ASTM F3067-14(2021)

(Guide)Standard Guide for Radial Loading of Balloon-Expandable and Self-Expanding Vascular Stents

Standard Guide for Radial Loading of Balloon-Expandable and Self-Expanding Vascular Stents

SIGNIFICANCE AND USE

4.1 Upon deployment, at the site of the vascular stenosis, the stent establishes the patency of the lumen until vascular remodeling occurs. The radial load acting upon the stent is imparted by vessel and lesion stretch. Additionally, the vessel might be affected by excursions due to pulsation (systolic and diastolic variation), muscle-skeletal interactions due to patient movement, as well as external sources (e.g., patient is struck in the neck during a car accident). The excursions vary in magnitude and type based on the location of the vessel.

4.2 In order to maintain vessel patency, the stent has to withstand the forces acting on it without experiencing excessive deformation, migration, or sustained collapse; therefore, it is required that the stent possess adequate resistance to these loads.

4.3 Depending on the type of device and the clinical concern, the resistance to these loads can be presented through multiple test outputs: radial strength, collapse pressure, or chronic outward force.

4.4 The guidelines presented here can be used in the development of test methods to determine the radial loading properties of stents. This guide provides examples of different test apparatus (equipment and tooling), radial loading curves, and calculations. Although the apparatus and methods presented can be used as a reasonable simulation of actual clinical use, they have not been demonstrated to predict the actual in vivo clinical performance of any stent.

SCOPE

1.1 This document provides guidance for developing in vitro test methods for measuring the radial strength or collapse pressure of balloon-expandable vascular stents and chronic outward force of self-expanding vascular stents.

1.2 This guide is applicable to balloon-expandable and self-expanding stents of tubular geometry. It covers both stent and stent grafts. It does not cover bifurcated stents. It does not cover stents with non-circular cross sections or tapered stents.

1.3 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This guide does not recommend any specific test method or apparatus for measuring the radial strength, collapse pressure, or chronic outward force. Instead, this guide provides examples of test methodologies and equipment that could be used and recommends the format for presenting test results.

1.5 This guide covers only in vitro bench testing methods. In vivo behavior might be different.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3067 − 14 (Reapproved 2021)

Standard Guide for

Radial Loading of Balloon-Expandable and Self-Expanding

Vascular Stents

This standard is issued under the fixed designation F3067; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This document provides guidance for developing in

E4 Practices for Force Verification of Testing Machines

vitro test methods for measuring the radial strength or collapse

E177 Practice for Use of the Terms Precision and Bias in

pressure of balloon-expandable vascular stents and chronic

ASTM Test Methods

outward force of self-expanding vascular stents.

F2079 Test Method for Measuring Intrinsic Elastic Recoil of

1.2 This guide is applicable to balloon-expandable and

Balloon-Expandable Stents

self-expanding stents of tubular geometry. It covers both stent

F2081 Guide for Characterization and Presentation of the

and stent grafts. It does not cover bifurcated stents. It does not

Dimensional Attributes of Vascular Stents

cover stents with non-circular cross sections or tapered stents.

F2477 Test Methods for in vitro Pulsatile Durability Testing

of Vascular Stents

1.3 Units—The values stated in SI units are to be regarded

as standard. No other units of measurement are included in this

3. Terminology

standard.

3.1 Definitions:

1.4 Thisguidedoesnotrecommendanyspecifictestmethod

3.1.1 balloon-expandable stent—a stent that is expanded at

or apparatus for measuring the radial strength, collapse

the treatment site by a balloon catheter. The stent material is

pressure, or chronic outward force. Instead, this guide provides

plastically deformed by the balloon expansion such that the

examples of test methodologies and equipment that could be

stent remains expanded after deflation of the balloon.

used and recommends the format for presenting test results.

3.1.2 chronic outward force—the minimum continued open-

ing force of a self-expanding stent acting on the vessel wall at

1.5 This guide covers only in vitro bench testing methods.

a specified diameter. The range of chronic outward force is

In vivo behavior might be different.

defined by the unloading curve at the maximum and minimum

1.6 This standard does not purport to address all of the

indicated use diameters. Additional loading force consider-

safety concerns, if any, associated with its use. It is the

ations for self-expanding stents are evaluated as load excur-

responsibility of the user of this standard to establish appro-

sions and described in Appendix X2. Chronic outward force is

priate safety, health, and environmental practices and deter-

not defined for balloon-expandable stents.

mine the applicability of regulatory limitations prior to use.

