition approved May 1, 2007. Published May 2007. Originally

2.2 Other Standards:

approved in 1965. Last previous edition approved in 2001 as D2442–75(2001).

DOI: 10.1520/D2442-75R07.

MIL-STD-105 Sampling Procedures and Tables for Inspec-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4

tion by Attributes

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Withdrawn. The last approved version of this historical standard is referenced Available from the Superintendent of Documents, Government Printing Office,

on www.astm.org. Washington, D.C. 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2442 – 75 (2007)

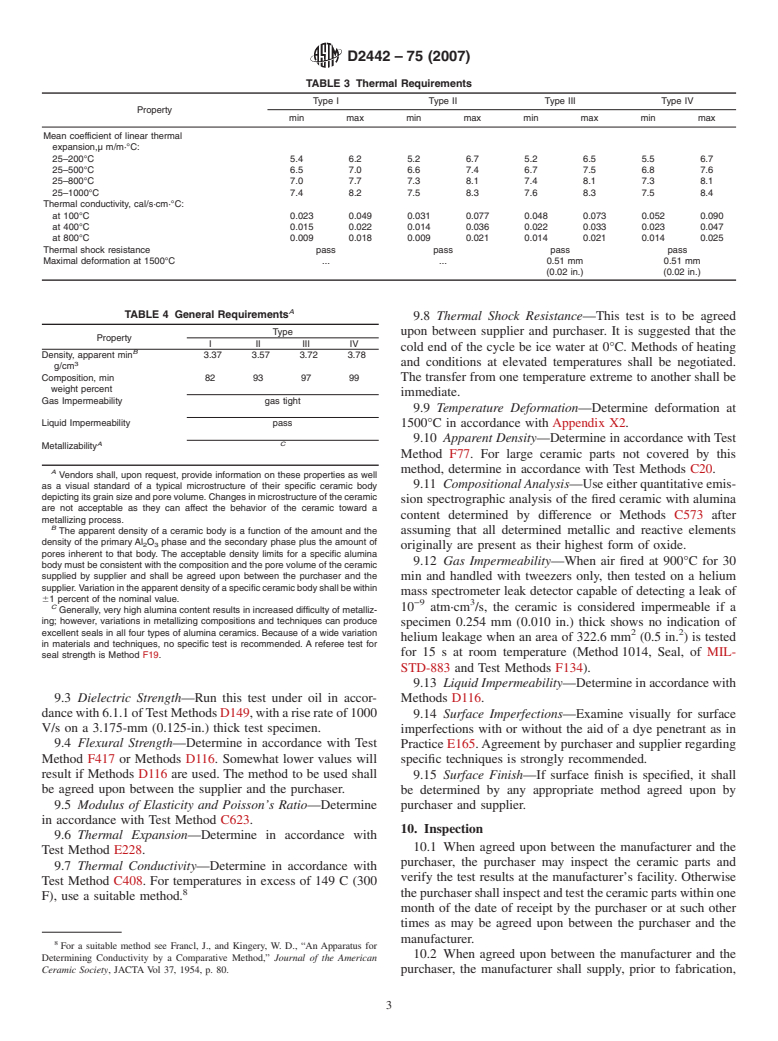

TABLE 2 Mechanical Requirements

MIL-STD-883 TestMethodsandProceduresforMicroelec-

5

tronics Property Type I Type II Type III Type IV

6

ANSIB46.1 Surface Texture

Flexural strength, 240 275 275 275

A

min avg, (35 000) (40 000) (40 000) (40 000)

MPa (p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.