ASTM D5209-92

(Test Method)Standard Test Method for Determining the Aerobic Biodegradation of Plastic Materials in the Presence of Municipal Sewage Sludge (Withdrawn 2004)

Standard Test Method for Determining the Aerobic Biodegradation of Plastic Materials in the Presence of Municipal Sewage Sludge (Withdrawn 2004)

SCOPE

1.1 This test method covers the determination of the degree and rate of aerobic biodegradation of synthetic plastic materials (including formulation additives that may be biodegradable) on exposure to activated-sewage sludge inoculum under laboratory conditions.

1.2 This test method is designed to index plastic materials that are more or less biodegradable relative to a standard in an aerobic environment.

1.3 This test method is designed to be applicable to all plastic materials that are not inhibitory to the bacteria present in the activated sewage sludge.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards are given in Section 8.

WITHDRAWN RATIONALE

This test method covers the determination of the degree and rate of aerobic biodegradation of synthetic plastic materials (including formulation additives that may be biodegradable) on exposure to activated-sewage sludge inoculum under laboratory conditions.

Formerly under the jurisdiction of Committee D20 on Plastics, this test method was withdrawn in April 2001 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation:D5209–92

Standard Test Method for

Determining the Aerobic Biodegradation of Plastic Materials

in the Presence of Municipal Sewage Sludge

This standard is issued under the fixed designation D 5209; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Liquid Size-Exclusion Chromatography (Gel Permeation

Chromatography-GPC) Using Universal Calibration

1.1 This test method covers the determination of the degree

andrateofaerobicbiodegradationofsyntheticplasticmaterials

3. Terminology

(includingformulationadditivesthatmaybebiodegradable)on

3.1 Definitions:

exposure to activated-sewage sludge inoculum under labora-

3.1.1 Definitions of terms applicable to this test method

tory conditions.

appear in Terminology D 883D 883.

1.2 This test method is designed to index plastic materials

that are more or less biodegradable relative to a standard in an

4. Summary of Test Method

aerobic environment.

4.1 The test method described consists of selection of

1.3 This test method is designed to be applicable to all

plastic material for the determination of aerobic biodegradabil-

plastic materials that are not inhibitory to the bacteria present

ity, obtaining activated sewage sludge from a municipal-

in the activated sewage sludge.

wastewater-treatment plant and preparing inoculum, exposing

1.4 The values stated in SI units are to be regarded as the

plastic material to the aerated inoculum, measuring carbon

standard.

dioxide evolved as a function of time, soluble organic carbon

1.5 This standard does not purport to address all of the

(SOC) content and residual polymer weight, and assessing

safety problems, if any, associated with its use. It is the

degree of biodegradability.

responsibility of the user of this standard to establish appro-

4.2 The percent of theoretical gas production based on

priate safety and health practices and determine the applica-

measured or calculated carbon content is reported with respect

bility of regulatory limitations prior to use.Specifichazardsare

to time from which the degree of biodegradability is assessed.

given in Section 8.

5. Significance and Use

2. Referenced Documents

5.1 The degree and rate of aerobic biodegradability of a

2.1 ASTM Standards:

plastic material in the environment determines to what extent

D 618 Practice for Conditioning of Plastics and Electrical

2 andinwhattimeperiodthatplasticmaybeeliminatedfromthe

Insulating Materials for Testing

environment. With increasing use of plastics, disposal is

D 883 Terminology Relating to Plastics

3 becoming a major issue and the results of this test method may

D 1193 Specification for Reagent Water

permit an estimation of the degree of biodegradability and over

D 1898 Practice for Sampling of Plastics

what time period plastics will remain in an aerobic environ-

D 2667 Test Method for Biodegradability of Alkylbenzene

ment. This test method determines the degree of aerobic

Sulfonates

biodegradation by measuring evolved carbon dioxide, SOC,

D 3593 Test Method for Molecular Weight Averages and

and residual polymeric material as a function of time, when the

Molecular Weight Distribution of Certain Polymers by

plastic is exposed to activated sewage-sludge.

