ASTM E1877-13

(Practice)Standard Practice for Calculating Thermal Endurance of Materials from Thermogravimetric Decomposition Data

Standard Practice for Calculating Thermal Endurance of Materials from Thermogravimetric Decomposition Data

SIGNIFICANCE AND USE

5.1 Thermogravimetry provides a rapid method for the determination of the temperature-decomposition profile of a material.

5.2 This practice is useful for quality control, specification acceptance, and research.

5.3 This test method is intended to provide an accelerated thermal endurance estimation in a fraction of the time require for oven-aging tests. The primary product of this test method is the thermal index (temperature) for a selected estimated thermal endurance (time) as derived from material decomposition.

5.4 Alternatively, the estimated thermal endurance (time) of a material may be estimated from a selected thermal index (temperature).

5.5 Additionally, the estimated thermal endurance of a material at selected failure time and temperature may be estimated when compared to a reference value for thermal endurance and thermal index obtained from electrical or mechanical oven aging tests.

5.6 This practice shall not be used for product lifetime predications unless a correlation between test results and actual lifetime has been demonstrated. In many cases, multiple mechanisms occur during the decomposition of a material, with one mechanism dominating over one temperature range, and a different mechanism dominating in a different temperature range. Users of this practice are cautioned to demonstrate for their system that any temperature extrapolations are technically sound.

SCOPE

1.1 This practice describes the determination of thermal endurance, thermal index, and relative thermal index for organic materials using the Arrhenius activation energy generated by thermogravimetry.

1.2 This practice is generally applicable to materials with a well-defined thermal decomposition profile, namely a smooth, continuous mass change.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 There is no ISO standard equivalent to this practice.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1877 − 13

StandardPractice for

Calculating Thermal Endurance of Materials from

1

Thermogravimetric Decomposition Data

This standard is issued under the fixed designation E1877; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 thermal index (TI), n—the temperature corresponding

to a selected time-to-failure.

1.1 This practice describes the determination of thermal

3.1.4 relative thermal index (RTI), n—the temperature cor-

endurance, thermal index, and relative thermal index for

responding to a selected time-to-failure when compared with

organic materials using the Arrhenius activation energy gener-

that of a control with proven thermal endurance characteristics.

ated by thermogravimetry.

3.1.4.1 Discussion—The TIand RTIareconsideredtobethe

1.2 This practice is generally applicable to materials with a

maximum temperature below which the material resists

well-defined thermal decomposition profile, namely a smooth,

changes in its properties over a selected period of time. In the

continuous mass change.

absence of comparison data for a control material, a thermal

1.3 The values stated in SI units are to be regarded as

endurance (time-to-failure) of 60 000 h has been arbitrarily

standard. No other units of measurement are included in this

selected for measuring TI and RTI.

standard.

3.1.5 thermal endurance, n—the time-to-failure correspond-

1.4 There is no ISO standard equivalent to this practice.

ing to a selected temperature. Also known as thermal lifetime.

1.5 This standard does not purport to address all of the

4. Summary of Practice

safety concerns, if any, associated with its use. It is the

4.1 The Arrhenius activation energy obtained from other

responsibility of the user of this standard to establish appro-

3

Test Methods (such as Test Method E1641, Refs (1, 2), etc.)

priate safety and health practices and determine the applica-

is used to construct the thermal endurance curve of an organic

bility of regulatory limitations prior to use.

material from which an estimate of lifetime at selected tem-

2. Referenced Documents

peratures may be obtained.

2

2.1 ASTM Standards:

5. Significance and Use

E1641 Test Method for Decomposition Kinetics by Thermo-

5.1 Thermogravimetry provides a rapid method for the

gravimetry Using the Ozawa/Flynn/Wall Method

determination of the temperature-decomposition profile of a

E2550 Test Method for Thermal Stability by Thermogravi-

material.

metry

5.2 This practice is useful for quality control, specification

3. Terminology

acceptance, and research.

3.1 Definitions of Terms Specific to This Standard:

5.3 This test method is intended to provide an accelerated

3.1.1 failure, n—change in some chemical, physical,

thermal endurance estimation in a fraction of the time require

mechanical, electrical or other property of sufficient magnitude

for oven-aging tests.The primary product of this test method is

to make it unsuitable for a particular use.

the thermal index (temperature) for a selected estimated

3.1.2 failure temperature (T), n—thetemperatureatwhicha

f

thermal endurance (time) as derived from material decompo-

material fails after a selected time.

sition.

5.4 Alternatively, the estimated thermal endurance (time) of

1

This practice is under the jurisdiction of Committee E37 on Thermal Measure-

a material may be estimated from a selected thermal index

ments and is the direct responsibility of Subcommittee E37.10 on Fundamental,

Statistical and Mechanical Properties.

(temperature).

Current edition approved Oct. 15, 2013. Published December 2013. Originally

5.5 Additionally, the estimated thermal endurance of a

approved in 1997. Last previous edition approved in 2011 as E1877 – 11. DOI:

10.1520/E1877-13.

