ASTM F1802-97

(Test Method)Standard Test Method for Performance Testing of Excess Flow Valves

Standard Test Method for Performance Testing of Excess Flow Valves

SCOPE

1.1 this test method covers a standardized method to determine the performance of excess flow valves (EFVs) designed to limit flow or stop flow in thermoplastic natural gas service lines.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1802 – 97

Standard Test Method for

Performance Testing of Excess Flow Valves

This standard is issued under the fixed designation F 1802; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 The EFVs covered by this test method shall be con-

structed to fit piping systems no smaller than ⁄2 in. (15.9 mm)

1.1 This test method covers a standardized method to

CTS and no larger than 1 ⁄4 in. (42.1 mm) IPS, including both

determine the performance of excess flow valves (EFVs)

pipe and tubing sizes.

designed to limit flow or stop flow in thermoplastic natural gas

1.7 Tests will be performed at 67 6 10°F (19.4 6 5.5°C).

service lines.

Alternative optional test temperatures are 100 6 10°F (37.7 6

1.2 All tests are intended to be performed using air as the

5.5°C) and 0 6 10°F (–18 6 5.5°C). All flow rates must be

test fluid. Unless otherwise stated, all flow rates are reported in

corrected to standard conditions.

standard cubic feet per hour of 0.6 relative density natural gas.

1.8 This test method was written for EFVs installed in

1.3 The test method recognizes two types of EFV. One type,

thermoplastic piping systems. However, it is expected that the

an excess flow valve-bypass (EFVB), allows a small amount of

test method may also be used for similar devices in other

gas to bleed through (bypass) after it has tripped, usually as a

piping systems.

means of automatically resetting the device. The second type,

1.9 The values stated in inch-pound units are to be regarded

an excess flow valve-non bypass (EFVNB), is intended to trip

as the standard. The SI units given in parentheses are for

shut forming an essentially gas tight seal.

information only.

1.4 The performance characteristics covered in this test

1.10 This standard does not purport to address all of the

method include flow at trip point, pressure drop across the

safety concerns, if any, associated with its use. It is the

EFV, bypass flow rate of the EFVB or leak rate through the

responsibility of the user of this standard to establish appro-

EFVNB after trip, and verification that the EFV can be reset.

priate safety and health practices and determine the applica-

1.4.1 Gas distribution systems may contain condensates and

bility of regulatory limitations prior to use. For specific

particulates such as organic matter, sand, dirt, and iron com-

precautions, see Section 8.

pounds. Field experience has shown that the operating charac-

teristics of some EFVs may be affected by accumulations of

2. Referenced Documents

these materials. The tests of Section 11 were developed to

2.1 ASTM Standards:

provide a simple, inexpensive, reproducible test that quantifies

D 1600 Terminology for Abbreviations, Acronyms, and

the effect, if any, of a uniform coating of kerosine and of

Codes for Terms Relating to Plastics

kerosine contaminated with a specified amount of ferric oxide

D 2122 Test Method for Determining Dimensions for Ther-

powder on an EFV’s operating characteristics.

moplastic Pipe and Fittings

1.5 Excess flow valves covered by this test method will

D 2513 Specification for Thermoplastic Gas Pressure Pipe,

normally have the following characteristics: a pressure rating

Tubing, and Fittings

of up to 125 psig (0.86 MPa); a trip flow of between 200 and

3 3

F 412 Terminology Relating to Plastic Piping Systems

2500 ft /h (5.66 and 70.8 m /h) at 10 psig (07 MPa); a

2.2 ANSI Standard:

minimum temperature rating of 0°F(–18°C), and a maximum

B31.8 Gas Transmission and Distribution Piping Systems

temperature rating of 100°F (38°C).

2.3 Federal Specification:

DOT Part 192 Title 49 Code of Federal Regulations

This test method is under the jurisdiction of ASTM Committee F-17 on Plastic

3. Terminology

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test

Methods.

3.1 Definitions:

Current edition approved May 10, 1997. Published December 1997. Originally

published as PS 13–95. Last previous edition PS 13–95.

