ASTM E1114-09

(Test Method)Standard Test Method for Determining the Size of Iridium-192 Industrial Radiographic Sources

Standard Test Method for Determining the Size of Iridium-192 Industrial Radiographic Sources

SIGNIFICANCE AND USE

One of the factors affecting the quality of a radiographic image is geometric unsharpness. The degree of geometric unsharpness is dependent upon the size of the source, the distance between the source and the object to be radiographed, and the distance between the object to be radiographed and the film or digital detector. This test method allows the user to determine the size of the source and to use this result to establish source to object and object to film or detector distances appropriate for maintaining the desired degree of geometric unsharpness.

Note 1—The European standard CEN EN 12579 describes a simplified procedure for measurement of source sizes of Ir-192, Co-60 and Se-75. The resulting source size of Ir-192 is comparable to the results obtained by this test method.

SCOPE

1.1 This test method covers the determination of the size of an Iridium-192 radiographic source. The determination is based upon measurement of the image of the Iridium metal source in a projection radiograph of the source assembly and comparison to the measurement of the image of a reference sample in the same radiograph.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1114–09

Standard Test Method for

Determining the Size of Iridium-192 Industrial Radiographic

1

Sources

This standard is issued under the fixed designation E1114; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other International Standards:

EN 12579 Industrial Radiography—Radiographic Method

1.1 This test method covers the determination of the size of

for the Determination of the Source Size for Radioiso-

an Iridium-192 radiographic source. The determination is

3

topes

based upon measurement of the image of the Iridium metal

source in a projection radiograph of the source assembly and

3. Terminology

comparison to the measurement of the image of a reference

3.1 Fordefinitionsoftermsrelatingtothistestmethod,refer

sample in the same radiograph.

to Terminology E1316.

1.2 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

4. Significance and Use

each system may not be exact equivalents; therefore, each

4.1 One of the factors affecting the quality of a radiographic

system shall be used independently of the other. Combining

image is geometric unsharpness. The degree of geometric

values from the two systems may result in non-conformance

unsharpness is dependent upon the size of the source, the

with the standard.

distance between the source and the object to be radiographed,

1.3 This standard does not purport to address all of the

and the distance between the object to be radiographed and the

safety concerns, if any, associated with its use. It is the

film or digital detector. This test method allows the user to

responsibility of the user of this standard to establish appro-

determine the size of the source and to use this result to

priate safety and health practices and determine the applica-

establish source to object and object to film or detector

bility of regulatory limitations prior to use.

distances appropriate for maintaining the desired degree of

geometric unsharpness.

2. Referenced Documents

2

2.1 ASTM Standards:

NOTE 1—TheEuropeanstandardCENEN 12579describesasimplified

E999 Guide for Controlling the Quality of Industrial Radio- procedure for measurement of source sizes of Ir-192, Co-60 and Se-75.

TheresultingsourcesizeofIr-192iscomparabletotheresultsobtainedby

graphic Film Processing

this test method.

E1316 Terminology for Nondestructive Examinations

E1815 Test Method for Classification of Film Systems for

5. Apparatus

Industrial Radiography

5.1 Subject Iridium-192 Source, the source size of which is

E2445 Practice for Qualification and Long-Term Stability

to be determined.The appropriate apparatus and equipment for

of Computed Radiology Systems

the safe storage, handling, and manipulation of the subject

E2597 Practice for Manufacturing Characterization of Digi-

source,suchasaradiographicexposuredevice(alsoreferredto

tal Detector Arrays

as a gamma ray projector or camera), remote control, source

guide tube, and source stop are also required.

