ASTM F2437/F2437M-17(2023)

(Specification)Standard Specification for Carbon and Alloy Steel Compressible-Washer-Type Direct Tension Indicators for Use with Cap Screws, Bolts, Anchors, and Studs

Standard Specification for Carbon and Alloy Steel Compressible-Washer-Type Direct Tension Indicators for Use with Cap Screws, Bolts, Anchors, and Studs

ABSTRACT

This specification covers the requirements for carbon and alloy steel compressible-washer-type direct tension indicators (DTIs) capable of indicating a specified bolt tension in cap screws, bolts, anchors, and studs. These DTIs are intended for installation under a bolt or cap screw head, a hex nut, or against a hardened washer or other flat hardened surface. The following are two types of DTIs: Type 1 DTIs are suitable for comparatively large bearing surfaces and Type 2 DTIs are suitable for comparatively smaller bearing surfaces. DTIs shall have a configuration produced by extrusion, punching, pressing, or similar forming to permit a measurable decrease in thickness when placed in compression. The design shall be such that the degree of plastic deformation of the protrusions shall indicate the tension in a tightened cap screw, bolt, anchor, or stud. The process used for heat treatment of DTIs, if required, shall be through-hardening by heating to a temperature above the upper transformation temperature, quenching in oil, and then tempering by reheating to a suitable temperature to attain desired mechanical/performance properties. Protective coatings, platings, or finishes may be applied on the DTIs if specified. Compression load and hardness of the DTIs shall be determined by performing mechanical tests.

SCOPE

1.1 This specification covers the requirements for carbon and alloy steel compressible-washer-type direct tension indicators (DTIs) capable of indicating a specified bolt tension in cap screws, bolts, anchors, and studs.

1.2 Direct tension indicators in inch sizes 1/4 through 21/2 in. and metric sizes M6 and M72 are covered.

1.3 Direct tension indicators have two styles and four grades for inch fasteners, Grades 5, 8, 55, and 105, and two property classes for metric fasteners, property classes 8.8 and 10.9 each of which differ in their compressive load requirements at a given gap (see Table 1 and Table 2).

1.3.1 Style 1 DTIs are suitable for comparatively smaller bearing surfaces. Style 1 DTIs are available in Grades 5 and 8, which differ in the amount of tension they indicate at a prescribed gap (see Table 1 and Table 3).

1.3.2 Style 2 DTIs are suitable for comparatively large bearing surfaces. Style 2 DTIs are available in Grades 55 and 105, which differ in the amount of tension they indicate at a prescribed gap (see Table 1 and Table 3).

1.4 Direct tension indicators are intended for installation under a bolt or cap screw head, a hex nut, or against a hardened washer or other flat hardened surface.

