ASTM C586-11(2019)

(Test Method)Standard Test Method for Potential Alkali Reactivity of Carbonate Rocks as Concrete Aggregates (Rock-Cylinder Method)

Standard Test Method for Potential Alkali Reactivity of Carbonate Rocks as Concrete Aggregates (Rock-Cylinder Method)

SIGNIFICANCE AND USE

5.1 This test method is intended to give a relatively rapid indication of the potential expansive reactivity of certain carbonate rocks that may be used as concrete aggregates. The test method has been successfully used in (1) research and (2) preliminary screening of aggregate sources to indicate the presence of material with a potential for deleterious expansion when used in concrete.

5.2 The test method is intended as a research and screening method rather than as the basis of a specification requirement. It is intended to supplement data from field service records, petrographic examinations according to Guide C295, and tests of aggregate in concrete according to Test Method C1105.

5.3 Alkalies participating in the expansive reactions with aggregate constituents in concrete usually are derived from the hydraulic cement; under certain circumstances they may be derived from other constituents of concrete or from external sources. Two types of alkali reactivity of aggregates are recognized: (1) alkali-silica reaction involving certain siliceous rocks, minerals, and artificial glasses, and (2) alkali carbonate reaction involving dolomite in certain calcitic dolomites, dolomitic limestones, and dolostones. This test method is not suitable as a means to detect alkali-silica reaction.

SCOPE

1.1 This test method covers the determination of the expansion of a specimen of carbonate rock while immersed in a solution of sodium hydroxide (NaOH) at room temperature. The length changes occurring during such immersion indicate the general level of reactivity of the rock and whether tests should be made to determine the effect of aggregate prepared from the rock upon the volume change in concrete.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C586 − 11 (Reapproved 2019)

Standard Test Method for

Potential Alkali Reactivity of Carbonate Rocks as Concrete

Aggregates (Rock-Cylinder Method)

This standard is issued under the fixed designation C586; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D75Practice for Sampling Aggregates

D1248Specification for Polyethylene Plastics Extrusion

1.1 This test method covers the determination of the expan-

Materials for Wire and Cable

sion of a specimen of carbonate rock while immersed in a

E177Practice for Use of the Terms Precision and Bias in

solution of sodium hydroxide (NaOH) at room temperature.

ASTM Test Methods

The length changes occurring during such immersion indicate

the general level of reactivity of the rock and whether tests

3. Terminology

should be made to determine the effect of aggregate prepared

from the rock upon the volume change in concrete.

3.1 For definitions of terms relating to aggregates used in

this test method, refer to Descriptive Nomenclature C294.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

4. Summary of Test Method

standard.

1.3 This standard does not purport to address all of the

4.1 Small rock cylinders are immersed in a solution of

safety concerns, if any, associated with its use. It is the

NaOH except when removed for determination of length

responsibility of the user of this standard to establish appro-

change. The length change of each specimen is periodically

priate safety, health, and environmental practices and deter-

determined.

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

5. Significance and Use

dance with internationally recognized principles on standard-

5.1 This test method is intended to give a relatively rapid

ization established in the Decision on Principles for the

indication of the potential expansive reactivity of certain

Development of International Standards, Guides and Recom-

carbonate rocks that may be used as concrete aggregates. The

mendations issued by the World Trade Organization Technical

test method has been successfully used in (1) research and (2)

Barriers to Trade (TBT) Committee.

preliminary screening of aggregate sources to indicate the

presence of material with a potential for deleterious expansion

2. Referenced Documents

when used in concrete.

2.1 ASTM Standards:

C294Descriptive Nomenclature for Constituents of Con-

5.2 The test method is intended as a research and screening

crete Aggregates

method rather than as the basis of a specification requirement.

C295GuideforPetrographicExaminationofAggregatesfor

It is intended to supplement data from field service records,

Concrete

petrographic examinations according to Guide C295, and tests

C1105Test Method for Length Change of Concrete Due to

of aggregate in concrete according to Test Method C1105.