5.2 Activated sewage-sludge from a sewage-treatment plant

that treats principally municipal waste is considered an accept-

able active aerobic environment available over a wide geo-

graphical area in which to test a broad range of plastic

ThistestmethodisunderthejurisdictionofASTMCommitteeD-20onPlastics

and is the direct responsibility of Subcommittee D20.96 on Environmentally materials. Because of the enriched environment of activated

Degradable Plastics.

Current edition published July 31, 1992. Approved September 1992. Originally

published as D 5209 – 91. Last previous edition D 5209 – 91.

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 11.01.

4 5

Annual Book of ASTM Standards, Vol 15.04. Annual Book of ASTM Standards, Vol 08.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

D5209–92

sewage-sludge, the inoculum may be more diverse in compo- 7. Reagents and Materials

sition than a typical aerobic environment that plastics encoun-

7.1 Prepare synthetic stock solutions by dissolving each of

ter in usual disposal methods.

the following in distilled water to 1 L:

7.1.1 Ferric Chloride (FeCl ·6H O)—0.25 g.

3 2

6. Apparatus

7.1.2 Magnesium Sulfate, (MgSO ·7H O)—22.5 g.

4 2

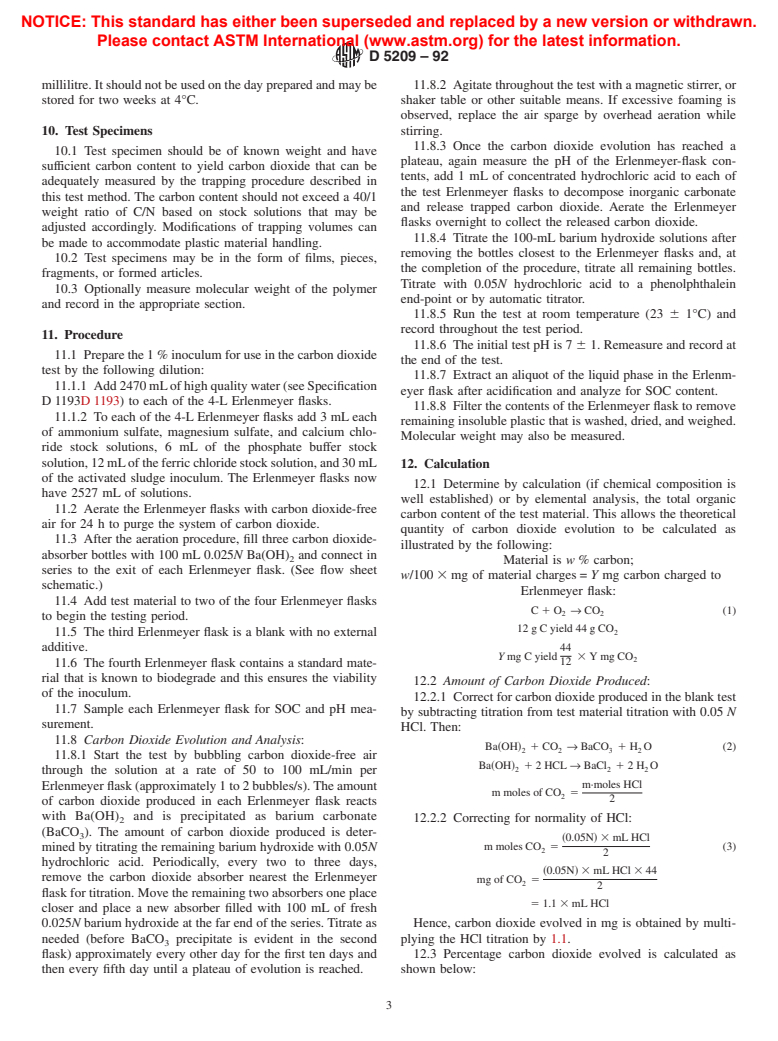

6.1 Carbon Dioxide Scrubbing Apparatus—(See Fig. 1) for

7.1.3 Calcium Chloride (CaCl )—27.5 g.

each specimen the following is required:

7.1.4 Phosphate Buffer—KH HPO 8.5 g, K HPO 21.75 g,

2 4 2 4

6.1.1 A series of twelve 4 L Erlenmeyer flasks (three test

Na HPO 7H O 33.4 g, and NH Cl 1.7 g, for a total of 65.35 g.

