ASTM A485-00

(Specification)Standard Specification for High Hardenability Antifriction Bearing Steel

Standard Specification for High Hardenability Antifriction Bearing Steel

SCOPE

1.1 This specification covers high hardenability modifications of high-carbon bearing quality steel to be used in the manufacture of antifriction bearings.

1.2 Supplementary requirements of an optional nature are provided and when desired shall be so stated in the order.

1.3 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 485 – 00

Standard Specification for

High Hardenability Antifriction Bearing Steel

This standard is issued under the fixed designation A 485; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope ISO 683 Part 17: Ball and Roller Bearing Steels

1.1 This specification covers high hardenability modifica-

3. Ordering Information

tions of high-carbon bearing quality steel to be used in the

3.1 Orders for material under this specification should

manufacture of antifriction bearings.

include the following information:

1.2 Supplementary requirements of an optional nature are

3.1.1 Quantity (weight or number of pieces),

provided and when desired shall be so stated in the order.

3.1.2 Grade identification,

1.3 The values stated in inch-pound units are to be regarded

3.1.3 ASTM designation and year of issue,

as the standard.

3.1.4 Dimensions,

2. Referenced Documents 3.1.5 Supplementary requirements, if included.

2.1 ASTM Standards:

4. Process

A 29/A 29M Specification for Steel Bars, Carbon and

4.1 The steel shall be made by a process that is capable of

Alloy, Hot-Wrought and Cold-Finished, General Require-

2 providing a high quality product meeting the requirements of

ments for

this specification.

A 255 Test Method of End-Quench Test for Hardenability

of Steel

5. Chemical Composition and Analysis

A 751 Test Methods, Practices, and Terminology for

3 5.1 Typical examples of chemical compositions are shown

Chemical Analysis of Steel Products

in Table 1. Other compositions may be specified.

E 45 Test Methods For Determining the Inclusion Content

4 5.2 An analysis of each heat of steel shall be made by the

of Steel

steel manufacturer in accordance with Test Methods, Practices,

E 381 Method of Macroetch Testing, Inspection, and Rating

and Terminology A 751. The chemical composition thus deter-

Steel Products, Comprising Bars, Billets, Blooms, and

4 mined shall conform to the requirements specified in Table 1

Forgings

for the ordered grade or to other requirements agreed upon

E 1019 Test Methods for Determination of Carbon, Sulfur,

between manufacturer and purchaser.

Nitrogen, and Oxygen in Steel and in Iron, Nickel, and

5 5.3 Product analysis may be made by the purchaser in

Cobalt Alloys

accordance with Test Methods, Practice, and Terminology

E 1077 Test Method for Estimating the Depth of Decarbur-

4 A 751. Permissible variations in product analysis shall be in

ization of Steel Specimens

accordance with Specification A 29/A 29M.

2.2 Other Standards:

SAE J148a Grain Size Determination of Steel

6. Sizes, Shapes, and Dimensional Tolerances

6.1 The physical size and shape of the material shall be

agreed upon between manufacturer and purchaser.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys , and is the direct responsibility of Subcommittee

6.2 Dimensional tolerances for hot-rolled or hot-rolled and

A01.28 on Bearing Steels.

annealed bars, in straight lengths or coils, and cold-finished

Current edition approved May 10, 2000. Published August 2000. Originally

bars furnished under this specification shall conform to the

published as A 485–63. Last previous edition A 485–94.

Annual Book of ASTM Standards, Vol 01.05. requirements specified in the latest edition of Specification

Annual Book of ASTM Standards, Vol 01.03.

A 29/A 29M.

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 03.06.

Available from The Engineering Society for Advanced Mobility of Land, Sea,

Available from the International Organization for Standardization (ISO), 1, rue

Air and Space, 400 Commonwealth Drive, Warrendale, PA 15096-001.

de Varembé, Case postale 56, CH-1211, Genève 20, Switzerland.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