Alkali-Carbonate Rock Reaction

5.3 Alkalies participating in the expansive reactions with

aggregateconstituentsinconcreteusuallyarederivedfromthe

This test method is under the jurisdiction of ASTM Committee C09 on

hydraulic cement; under certain circumstances they may be

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

derived from other constituents of concrete or from external

C09.50 on Aggregate Reactions in Concrete.

sources. Two types of alkali reactivity of aggregates are

Current edition approved Aug. 1, 2019. Published August 2019. Originally

recognized:(1)alkali-silicareactioninvolvingcertainsiliceous

approved in 1966. Last previous edition approved in 2011 as C586–11. DOI:

10.1520/C0586-11R19.

rocks, minerals, and artificial glasses, and (2) alkali carbonate

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

reaction involving dolomite in certain calcitic dolomites, do-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

lomitic limestones, and dolostones. This test method is not

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. suitable as a means to detect alkali-silica reaction.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C586 − 11 (2019)

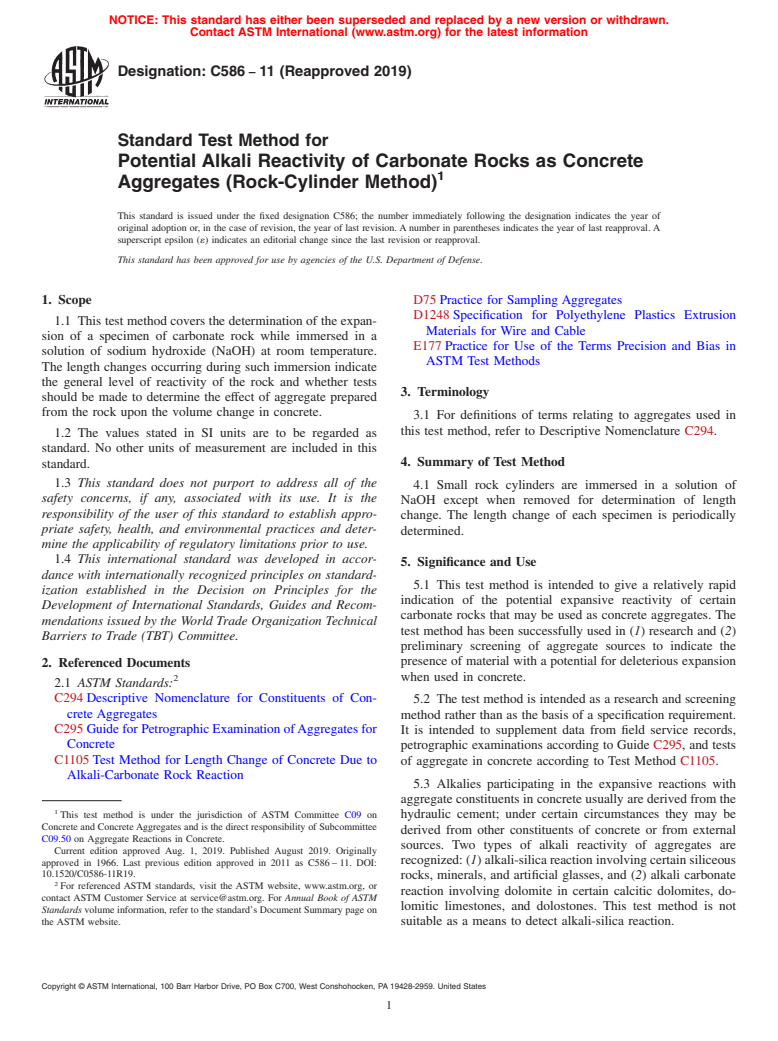

6. Apparatus and Reagents ing device shall be checked by use of the reference bar at least

atthebeginningandendofthereadingsmadewithinahalfday

6.1 1 N Sodium Hydroxide Solution—Dissolve 40 61gof

when the apparatus is kept in a room maintained at constant

reagent-grade sodium hydroxide (NaOH) in distilled water,

temperature. It shall be checked more often when kept in a

dilute to 1 L and store in a polyethylene bottle.

room where temperature is not constant.