material at selected failure time and temperature may be

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to a list of references at the end of

the ASTM website. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1877 − 13

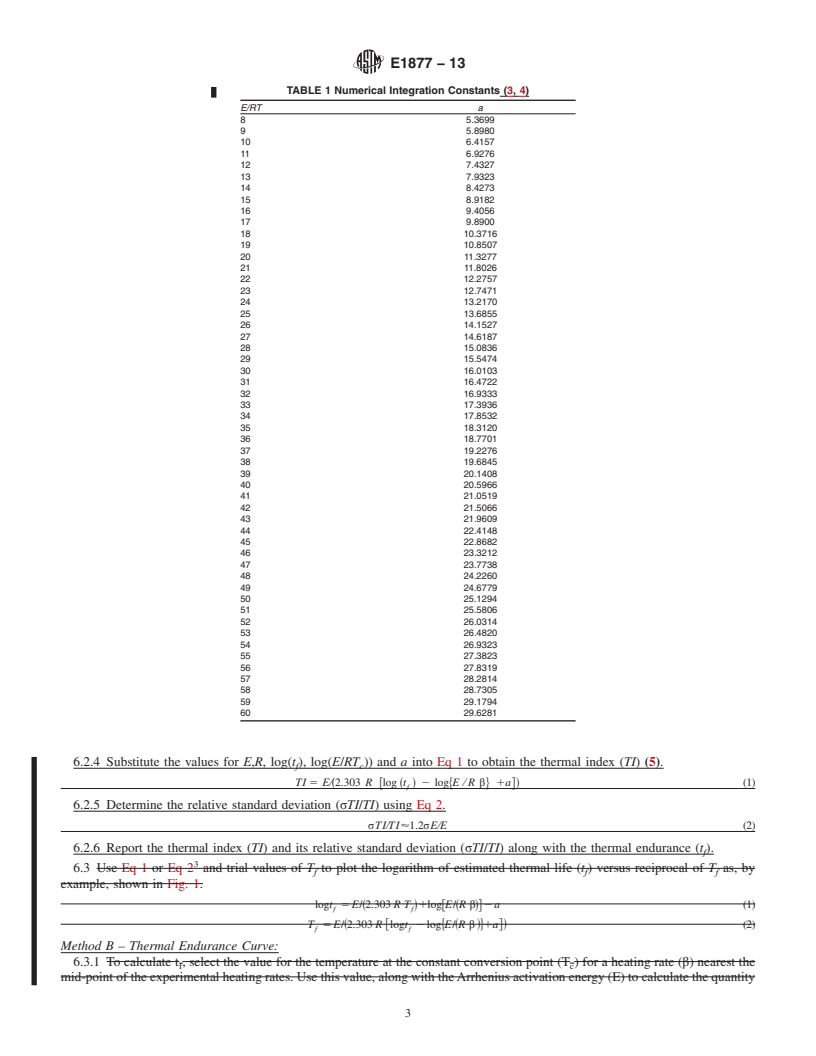

TABLE 1 Numerical Integration Constants (3, 4)

estimated when compared to a reference value for thermal

endurance and thermal index obtained from electrical or E/RT a

8 5.3699

mechanical oven aging tests.

9 5.8980

10 6.4157

5.6 This practice shall not be used for product lifetime

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1877 − 11 E1877 − 13

Standard Practice for

Calculating Thermal Endurance of Materials from

1

Thermogravimetric Decomposition Data

This standard is issued under the fixed designation E1877; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers additional treatment of the Arrhenius activation energy data determined by Test Methoddescribes the

determination of thermal endurance, thermal index, and relative thermal index for E1641 to develop a thermal endurance curve

and derive a relative thermal index for materials.organic materials using the Arrhenius activation energy generated by

thermogravimetry.

1.2 This practice is generally applicable to materials with a well-defined thermal decomposition profile, namely a smooth,

continuous mass change with a single maximum rate.change.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 There is no ISO standard equivalent to this practice.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E1641 Test Method for Decomposition Kinetics by Thermogravimetry Using the Ozawa/Flynn/Wall Method

E2550 Test Method for Thermal Stability by Thermogravimetry

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 failure, n—change in some chemical, physical, mechanical, electrical or other property of sufficient magnitude to make

it unsuitable for a particular use.

3.1.2 failure temperature (T ), n—the temperature at which a material fails after a selected time.

f

3.1.3 thermal index (TI), n—the temperature corresponding to a selected time-to-failure.

3.1.4 relative thermal index (RTI), n—a measure of the thermal endurance of a material the temperature corresponding to a

selected time-to-failure when compared with that of a control with proven thermal endurance characteristics.

1

This practice is under the jurisdiction of Committee E37 on Thermal Measurements and is the direct responsibility of Subcommittee E37.10 on Fundamental, Statistical

and Mechanical Properties.

Current edition approved Aug. 1, 2011Oct. 15, 2013. Published September 2011December 2013. Originally approved in 1997. Last previous edition approved in 20102011

as E1877 – 00 (2010).E1877 – 11. DOI: 10.1520/E1877-11.10.1520/E1877-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.4.1 Discussion—

The RTITI isand alsoRTI are considered to be the maximum temperature below which the material resists changes in its properties

over a definedselected period of time. In the absence of comparison data for a control material, a time-to-failure thermal endurance

(time-to-failure) of 60 000 h has been arbitrarily selected for measuring RTI. The RTI is therefore, the failure temperature, TTI ,

f

obtainedand from RTI.the thermal endurance curve.

3.1.5 thermal endurance, n—the time-to-failure corresponding to a selected temperature. Also known as thermal lifetime.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1877 − 13

4. Summary of Practice

3

4.1 The Arrhenius activation energy obtained from Test other Test Methods (such as Test Method E1641, Refs (1, 2), etc.) is

used to construct the thermal endurance curve of a an organic material from which an estimate of lifetime at certainselected

temperatures may be obtained.

5. Significance and Use

5.1 Thermogravimetry provides a rapid method for the determination of the temperature-decomposition profile of a material.

5.2 This practice is useful for quality control, specification acceptance, and research.

5.3 This test method is intended to provide an accelerated thermal endurance estimation in a fraction of the time require for

oven-aging tests. The primary product of this

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.