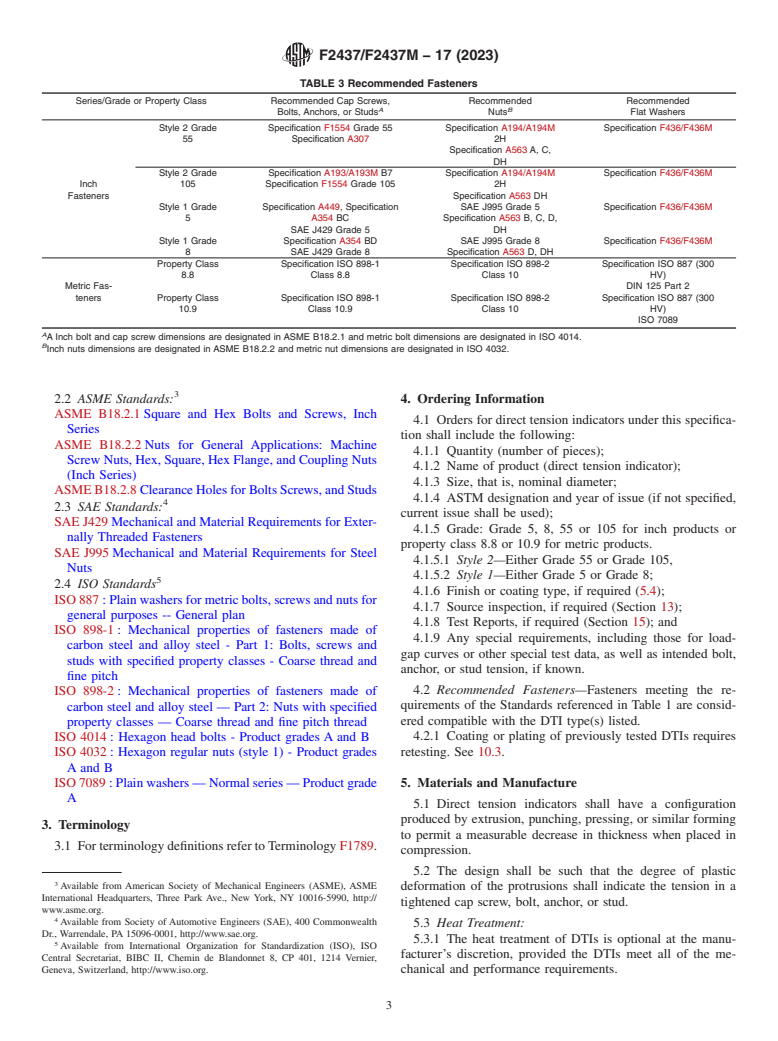

1.5 Recommended Fasteners—Fasteners meeting the requirements of the standards referenced in Table 3 are considered compatible with the DTI grade or class listed.

1.6 The values stated for Inch DTIs are expressed in inch-pound units and for Metric DTIs values are expressed in SI units. The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.7 The following precautionary statement pertains only to the test method portions, Section 12of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2437/F2437M − 17 (Reapproved 2023)

Standard Specification for

Carbon and Alloy Steel Compressible-Washer-Type Direct

Tension Indicators for Use with Cap Screws, Bolts, Anchors,

and Studs

This standard is issued under the fixed designation F2437/F2437M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* used independently of the other, and values from the two

systems shall not be combined.

1.1 This specification covers the requirements for carbon

1.7 The following precautionary statement pertains only to

and alloy steel compressible-washer-type direct tension indi-

the test method portions, Section 12of this specification: This

cators (DTIs) capable of indicating a specified bolt tension in

standard does not purport to address all of the safety concerns,

cap screws, bolts, anchors, and studs.

if any, associated with its use. It is the responsibility of the user

1 1

1.2 Direct tension indicators in inch sizes ⁄4 through 2 ⁄2 in.

of this standard to establish appropriate safety, health, and

and metric sizes M6 and M72 are covered.

environmental practices and determine the applicability of

1.3 Direct tension indicators have two styles and four

regulatory limitations prior to use.

grades for inch fasteners, Grades 5, 8, 55, and 105, and two

1.8 This international standard was developed in accor-

property classes for metric fasteners, property classes 8.8 and

dance with internationally recognized principles on standard-

10.9 each of which differ in their compressive load require-

ization established in the Decision on Principles for the

ments at a given gap (see Table 1 and Table 2).

Development of International Standards, Guides and Recom-

1.3.1 Style 1 DTIs are suitable for comparatively smaller

mendations issued by the World Trade Organization Technical

bearing surfaces. Style 1 DTIs are available in Grades 5 and 8,

Barriers to Trade (TBT) Committee.

which differ in the amount of tension they indicate at a

prescribed gap (see Table 1 and Table 3). 2. Referenced Documents

1.3.2 Style 2 DTIs are suitable for comparatively large

2.1 ASTM Standards:

bearing surfaces. Style 2 DTIs are available in Grades 55 and

A193/A193M Specification for Alloy-Steel and Stainless

105, which differ in the amount of tension they indicate at a

Steel Bolting for High Temperature or High Pressure

prescribed gap (see Table 1 and Table 3).

Service and Other Special Purpose Applications

A194/A194M Specification for Carbon Steel, Alloy Steel,

1.4 Direct tension indicators are intended for installation

and Stainless Steel Nuts for Bolts for High Pressure or

under a bolt or cap screw head, a hex nut, or against a hardened

High Temperature Service, or Both

washer or other flat hardened surface.

