ASTM D4032-08(2016)

(Test Method)Standard Test Method for Stiffness of Fabric by the Circular Bend Procedure

Standard Test Method for Stiffness of Fabric by the Circular Bend Procedure

SIGNIFICANCE AND USE

5.1 Test Method D4032 for testing stiffness of fabrics is considered satisfactory for quality control testing. It may also be used for acceptance testing of commercial shipments since the test method has been used extensively in the trade field. In cases of differences in values reported by purchaser and seller using Test Method D4032 for acceptance testing, the statistical bias, if any, between the laboratories of the purchaser and the seller should be determined with each comparison being based on the testing of specimens taken homogeneously from a lot of material of the type being evaluated. Specimens should be randomly assigned in equal numbers to each of the laboratories.

5.2 The circular bend procedure gives a force value related to fabric stiffness, simultaneously averaging stiffness in all directions. The stiffness tests in Test Methods D1388 are of the single directional type.

5.3 The circular bend procedure is simple to perform and may be used for knitted, woven, or nonwoven fabrics, provided gage capacity is in keeping with fabric range tested.

SCOPE

1.1 This test method covers the determination of the stiffness of fabrics by the circular bend procedure.

1.2 This test method is generally applicable to all types of fabrics, including woven, knitted and nonwovens, of any fiber content.

Note 1: For other methods of testing for stiffness, refer to Test Methods D1388.

1.3 The values stated in SI units are to be considered as standard; the values in inch-pound units are included for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4032 − 08 (Reapproved 2016)

Standard Test Method for

Stiffness of Fabric by the Circular Bend Procedure

This standard is issued under the fixed designation D4032; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method covers the determination of the stiff- 4.1 A plunger forces a flat, folded swatch of fabric through

ness of fabrics by the circular bend procedure. an orifice in a platform. The maximum force required to push

the fabric through the orifice is an indication of the fabric

1.2 This test method is generally applicable to all types of

stiffness (resistance to bending).

fabrics, including woven, knitted and nonwovens, of any fiber

content.

5. Significance and Use

NOTE 1—For other methods of testing for stiffness, refer to Test

5.1 Test Method D4032 for testing stiffness of fabrics is

Methods D1388.

considered satisfactory for quality control testing. It may also

1.3 The values stated in SI units are to be considered as

be used for acceptance testing of commercial shipments since

standard; the values in inch-pound units are included for

the test method has been used extensively in the trade field. In

information only.

cases of differences in values reported by purchaser and seller

using Test Method D4032 for acceptance testing, the statistical

1.4 This standard does not purport to address all of the

bias, if any, between the laboratories of the purchaser and the

safety concerns, if any, associated with its use. It is the

seller should be determined with each comparison being based

responsibility of the user of this standard to establish appro-

on the testing of specimens taken homogeneously from a lot of

priate safety and health practices and determine the applica-

material of the type being evaluated. Specimens should be

bility of regulatory limitations prior to use.

randomly assigned in equal numbers to each of the laborato-

2. Referenced Documents

ries.

2.1 ASTM Standards:

5.2 The circular bend procedure gives a force value related

D123 Terminology Relating to Textiles

to fabric stiffness, simultaneously averaging stiffness in all

D1388 Test Method for Stiffness of Fabrics

directions. The stiffness tests in Test Methods D1388 are of the

D1776/D1776M Practice for Conditioning and Testing Tex-

single directional type.

tiles

5.3 The circular bend procedure is simple to perform and

D4850 Terminology Relating to Fabrics and Fabric Test

maybeusedforknitted,woven,ornonwovenfabrics,provided

Methods

gage capacity is in keeping with fabric range tested.