3.1.3 collapse pressure—the uniform radial load during

1.7 This international standard was developed in accor-

testing with a hydraulic or pneumatic apparatus in which a

dance with internationally recognized principles on standard-

balloon-expandable stent undergoes buckling over a specific

ization established in the Decision on Principles for the

region or the entire stent length.

Development of International Standards, Guides and Recom-

3.1.4 load—a normalized, scalar value of force applied by

mendations issued by the World Trade Organization Technical

the stent to the vessel and, at equilibrium, the vessel upon the

Barriers to Trade (TBT) Committee.

stent. Load should be normalized by length (newton or

millinewton per millimeter length) or by area (pascal or

kilopascal).

This guide is under the jurisdiction of ASTM Committee F04 on Medical and

Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.30 on Cardiovascular Standards. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2021. Published August 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2014. Last previous edition approved in 2014 as F3067 – 14. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F3067-14R21. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3067 − 14 (2021)

3.1.5 loading line—for balloon-expandable stents, the line shape that is close to the desired final size and shape, when

derived from the substantially linear portion of the radial released from the delivery system.

loading curve during initial compression. The term is not

3.1.13 stent graft—transluminally placed tubular vascular

defined for balloon-expandable stents tested using collapse

prosthesis, with one or more integral stent components to

pressure apparatus.

provide fixation or radial support, or both, residing partially or

completelywithinavascularconduittoformaninternalbypass

3.1.6 radial force—output of radial loading that equals the

or shunt between sections of the vascular system.

radialpressuretimesthestentcylindricalarea.Therelationship

betweenradialforce(F )andradialpressure(P)isgiveninthe

R 3.1.14 stent length—unstressed length of the stent after

equation:

deployment. If the stent has marker bands on non-radial

force-producing components, the length is measured from the

F

R

P 5 (1)

ends of the radial force-producing sections. The measured

A

length of mounted or expanded stents should be measured by

where:

non-contacting instruments (profile projection, laser

P = radial pressure,

micrometer, and so forth) with a resolution of 0.1 mm or better

F = radial force, and

R (see Guide F2081).

A = instantaneous stent cylindrical area:

3.1.15 unloading line—for balloon-expandable stents, the

line derived from the substantially linear portion of the radial

A 5 πDL

unloading curve. The term does not apply for balloon-

where:

expandable stents tested using collapse pressure apparatus.

D = instantaneous stent expanded outer diameter, and

3.1.16 vascular patency—a measure of the extent to which

L = L for length change less than 10 % and L = L(D) for

thevesselisopen(unrestricted).Typicallyreportedasapercent

length change greater than 10 %. L:L is the expanded

of the reference (unrestricted, adjacent) vessel diameter or

stent length for balloon-expandable stents and uncon-

cross-sectional area.

strained length for self-expanding stents. L(D)isthe

3.1.17 vascular stent—a tubular synthetic structure that is

instantaneous length of the stent as a function of the

implanted in the native or grafted vasculature and that is

current instantaneous diameter. L(D) may be either

intended to provide mechanical radial support to enhance

experimentally determined or computationally derived.

vessel patency. For the purpose of this guide, a stent might be

3.1.7 radial loading—a mechanical loading mode in which

metallic or non-metallic. It might be durable or absorbable.

the load is directed perpendicular to the longitudinal axis of a

3.1.18 zero compression diameter—the diameter reference

cylinder and applied to the outer cylindrical surface of the

pointrequiredforthetestingapparatustofullyengagethestent

stent. The load is applied to the entire outer surface or to at

outer surface. Stent compression is calculated in comparison to

least three areas that are equally distributed around the outer

this diameter.

circumference and extend over the entire cylinder length. Load

might be expressed as radial force or radial pressure.