This contamination test procedure may be utilized to determine the effect, if

any, of contaminants from a specific gas distribution system on the operational Annual Book of ASTM Standards, Vol 08.01.

characteristics of an EFV under consideration for use in that system. Condensates, Annual Book of ASTM Standards, Vol 08.04.

oils and particulates removed from that distribution system could be substituted for Available from American National Standards Institute, 11 W. 42nd St., 13th

kerosine and iron oxide. Results obtained from using reagents or contaminants other Floor, New York, NY 10036.

than those specified in this test method must not be used in comparison with results Available from Superintendent of Documents, U.S. Government Printing

obtained using the reagents specified in this test method. Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1802–97

3.1.1 General—Definitions are in accordance with Termi- 3.2.7 trip, n—activation of the mechanism of an EFV to

nology F 412, unless otherwise specified. Abbreviations are in stop or limit the flow of natural gas in the service line.

accordance with Terminology D 1600.

3.2.8 trip flow, n—the flow passing through an EFV re-

3.1.2 The gas industry terminology used in this test method

quired to cause its activation to stop or limit flow.

is in accordance with ANSI B31.8 or DOT Part 192 Title 49,

unless otherwise indicated.

4. Summary of Test Method

3.2 Definitions of Terms Specific to This Standard:

4.1 For all tests, air is intended to be the test fluid. All flows

3.2.1 bypass flow, n—the flow through an EFVB after it has

are given in cubic feet per hour of 0.6 relative density natural

been activated or tripped.

gas, unless otherwise specified. All tests are to be performed at

3.2.2 excess flow valve (EFV), n—a device installed in a

67 6 10°F (19.4 6 5.5°C), with alternative test temperatures of

natural gas service line having the ability to automatically stop

0 and 100°F (–17.7 and 37.7°C). All flow rates must be

or limit the flow of gas in the event that the flow in the service

corrected to standard conditions using the temperature of the

line exceeds a predetermined level.

air flow measured just upstream of the flowmeter (T ) in Fig.

3.2.2.1 excess flow valve-bypass (EFVB), n—an EFV de-

1.

signed to limit the flow of gas upon closure to a small

4.2 The EFV is installed in the standardized test apparatus

predetermined level. The EFVBs reset automatically, once the

shown in Fig. 1. This apparatus provides regulated inlet

service line downstream is made gas tight and pressure is

pressure, pressure measurement at specified locations, tem-

equalized across the valve.

perature measurement, flow measurement, and flow control.

3.2.2.2 excess flow valve-non bypass (EFVNB), n—an EFV

Four discrete tests are performed on each sample, as follows:

which is designed to stop the flow of gas upon closure. The

4.2.1 Trip Flow Rate—The EFV is installed in the test

EFVNBs must be manually reset.

apparatus and the flow control valve is slowly opened. At the

3.2.3 leak rate, n—the flow of test fluid passing through an

trip point, the inlet pressure and flow rate are recorded.

EFVNB after it has been activated or tripped.

4.2.2 Bypass or Leak Rate—After completion of trip flow

3.2.4 Piezometer ring, n—a device installed at a pressure

rate test, the flow past the tripped device is measured on

measurement point in a flowing gas stream intended to

Flowmeter 2. For an EFVB, this flow is the bypass flow. For an

eliminate the effect of the flowing gas on the measurement

EFVNB, this flow is the leak rate.

device. See Appendix X1.

3.2.5 pipe, n—refers to both pipe and tubing. 4.2.3 Pressure Drop at Flow Rates Less than Closure—after

3.2.6 standard conditions, n—for gas flow conversion, 0.6 setting the inlet pressure to the desired value, pressure drop

relative density natural gas at 14.7 psia (0.1 MPa) and 60°F measurements shall be taken at each of the following flow rates