1

This test method is under the jurisdictioin of ASTM Committee E07 on

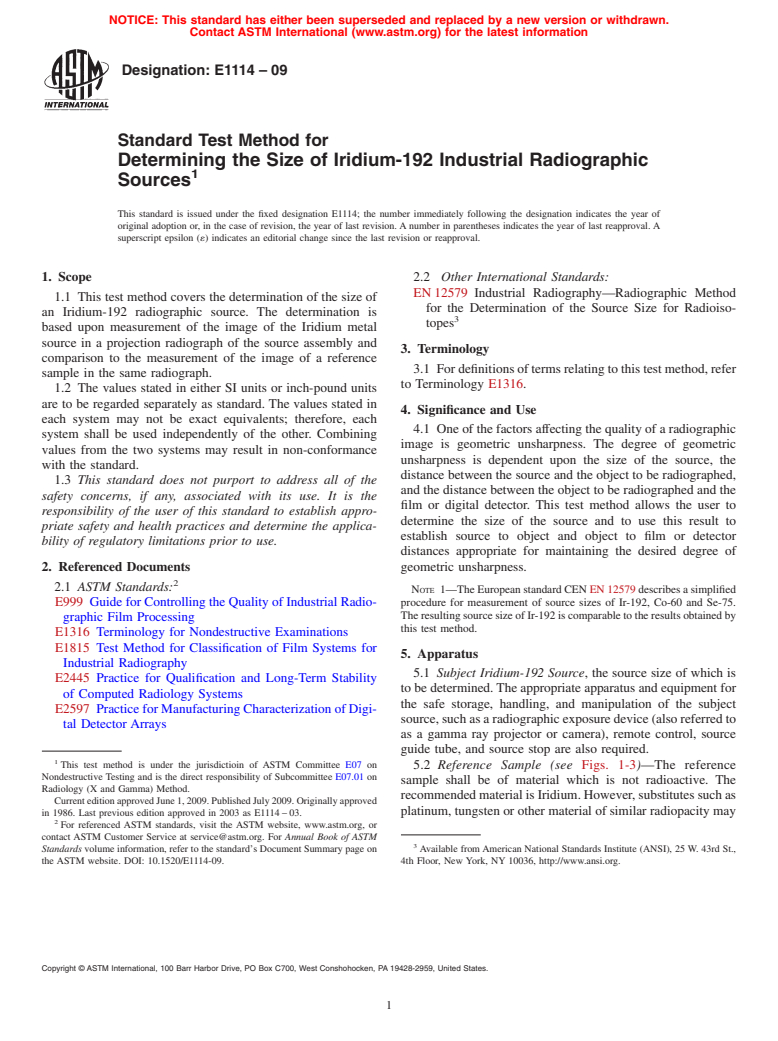

5.2 Reference Sample (see Figs. 1-3)—The reference

Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on

sample shall be of material which is not radioactive. The

Radiology (X and Gamma) Method.

recommendedmaterialisIridium.However,substitutessuchas

CurrenteditionapprovedJune1,2009.PublishedJuly2009.Originallyapproved

platinum, tungsten or other material of similar radiopacity may

in 1986. Last previous edition approved in 2003 as E1114 – 03.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. DOI: 10.1520/E1114-09. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1114 – 09

