ASTM F1130-99(2014)

(Practice)Standard Practice for Inspecting the Coating System of a Ship

Standard Practice for Inspecting the Coating System of a Ship

SIGNIFICANCE AND USE

3.1 This practice establishes the procedure for the inspection of coating systems on board ships. It contains a series of diagrams to be used to report the extent of damage to coatings.

SCOPE

1.1 This practice covers a standard procedure for inspecting the coating system of a ship's topside and superstructure, tanks and voids, decks and deck machinery, and underwater hull and boottop during drydocking. Included are a standard inspection form to be used for reporting the inspection data, a diagram that divides topside and superstructure individual inspection areas, and a series of diagrams that are used to report the extent of damage to the coating system.

1.2 This practice is intended for use only by an experienced marine coating inspector.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1130 − 99 (Reapproved 2014) An American National Standard

Standard Practice for

Inspecting the Coating System of a Ship

This standard is issued under the fixed designation F1130; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

1.1 This practice covers a standard procedure for inspecting 3.1 This practice establishes the procedure for the inspec-

the coating system of a ship’s topside and superstructure, tanks tion of coating systems on board ships. It contains a series of

and voids, decks and deck machinery, and underwater hull and diagrams to be used to report the extent of damage to coatings.

boottop during drydocking. Included are a standard inspection

form to be used for reporting the inspection data, a diagram

4. Reference Standards

that divides topside and superstructure individual inspection

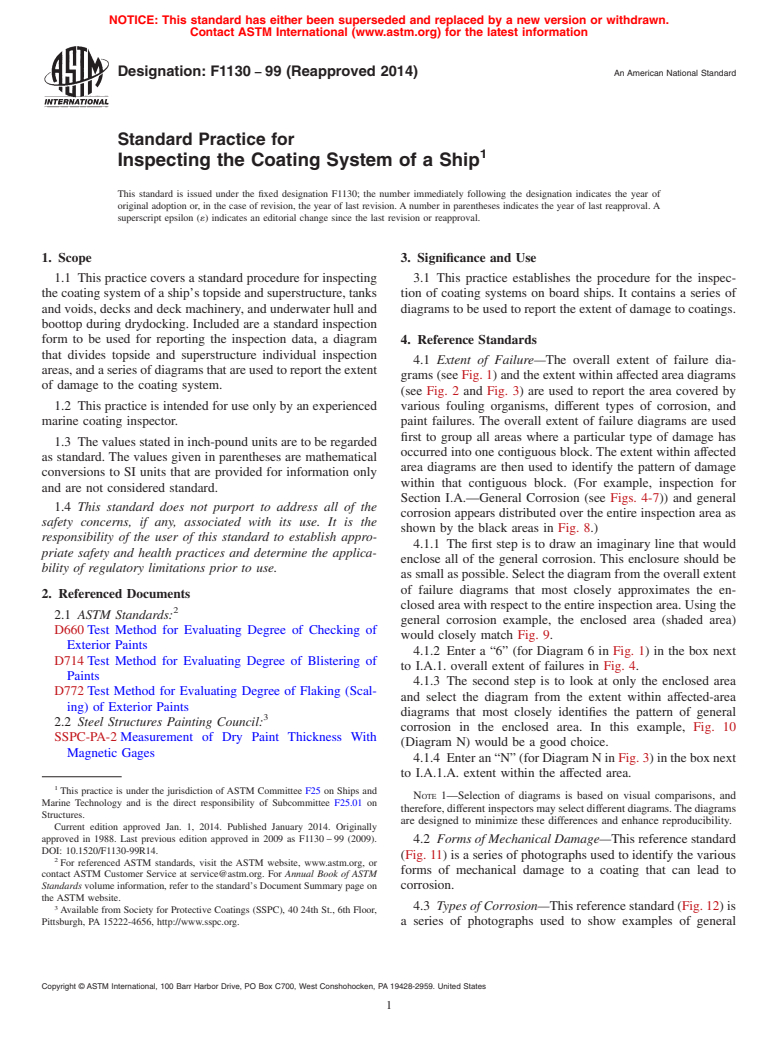

4.1 Extent of Failure—The overall extent of failure dia-

areas,andaseriesofdiagramsthatareusedtoreporttheextent

grams (see Fig. 1) and the extent within affected area diagrams

of damage to the coating system.