6.2 Sawing, Drilling, and Grinding Equipment, suitable for

NOTE1—Steelalloyswithlowthermalexpansioncoefficientshouldnot

preparing test specimens of the dimensions given in Section 8.

be heat treated because they lose their low coefficient of thermal

This will require one or more rock saws, depending upon the

expansion when so treated.

size of the original sample, a drill press equipped with a small

diamond core barrel for removing the cylindrical core, and a

7. Sampling

lap, grinder, or suitable modified lathe for shaping the ends of

7.1 Sample the rock in accordance with the applicable

the specimens.

requirements of Practice D75, except that the sample mass of

6.3 Storage Bottles, approximately 50 to 100-mL capacity

each discernable stratum shall be at least 1 kg, and individual

with caps and openings of sufficient size to facilitate removal

pieces shall be not less than 75 × 75 × 75 mm in size.

of specimens. The polyethylene bottle shall be selected to

7.2 Sampling should be under the direction of an individual

ensure that the solution will not be modified by reaction with

capable of distinguishing differences in lithology, and the

the material composing the container, including pigments or

sample of rock should be taken to represent only the particular

other additives or by transpiration of phases through the walls

lithology under consideration bearing in mind the limitations

of the container. Bottles with wall thickness not less than 0.50

and significance of this method as stated in Section 5. Each

mm and composed of high density polyethylene meeting the

sample of rock should be in one piece of sufficient size for

requirements of Specification D1248 for materials of Type III,

preparing the necessary test specimens.

Class A, are suitable.

