ASTM C1761/C1761M-12

(Specification)Standard Specification for Lightweight Aggregate for Internal Curing of Concrete

Standard Specification for Lightweight Aggregate for Internal Curing of Concrete

SCOPE

1.1 This specification covers lightweight aggregate intended to provide water for internal curing of concrete. It includes test methods for determining the absorption and desorption properties of lightweight aggregate.

Note 1—Internal curing provides an additional source of water to sustain hydration and substantially reduce the early-age autogenous shrinkage and self-desiccation that can be significant contributors to early-age cracking. Appendix X1 provides guidance on calculating the quantity of lightweight aggregate for internal curing.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance. Some values have only SI units because the inch-pound equivalents are not used in practice.

Note 2—Sieve size is identified by its standard designation in Specification E11. The alternative designation given in parentheses is for information only and does not represent a different standard sieve size.

1.3 The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1761/C1761M −12

StandardSpecification for

Lightweight Aggregate for Internal Curing of Concrete

This standard is issued under the fixed designation C1761/C1761M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C87 Test Method for Effect of Organic Impurities in Fine

Aggregate on Strength of Mortar

1.1 Thisspecificationcoverslightweightaggregateintended

C114 Test Methods for Chemical Analysis of Hydraulic

to provide water for internal curing of concrete. It includes test

Cement

methods for determining the absorption and desorption prop-

C125 Terminology Relating to Concrete and Concrete Ag-

erties of lightweight aggregate.

gregates

NOTE 1—Internal curing provides an additional source of water to

C128 Test Method for Density, Relative Density (Specific

sustain hydration and substantially reduce the early-age autogenous

shrinkage and self-desiccation that can be significant contributors to

Gravity), and Absorption of Fine Aggregate

early-age cracking. Appendix X1 provides guidance on calculating the

C136 Test Method for Sieve Analysis of Fine and Coarse

quantity of lightweight aggregate for internal curing.

Aggregates

1.2 The values stated in either SI units or inch-pound units

C142 Test Method for Clay Lumps and Friable Particles in

are to be regarded separately as standard. The values stated in

Aggregates

each system may not be exact equivalents; therefore, each

C330/C330M Specification for Lightweight Aggregates for

system shall be used independently of the other. Combining

Structural Concrete

values from the two systems may result in non-conformance.

C641 Test Method for Iron Staining Materials in Light-

Some values have only SI units because the inch-pound

weight Concrete Aggregates

equivalents are not used in practice.

C702 PracticeforReducingSamplesofAggregatetoTesting

NOTE 2—Sieve size is identified by its standard designation in Speci-

Size

fication E11. The alternative designation given in parentheses is for

C1498 Test Method for Hygroscopic Sorption Isotherms of

information only and does not represent a different standard sieve size.

Building Materials

1.3 The text of this standard references notes and footnotes

C1608 Test Method for Chemical Shrinkage of Hydraulic

that provide explanatory material. These notes and footnotes

Cement Paste

(excluding those in tables and figures) shall not be considered

C1698 Test Method for Autogenous Strain of Cement Paste

as requirements of the standard.

and Mortar

1.4 This standard does not purport to address all of the

D75 Practice for Sampling Aggregates

safety concerns, if any, associated with its use. It is the

E11 Specification for Woven Wire Test Sieve Cloth and Test

responsibility of the user of this standard to establish appro-

Sieves

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use.

3.1 Definitions:

2. Referenced Documents

3.1.1 For definitions of terms used in this practice, refer to

2.1 ASTM Standards: Terminology C125.

C29/C29M Test Method for Bulk Density (“Unit Weight”) 3.2 Definitions of Terms Specific to This Standard:

and Voids in Aggregate 3.2.1 absorption, A , n—of lightweight aggregate, the in-

C40 Test Method for Organic Impurities in FineAggregates creaseinmassofaspecimenofoven-drylightweightaggregate

for Concrete due to water penetrating into the permeable pores of the

particles after being submerged for 72 h, expressed as percent-

1 age of oven-dry mass.