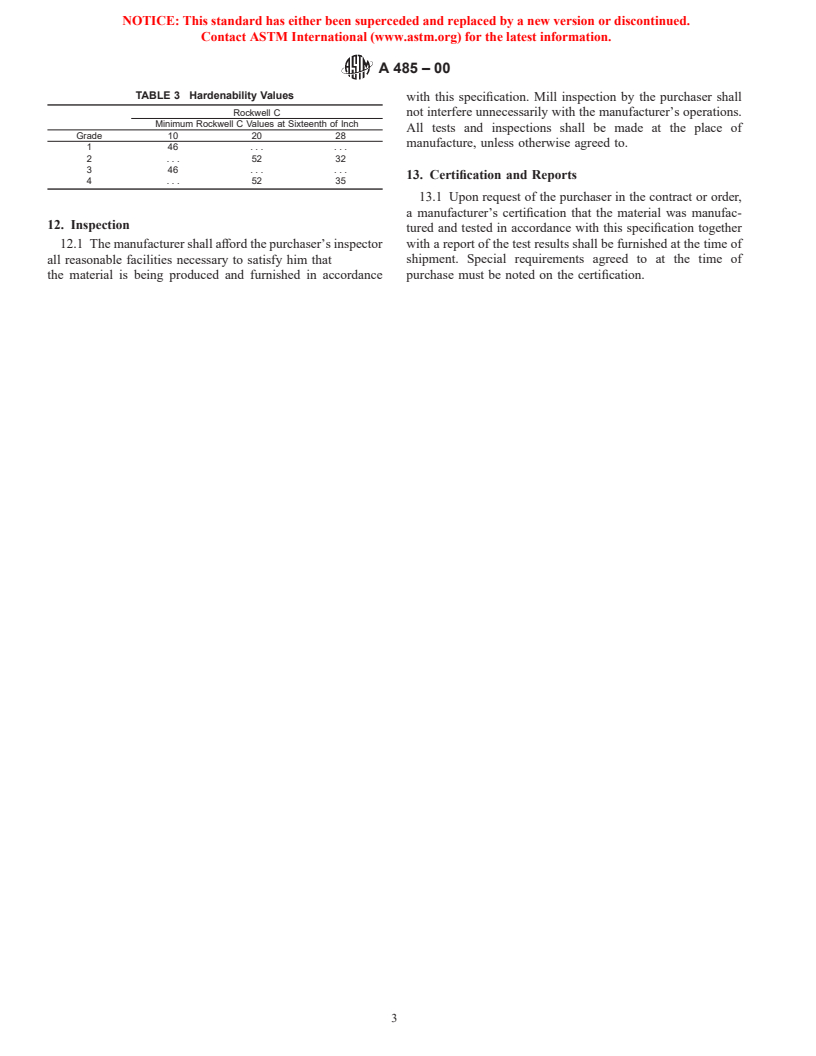

A 485–00

A,B

TABLE 1 Chemical Composition

C D

Number Name C Mn P (max) S (max) Si Cr Ni (max) Ti Cu Mo O (max) Al (max)

1 Grade 1 0.90–1.05 0.90–1.20 0.025 0.015 0.45–0.75 0.90–1.20 0.25 0.0050 0.30 0.10 (max) 0.0015 0.050

2 Grade 2 0.85–1.00 1.40–1.70 0.025 0.015 0.50–0.80 1.40–1.80 0.25 0.0050 0.30 0.10 (max) 0.0015 0.050

3 Grade 3 0.95–1.10 0.65–0.90 0.025 0.015 0.15–0.35 1.10–1.50 0.25 0.0050 0.30 0.20–0.30 0.0015 0.050

4 Grade 4 0.95–1.10 1.05–1.35 0.025 0.015 0.15–0.35 1.10–1.50 0.25 0.0050 0.30 0.45–0.60 0.0015 0.050

E

B2 100CrMnSi4–4 0.93–1.05 0.90–1.20 0.025 0.015 0.45–0.75 0.90–1.20 . . . 0.30 0.10 (max) 0.0015 0.050

E

B3 100CrMnSi6–4 0.93–1.05 1.00–1.20 0.025 0.015 0.45–0.75 1.40–1.65 . . . 0.30 0.10 (max) 0.0015 0.050

E

B4 100CrMnSi6–6 0.93–1.05 1.40–1.70 0.025 0.015 0.45–0.75 1.40–1.65 . . . 0.30 0.10 (max) 0.0015 0.050

E

B5 100CrMo7 0.93–1.05 0.25–0.45 0.025 0.015 0.15–0.35 1.65–1.95 . . . 0.30 0.15–0.30 0.0015 0.050

E

B6 100CrMo7–3 0.93–1.05 0.60–0.80 0.025 0.015 0.15–0.35 1.65–1.95 . . . 0.30 0.20–0.35 0.0015 0.050

E

B7 100CrMo7–4 0.93–1.05 0.60–0.80 0.025 0.015 0.15–0.35 1.65–1.95 . . . 0.30 0.40–0.50 0.0015 0.050

E

B8 100CrMnMoSi8–4–6 0.93–1.05 0.80–1.10 0.025 0.015 0.40–0.60 1.80–2.05 . . . 0.30 0.50–0.60 0.0015 0.050

A

Elements not quoted shall not be intentionally added to the steel without the agreement of the purchaser.

B

Intentional additions of calcium or calcium alloys for deoxidation or inclusion shape control are not permitted unless specifically approved by the purchaser.

C

Steels B2 through B8 meet the requirements of ISO 683, Part 17, Second Edition, Table 3.

D

Oxygen content applies to product analysis and shall be determined in accordance with Test Methods E 1019.

E

A maximum titanium content may be agreed upon at the time of inquiry and order.

7. Quality Tests worst field of each inclusion type from each specimen shall be

recorded as the rating for the specimen. Two thirds of all

7.1 The supplier shall be held responsible for the quality of

specimens and at least one from each ingot tested, or from the

the material furnished and shall make the necessary tests

first, middle and last portion of the strands tested as well as the

detailed below: Quality tests shown in 7.1 through 7.4 are

average of all specimens, shall not exceed the rating specified

based upon procedures established in Practice E 45.

in Table 2.

7.2 Sampling—Samples taken in accordance with the fol-

lowing paragraphs shall be obtained from 4 by 4 in. (102 by

8. Grain Size

102 mm) rolled billets or forged sections. Tests may be made

8.1 The steels covered by this specification shall have the

on smaller or larger sections by agreement with the purchaser.

capability of showing fine fracture grain size (approximately

A minimum of 3 to 1 reduction of rolled billets or forged

ASTM No. 8) (SAE J418a) when quenched from normal

sections is required for strand cast products.

austenizing temperatures not exceeding 1550°F (843°C).

7.2.1 For top poured products, a minimum of six samples

representing the top and bottom of the first, middle and last

9. Hardenability

usable ingots shall be examined.

9.1 Each heat shall be tested for hardenability. Normalizing

7.2.2 For bottom poured products, a minimum of six

followed by spheroidize annealing shall precede heating for

samples shall be taken from semi-finished or finished product

end quenching. In heating for end quenching, the test speci-

representing the top and bottom of three ingots. One ingot shall

mens shall be held for a minimum of 30 min at 1500 6 8°F

be taken at random from the first usable plate poured, one ingot

(815 6 4.5°C). End-quench procedure shall be in accordance

at random from the usable plate poured nearest to the middle of

with Test Method A 255. The “J” values for hardenability as

the heat, a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.