7.3 One test specimen will sufficiently represent the sample

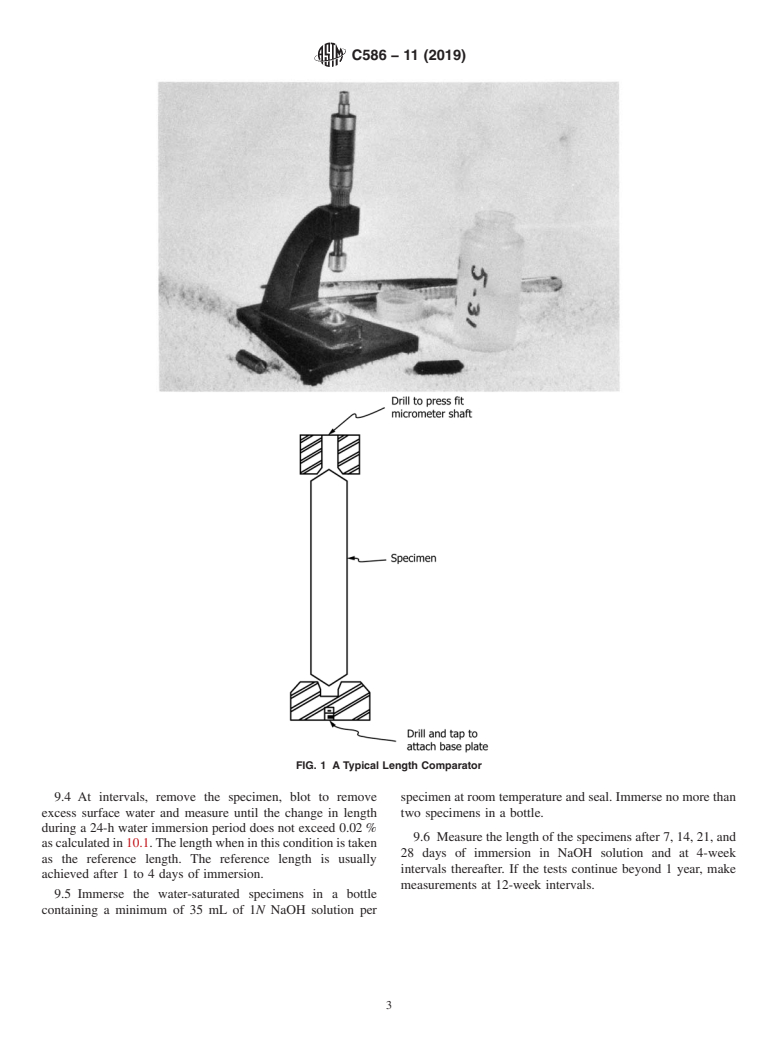

6.4 Length Comparator, for convenient and rapid measure-

of rock unless shale seams or other discontinuities are present

ment of lengths of specimens, the comparator shall be of such

or the bedding is not discernible. In these cases, prepare and

design as to provide, permit, or include the following charac-

test 3 mutually perpendicular specimens. Of these three

teristics. One type of comparator which has been found

specimens, testing shall be continued on that one showing the

satisfactory is shown in Fig. 1.

greatestcalculatedlengthchangeafter28daysofimmersionin

6.4.1 A positive means of contact with the conical ends of

alkali solution. Discard the remaining two.

the specimen to ensure reproducible measurement of length.A

variety of contact points have been used successfully. Care

8. Test Specimens

should be exercised to ensure that when using specimens with

8.1 Test specimens shall be in the form of right circular

conical ends as described in 8.3, contact is made on the end

cylinders or square prisms with conical or plane parallel ends,

along a circle which is concentric about the long axis of the

unless otherwise specified.

specimen. If the measuring device is a barrel micrometer, it

shall have a ratchet stop to produce a constant pressure on the

8.2 The specimen shall have an over-all length of 35 6 5

specimen.

mm and a diameter or sides of 9 6 1 mm for cylinders and

6.4.2 A high-grade barrel or dial micrometer graduated to

prisms respectively. Care shall be exercised in the preparation

read in 0.001 or 0.002-mm units, and accurate within 0.002

of the specimens to avoid alteration of the cylindrical surface

mm in any 0.020-mm range, and within 0.004 mm in any

by polishing or with materials which will affect the rate of

0.200-mm range. The measuring device should be calibrated

entry of alkali solution into the rock.

throughoutitsrangetodeterminebothperiodicandcumulative

8.3 Theincludedangleoftheconicalendsshallbeapproxi-

errors for proper correction of observed data.

mately 120°.

6.4.3 Asufficientrangetoallowforsmalldifferencesamong

8.4 Fabricate specimens having flat–end faces in such a

gage lengths of various specimens. If care is taken in

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C586 − 11 C586 − 11 (Reapproved 2019)

Standard Test Method for

Potential Alkali Reactivity of Carbonate Rocks as Concrete

Aggregates (Rock-Cylinder Method)

This standard is issued under the fixed designation C586; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*Scope

1.1 This test method covers the determination of the expansion of a specimen of carbonate rock while immersed in a solution

of sodium hydroxide (NaOH) at room temperature. The length changes occurring during such immersion indicate the general level

of reactivity of the rock and whether tests should be made to determine the effect of aggregate prepared from the rock upon the

volume change in concrete.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

C294 Descriptive Nomenclature for Constituents of Concrete Aggregates

C295 Guide for Petrographic Examination of Aggregates for Concrete

C1105 Test Method for Length Change of Concrete Due to Alkali-Carbonate Rock Reaction

D75 Practice for Sampling Aggregates

D1248 Specification for Polyethylene Plastics Extrusion Materials for Wire and Cable

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

3. Terminology

3.1 For definitions of terms relating to aggregates used in this test method, refer to Descriptive Nomenclature C294.

4. Summary of Test Method

4.1 Small rock cylinders are immersed in a solution of NaOH except when removed for determination of length change. The

length change of each specimen is periodically determined.

5. Significance and Use

5.1 This test method is intended to give a relatively rapid indication of the potential expansive reactivity of certain carbonate

rocks that may be used as concrete aggregates. The test method has been successfully used in (1) research and (2) preliminary

screening of aggregate sources to indicate the presence of material with a potential for deleterious expansion when used in

concrete.

