ASTM B839-94(2003)

(Test Method)Standard Test Method for Residual Embrittlement in Metallic Coated, Externally Threaded Articles, Fasteners, and Rod—Inclined Wedge Method

Standard Test Method for Residual Embrittlement in Metallic Coated, Externally Threaded Articles, Fasteners, and Rod—Inclined Wedge Method

SCOPE

1.1 This test method covers the determination of, on a statistical basis, the probability of the existence of hydrogen embrittlement or degradation in:

1.1.1 A batch of barrel electroplated, autocatalytic plated, phosphated, or chemically processed threaded articles or fasteners and

1.1.2 A batch of rack plated threaded articles, fasteners, or rod.

1.2 Industrial practice for threaded articles, fasteners, and rod has evolved three graduated levels of test exposure to ensure reduced risk of hydrogen embrittlement (see Section 3). These levels have evolved from commercial applications having varying levels of criticality. In essence, they represent the confidence level that is required. They also represent the time that finished goods are held before they can be shipped and used. This time equates to additional cost to the manufacturer that may of necessity be added to the cost of the finished goods.

1.3 This test method is applicable to threaded articles, fasteners, and rod made from steel with ≥1000 MPa (with corresponding hardness values of 300 HV10 kgf, 303 HB, or 31 HRc) or surface hardened threaded articles, fasteners, or rod.

1.4 This test method shall be carried out after hydrogen embrittlement relief heat treatment in accordance with the requirements of Guide B 850. It may also be used for assessing differences in processing solutions, conditions, and techniques. This test method has two main functions: first, when used with a statistical sampling plan it can be used for lot acceptance or rejection, and second, it can be used as a control test to determine the effectiveness of the various processing steps including pre- and post-baking treatments to reduce the mobile hydrogen in the articles, fasteners, or rod. While this test method is capable of indicating those items that are embrittled to the extent defined in Section 3, it does not guarantee complete freedom from embrittlement.

1.5 This test method does not relieve the processor from imposing and monitoring suitable process control.

1.6 This test method has been coordinated with ISO/DIS 10587 and is technically equivalent. (Warning—Great care should be taken when applying this test method. The heads of embrittled articles, fasteners, or rod may suddenly break off and become flying projectiles capable of causing blindness or other serious injury. This hazard can occur as long as 200 h after the test has started. Hence, shields or other apparatus should be provided to avoid such injury.)

Note 1—The use of inhibitors in acid pickling baths does not necessarily guarantee avoidance of hydrogen embrittlement.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 839 – 94 (Reapproved 2003)

Standard Test Method for

Residual Embrittlement in Metallic Coated, Externally

Threaded Articles, Fasteners, and Rod—Inclined Wedge

1

Method

This standard is issued under the fixed designation B 839; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

When atomic hydrogen enters steels and certain other alloys, it can cause loss of ductility or load

carrying ability or cracking (usually as submicroscopic cracks), or catastrophic brittle failures at

applied stresses well below the yield strength or even the normal design strength for the alloys. This

phenomenon often occurs in alloys that show no significant loss in ductility, when measured by

conventional tensile tests, and is frequently referred to as hydrogen-induced delayed brittle failure,

hydrogen stress cracking, or hydrogen embrittlement. The hydrogen can be introduced during

cleaning, pickling, phosphating, electroplating, autocatalytic processes, and in the service environment

as a result of cathodic protection reactions or corrosion reactions. Hydrogen can also be introduced

during fabrication, for example, during roll forming, machining, and drilling due to lubricant

breakdown as well as during welding or brazing operations.

