ASTM D2838-09

(Test Method)Standard Test Method for Shrink Tension and Orientation Release Stress of Plastic Film and Thin Sheeting

Standard Test Method for Shrink Tension and Orientation Release Stress of Plastic Film and Thin Sheeting

SIGNIFICANCE AND USE

As a result of the manufacturing process, internal stresses are locked into the film and these can be released by heating. For any given type of film or sheeting, the temperatures at which shrinkage will begin are related to processing techniques employed to manufacture the film and also may be related to a phase transition in the base resin.

Shrink tension affects the appearance and performance of a film in a shrink-packaging application. It may also be used to determine the degree and direction of orientation. The orientation exerts a great influence upon important physical characteristics such as tensile strength, stiffness, tear resistance, and impact strength.

Data from Procedure A are most useful for determining the degree and direction of orientation, orientation release stress, and the maximum force that the film can exert at a given temperature.

Since, in actual applications, film is seldom, if ever, totally restrained, data from Procedure B are useful in estimating the force an item to be packaged will actually receive and in predicting the appearance of packaged items.

The characterization of shrink tension as a function of temperature, and the resultant determination of orientation release stress and its corresponding temperature, is usually carried out only for a particular material of specified thickness for a defined fabrication process. For product development purposes, quality control and determination of conformity to specification limits, the measurement of shrink tension at only one or two specified temperatures is normally sufficient.

Before proceeding with this test method, reference shall be made to the specification of the material being tested. Any test specimen preparation, conditioning, dimensions, or testing parameters, or combination thereof, covered in the relevant ASTM material specification shall take precedence over those mentioned in this test method. If there are no relevant ASTM material specifications, then the default ...

SCOPE

1.1 This test method covers the determination of the shrink tension and related characteristics, that is, shrink force and orientation release stress, of heat-shrinkable plastic film and sheeting of less than 1.0 mm (0.04 in.) thickness. Two procedures are described that permit the measurement of shrink forces at predetermined temperatures. They are as follows:

1.1.1 Procedure A is designed to measure the maximum force exerted by a specimen that is totally restrained from shrinking as it is heated rapidly to a specific temperature.

1.1.2 Procedure B is designed to measure the maximum force exerted by a specimen that is permitted to shrink a predetermined amount prior to restraint while being heated rapidly to a specific temperature.

1.2 Orientation release stress can be determined from the data obtained using Procedure A.

1.3 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—Film has been arbitrarily defined as sheeting having nominal thickness not greater than 0.25 μm (0.010 in.).

Note 2—There is no known ISO equivalent to this test method.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2838 − 09

StandardTest Method for

Shrink Tension and Orientation Release Stress of Plastic

1

Film and Thin Sheeting

This standard is issued under the fixed designation D2838; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D4000Classification System for Specifying Plastic Materi-

als

1.1 This test method covers the determination of the shrink

D5947Test Methods for Physical Dimensions of Solid

tension and related characteristics, that is, shrink force and

Plastics Specimens

orientation release stress, of heat-shrinkable plastic film and

D6287Practice for Cutting Film and Sheeting Test Speci-

sheeting of less than 1.0 mm (0.04 in.) thickness. Two

mens

proceduresaredescribedthatpermitthemeasurementofshrink

D6988GuideforDeterminationofThicknessofPlasticFilm

forces at predetermined temperatures. They are as follows:

Test Specimens

1.1.1 Procedure A is designed to measure the maximum

E2251Specification for Liquid-in-Glass ASTM Thermom-

force exerted by a specimen that is totally restrained from

eters with Low-Hazard Precision Liquids

shrinking as it is heated rapidly to a specific temperature.

1.1.2 Procedure B is designed to measure the maximum

3. Terminology

force exerted by a specimen that is permitted to shrink a

3.1 Definitions of Terms Specific to This Standard:

predetermined amount prior to restraint while being heated

3.1.1 orientation release stress, n—the maximum shrink

rapidly to a specific temperature.

tension developed by a film in a specified direction throughout

1.2 Orientation release stress can be determined from the

its range of shrink temperatures while totally restrained from

data obtained using Procedure A.

shrinking.

1.3 The values stated in SI units are to be regarded as the

3.1.2 shrink force, n—the force per original unit width

standard. The values in parentheses are for information only.

developed by a film in a specified direction and at a specified

temperature in its attempt to shrink while under restraint.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1.3 shrink tension, n—the force per original average

responsibility of the user of this standard to establish appro-

cross-sectionalareadevelopedbyafilminaspecifieddirection

priate safety and health practices and determine the applica-

and at a specified temperature in its attempt to shrink while

bility of regulatory limitations prior to use.

under restraint.

NOTE 1—Film has been arbitrarily defined as sheeting having nominal

3.2 Definitions:

thickness not greater than 0.25 µm (0.010 in.).