(see Fig. 2 and Fig. 3) are used to report the area covered by

1.2 This practice is intended for use only by an experienced various fouling organisms, different types of corrosion, and

marine coating inspector. paint failures. The overall extent of failure diagrams are used

first to group all areas where a particular type of damage has

1.3 The values stated in inch-pound units are to be regarded

occurred into one contiguous block. The extent within affected

as standard. The values given in parentheses are mathematical

area diagrams are then used to identify the pattern of damage

conversions to SI units that are provided for information only

within that contiguous block. (For example, inspection for

and are not considered standard.

Section I.A.—General Corrosion (see Figs. 4-7)) and general

1.4 This standard does not purport to address all of the

corrosion appears distributed over the entire inspection area as

safety concerns, if any, associated with its use. It is the

shown by the black areas in Fig. 8.)

responsibility of the user of this standard to establish appro-

4.1.1 The first step is to draw an imaginary line that would

priate safety and health practices and determine the applica-

enclose all of the general corrosion. This enclosure should be

bility of regulatory limitations prior to use.

as small as possible. Select the diagram from the overall extent

of failure diagrams that most closely approximates the en-

2. Referenced Documents

closed area with respect to the entire inspection area. Using the

2.1 ASTM Standards:

general corrosion example, the enclosed area (shaded area)

D660 Test Method for Evaluating Degree of Checking of

would closely match Fig. 9.

Exterior Paints

4.1.2 Enter a “6” (for Diagram 6 in Fig. 1) in the box next

D714 Test Method for Evaluating Degree of Blistering of

to I.A.1. overall extent of failures in Fig. 4.

Paints

4.1.3 The second step is to look at only the enclosed area

D772 Test Method for Evaluating Degree of Flaking (Scal-

and select the diagram from the extent within affected-area

ing) of Exterior Paints

diagrams that most closely identifies the pattern of general

2.2 Steel Structures Painting Council:

corrosion in the enclosed area. In this example, Fig. 10

SSPC-PA-2 Measurement of Dry Paint Thickness With

(Diagram N) would be a good choice.

Magnetic Gages

4.1.4 Enter an “N” (for Diagram N inFig. 3) in the box next

to I.A.1.A. extent within the affected area.

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

NOTE 1—Selection of diagrams is based on visual comparisons, and

Marine Technology and is the direct responsibility of Subcommittee F25.01 on

therefore,differentinspectorsmayselectdifferentdiagrams.Thediagrams

Structures.

are designed to minimize these differences and enhance reproducibility.

Current edition approved Jan. 1, 2014. Published January 2014. Originally

approved in 1988. Last previous edition approved in 2009 as F1130 – 99 (2009).

4.2 FormsofMechanicalDamage—This reference standard

DOI: 10.1520/F1130-99R14.

(Fig. 11) is a series of photographs used to identify the various

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

forms of mechanical damage to a coating that can lead to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on corrosion.

the ASTM website.

4.3 TypesofCorrosion—This reference standard (Fig. 12)is

Available from Society for Protective Coatings (SSPC), 40 24th St., 6th Floor,

Pittsburgh, PA 15222-4656, http://www.sspc.org. a series of photographs used to show examples of general

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1130 − 99 (2014)

FIG. 2 Extent Within Affected Area Diagrams (B Through K)

NOTE 1—The specific type of failure is to be defined. The failure may

be fouling, corrosion, and so forth. Do not combine all failures into one

overall extent diagram.

6. Procedure

FIG. 1 Overall Extent of Failure Diagrams

6.1 The inspection form consists of two pages to be com-

pleted by the inspector and four pages of reference standards.