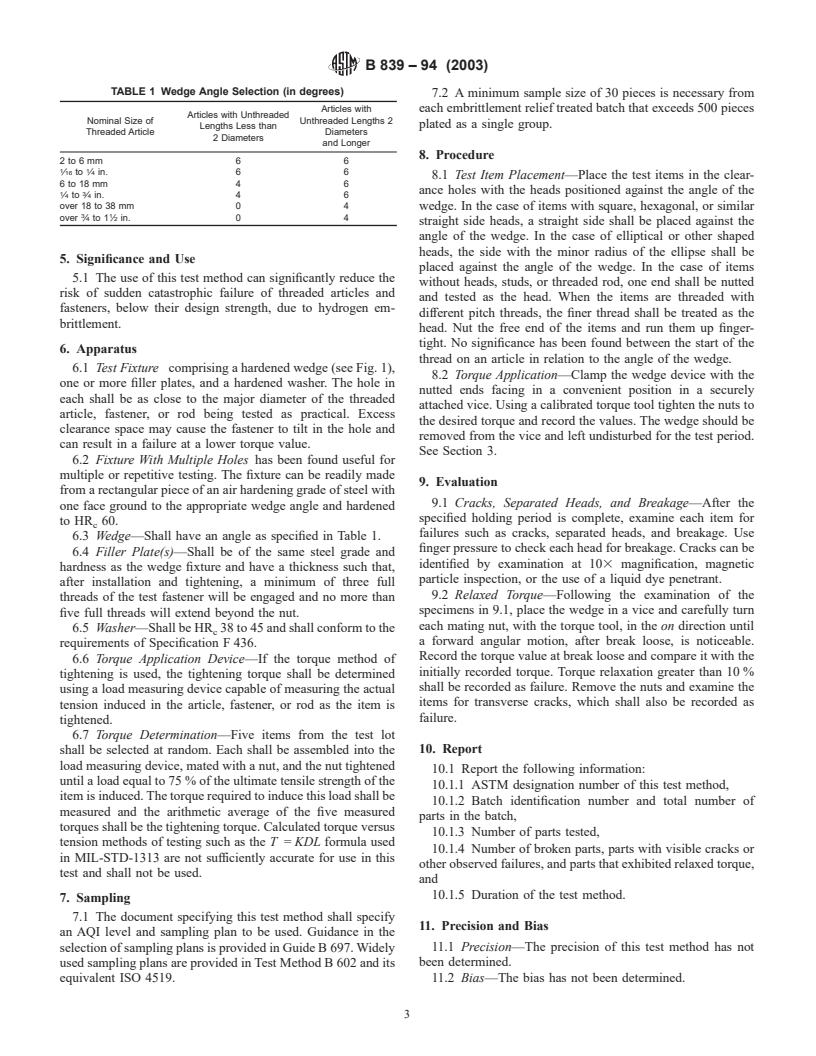

1. Scope corresponding hardness values of 300 HV , 303 HB, or 31

10 kgf

HR ) or surface hardened threaded articles, fasteners, or rod.

c

1.1 This test method covers the determination of, on a

1.4 This test method shall be carried out after hydrogen

statistical basis, the probability of the existence of hydrogen

embrittlement relief heat treatment in accordance with the

embrittlement or degradation in:

requirements of Guide B 850. It may also be used for assessing

1.1.1 A batch of barrel electroplated, autocatalytic plated,

differences in processing solutions, conditions, and techniques.

phosphated, or chemically processed threaded articles or fas-

This test method has two main functions: first, when used with

teners and

a statistical sampling plan it can be used for lot acceptance or

1.1.2 A batch of rack plated threaded articles, fasteners, or

rejection, and second, it can be used as a control test to

rod.

determine the effectiveness of the various processing steps

1.2 Industrial practice for threaded articles, fasteners, and

including pre- and post-baking treatments to reduce the mobile

rod has evolved three graduated levels of test exposure to

hydrogen in the articles, fasteners, or rod. While this test

ensure reduced risk of hydrogen embrittlement (see Section 3).

method is capable of indicating those items that are embrittled

These levels have evolved from commercial applications

to the extent defined in Section 3, it does not guarantee

having varying levels of criticality. In essence, they represent

complete freedom from embrittlement.

the confidence level that is required. They also represent the

1.5 This test method does not relieve the processor from

time that finished goods are held before they can be shipped

imposing and monitoring suitable process control.

and used. This time equates to additional cost to the manufac-

1.6 This test method has been coordinated with ISO/DIS

turer that may of necessity be added to the cost of the finished

10587 and is technically equivalent. (Warning—Great care

goods.

should be taken when applying this test method. The heads of

1.3 This test method is applicable to threaded articles,

embrittled articles, fasteners, or rod may suddenly break off

fasteners, and rod made from steel with $1000 MPa (with

and become flying projectiles capable of causing blindness or

other serious injury. This hazard can occur as long as 200 h

1

This test method is under the jurisdiction of ASTM Committee B08 on Metallic

after the test has started. Hence, shields or other apparatus

and Inorganic Coatings and is the direct responsibility of Subcommittee B08.10 on

should be provided to avoid such injury.)

Test Methods.

Current edition approved May 10, 2003. Published July 2003. Originally

approved in 1994. Last previous edition approved in 1994 as B 839 – 94.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 839 – 94 (2003)

NOTE 1—The use of inhibitors in acid pickling baths does not neces-

sarily guarantee avoidance of hydrogen embrittlement.

1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate sa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.