(16.6 °C). that are less than the valve’s minimum closure flow rate: 100,

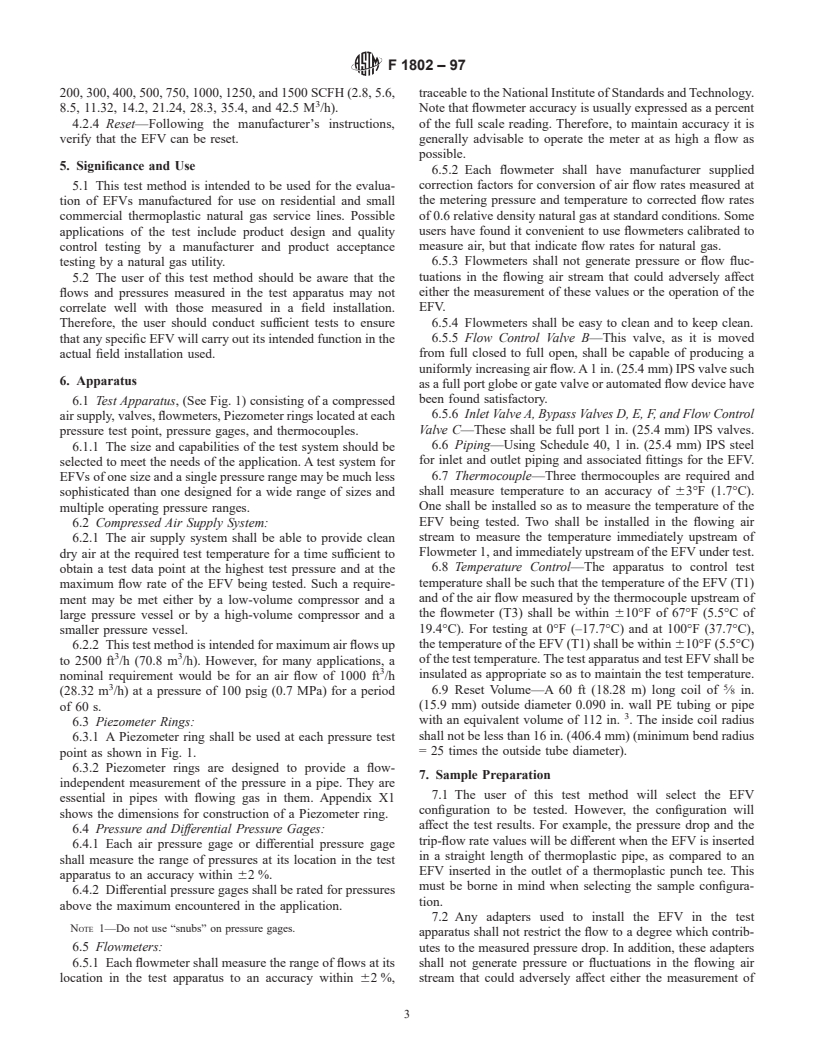

FIG. 1 Test Apparatus For Excess Flow Valves

F1802–97

200, 300, 400, 500, 750, 1000, 1250, and 1500 SCFH (2.8, 5.6, traceable to the National Institute of Standards and Technology.

8.5, 11.32, 14.2, 21.24, 28.3, 35.4, and 42.5 M /h). Note that flowmeter accuracy is usually expressed as a percent

4.2.4 Reset—Following the manufacturer’s instructions, of the full scale reading. Therefore, to maintain accuracy it is

verify that the EFV can be reset. generally advisable to operate the meter at as high a flow as

possible.

5. Significance and Use

6.5.2 Each flowmeter shall have manufacturer supplied

correction factors for conversion of air flow rates measured at

5.1 This test method is intended to be used for the evalua-

tion of EFVs manufactured for use on residential and small the metering pressure and temperature to corrected flow rates

of 0.6 relative density natural gas at standard conditions. Some

commercial thermoplastic natural gas service lines. Possible

applications of the test include product design and quality users have found it convenient to use flowmeters calibrated to

measure air, but that indicate flow rates for natural gas.

control testing by a manufacturer and product acceptance

testing by a natural gas utility. 6.5.3 Flowmeters shall not generate pressure or flow fluc-

tuations in the flowing air stream that could adversely affect

5.2 The user of this test method should be aware that the

flows and pressures measured in the test apparatus may not either the measurement of these values or the operation of the

EFV.

correlate well with those measured in a field installation.

6.5.4 Flowmeters shall be easy to clean and to keep clean.

Therefore, the user should conduct sufficient tests to ensure

6.5.5 Flow Control Valve B—This valve, as it is moved

that any specific EFV will carry out its intended function in the

from full closed to full open, shall be capable of producing a

actual field installation used.

uniformly increasing air flow. A 1 in. (25.4 mm) IPS valve such

6. Apparatus

as a full port globe or gate valve or automated flow device have

been found satisfactory.