This test method is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.50 on

Aggregate Reactions in Concrete.

Current edition approved Oct. 1, 2011Aug. 1, 2019. Published November 2011August 2019. Originally approved in 1966. Last previous edition approved in 20052011

as C586C586 – 11. – 05. DOI: 10.1520/C0586-11.10.1520/C0586-11R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C586 − 11 (2019)

5.2 The test method is intended as a research and screening method rather than as the basis of a specification requirement. It

is intended to supplement data from field service records, petrographic examinations according to Guide C295, and tests of

aggregate in concrete according to Test Method C1105.

5.3 Alkalies participating in the expansive reactions with aggregate constituents in concrete usually are derived from the

hydraulic cement; under certain circumstances they may be derived from other constituents of concrete or from external sources.

Two types of alkali reactivity of aggregates are recognized: (1) alkali-silica reaction involving certain siliceous rocks, minerals,

and artificial glasses, and (2) alkali carbonate reaction involving dolomite in certain calcitic dolomites, dolomitic limestones, and

dolostones. This test method is not suitable as a means to detect alkali-silica reaction.

6. Apparatus and Reagents

6.1 1 N Sodium Hydroxide Solution—Dissolve 40 6 1 g of reagent-grade sodium hydroxide (NaOH) in distilled water, dilute

to 1 L and store in a polyethylene bottle.

6.2 Sawing, Drilling, and Grinding Equipment, suitable for preparing test specimens of the dimensions given in Section 8. This

will require one or more rock saws, depending upon the size of the original sample, a drill press equipped with a small diamond

core barrel for removing the cylindrical core, and a lap, grinder, or suitable modified lathe for shaping the ends of the specimens.

6.3 Storage Bottles, approximately 50 to 100-mL capacity with caps and openings of sufficient size to facilitate removal of

specimens. The polyethylene bottle shall be selected to ensure that the solution will not be modified by reaction with the material

composing the container, including pigments or other additives or by transpiration of phases through the walls of the container.

Bottles with wall thickness not less than 0.50 mm and composed of high density polyethylene meeting the requirements of

Specification D1248 for materials of Type III, Class A, are suitable.

