ASTM E1709-16e1

(Test Method)Standard Test Method for Measurement of Retroreflective Signs Using a Portable Retroreflectometer at a 0.2 Degree Observation Angle

Standard Test Method for Measurement of Retroreflective Signs Using a Portable Retroreflectometer at a 0.2 Degree Observation Angle

SIGNIFICANCE AND USE

5.1 Measurements made by this test method are related to the night time brightness of retroreflective traffic signs approximately facing the driver of a mid-sized automobile equipped with tungsten filament headlights at about 200 m distance.

5.2 Retroreflective material used on traffic signs degrades with time and requires periodic measurement to ensure that the performance of the retroflection provides adequate safety to the driver.

5.3 The quality of the sign as to material used, age, and wear pattern will have an effect on the coefficient of retroreflection. These conditions need to be observed and noted by the user.

5.4 This test method is not intended for use for the measurement of signs when the instrument entrance and observation angles differ from those specified herein.

SCOPE

1.1 This test method covers measurement of the retroreflective properties of sign materials such as traffic signs and symbols (vertical surfaces) using a portable retroreflectometer that can be used in the field. The portable retroreflectometer is a hand-held instrument with a defined standard geometry that can be placed in contact with sign material to measure the retroreflection in a standard geometry. The measurements can be compared to minimum requirements to determine the need for replacement. Entrance and observation angles specified in this test method are those used currently in the United States and may differ from the angles used elsewhere in the world.

1.2 This test method is intended to be used for the field measurement of traffic signs but may be used to measure the performance of materials before placing the sign in the field or before placing the sign material on the sign face.

1.3 This test method covers measurements at a 0.2 degree observation angle. See Test Method E2540 for measurements at a 0.5 degree observation angle.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:E1709 −16

Standard Test Method for

Measurement of Retroreflective Signs Using a Portable

1

Retroreflectometer at a 0.2 Degree Observation Angle

This standard is issued under the fixed designation E1709; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Paragraph 6.5.2 was editorially corrected in April 2017.

1. Scope 2. Referenced Documents

2

1.1 This test method covers measurement of the retroreflec- 2.1 ASTM Standards:

tive properties of sign materials such as traffic signs and D4956Specification for Retroreflective Sheeting for Traffic

symbols (vertical surfaces) using a portable retroreflectometer Control

that can be used in the field. The portable retroreflectometer is E177Practice for Use of the Terms Precision and Bias in

a hand-held instrument with a defined standard geometry that ASTM Test Methods

can be placed in contact with sign material to measure the E284Terminology of Appearance

retroreflection in a standard geometry. The measurements can E691Practice for Conducting an Interlaboratory Study to

be compared to minimum requirements to determine the need Determine the Precision of a Test Method

for replacement. Entrance and observation angles specified in E808Practice for Describing Retroreflection

this test method are those used currently in the United States E809Practice for Measuring Photometric Characteristics of

and may differ from the angles used elsewhere in the world. Retroreflectors

E810Test Method for Coefficient of Retroreflection of

1.2 This test method is intended to be used for the field

Retroreflective Sheeting Utilizing the Coplanar Geometry

measurement of traffic signs but may be used to measure the

E2540Test Method for Measurement of Retroreflective

performance of materials before placing the sign in the field or

Signs Using a Portable Retroreflectometer at a 0.5 Degree

before placing the sign material on the sign face.

Observation Angle

1.3 This test method covers measurements at a 0.2 degree

3. Terminology

observation angle. See Test Method E2540 for measurements

at a 0.5 degree observation angle.

3.1 The terminology used in this test method generally

agrees with that used in Terminology E284.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.2 Definitions—The delimiting phrase “in retroreflection”

responsibility of the user of this standard to establish appro-

applies to each of the following definitions when used outside

priate safety and health practices and to determine the

the context of this or other retroreflection standards.

applicability of regulatory limitations prior to use.