6.1 Test Apparatus, (See Fig. 1) consisting of a compressed

6.5.6 Inlet Valve A, Bypass Valves D, E, F, and Flow Control

air supply, valves, flowmeters, Piezometer rings located at each

Valve C—These shall be full port 1 in. (25.4 mm) IPS valves.

pressure test point, pressure gages, and thermocouples.

6.6 Piping—Using Schedule 40, 1 in. (25.4 mm) IPS steel

6.1.1 The size and capabilities of the test system should be

for inlet and outlet piping and associated fittings for the EFV.

selected to meet the needs of the application. A test system for

6.7 Thermocouple—Three thermocouples are required and

EFVs of one size and a single pressure range may be much less

shall measure temperature to an accuracy of 63°F (1.7°C).

sophisticated than one designed for a wide range of sizes and

One shall be installed so as to measure the temperature of the

multiple operating pressure ranges.

EFV being tested. Two shall be installed in the flowing air

6.2 Compressed Air Supply System:

stream to measure the temperature immediately upstream of

6.2.1 The air supply system shall be able to provide clean

Flowmeter 1, and immediately upstream of the EFV under test.

dry air at the required test temperature for a time sufficient to

6.8 Temperature Control—The apparatus to control test

obtain a test data point at the highest test pressure and at the

temperature shall be such that the temperature of the EFV (T1)

maximum flow rate of the EFV being tested. Such a require-

and of the air flow measured by the thermocouple upstream of

ment may be met either by a low-volume compressor and a

the flowmeter (T3) shall be within 610°F of 67°F (5.5°C of

large pressure vessel or by a high-volume compressor and a

19.4°C). For testing at 0°F (–17.7°C) and at 100°F (37.7°C),

smaller pressure vessel.

the temperature of the EFV (T1) shall be within 610°F (5.5°C)

6.2.2 This test method is intended for maximum air flows up

3 3

of the test temperature. The test apparatus and test EFV shall be

to 2500 ft /h (70.8 m /h). However, for many applications, a

insulated as appropriate so as to maintain the test temperature.

nominal requirement would be for an air flow of 1000 ft /h

3 5

6.9 Reset Volume—A 60 ft (18.28 m) long coil of ⁄8 in.

(28.32 m /h) at a pressure of 100 psig (0.7 MPa) for a period

(15.9 mm) outside diameter 0.090 in. wall PE tubing or pipe

of 60 s.

with an equivalent volume of 112 in. . The inside coil radius

6.3 Piezometer Rings:

shall not be less than 16 in. (406.4 mm) (minimum bend radius

6.3.1 A Piezometer ring shall be used at each pressure test

= 25 times the outside tube diameter).

point as shown in Fig. 1.

6.3.2 Piezometer rings are designed to provide a flow-

7. Sample Preparation

independent measurement of the pressure in a pipe. They are

7.1 The user of this test method will select the EFV

essential in pipes with flowing gas in them. Appendix X1

configuration to be tested. However, the configuration will

shows the dimensions for construction of a Piezometer ring.

affect the test results. For example, the pressure drop and the

6.4 Pressure and Differential Pressure Gages:

trip-flow rate values will be different when the EFV is inserted

6.4.1 Each air pressure gage or differential pressure gage

in a straight length of thermoplastic pipe, as compared to an

shall measure the range of pressures at its location in the test

EFV inserted in the outlet of a thermoplastic punch tee. This

apparatus to an accuracy within 62%.

must be borne in mind when selecting the sample configura-

6.4.2 Differential pressure gages shall be rated for pressures

tion.

above the maximum encountered in the application.

7.2 Any adapters used to install the EFV in the test

NOTE 1—Do not use “snubs” on pressure gages.

apparatus shall not restrict the flow to a degree which contrib-

6.5 Flowmeters: utes to the measured pressure drop. In addition, these adapters

6.5.1 Each flowmeter shall measure the range of flows at its shall not generate pressure or fluctuations in the flowing air

location in the test apparatus to an accuracy within 62%, stream that could adversely affect either the measurement of

F1802–97

these values or the operation of the EFV. Five samples of each 10.3.3 Open Valve D to the full open posi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.