4. Significance and Use

3.1.8 radial loading curve—the graph of radial loading

4.1 Upon deployment, at the site of the vascular stenosis,

output on the y-axis versus diametric deformation of a stent on

the stent establishes the patency of the lumen until vascular

the x-axis.

remodeling occurs. The radial load acting upon the stent is

3.1.9 radial pressure—the area normalized output of radial

imparted by vessel and lesion stretch. Additionally, the vessel

loading equaling the average pressure applied to the stent by

might be affected by excursions due to pulsation (systolic and

the loading fixture in the radial direction toward the stent diastolic variation), muscle-skeletal interactions due to patient

cylindrical axis.

movement, as well as external sources (e.g., patient is struck in

the neck during a car accident). The excursions vary in

3.1.10 radial resistive load—the peak load during a com-

magnitude and type based on the location of the vessel.

pression excursion of a self-expanding stent. The excursion

might be a single event or a cycle. A typical example is 4.2 In order to maintain vessel patency, the stent has to

pulsatile cycling of an implanted self-expanding stent (refer to

withstand the forces acting on it without experiencing exces-

Appendix X2). sive deformation, migration, or sustained collapse; therefore, it

is required that the stent possess adequate resistance to these

3.1.11 radial strength—a specific load on the radial loading

loads.

curve that corresponds with a specific and clinically (practi-

cally) relevant amount of inward plastic deformation from the

4.3 Depending on the type of device and the clinical

unloaded state. The term is defined only for balloon- concern, the resistance to these loads can be presented through

expandablestentstestedwhosesolemechanismofexpansionis

multiple test outputs: radial strength, collapse pressure, or

byaballoon.Additionally,thetermappliesonlytostentstested chronic outward force.

using a segmented head or sling type apparatus and not using

4.4 The guidelines presented here can be used in the

a hydraulic or pneumatic pressure apparatus.

development of test methods to determine the radial loading

3.1.12 self-expanding stent—a stent that expands without properties of stents. This guide provides examples of different

the application of external forces or pressure, to a size and test apparatus (equipment and tooling), radial loading curves,

F3067 − 14 (2021)

and calculations. Although the apparatus and methods pre- 5.4 In order to distinguish between different stent types as

sented can be used as a reasonable simulation of actual clinical well as the apparatus used, separate test outputs are defined in

use, they have not been demonstrated to predict the actual in ordertoclarify,andlimit,thecomparisonsbetweentestresults.

vivo clinical performance of any stent. For example, a distal ring (edge, local) collapse of a balloon-