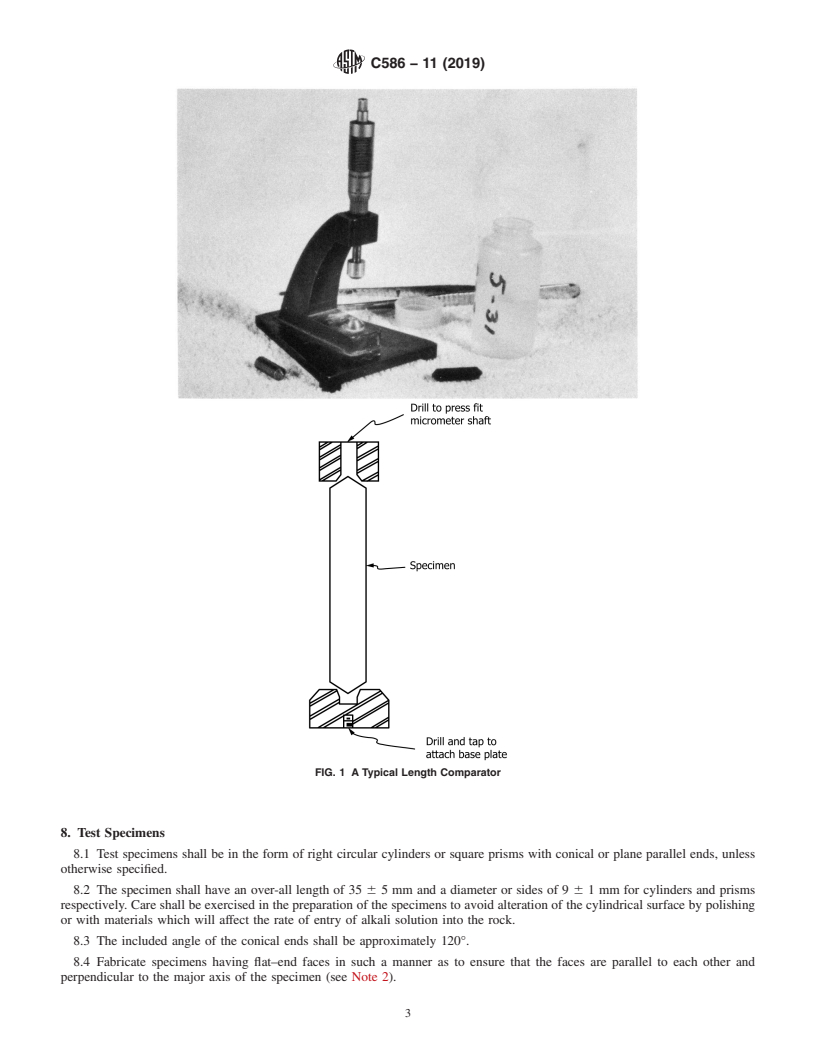

6.4 Length Comparator, for convenient and rapid measurement of lengths of specimens, the comparator shall be of such design

as to provide, permit, or include the following characteristics. One type of comparator which has been found satisfactory is shown

in Fig. 1.

6.4.1 A positive means of contact with the conical ends of the specimen to ensure reproducible measurement of length. A variety

of contact points have been used successfully. Care should be exercised to ensure that when using specimens with conical ends

as described in 8.3, contact is made on the end along a circle which is concentric about the long axis of the specimen. If the

measuring device is a barrel micrometer, it shall have a ratchet stop to produce a constant pressure on the specimen,specimen.

6.4.2 A high-grade barrel or dial micrometer graduated to read in 0.001 or 0.002–mm0.002-mm units, and accurate within 0.002

mm in any 0.020–mm0.020-mm range, and within 0.004 mm in any 0.200–mm0.200-mm range. The measuring device should be

calibrated throughout its range to determine both periodic and cumulative errors for proper correction of observed data.

6.4.3 A sufficient range to allow for small differences among gage lengths of various specimens. If care is taken in the

fabrication of the specimens, a measuring device with a travel of not less than 7.5 mm provides ample range in the instrument,

and

6.4.4 A standard or reference shall be used for checking the measuring device at regular intervals. The bar that serves as a

reference for the length comparator shall have an over-all length of 35 6 2 mm. The length of the bar shall be known to an accuracy

−6

of 0.002 mm. The bar shall be fused silica or a steel alloy having a coefficient of thermal expansion not greater than 1.0 × 10 °C.

Each end shall be machined to the same shape as that of the rock specimens. If a steel alloy is used, it shall be polished (see Note

1). The reference bar shall be placed in the instrument in the same position each time a length measurement is made. The

micrometer setting of the measuring device shall be checked by use of the reference bar at least at the beginning and end of the

readings made within a half day when the apparatus is kept in a room maintained at constant temperature. It shall be checked more

often when kept in a room where temperature is not constant.

NOTE 1—Steel alloys with low thermal expansion coefficient should not be heat treated because they lose their low coefficient of thermal expansion

when so treated.

7. Sampling

7.1 Sample the rock in accordance with the applicable requirements of Practice D75, except that the sample mass of each

discernable stratum shall be at least 1 kg, and individual pieces shall be not less than 75 × 75 × 75 mm in size.

7.2 Sampling should be under the direction of an individual capable of distinguishing differences in lithology, and the sample

of rock should be taken to represent only the particular lithology under consideration bearing in mind the limitations and

significance of this method as stated in Section 5. Each sample of rock should be in one piece of sufficient size for preparing the

necessary test specimens.

7.3 One test specimen will sufficiently represent the sample of rock unless shale seams or other discontinuities are present or

the bedding is not discernible. In these cases, prepare and test 3 mutually perpendicular specimens. Of these three specimens,

testing shall be continued on that one showing the greatest calcu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.