3. Terminology

6. Apparatus

3.1 For all terminology relating to D13.60, Fabric Test

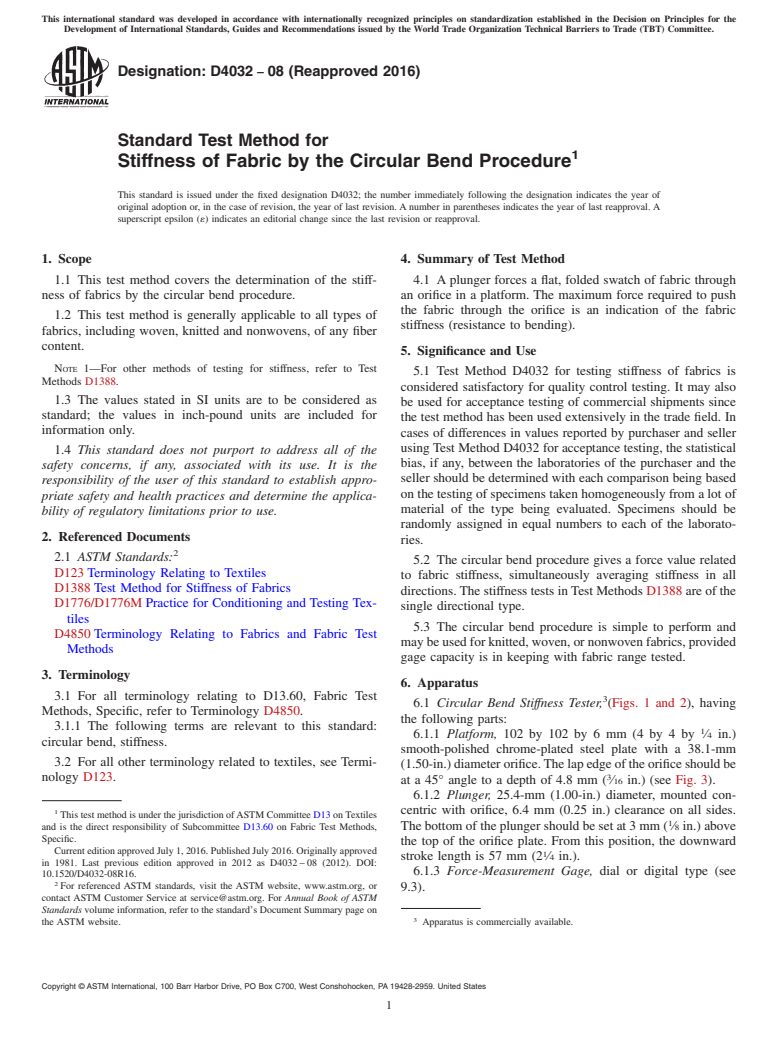

6.1 Circular Bend Stiffness Tester, (Figs. 1 and 2), having

Methods, Specific, refer to Terminology D4850.

the following parts:

3.1.1 The following terms are relevant to this standard:

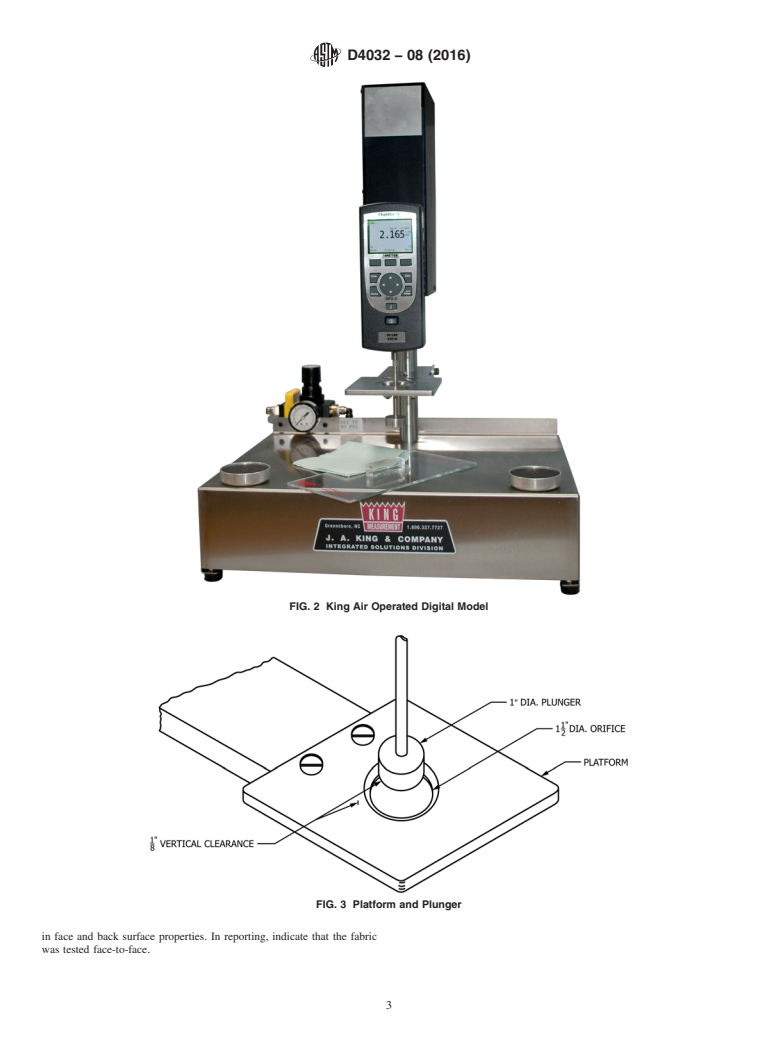

6.1.1 Platform,102by102by6mm(4by4by ⁄4 in.)

circular bend, stiffness.

smooth-polished chrome-plated steel plate with a 38.1-mm

3.2 For all other terminology related to textiles, see Termi-

(1.50-in.)diameterorifice.Thelapedgeoftheorificeshouldbe

nology D123.

at a 45° angle to a depth of 4.8 mm ( ⁄16 in.) (see Fig. 3).

6.1.2 Plunger, 25.4-mm (1.00-in.) diameter, mounted con-

1 centric with orifice, 6.4 mm (0.25 in.) clearance on all sides.

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods, The bottom of the plunger should be set at 3 mm ( ⁄8 in.) above

Specific.

the top of the orifice plate. From this position, the downward

Current edition approved July 1, 2016. Published July 2016. Originally approved

stroke length is 57 mm (2 ⁄4 in.).

in 1981. Last previous edition approved in 2012 as D4032 – 08 (2012). DOI:

6.1.3 Force-Measurement Gage, dial or digital type (see

10.1520/D4032-08R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

9.3).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Apparatus is commercially available.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4032 − 08 (2016)

FIG. 1 King Manual Operated Dial Model

of fabric to provide a sampling plan with a meaningful producer’s risk,

6.1.3.1 Dial gages with maximum reading pointer in differ-

consumer’s risk, acceptable quality level, and limiting quality level.

ent capacities ranging from 1 to 50 lbf, 0.5 to 25 kgf, or 5 to

200 N with 100 graduations minimum; or 7.3 Laboratory Sample—As a laboratory sample for accep-

6.1.3.2 Digital gage with maximum reading “hold” feature tance testing, take a full swatch 1 m (1 yd) long from the end

and capacity of 100 lbf, 50 kgf, or 500 N, with 1000 of each roll of fabric in the lot sample, after first discarding a

graduations minimum.

minimum of1m(1yd)of fabric from the very outside of the

6.1.4 Actuator, manual or pneumatic. rolls.

6.2 Specimen Marking Template, (102 by 204 mm) 4.0 by

8. Number and Preparation of Test Specimens

8.0 in.

8.1 Using the specimen marking template specified in 6.2,

6.3 Stop Watch, for checking stroke speed.

mark and cut five test specimens from staggered areas of each

7. Sampling swatchinthelaboratorysample.Theshortsideofthespecimen

must be parallel to the machine (length) direction of the fabric.

7.1 Lot Size—For sampling purposes, a lot is defined as a

Cut no specimens closer to the selvage than one tenth of the

single shipment of a single style of fabric.Alot may constitute

fabric width. Lay each specimen face down and fold the

all or part of a single customer order.

specimen once to form a square 4 by 4 in. (102 by 102 mm).

7.2 Lot Sample—As a lot sample for acceptance testing;

After folding, use the template and hand pressure to flatten the

take at random the number of rolls of fabric directed in an

crease. Handling of specimens must be kept to a minimum and

applicable material specification or other agreement between

to the edges to avoid affecting stiffness properties.

thepurchaserandthesupplier.Considerrollsoffabrictobethe

NOTE 3—When otherwise agreed upon, as when specified in an

primary sampling units.

applicable material specification, the purchaser and the seller may change

NOTE 2—An adequate specification or other agreement between the the number of test specimens per swatch from the laboratory sample.

purchaser and the supplier requires taking into account the variability NOTE 4—Fabrics may also be tested face-to-face

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.