3.2.1 For definitions of terms used in this test method, refer

NOTE 2—There is no known ISO equivalent to this test method.

to Terminology D883.

2. Referenced Documents

4. Summary of Test Method

2

2.1 ASTM Standards:

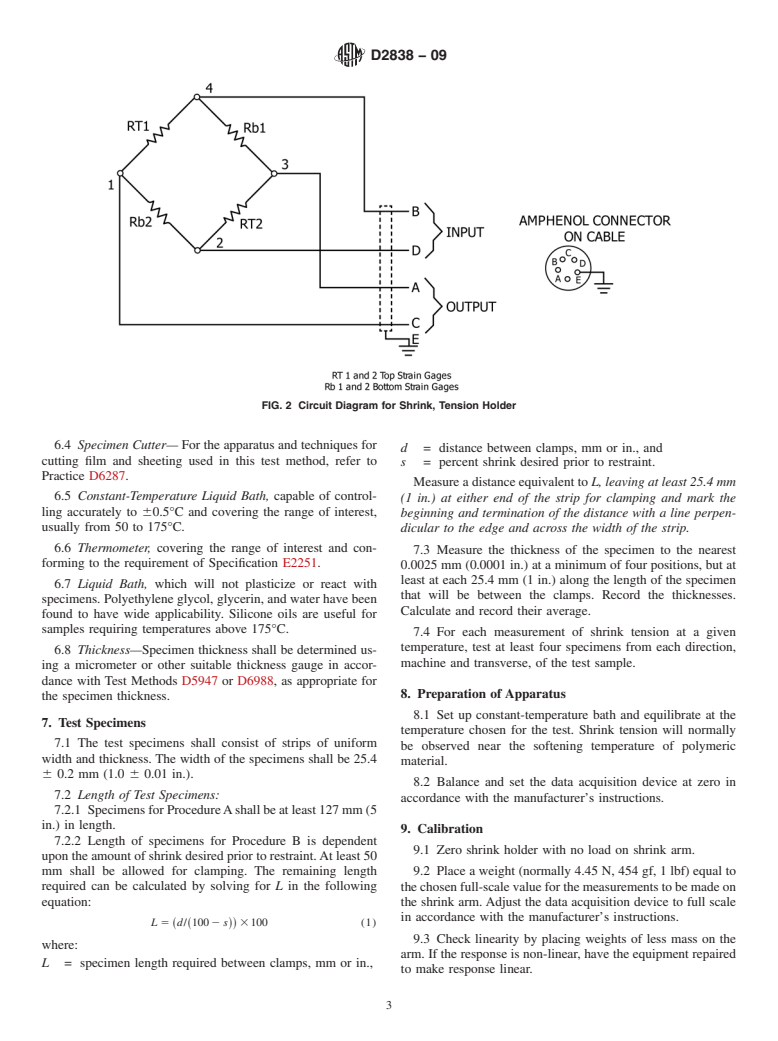

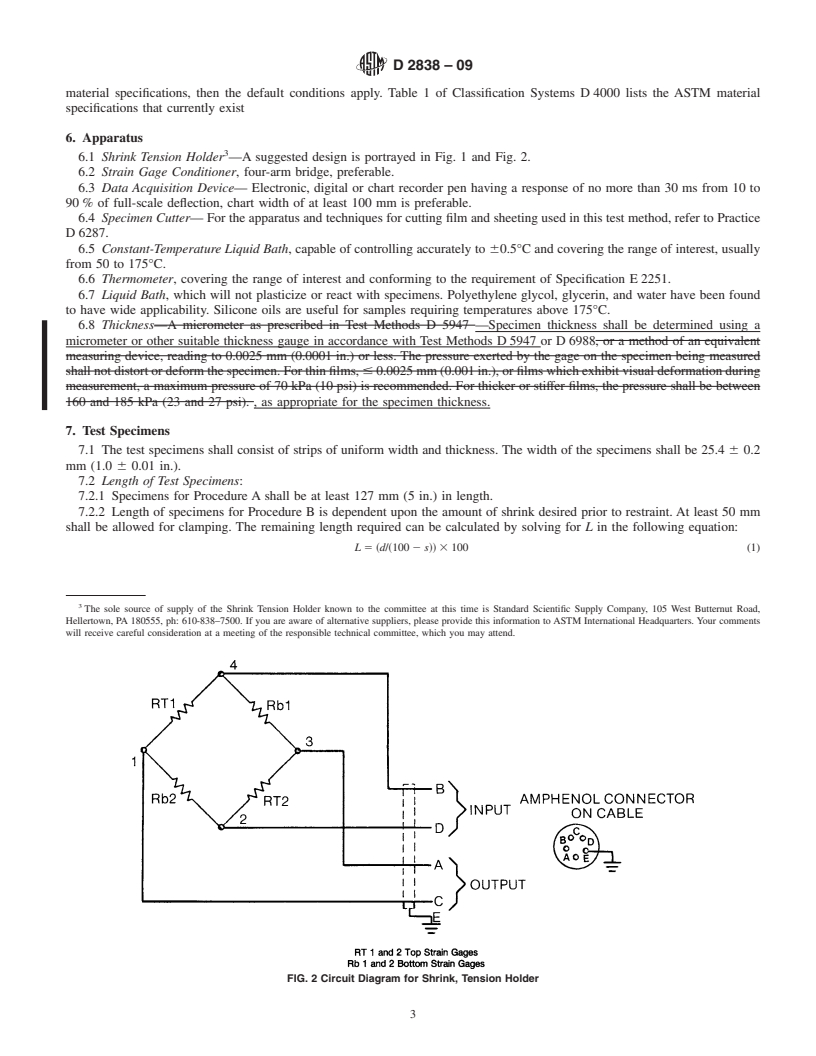

4.1 A 25.4-mm (1-in.) wide strip of film or sheeting is

D618Practice for Conditioning Plastics for Testing

clampedinthearmsofashrinktensionholder(seeFig.1),one

D883Terminology Relating to Plastics

armofwhichcontainsastraingage.Theholderisimmersedin

a hot bath and the force exerted by the film is measured by the

strain gage. The data is collected by a data acquisition device.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

The tests may be carried out with or without free shrinkage of

and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and

the material before restraint.

Molded Products.

Current edition approved May 1, 2009. Published June 2009. Originally

5. Significance and Use

approved in 1969. Last previous edition approved in 2008 as D2838-08. DOI:

10.1520/D2838-09.

5.1 As a result of the manufacturing process, internal

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

stresses are locked into the film and these can be released by

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

heating. For any given type of film or sheeting, the tempera-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tures at which shrinkage will begin are related to processing

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2838 − 09

FIG. 1 Design for Shrink Tension Holder

techniques employed to manufacture the film and also may be 5.6 Before proceeding with this test method, reference shall

related to a phase transition in the base resin. be made to the spec

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D2838–08 Designation:D2838–09

Standard Test Method for

Shrink Tension and Orientation Release Stress of Plastic

1

Film and Thin Sheeting

This standard is issued under the fixed designation D 2838; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of the shrink tension and related characteristics, that is, shrink force and

orientation release stress, of heat-shrinkable plastic film and sheeting of less than 1.0 mm (0.04 in.) thickness. Two procedures are

described that permit the measurement of shrink forces at predetermined temperatures. They are as follows:

1.1.1 Procedure A is designed to measure the maximum force exerted by a specimen that is totally restrained from shrinking