A307 Specification for Carbon Steel Bolts, Studs, and

1.5 Recommended Fasteners—Fasteners meeting the re-

Threaded Rod 60 000 PSI Tensile Strength

quirements of the standards referenced in Table 3 are consid-

A354 Specification for Quenched and Tempered Alloy Steel

ered compatible with the DTI grade or class listed.

Bolts, Studs, and Other Externally Threaded Fasteners

1.6 The values stated for Inch DTIs are expressed in

A449 Specification for Hex Cap Screws, Bolts and Studs,

inch-pound units and for Metric DTIs values are expressed in

Steel, Heat Treated, 120/105/90 ksi Minimum Tensile

SI units. The values stated in either SI units or inch-pound units

Strength, General Use

are to be regarded separately as standard. The values stated in

A563 Specification for Carbon and Alloy Steel Nuts

each system are not necessarily exact equivalents; therefore, to

B695 Specification for Coatings of Zinc Mechanically De-

ensure conformance with the standard, each system shall be

posited on Iron and Steel

F436/F436M Specification for Hardened Steel Washers Inch

and Metric Dimensions

This specification is under the jurisdiction of ASTM Committee F16 on

Fasteners and is the direct responsibility of Subcommittee F16.06 on Steel Washers

and Rivets. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2023. Published November 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2006. Last previous edition approved in 2017 as F2437 – 17. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2437_F2437M-17R23. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2437/F2437M − 17 (2023)

A

TABLE 1 Acceptable Range of Compression Load for Inch DTIs

B C

DTI Mean Compression Load Range Mean Compression Load Range

in Pounds (lbs) in Pounds (lbs)

Nominal

Style 1 Style 2

Diameter

(in.) Grade 5 Grade 8 Grade 55 Grade 105

⁄4 2200 to 2450 3100 to 3450 . . . . . .

⁄16 3500 to 3850 4950 to 5500 . . . . . .

⁄8 5300 to 5850 7500 to 8300 . . . . . .

⁄16 7200 to 7900 10 100 to 11 200 . . . . . .

⁄2 9700 to 10 700 13 700 to 15 340 4450 to 4900 8500 to 9400

⁄16 12 350 to 13 600 17 400 to 19 200 5700 to 6300 10 900 to 12 050

⁄8 15 550 to 17 200 21 850 to 24 200 7050 to 7800 13 500 to 15 000

⁄4 22 600 to 25 000 31 900 to 35 300 10 500 to 11 600 20 000 to 22 150

⁄8 30 850 to 34 100 43 550 to 48 100 14 500 to 16 000 27 650 to 30 550

1 40 200 to 44 400 56 700 to 62 700 19 000 to 21 000 36 250 to 40 100

1 ⁄8 40 250 to 44 450 73 150 to 80 900 23 950 to 26 450 47 300 to 52 300

1 ⁄4 51 100 to 56 450 91 750 to 101 450 30 400 to 33 600 59 850 to 66 150

1 ⁄8 61 150 to 67 600 112 450 to 124 250 38 550 to 42 600 73 800 to 81 600

1 ⁄2 74 350 to 82 150 135 150 to 149 400 44 050 to 48 700 89 300 to 98 700

1 ⁄8 . . . . . . 55 800 to 61 700 106 200 to 117 400

1 ⁄4 74 450 to 82 300 177 850 to 196 500 59 550 to 65 850 124 600 to 137 750

1 ⁄8 . 206 050 to 227 750 75 550 to 83 500 144 500 to 159 700

2 98 000 to 108 300 236 850 to 261 750 78 650 to 86 950 165 800 to 183 300

2 ⁄4 127 400 to 140 800 277 900 to 307 100 102 050 to 112 750 212 900 to 235 350

2 ⁄2 156 750 to 173 250 379 600 to 419 600 125 400 to 138 600 240 550 to 265 850

A

Compression load requirements establish the capability of the direct tension indicators to satisfy typical tension requirements for these grades. The user is not obliged

to install fasteners and DTIs to these tensions, and is free to specify installation to lower tension values. When so specified, the DTI supplier shall provide a load-gap curve

in accordance with 15.2 to enable the user to select the appropriate gap criteria for the intended target tension of the application.