expandable stent as measured (collapse pressure) using a

5. Summary of Guide

hydraulic/pneumatic test apparatus might not directly convert

or correlate to the radial strength output of the same device

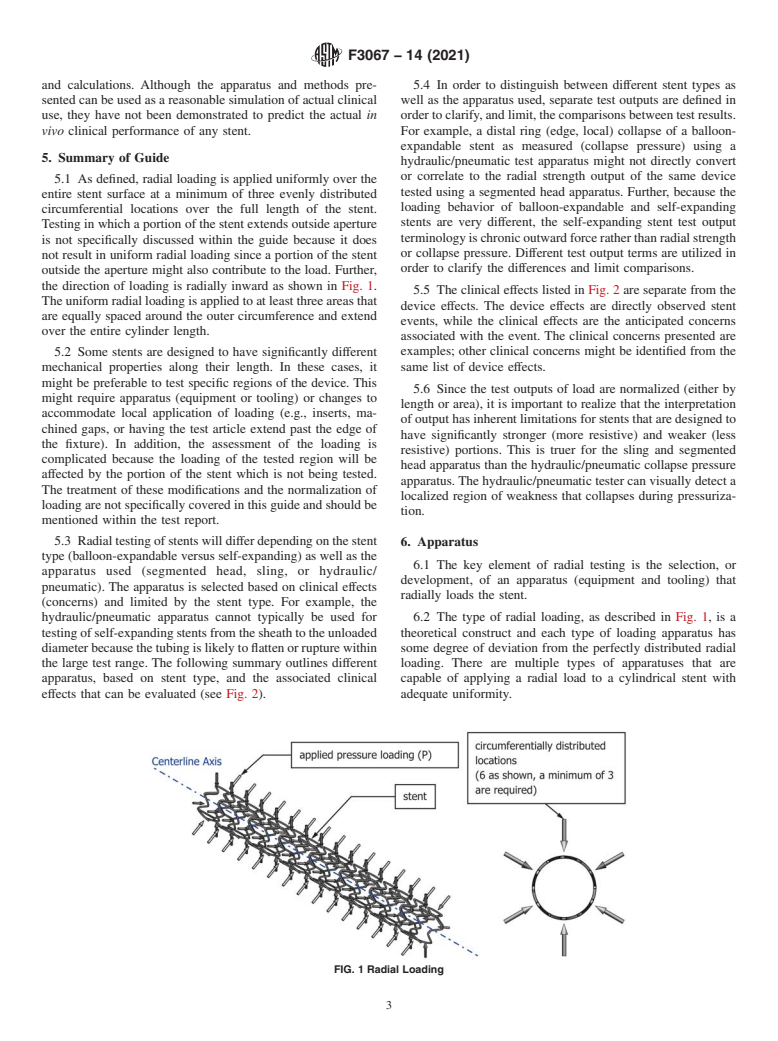

5.1 As defined, radial loading is applied uniformly over the

tested using a segmented head apparatus. Further, because the

entire stent surface at a minimum of three evenly distributed

loading behavior of balloon-expandable and self-expanding

circumferential locations over the full length of the stent.

stents are very different, the self-expanding stent test output

Testing in which a portion of the stent extends outside aperture

terminologyischronicoutwardforceratherthanradialstrength

is not specifically discussed within the guide because it does

or collapse pressure. Different test output terms are utilized in

not result in uniform radial loading since a portion of the stent

order to clarify the differences and limit comparisons.

outside the aperture might also contribute to the load. Further,

the direction of loading is radially inward as shown in Fig. 1.

5.5 The clinical effects listed in Fig. 2 are separate from the

The uniform radial loading is applied to at least three areas that

device effects. The device effects are directly observed stent

are equally spaced around the outer circumference and extend

events, while the clinical effects are the anticipated concerns

over the entire cylinder length.

associated with the event. The clinical concerns presented are

examples; other clinical concerns might be identified from the

5.2 Some stents are designed to have significantly different

mechanical properties along their length. In these cases, it same list of device effects.

might be preferable to test specific regions of the device. This

5.6 Since the test outputs of load are normalized (either by

might require apparatus (equipment or tooling) or changes to

length or area), it is important to realize that the interpretation

accommodate local application of loading (e.g., inserts, ma-

of output has inherent limitations for stents that are designed to

chined gaps, or having the test article extend past the edge of

have significantly stronger (more resistive) and weaker (less

the fixture). In addition, the assessment of the loading is

resistive) portions. This is truer for the sling and segmented

complicated because the loading of the tested region will be

head apparatus than the hydraulic/pneumatic collapse pressure

affected by the portion of the stent which is not being tested.

apparatus. The hydraulic/pneumatic tester can visually detect a

The treatment of these modifications and the normalization of

localized region of weakness that collapses during pressuriza-

loading are not specifically covered in this guide and should be

tion.

mentioned within the test report.

5.3 Radialtestingofstentswilldifferdependingonthestent

6. Apparatus

type (balloon-expandable versus self-expanding) as well as the

6.1 The key element of radial testing is the selection, or

apparatus used (segmented head, sling, or hydraulic/

development, of an apparatus (equipment and tooling) that

pneumatic). The apparatus is selected based on clinical effects

radially loads the stent.

(concerns) and limited by the stent type. For example, the

hydraulic/pneumatic apparatus cannot typically be used for 6.2 The type of radial loading, as described in Fig. 1,isa

theoretical construct and each type of loading apparatus has

testingofself-expandingstentsfromthesheathtotheunloaded

diameterbecausethetubingislikelytoflattenorrupturewithin some degree of deviation from the perfectly distributed radial

the large test range. The following summary outlines different loading. There are multiple types of apparatuses that are

apparatus, based on stent type, and the associated clinical capable of applying a radial load to a cylindrical stent with

effects that can be evaluated (see Fig. 2). adequate uniformity.

FIG. 1 Radial Loading

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.