ASTM F1005-91(1997)

(Practice)Standard Practice for HVAC Duct Shapes; Identification and Description of Design Configuration

Standard Practice for HVAC Duct Shapes; Identification and Description of Design Configuration

General Information

Standards Content (Sample)

STD.ASTM FLIIOS-ENGL 197L - 0757530 Obllb3b4 323 -

Designation: F 1005 - 91 (Reapproved 1997) AnAmerkanNatbnalsEMderd

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Ban Harbor Dr., West Conshchocken. PA 19429

Reprlnted from the Annual Book of ASTM Standards. Copyright ASTM

If not listed on the current combned index. will appear m the next editm.

Standard Practice for

HVAC Duct Shapes; Identification and Description of Design

Configuration’

This standard is issued under the 6xed designation F 1005; the number immediately following the designation indicates the year of

original adoption of, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope number and location of splitters is determined by calculation

or from a nomograph.

1.1 This practice covers the identification of design con-

2.1.13 straight--duct that remains constant in cross-

figurations and descriptive nomenclature for she&metal

section and size throughout its length.

HVAC ductwork shapes frequently used in shipbuilding.

2.1.14 throat-wrapper around the inside of a fitting.

This practice also covers parametric dimensions of these

2.1.15 transition-fitting that changes the cross-section

shapes.

type of the duct.

1.2 This practice does not cover the location of seams or

2.1.16 vane-internal part of vaned turns. Used to pro-

joints within a shape or the method of joining shapes

vide more uniform velocity of air flow. Cordiguration,

together.

1.3 Since this practice is not measurement sensitive, it is number, and location of vanes is determined from drawing,

applicable whether inch-pound or SI metric dimensions are NAVSHIPS No. S3801-385260.2 The direction of airflow

Used. must be marked on vaned turns.

1.4 This standard does not purport to address all of the

2.1.17 vaned turn-a fitting containing vanes that is used

safety problems, if any, associated with its use. It is the to change the direction of air flow.

responsibility of the user of this standard to establish appro-

2.2 Variables Specific to This Standard:

priate safety and health practices and determine the applica-

A-Angle. Included angle of an elbow, branch, vaned

bility of regulatory limitations prior to use.

turn, or slant-top fitting.

AI-Air In indicates the length of the straight portion of a

vaned turn in the “air in-flow” side.

2. Terminology

AO-Air Out indicates the length of the straight portion of

2.1 Descriptions of Terms Specific to this Standard:

a vaned turn on the “air out-flow” side.

2.1.1 branch-portion of a duct system connection to a

B-Distance from the intersection of the center lines of a

main duct.

branch and the main duct to the end of the main duct.

2.1.2 elbow-a fitting used to change direction of air flow.

CY-Distance between centers of a Y branch.

2.1.3 jlat oval-cross-section that has flat sides and semi-

D-Depth of a part.

circular ends.

DB-Depth of a branch.

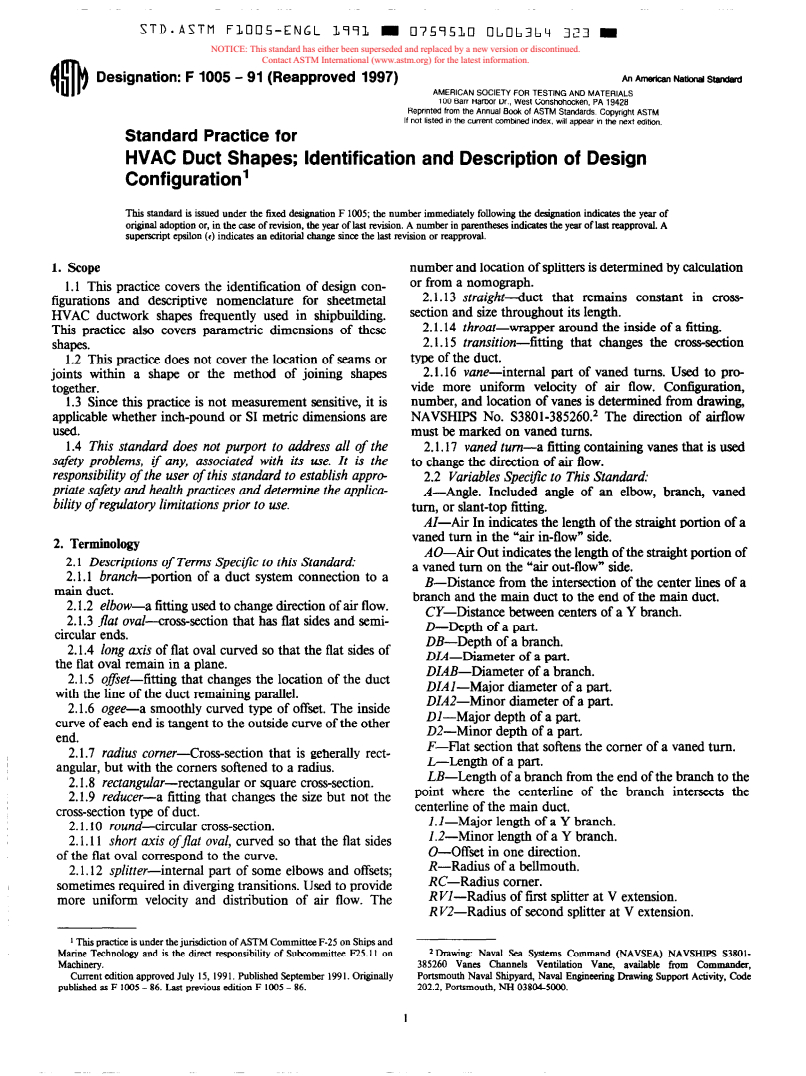

2.1.4 long axis of flat oval curved so that the flat sides of

DZA-Diameter of a part.

the flat oval remain in a plane.