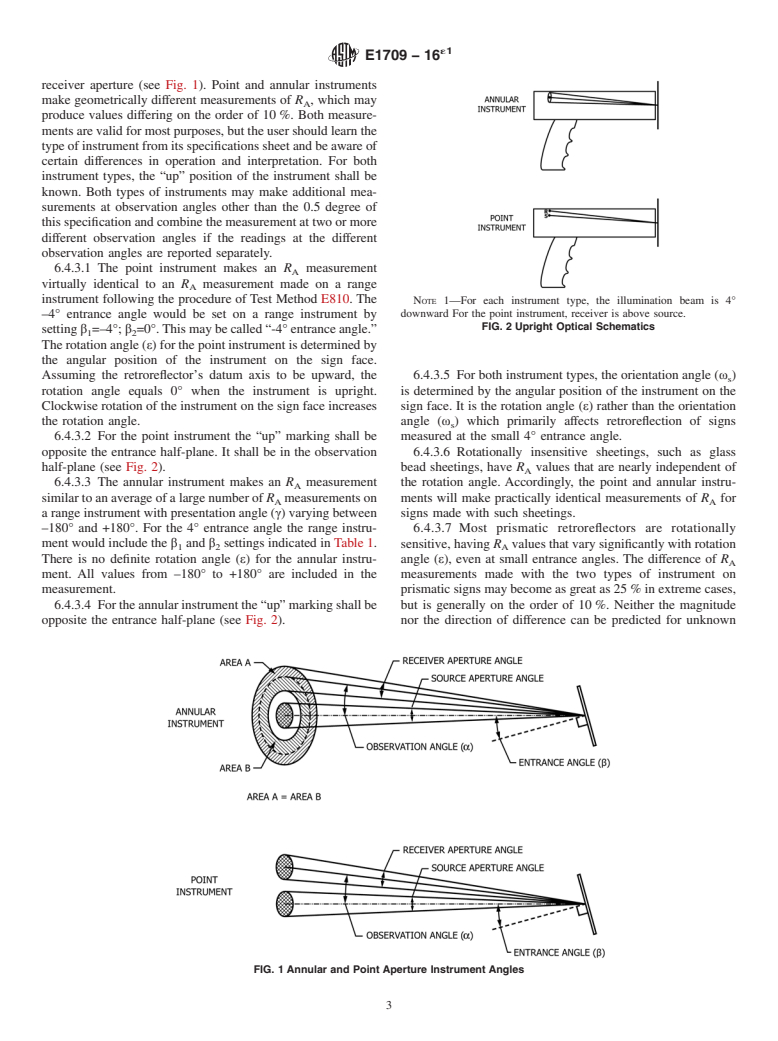

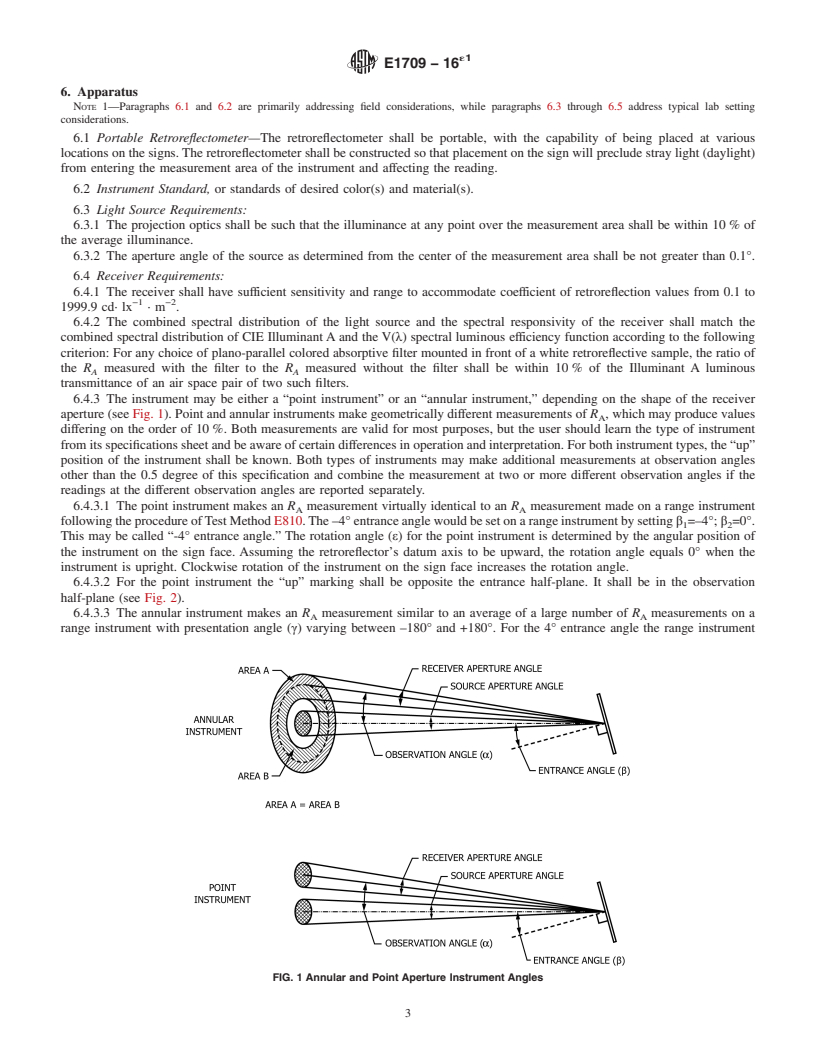

3.2.1 annular geometry, n—the portable instrument retrore-

1.5 This international standard was developed in accor-

flection collection method where an annular area 0.1 degrees

dance with internationally recognized principles on standard-

wide around the illumination axis collects the retroreflected

ization established in the Decision on Principles for the

energyatanangletothecenteroftheannularareacorrespond-

Development of International Standards, Guides and Recom-

ing to a specific observation angle.

mendations issued by the World Trade Organization Technical

3.2.2 coeffıcient of retroreflection, R ,n—of a plane retrore-

A

Barriers to Trade (TBT) Committee.

flecting surface, the ratio of the coefficient of luminous

intensity (R) of a plane retroreflecting surface to its area (A),

I

−1 −2

expressedincandelasperluxpersquaremetre(cd·lx ·m ).

1

This test method is under the jurisdiction of ASTM Committee E12 on Color

and Appearance and is the direct responsibility of Subcommittee E12.10 on

2

Retroreflection. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2016. Published November 2016. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1995. Last previous edition approved in 2009 as E1709–09. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E1709-16E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

E1709−16

3.2.3 datum axis, n—adesignatedhalf-linefromtheretrore- 4.6 The reading displayed by the retroreflectometer is re-

flector center perpendicular to the retroreflector axis. corded. The retroreflectometer is then moved to another

position on the sign, and this value is recorded.Aminimum of

3.2.4 entrance angle, β,n—the angle between the illumi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E1709 − 16 E1709 − 16

Standard Test Method for

Measurement of Retroreflective Signs Using a Portable

1

Retroreflectometer at a 0.2 Degree Observation Angle

This standard is issued under the fixed designation E1709; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Paragraph 6.5.2 was editorially corrected in April 2017.

1. Scope

1.1 This test method covers measurement of the retroreflective properties of sign materials such as traffic signs and symbols

(vertical surfaces) using a portable retroreflectometer that can be used in the field. The portable retroreflectometer is a hand-held

instrument with a defined standard geometry that can be placed in contact with sign material to measure the retroreflection in a