B

The Mean compression load values for Grades 5 and 8 in nominal sizes up through 1- ⁄2 in are based upon 75 % of the proof load for SAE J429 cap screws. For Grade

1 1

5 in nominal sizes over 1- ⁄2 in and up to 2- ⁄2 in inclusive, the mean compression load values are based on 75 % of the proof load for ASTM A449. For grade 8 in nominal

1 1

sizes over 1- ⁄2 in and up to 2- ⁄2 in inclusive, mean compression load values are based upon 75 % of the proof load for ASTM A354BD.

C

Mean compression load values for Grades 55 and 105 are based upon 60 % of the yield strength for the matching fasteners on which they are used.

A

TABLE 2 Acceptable Range of Compression Load for Metric DTIs

Nominal Diameter (M) Mean Compression Load Range in kN

Property Class 8.8 Property Class 10.9

M6 8 to 9 12 to 13

M8 15 to 17 22 to 24

M10 24 to 27 35 to 38

M12 35 to 39 50 to 55

M14 48 to 53 68 to 75

M16 65 to 72 93 to 103

M18 82 to 91 114 to 125

M20 105 to 116 145 to 160

M22 130 to 143 179 to 198

M24 151 to 167 209 to 231

M27 196 to 217 271 to 300

M30 240 to 265 332 to 367

M33 297 to 328 410 to 454

M36 349 to 386 483 to 534

M39 417 to 461 577 to 638

M42 479 to 529 662 to 732

M45 560 to 619 775 to 856

M48 628 to 695 869 to 961

M52 752 to 832 1041 to 1150

M56 868 to 959 1200 to 1327

M60 1009 to 1115 1396 to 1543

M64 1146 to 1266 1585 to 1752

M68 1308 to 1446 1810 to 2000

M72 1479 to 1635 2046 to 2262

A

The Mean compression load values for property classes 8.8 and 10.9 are based upon 75 % of the proof load for ISO 898-1 Bolts/Stud/Screws.

F606/F606M Test Methods for Determining the Mechanical F1554 Specification for Anchor Bolts, Steel, 36, 55, and

Properties of Externally and Internally Threaded 105-ksi Yield Strength

Fasteners, Washers, Direct Tension Indicators, and Rivets F1789 Terminology for F16 Mechanical Fasteners

F1470 Practice for Fastener Sampling for Specified Me- F1941/F1941M Specification for Electrodeposited Coatings

chanical Properties and Performance Inspection on Mechanical Fasteners, Inch and Metric

F2437/F2437M − 17 (2023)

TABLE 3 Recommended Fasteners

Series/Grade or Property Class Recommended Cap Screws, Recommended Recommended

A B

Bolts, Anchors, or Studs Nuts Flat Washers

Style 2 Grade Specification F1554 Grade 55 Specification A194/A194M Specification F436/F436M

55 Specification A307 2H

Specification A563 A, C,

DH

Style 2 Grade Specification A193/A193M B7 Specification A194/A194M Specification F436/F436M

Inch 105 Specification F1554 Grade 105 2H

Fasteners Specification A563 DH

Style 1 Grade Specification A449, Specification SAE J995 Grade 5 Specification F436/F436M

5 A354 BC Specification A563 B, C, D,

SAE J429 Grade 5 DH

Style 1 Grade Specification A354 BD SAE J995 Grade 8 Specification F436/F436M

8 SAE J429 Grade 8 Specification A563 D, DH

Property Class Specification ISO 898-1 Specification ISO 898-2 Specification ISO 887 (300

8.8 Class 8.8 Class 10 HV)

Metric Fas- DIN 125 Part 2

teners Property Class Specification ISO 898-1 Specification ISO 898-2 Specification ISO 887 (300

10.9 Class 10.9 Class 10 HV)

ISO 7089

A

A Inch bolt and cap screw dimensions are designated in ASME B18.2.1 and metric bolt dimensions are designated in ISO 4014.

B

Inch nuts dimensions are designated in ASME B18.2.2 and metric nut dimensions are designated in ISO 4032.