This specification is under the jurisdiction of ASTM Committee C09 on

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

3.2.2 autogenous shrinkage, n—reduction in volume due to

C09.21 on Lightweight Aggregates and Concrete.

chemical shrinkage of a sealed cementitious mixture, not

Current edition approved June 15, 2012. Published August 2012. DOI: 10.1520/

subjected to external forces and under constant temperature,

C1761_C1761M-12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

measured from the time of final setting.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.3 chemical shrinkage, n—the reduction in volume of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. cementitious paste that occurs during hydration because the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1761/C1761M−12

hydration products occupy less volume than the volume CS = chemicalshrinkageofcementitiousmaterial,expressed

occupied originally by the water and unhydrated cementitious as kg water/kg of cement [lb/lb] (see Note 3).

materials. S = degree of saturation of lightweight aggregate relative to

wetted surface-dry condition (0 to 1.0).

3.2.4 density (OD), n—the mass of oven-dry lightweight

w/cm = water-cementitious materials ratio, kg/kg [lb/lb].

aggregate particles per unit volume of aggregate particles,

α = maximum potential degree of hydration of cementi-

max

where the volume includes the permeable and impermeable

tious materials expressed as a decimal fraction (0 to 1.0).

pores within the particles but does not include the voids

W = mass of water released by lightweight aggregate in

LWA

between the particles.

going from the wetted surface-dry condition to the equilibrium

3.2.5 desorption, n—the decrease in mass of lightweight

mass at a relative humidity of 94 %, expressed as a fraction of

aggregate originally containing absorbed water due to water

the oven-dry mass.

leaving the permeable pores as the aggregate attains moisture

NOTE 3—Chemical shrinkage is measured in units of volume of water

equilibrium with the surrounding environment maintained at

per unit mass of cement. In using the value of chemical shrinkage to

constant temperature and a relative humidity less than 100 %.

calculate the required amount of lightweight aggregate for internal curing,

the volume of water is converted to the mass of water. Hence chemical

3.2.6 internal curing, n—supplying water within a cemen-

shrinkage is expressed as mass of water per unit mass of cement.

titiousmixtureusingpre-wettedlightweightaggregate,orother

materials that readily release water from within the particles,

4. Ordering Information

thereby mitigating self-desiccation and sustaining hydration.

4.1 The direct purchaser of lightweight aggregate for inter-

3.2.7 oven-dry (OD), adj—related to aggregate particles,

nal curing shall include the following information in the

the condition in which the specimen of lightweight aggregate

purchase order as applicable.

has been dried by heating in an oven at 110 6 5 °C [230 6 10

4.1.1 Reference to this specification, as Specification

°F] for sufficient time to reach a constant mass.

C1761.

3.2.8 relative density, (OD), n—theratioofthedensity(OD)

4.1.2 Whether the order is for fine aggregate, coarse

of the lightweight aggregate to the density of water at a stated

aggregate, or combined fine and coarse aggregate.

temperature.

4.1.3 Quantity in metric tons [tons] or cubic meters [cubic

yards].

3.2.9 wetted surface-dry (WSD), adj—related to lightweight

4.1.4 If the order is for coarse aggregate or combined fine

aggregate particles, the condition in which the permeable

and coarse aggregate, provide the nominal size designation as

poresoflightweightaggregateparticlesarefilledwithwater,to

given in Table 1 or alternative grading as agreed between the

the extent achieved by submerging an oven-dry specimen for

purchaser and aggregate supplier.

72 h, and the surfaces of the particles are dry.

4.1.5 Whethercertificationshallbefurnishedindicatingthat

3.2.10 self-desiccation, n—reduction in the internal relative

the material was sampled and tested in accordance with this

humidity of a sealed cementitious mixture as a result of

specification and found to meet the requirements.

chemical shrinkage.

4.1.6 Whether a report of the results of aggregate tests shall

3.3 Symbols: be furnished.

A = the 72-h absorption, expressed as a percentage of the

4.1.7 Whether the results of tests of concrete properties are

oven-dry mass. required.

G = relative density (oven-dry) of lightweight aggregate. 4.1.8 Any exceptions or additions to this specification.

OD

G = relative density (oven-dry) of normal weight aggre-

ODN

5. Materials and Manufacture

gate.

M = calculated mass of oven-dry lightweight aggregate 5.1 Two general types of lightweight aggregate are covered

LWA

needed for internal curing per unit volume of concrete,

by this specification, as follows:

3 3

kg/m [lb/yd ]. 5.1.1 Aggregates produced by expanding, pelletizing, or

M = mass of normal weight aggregate in oven-dry con- sintering products such as blast-furnace slag, clay, diatomite,

NWA

3 3

fly ash, shale, or slate, and

dition to be removed, kg/m [lb/yd ].