2 4 2 4

materials, and four Erlenmeyer flasks per test) requires the

7.1.5 Ammonium Sulfate, ((NH ) SO )—40.0 g.

4 2 4

following

7.2 The test medium will contain the following reagents

6.1.1.1 Four 1-L plastic bottles, containing 700 mL of 10N

diluted to 1 L with high-quality distilled water:

sodium hydroxide (NaOH),

7.2.1 Magnesium Sulfate Solution, 1 mL,

6.1.1.2 Two empty 1-L Erlenmeyer flasks, to prevent liquid

7.2.2 Calcium Chloride Solution, 1 mL,

carry over, and

7.2.3 Phosphate Buffer Solution, 2 mL,

6.1.1.3 One 1-L Erlenmeyer flask, containing 700 mL of

7.2.4 Ferric Chloride Solution, 4 mL, and

0.025N barium hydroxide [Ba(OH )] solution. 7.2.5 Ammonium Sulfate Solution, 1 mL.

6.1.2 Connect the bottles in series, using vinyl, or other

7.3 Barium Hydroxide Solution, 0.025N, is prepared dis-

suitable non gas-permeable tubing, to a pressurized air system, solving 4.0 g Ba(OH) per litre of distilled water. Filter free of

and purge air through the scrubbing solution at a constant rate.

solid material, confirm normality by titration with standard

6.1.3 For each additional set of four Erlenmeyer flasks add acid, and store sealed as a clear solution to prevent absorption

one additional 1-L glass bottle filled with 700 mL of 10N

of CO from the air. It is recommended that five Lbe prepared

sodium hydroxide.

at a time when running a series of tests.

6.2 Carbon dioxide production and trapping apparatus for

each test plastic material requires the following:

8. Hazards

6.2.1 Four 4-L Erlenmeyer flasks,

8.1 This test method includes the use of hazardous chemi-

6.2.2 Stoppers, flexible non-permeable to carbon dioxide

cals. Avoid contact with chemicals and follow manufacturers

(CO ) plastic tubing,

instructions and Material Safety Data Sheets.

6.2.3 Several 100 mL bottles, fitted with gas bubblers and

NOTE 1—Precaution: This test method includes the use of hazardous

containing 100 mL Ba(OH ) carbon dioxide scrubbing solu-

material from a waste treatment plant. Avoid contact with the sludge by

tion,

using gloves and other appropriate protective equipment. Use good

6.2.4 Analytical equipment, to measure total carbon content

personal hygiene to minimize exposure to harmful microbial agents.

of the test specimen,

9. Inoculum Test Organisms

6.2.5 Analytical balance, to weigh test specimen before and

after exposure,

9.1 The source of the test organisms is activated sludge

6.2.6 100-mL burette, and

freshly sampled from a well-operated municipal-sewage treat-

6.2.7 0.05N hydrochloric acid.

ment plant. This sewage treatment plant should receive no or

6.3 Analytical instrument, to measure soluble organic car-

minimal effluent from industry.

bon content (SOC) before and after the experiment is con-

9.2 Aeratesludgeinthelaboratoryfor4h.FivehundredmL

cluded.

of the mixed liquor is sampled and homogenized for 2 min at

6.4 Agitation or stirrers, for each 4-L Erlenmeyer flask.

medium speed in a blender or equivalent high speed mixer.

Allow to settle for 30 min.

9.3 If the supernatant still contains high levels of sludge-

suspended matter at the end of 30 min, allow to settle for a

further 30 to 40 min or adapt laboratory conditions to obtain

better settling.

9.4 Decant sufficient volume of the supernatant to provide a

1 % inoculum for each carbon dioxide (CO ) test Erlenmeyer

flask. Avoid carry-over of sludge which would interfere with

the measurement of carbon dioxide production.

9.5 Optionally, it is useful to perform counts on the super-

natant fraction to determine microbial numbers. The inoculum

6 6

should contain 10 to 20 3 10 colony-forming units per

High-quality distilled water, free of toxic substances (copper in particular) with

low carbon content (< 2.0 mg/L SOC) and with resistivity > 18 megohms/cm.

(Distilled water must never contain more than 10 % of the organic carbon

introduced by the test material.)

FIG. 1 Aerobic Testing Schematic A Waring blender has been found suitable for this purpose.

NOTICE: This standard has

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.