Complete the first of the two pages as shown in Fig. 17. This

coating damage. Included could be general corrosion, pitting

form, which is self-explanatory, requests general information

corrosion, pin-point corrosion, galvanic corrosion/coating

about the ship.

undercutting, cavitation corrosion, corrosion along welds, and

6.2 The second page of the applicable inspection form to be

rust staining.

completed by the inspector is shown in Figs. 4-7. Complete a

4.4 Levels of Delamination—This reference standard (Fig.

separate inspection form for each of the inspection areas

13) is a series of diagrams that identifies the levels in a coating

delineated in Figs. 14-16. Instructions for completing the form

system where delamination can occur.

(shown in Figs. 4-7) are given in Section 7.

6.2.1 For the ship’s topside and superstructure, divide the

5. Requirements for Inspectors

inspection area into six sections.These six inspection areas are

5.1 The inspector must be able to perform the following defined by the diagram in Fig. 14. For each complete

tasks: inspection, complete one form, shown in Fig. 4, for each

5.1.1 Calibrate and use a magnetic gage to measure dry film section.

thickness (DFT). 6.2.2 For the ship’s tanks and voids, divide the inspection

5.1.2 Use pH paper or pH meter properly. area into seven sections. These seven inspection areas are

5.1.3 Use a camera properly. defined by the diagram in Fig. 15. For each complete tank

5.1.4 Recognize the various types of corrosion and forms of inspection, complete one form, shown in Fig. 5, for each

paint failures (blistering, delamination, and so forth). section.

5.1.5 Recognize the various ship areas as described in Figs. 6.2.3 For the ship’s underwater hull and boottop, divide the

14-16. inspection area into twelve inspection areas. These twelve

F1130 − 99 (2014)

area being inspected. (For example, enter “SA” for the super-

structure aft; “SM” for the superstructure midships;“ SF” for

the superstructure forward; “SO” for other superstructure, that

is, bulwarks, vents, sideport openings, and so forth; “HS” for

hull starboard; and “HP” for hull port.)

7.1.1 A tank is segmented into seven inspection areas (see

Fig. 15. Enter the code for the area being inspected. (For

example, enter “B” for the bottom of tank inspection, “A” for

the aft bulkhead, and so forth.) A complete list of tank

segments and their codes is shown in Fig. 15.

7.1.2 The underwater hull and boottop are segmented into

twelve distinct inspection areas. Enter the code for the area

being inspected. (For example, enter “P1” for the port bow

inspection, “S1” for the starboard bow inspection, and so

forth.) A complete list of hull segments and their codes is

shown in Fig. 16.

7.1.3 Decks and deck machinery vary so greatly between

ship types that the development of a general diagram with

logical inspection areas and inspection area codes is not

feasible. It should be the responsibility of the organization that

authorizes the inspections to develop the ship diagram, logical

inspection areas, and inspection area codes and to make certain

that this same coding system is used during all subsequent

inspections.

7.2 Date—Enter the date of the inspection. If the inspection

requires more than one day, enter the date the inspection is

completed.

7.3 Ship Name—Enter the ship’s name (for example, LPH-

14, USS Trenton).

7.4 Hull Number—Enter the builder’s hull number of the

ship (for example, Nassco No. 1182).

FIG. 3 Extent Within Affected Area Diagrams (L Through V)

7.5 Inspector’sName—Theinspectorshouldprinthisname.

inspectionareasaredefinedbythediagraminFig.16.Foreach

complete underwater hull inspection, complete one form,

7.6 Tank Number—Enter tank designation.

shown in Fig. 6, for each section.

7.7 Tank Type—Enter type (for example, fuel oil, ballast,

6.2.4 For the ship’s deck and machinery, the inspection area

and so forth).

is a code which is used to designate an area of the ship’s deck

or a piece of deck machinery. The purpose of the code is to

7.8 Required Photographs—For each inspection area, a

identify positively the area being inspected so that a history of

photograph of the entire area is required. If the area is too large

inspection data can be gathered. For sections of the ship other

to capture in one photograph, the area should be divided into

than decks and deck machinery (that is, underwater hull,

equal-sized segments and each segment should be photo-

boottop,topside,superstructure,tanks,andvoids),itispossible

graphed. An individual close-up photograph of each damaged

to develop a general diagram of the ship section. Divide the

section in the inspection area is required. Each photograph

ship section into logical inspection areas, and provide inspec-

should be marked with the area number, ship name, and date.