5.1.2 Aggregate prepared by processing natural materials,

M = mass of lightweight aggregate specimen in oven-dry

OD

such as pumice, scoria, and tuff.

condition, g.

M = mass of pycnometer containing lightweight aggregate

5.2 The aggregate shall be composed predominately of

PS

specimen and filled with water, g.

lightweight-cellular and granular inorganic materials.

M = mass of pycnometer filled with water, g.

PW

6. Chemical Requirements

M = mass of lightweight aggregate specimen in wetted

SD

surface-dry condition, g.

6.1 Organic Impurities—Test Method C40. Lightweight

M = equilibrium mass of aggregate originally in wetted

aggregate shall not produce a color darker than the standard

surface-dry condition and subsequently stored at 94 % relative

color solution, unless it is demonstrated that when the aggre-

humidity, g.

gate is tested for the effect of organic impurities on strength of

C = cementitious materials content of concrete mixture, mortar, the relative strength at 7 days, determined in accor-

f

3 3

kg/m [lb/yd ]. dance with Test Method C87, is not less than 95 %.

C1761/C1761M−12

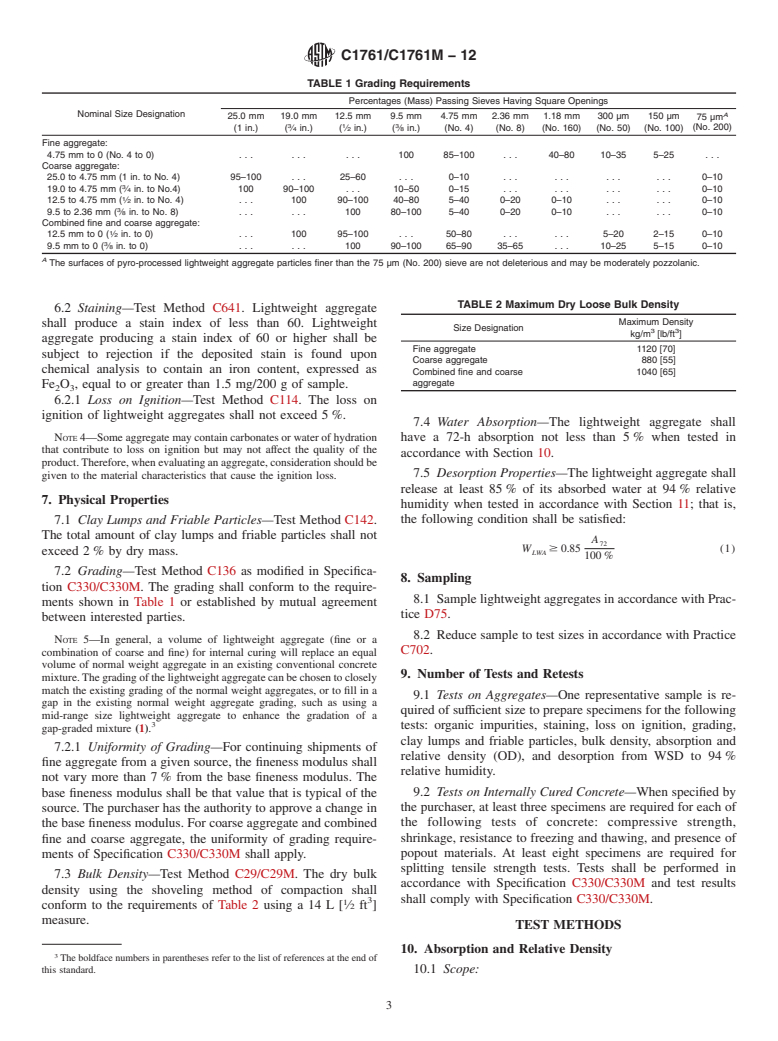

TABLE 1 Grading Requirements

Percentages (Mass) Passing Sieves Having Square Openings

A

Nominal Size Designation

25.0 mm 19.0 mm 12.5 mm 9.5 mm 4.75 mm 2.36 mm 1.18 mm 300 µm 150 µm

75 µm

3 1 3

(No. 200)

(1 in.) ( ⁄4 in.) ( ⁄2 in.) ( ⁄8 in.) (No. 4) (No. 8) (No. 160) (No. 50) (No. 100)

Fine aggregate:

4.75 mm to 0 (No. 4 to 0) . . . . . . . . . 100 85–100 . . . 40–80 10–35 5–25 . . .