standard geometry. The measurements can be compared to minimum requirements to determine the need for replacement. Entrance

and observation angles specified in this test method are those used currently in the United States and may differ from the angles

used elsewhere in the world.

1.2 This test method is intended to be used for the field measurement of traffic signs but may be used to measure the

performance of materials before placing the sign in the field or before placing the sign material on the sign face.

1.3 This test method covers measurements at a 0.2 degree observation angle. See Test Method E2540 for measurements at a

0.5 degree observation angle.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory

limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D4956 Specification for Retroreflective Sheeting for Traffic Control

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E284 Terminology of Appearance

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E808 Practice for Describing Retroreflection

E809 Practice for Measuring Photometric Characteristics of Retroreflectors

E810 Test Method for Coefficient of Retroreflection of Retroreflective Sheeting Utilizing the Coplanar Geometry

E2540 Test Method for Measurement of Retroreflective Signs Using a Portable Retroreflectometer at a 0.5 Degree Observation

Angle

3. Terminology

3.1 The terminology used in this test method generally agrees with that used in Terminology E284.

3.2 Definitions—The delimiting phrase “in retroreflection” applies to each of the following definitions when used outside the

context of this or other retroreflection standards.

1

This test method is under the jurisdiction of ASTM Committee E12 on Color and Appearance and is the direct responsibility of Subcommittee E12.10 on Retroreflection.

Current edition approved July 1, 2016. Published November 2016. Originally approved in 1995. Last previous edition approved in 2009 as E1709 – 09. DOI:

10.1520/E1709-16.10.1520/E1709-16E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

E1709 − 16

3.2.1 annular geometry, n—the portable instrument retroreflection collection method where an annular area 0.1 degrees wide

around the illumination axis collects the retroreflected energy at an angle to the center of the annular area corresponding to a

specific observation angle.

3.2.2 coeffıcient of retroreflection, R , n—of a plane retroreflecting surface, the ratio of the coefficient of luminous intensity (R )

A I

−1 −2

of a plane retroreflecting surface to its area (A), expressed in candelas per lux per square metre (cd · lx · m ).

3.2.3 d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.