ASTM C714-05

(Test Method)Standard Test Method for Thermal Diffusivity of Carbon and Graphite by Thermal Pulse Method

Standard Test Method for Thermal Diffusivity of Carbon and Graphite by Thermal Pulse Method

SCOPE

1.1 This test method covers the determination of the thermal diffusivity of carbons and graphite to 5 % at temperatures up to 500C. It requires only a small easily fabricated specimen. Thermal diffusivity values in the range from 0.04 to 2.0 cm2/s are readily measurable by this test method; however, for the reason outlined in Section , for materials outside this range this test method may require modification.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:C714–05

Standard Test Method for

Thermal Diffusivity of Carbon and Graphite by Thermal

1

Pulse Method

This standard is issued under the fixed designation C 714; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope experimentally from the oscilloscope trace, an example of

1 1

which is shown in Fig. 2.If D T (10 t ⁄2 )/D T (t ⁄2 ) > 1.98, the

1.1 Thistestmethodcoversthedeterminationofthethermal

heat losses are assumed to be zero.

diffusivity of carbons and graphite to 65 % at temperatures up

2.2.3 The oscilloscope trace must be such that DT , D T

to 500°C. It requires only a small easily fabricated specimen. max

1 1

2

(10 t ⁄2 ), and t ⁄2 can be determined to 62%.

Thermal diffusivity values in the range from 0.04 to 2.0 cm /s

2.2.4 The other conditions are less critical, and the experi-

are readily measurable by this test method; however, for the

menter is left to his discretion.

reason outlined in Section 5, for materials outside this range

this test method may require modification.

3. Significance and Use

1.2 This standard does not purport to address all of the

3.1 Thermaldiffusivityisanimportantpropertyrequiredfor

safety concerns, if any, associated with its use. It is the

such purposes as design applications under transient heat flow

responsibility of the user of this standard to establish appro-

conditions, determination of safe operating temperature, pro-

priate safety and health practices and determine the applica-

cess control, and quality assurance.

bility of regulatory limitations prior to use.

3.2 The flash method is used to measure values of thermal

2. Summary of Test Method diffusivity (a) of a wide range of solid materials. It is

particularly advantageous because of the simple specimen

2.1 A high-intensity short-duration thermal pulse from a

geometry, small specimen size requirements, rapidity of mea-

flash lamp is absorbed on the front surface of a specimen; and

surement, and ease of handling materials having a wide range

the rear surface temperature change as a function of time is

of thermal diffusivity values over a large temperature range

observed on an oscilloscope. The pulse raises the average

with a single apparatus.The short measurement times involved

temperature of the specimen only a few degrees above its

reduce the chances of contamination and change of specimen

initial value. The ambient temperature of the specimen is

properties due to exposure to high temperature environments.

controlled by a furnace or cryostat. Thermal diffusivity is

3.3 Thermal diffusivity results in many cases can be com-

calculated from the specimen thickness and the time required

bined with values for specific heat (C ) and density (r) and

for the temperature of the back surface to rise to one half of its p

2

used to derive thermal conductivity (l) from the relation l =

maximum value (1).

aC r.

2.2 The critical factors in this test method are: p

3.4 This test method can be used to characterize graphite for

1

2.2.1 t/t ⁄2 must be 0.02 or less. t is the pulse time as defined

design purposes.

1

in Fig. 1 and t ⁄2 is the time for the rear surface temperature to

rise to one half of its maximum value (see Fig. 2).

4. Apparatus

2.2.2 Heat losses from the specimen via radiation, convec-

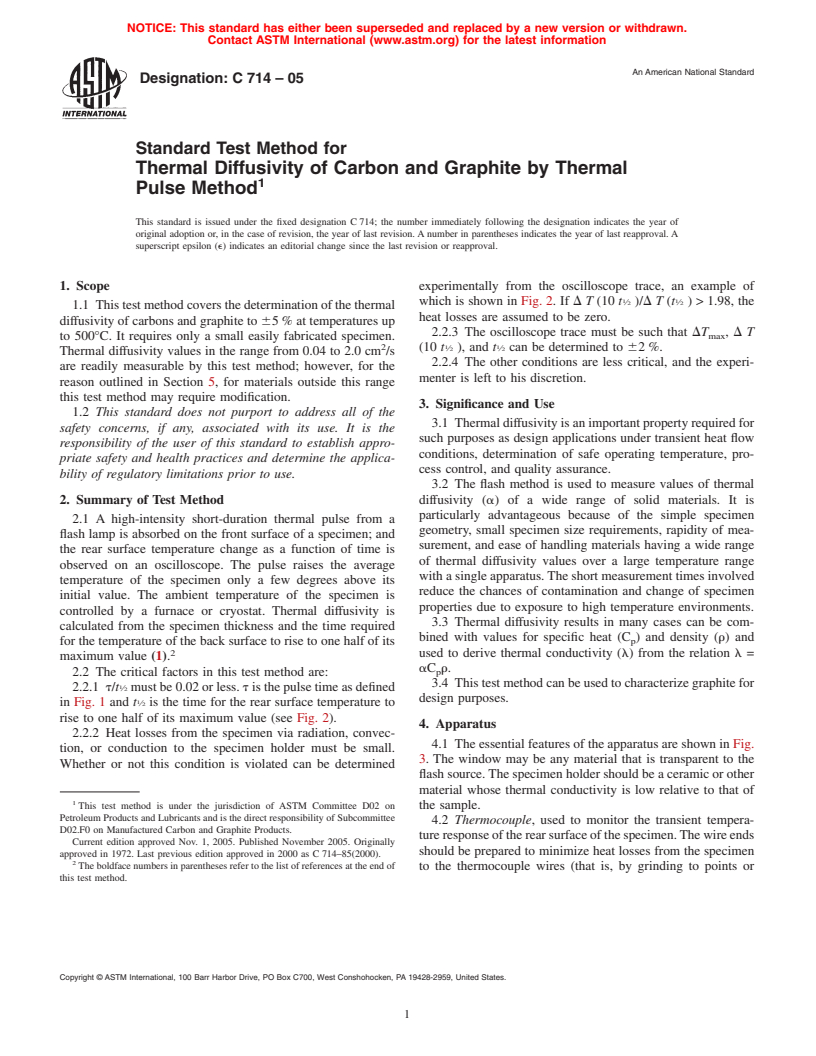

4.1 The essential features of the apparatus are shown in Fig.

tion, or conduction to the specimen holder must be small.

3. The window may be any material that is transparent to the

Whether or not this condition is violated can be determined

flash source.The specimen holder should be a ceramic or other

material whose thermal conductivity is low relative to that of

1

This test method is under the jurisdiction of ASTM Committee D02 on the sample.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

4.2 Thermocouple, used to monitor the transient tempera-

D02.F0 on Manufactured Carbon and Graphite Products.

tureresponseoftherearsurfaceofthespecimen.Thewireends

Current edition approved Nov. 1, 2005. Published November 2005. Originally

should be prepared to minimize heat losses from the specimen

approved in 1972. Last previous edition approved in 2000 as C 714–85(2000).

2

The boldface numbers in parentheses refer to the list of references at the end of

to the thermocouple wires (that is, by grinding to points or

this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C714–05

FIG. 1 Flash Tube Response

FIG. 2 Example of Oscillosco

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.