2.2 ASME Standards: 4. Ordering Information

ASME B18.2.1 Square and Hex Bolts and Screws, Inch

4.1 Orders for direct tension indicators under this specifica-

Series

tion shall include the following:

ASME B18.2.2 Nuts for General Applications: Machine

4.1.1 Quantity (number of pieces);

Screw Nuts, Hex, Square, Hex Flange, and Coupling Nuts

4.1.2 Name of product (direct tension indicator);

(Inch Series)

4.1.3 Size, that is, nominal diameter;

ASME B18.2.8 Clearance Holes for Bolts Screws, and Studs

4.1.4 ASTM designation and year of issue (if not specified,

2.3 SAE Standards:

current issue shall be used);

SAE J429 Mechanical and Material Requirements for Exter-

4.1.5 Grade: Grade 5, 8, 55 or 105 for inch products or

nally Threaded Fasteners

property class 8.8 or 10.9 for metric products.

SAE J995 Mechanical and Material Requirements for Steel

4.1.5.1 Style 2—Either Grade 55 or Grade 105,

Nuts

4.1.5.2 Style 1—Either Grade 5 or Grade 8;

2.4 ISO Standards

4.1.6 Finish or coating type, if required (5.4);

ISO 887 : Plain washers for metric bolts, screws and nuts for

4.1.7 Source inspection, if required (Section 13);

general purposes -- General plan

4.1.8 Test Reports, if required (Section 15); and

ISO 898-1 : Mechanical properties of fasteners made of

4.1.9 Any special requirements, including those for load-

carbon steel and alloy steel - Part 1: Bolts, screws and

gap curves or other special test data, as well as intended bolt,

studs with specified property classes - Coarse thread and

anchor, or stud tension, if known.

fine pitch

4.2 Recommended Fasteners—Fasteners meeting the re-

ISO 898-2 : Mechanical properties of fasteners made of

quirements of the Standards referenced in Table 1 are consid-

carbon steel and alloy steel — Part 2: Nuts with specified

ered compatible with the DTI type(s) listed.

property classes — Coarse thread and fine pitch thread

4.2.1 Coating or plating of previously tested DTIs requires

ISO 4014 : Hexagon head bolts - Product grades A and B

ISO 4032 : Hexagon regular nuts (style 1) - Product grades retesting. See 10.3.

A and B

ISO 7089 : Plain washers — Normal series — Product grade 5. Materials and Manufacture

A

5.1 Direct tension indicators shall have a configuration

produced by extrusion, punching, pressing, or similar forming

3. Terminology

to permit a measurable decrease in thickness when placed in

3.1 For terminology definitions refer to Terminology F1789.

compression.

5.2 The design shall be such that the degree of plastic

Available from American Society of Mechanical Engineers (ASME), ASME

deformation of the protrusions shall indicate the tension in a

International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

tightened cap screw, bolt, anchor, or stud.

www.asme.org.

Available from Society of Automotive Engineers (SAE), 400 Commonwealth

5.3 Heat Treatment:

Dr., Warrendale, PA 15096-0001, http://www.sae.org.

5.3.1 The heat treatment of DTIs is optional at the manu-

Available from International Organization for Standardization (ISO), ISO

facturer’s discretion, provided the DTIs meet all of the me-

Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier,

Geneva, Switzerland, http://www.iso.org. chanical and performance requirements.

F2437/F2437M − 17 (2023)

A,B

TABLE 4 Chemical Composition Requirements

5.3.2 When heat treatment is performed, the process shall be

Composition, %

through-hardening by heating to a temperature above the upper

Element Heat Product

transformation temperature, quenching in a liquid medium, and

Analysis Analysis

tempering by heating to a suitable temperature.

Carbon 0.30 to 0.55 0.27 to 0.58

Manganese 0.50 to 0.90 0.47 to 0.93

5.4 Protective Coatings or Platings:

Phosphorus, max 0.04 0.048

5.4.1 Unless otherwise specified, the direct tension indica- Sulfur, max 0.045 0.053

Silicon 0.15 to 0.35 0.13 to 0.37

tors shall be furnished “plain” with the “as-fabricated” surface

A

Steel is considered to be alloy by the American Iron and Steel Institute when the

finish without protective coatings.

maximum of the range given for the content of alloying elements exceeds one or

5.4.2 When “coated” is specified, the direct tension indica-

more of the following limits: manganese, 1.65 %; silicone, 0.60 %; copper, 0.60 %;

tors shall be processed in accordance with th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.