tion area codes for these inspection areas. Decks and deck

Also a size scale should be captured in each photograph. This

machinery vary so greatly between ship types that the devel-

size scale is a reference standard that would be used to

opment of a general diagram with logical inspection areas and

determine the approximate size of the photographed ship area.

inspection area codes is not feasible. It should be the respon-

(For example, a 12-in. (304.8-mm) rule might be an appropri-

sibility of the organization that authorizes the inspections to

ate size scale for a relatively small ship area.)

develop the ship diagram, logical inspection areas, and inspec-

7.9 Inspection Area Obscured—If the inspection area is

tion area codes and to make certain that this same coding

completely obscured and cannot be inspected, circle the “Y.”

system is used during all subsequent inspections.

This condition of being completely obscured will probably

7. Form Instructions

occur most frequently in the bottom inspection area (“B”)

where dirt and other contaminants have settled. If the inspec-

7.1 Inspection Area—The topside/superstructure is divided

into six inspection areas (see Fig. 14). Enter the code for the tion area is not completely obscured, circle the “N.”

F1130 − 99 (2014)

FIG. 4 Topside and Superstructure

F1130 − 99 (2014)

FIG. 5 Tanks and Voids

F1130 − 99 (2014)

FIG. 6 Underwater Hull and Boottop

F1130 − 99 (2014)

FIG. 7 Decks and Deck Machinery)

CORROSION corrosion, galvanic corrosion/coating undercutting, or rust

staining in 8.1.2, 8.1.3, 8.1.4, 8.1.5, and 8.1.6. Patches of

8. Classification of Corrosion

common, ordinary rusting are classified as general corrosion.

8.1 The inspector should distinguish between six types of 8.1.2 Mechanical Damage—Mechanical damage corrosion

corrosion and report each type separately. The six types of is corrosion that occurred because the paint was removed from

corrosion are as follows: the hull by some type of scraping or impact against the hull.

8.1.1 General Corrosion—General corrosion, for the pur- With the paint removed and the steel hull exposed to sea water,

poses of this inspection form, is all corrosion that is not corrosion occurred. Photographic examples of corrosion

covered in the mechanical damage, pitting corrosion, pinpoint caused by various forms of mechanical damage (that is,

F1130 − 99 (2014)

FIG. 8 General Corrosion

FIG. 9 Overall Extent of Failure—General Corrosion

FIG. 10 Extent Within Affected Area—General Corrosion

FIG. 12 Types of Corrosion

into the steel hull surface. These pits distinguish between

pitting corrosion and general corrosion, the latter being char-

FIG. 11 Forms of Mechanical Damage

acterized by a layer of rust that does not penetrate locally into

the surface but is more uniform in extent. A photographic

scraping/impact, anchor chains/ropes, and internal welds/ example of pitting corrosion is shown in Fig. 12.

burning) are shown in Fig. 8. 8.1.4 Pin-Point Corrosion—Pin-point corrosion is charac-

8.1.3 Pitting Corrosion—Pitting corrosion is a more ad- terized by a pattern of small spots (pin-points) of rust. A

vanced form of localized corrosion. Pitting corrosion is char- photographic example of pin-point corrosion is shown in Fig.

acterized by visible indentations or pits that have penetrated 12.

F1130 − 99 (2014)

NOTE 1—Each inspection area is to be inspected for all the properties

listed on the accompanying inspection form (Fig. 5).

FIG. 15 Standardized Inspection—Tanks and Voids

8.1.6 Rust Staining—Rust staining occurs on top of the

coating with no penetration to the substrate. A photographic

example is shown in Fig. 12.

FIG. 13 Levels of Delamination

FOULING

9. Examination of Fouling (Underwater Hull and

Boottop)

9.1 Slime:

9.1.1 Overall Extent of Failure—Using the overall extent of

failurediagrams(diagramsandinstructionforusein4.1),enter

the number of the diagram that most closely approximates the

overall extent of slime fouling. If there is no slime fouling in

this inspection area, enter the nu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.