FIG. 1 Reference Sample in Standard Source Encapsulation

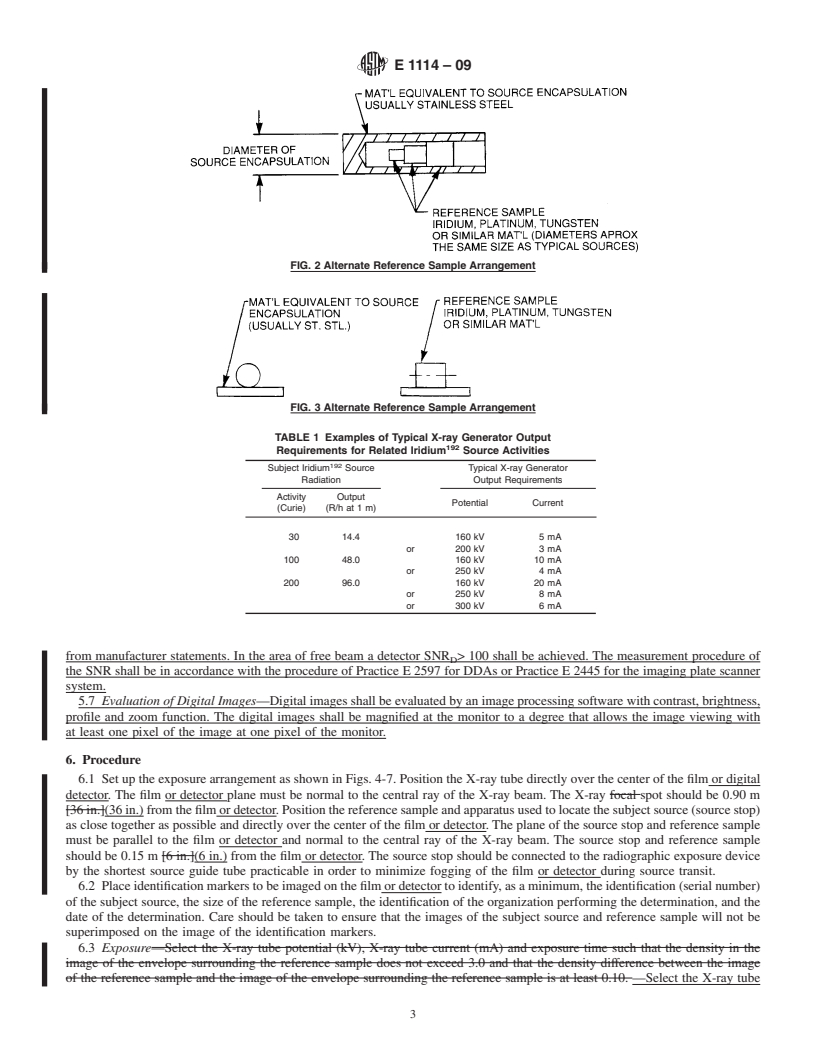

FIG. 2 Alternate Reference Sample Arrangement

FIG. 3 Alternate Reference Sample Arrangement

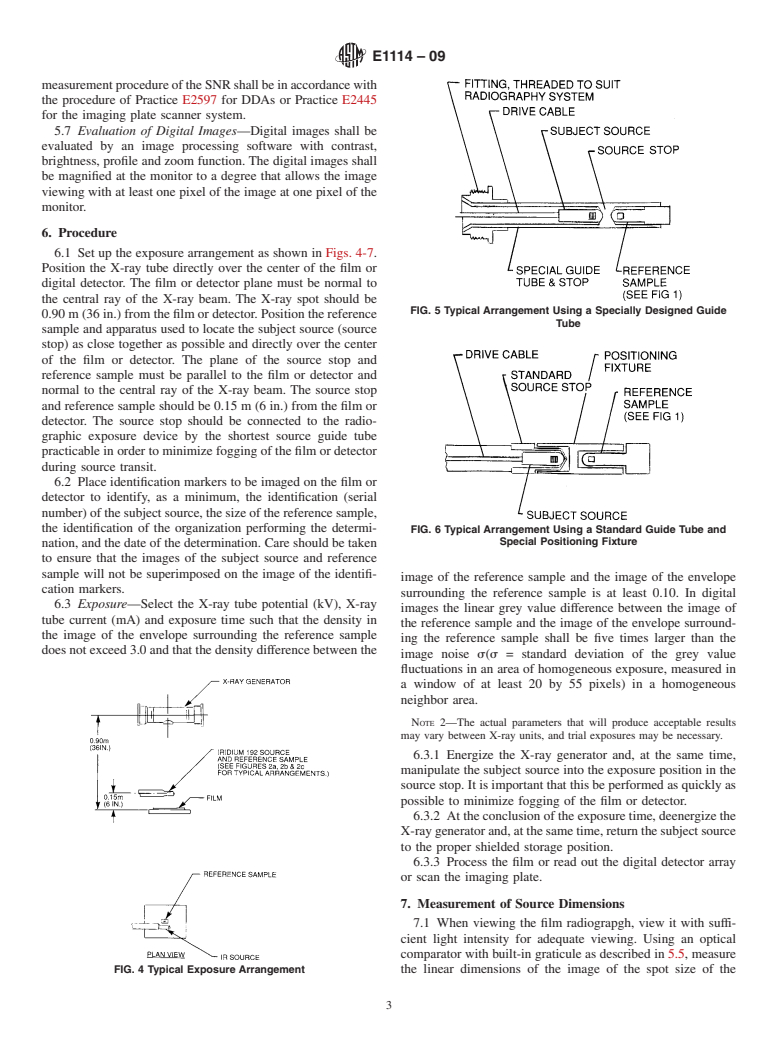

TABLE 1 Examples of Typical X-ray Generator Output

192

Requirements for Related Iridium Source Activities

be used. The sample should be of the same geometric shape as

192

Subject Iridium Source Typical X-ray Generator

the subject source, should be approximately the same size as

Radiation Output Requirements

the sub

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E1114–03 Designation:E1114–09

Standard Test Method for

Determining the Focal Size of Iridium-192 Industrial

1

Radiographic Sources

This standard is issued under the fixed designation E 1114; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1This test method covers the determination of the focal size of an iridium-192 radiographic source.The determination is based

upon measurement of the image of the iridium metal source in a projection radiograph of the source assembly and comparison to

the measurement of the image of a reference sample in the same radiograph.

1.2

1.1 This test method covers the determination of the size of an Iridium-192 radiographic source. The determination is based

upon measurement of the image of the Iridium metal source in a projection radiograph of the source assembly and comparison to

the measurement of the image of a reference sample in the same radiograph.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E 999 Guide for Controlling the Quality of Industrial Radiographic Film Processing

E 1316 Terminology for Nondestructive Examinations

2

E 1815 Test Method for Classification of Film Systems for Industrial Radiography Test Method for Classification of Film

Systems for Industrial Radiography

E 2445 Practice for Qualification and Long-Term Stability of Computed Radiology Systems

E 2597 Practice for Manufacturing Characterization of Digital Detector Arrays

1

This test method is under the jurisdictioin of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on Radiology

(X and Gamma) Method.

´1

Current edition approved March 10, 2003. Published May 2003. Originally approved in 1986. Last previous edition approved in 1997 as E1114–92 (1997) .

Current edition approved June 1, 2009. Published July 2009. Originally approved in 1986. Last previous edition approved in 2003 as E 1114 – 03.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

, Vol 03.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1114–09

2.2 Other International Standards:

3

EN 12579 Industrial Radiography—Radiographic Method for the Determination of the Source Size for Radioisotopes

3. Terminology

3.1 For definitions of terms relating to this test method, refer to Terminology E 1316.

4. Significance and Use

4.1One of the factors affecting the quality of a radiographic image is geometric unsharpness. The degree of geometric

unsharpness is dependent upon the focal size of the source, the distance between the source and the object to be radiographed, and

the distance between the object to be radiographed and the film. This test method allows the user to determine the focal size of

the source and to use this result to establish source to object and object to film distances appropriate for maintaining the desired

degree of geometric unsharpness.

4.1 One of the factors affecting the quality of a radiographic image is geometric unsharpness. The degree of geometric

unsharpness is dependent upon the size of the source, the distance between the source and the object to be radiographed, and the

distance between the object to be radiographed and the film or digital detector. This test method allows the user to determine the

size of the source and to use this result to establish source to object and object to film or detector distances appropriate for

maintaining the desired degree of geom

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.