Coarse aggregate:

25.0 to 4.75 mm (1 in. to No. 4) 95–100 . . . 25–60 . . . 0–10 . . . . . . . . . . . . 0–10

19.0to4.75mm( ⁄4 in. to No.4) 100 90–100 . . . 10–50 0–15 . . . . . . . . . . . . 0–10

12.5to4.75mm( ⁄2 in. to No. 4) . . . 100 90–100 40–80 5–40 0–20 0–10 . . . . . . 0–10

9.5to2.36mm( ⁄8 in. to No. 8) . . . . . . 100 80–100 5–40 0–20 0–10 . . . . . . 0–10

Combined fine and coarse aggregate:

12.5mmto0( ⁄2 in. to 0) . . . 100 95–100 . . . 50–80 . . . . . . 5–20 2–15 0–10

9.5mmto0( ⁄8 in. to 0) . . . . . . 100 90–100 65–90 35–65 . . . 10–25 5–15 0–10

A

The surfaces of pyro-processed lightweight aggregate particles finer than the 75 µm (No. 200) sieve are not deleterious and may be moderately pozzolanic.

TABLE 2 Maximum Dry Loose Bulk Density

6.2 Staining—Test Method C641. Lightweight aggregate

Maximum Density

shall produce a stain index of less than 60. Lightweight

Size Designation

3 3

kg/m [lb/ft ]

aggregate producing a stain index of 60 or higher shall be

Fine aggregate 1120 [70]

subject to rejection if the deposited stain is found upon

Coarse aggregate 880 [55]

chemical analysis to contain an iron content, expressed as

Combined fine and coarse 1040 [65]

aggregate

Fe O , equal to or greater than 1.5 mg/200 g of sample.

2 3

6.2.1 Loss on Ignition—Test Method C114. The loss on

ignition of lightweight aggregates shall not exceed 5 %.

7.4 Water Absorption—The lightweight aggregate shall

NOTE 4—Some aggregate may contain carbonates or water of hydration have a 72-h absorption not less than 5 % when tested in

that contribute to loss on ignition but may not affect the quality of the

accordance with Section 10.

product.Therefore,whenevaluatinganaggregate,considerationshouldbe

7.5 Desorption Properties—The lightweight aggregate shall

given to the material characteristics that cause the ignition loss.

release at least 85 % of its absorbed water at 94 % relative

7. Physical Properties

humidity when tested in accordance with Section 11; that is,

the following condition shall be satisfied:

7.1 Clay Lumps and Friable Particles—Test Method C142.

The total amount of clay lumps and friable particles shall not

A

W $ 0.85 (1)

exceed 2 % by dry mass. LWA

100 %

7.2 Grading—Test Method C136 as modified in Specifica-

8. Sampling

tion C330/C330M. The grading shall conform to the require-

8.1 Sample lightweight aggregates in accordance with Prac-

ments shown in Table 1 or established by mutual agreement

tice D75.

between interested parties.

8.2 Reduce sample to test sizes in accordance with Practice

NOTE 5—In general, a volume of lightweight aggregate (fine or a

C702.

combination of coarse and fine) for internal curing will replace an equal

volume of normal weight aggregate in an existing conventional concrete

9. Number of Tests and Retests

mixture.Thegradingofthelightweightaggregatecanbechosentoclosely

match the existing grading of the normal weight aggregates, or to fill in a

9.1 Tests on Aggregates—One representative sample is re-

gap in the existing normal weight aggregate grading, such as using a

quired of sufficient size to prepare specimens for the following

mid-range size lightweight aggregate to enhance the gradation of a

tests: organic impurities, staining, loss on ignition, grading,

gap-graded mixture (1).

clay lumps and friable particles, bulk density, absorption and

7.2.1 Uniformity of Grading—For continuing shipments of

relative density (OD), and desorption from WSD to 94 %

fine aggregate from a given source, the fineness modulus shall

relative humidity.

not vary more than 7 % from the base fineness modulus. The

9.2 Tests on Internally Cured Concrete—When specified by

base fineness modulus shall be that value that is typical of the

the purchaser, at least three specimens are required for each of

source. The purchaser has the authority to approve a change in

the following tests of concrete: compressive strength,

the base fineness modulus. For coarse aggregate and combined

shrinkage, resistance to freezing and thawing, and presence of

fine and coarse aggregate, the uniformity of grading require-

popout materials. At least eight specimens are required for

ments of Specification C330/C330M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.