as it is heated rapidly to a specific temperature.

1.1.2 Procedure B is designed to measure the maximum force exerted by a specimen that is permitted to shrink a

predetermined amount prior to restraint while being heated rapidly to a specific temperature.

1.2 Orientation release stress can be determined from the data obtained using Procedure A.

1.3 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE1—There is no known ISO equivalent to this test method.

1.4This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. 1—Filmhasbeenarbitrarilydefinedassheetinghavingnominalthicknessnotgreaterthan0.25µm(0.010

in.).

NOTE 2—There is no known ISO equivalent to this test method.

2. Referenced Documents

2

2.1 ASTM Standards:

D 618 Practice for Conditioning Plastics for Testing

D 883 Terminology Relating to Plastics

D 4000 Classification System for Specifying Plastic Materials

D 5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

D 6287 Practice for Cutting Film and Sheeting Test Specimens

D 6988 Guide for Determination of Thickness of Plastic Film Test Specimens

E 2251 Specification for Liquid-in-Glass ASTM Thermometers with Low-Hazard Precision Liquids

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 orientation release stress, n—themaximumshrinktensiondevelopedbyafilminaspecifieddirectionthroughoutitsrange

of shrink temperatures while totally restrained from shrinking.

3.1.2 shrink force, n—theforceperoriginalunitwidthdevelopedbyafilminaspecifieddirectionandataspecifiedtemperature

in its attempt to shrink while under restraint.

3.1.3 shrink tension, n—the force per original average cross-sectional area developed by a film in a specified direction and at

a specified temperature in its attempt to shrink while under restraint.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting .

Current edition approved Nov.May 1, 2008.2009. Published November 2008.June 2009. Originally approved in 1969. Last previous edition approved in 20072008 as

D 2838 - 078.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2838–09

3.2 Definitions:

3.2.1 For definitions of terms used in this test method, refer to Terminology D 883.

4. Summary of Test Method

4.1 A25.4-mm (1-in.) wide strip of film or sheeting is clamped in the arms of a shrink tension holder (see Fig. 1), one arm of

which contains a strain gage.The holder is immersed in a hot bath and the force exerted by the film is measured by the strain

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.