DIAE-Diameter of a branch.

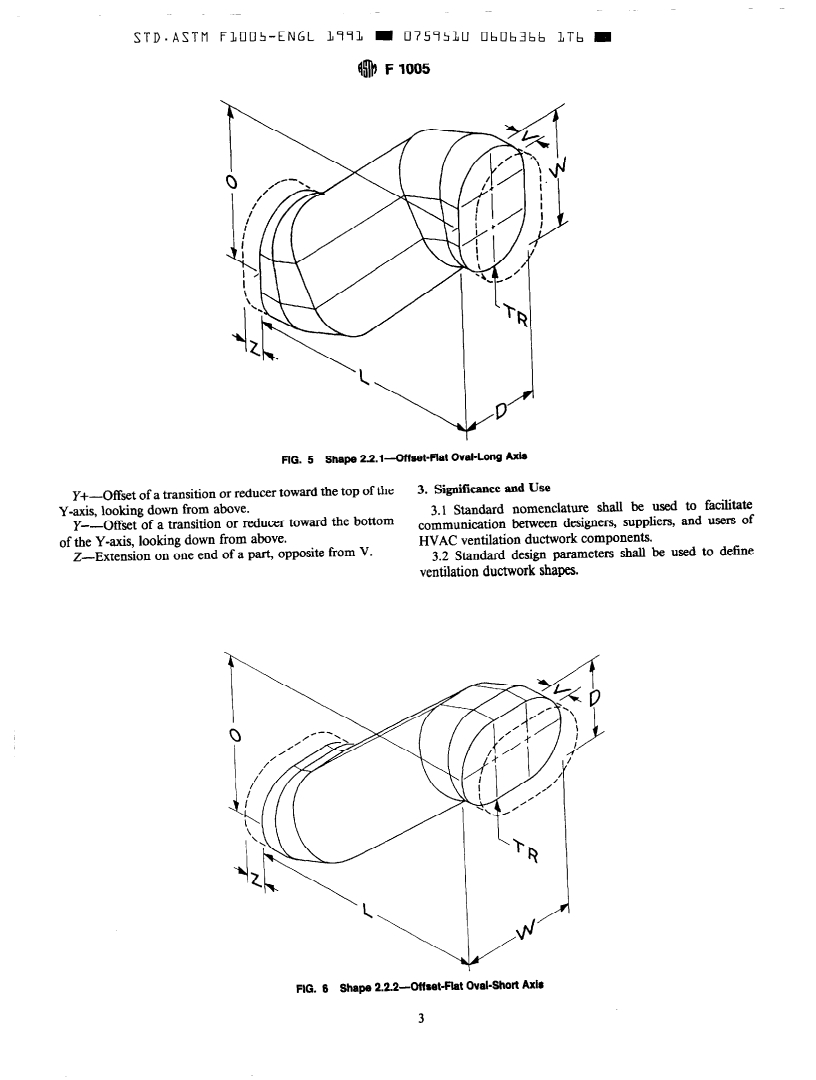

2.1.5 offset-fitting that changes the location of the duct

DZAI-Major diameter of a part.

with the line of the duct remaining parallel.

DIA2-Minor diameter of a part.

2.1.6 ogee-a smoothly curved type of offset The inside

Dl-Major depth of a part.

curve of each end is tangent to the outside curve of the other

DZ-Minor depth of a part.

end.

F-Flat section that softens the comer of a vaned turn.

2.1.7 radius comer-Cross-section that is geheralIy rect-

L-Length of a part.

angular, but with the comers softened to a radius.

LB-Length of a branch from the end of the branch to the

2. I .8 rectangular-rectangular or square cross-section.

point where the centerline of the branch intersects the

2.1.9 reducer-a fitting that changes the size but not the

centerline of the main duct.

cross-section type of duct.

l.l-Major length of a Y branch.

2.1.10 round-circular cross-section.

2.2--Minor length of a Y branch.

2.1.11 short axis offlat oval, curved so that the flat sides

O-Offset in one direction.

of the flat oval correspond to the curve.

R-Radius of a bellmouth.

2.1.12 splitter-internal part of some elbows and offsets;

RC-Radius corner.

sometimes required in diverging transitions. Used to provide

R W-Radius of first splitter at V extension.

more uniform velocity and distribution of air flow. The

RV2-Radius of second splitter at V extension.

1 This practice is under the jurisdiction of ASTM Committee F-25 on Ships and

Marine Technology and is the direct reswnsibility of Subcommittee F25.11 on 2Drwing: Naval Sea Systems Command (NAVSEA) NAVSHIPS S3801-

Machinery. 385260 Vanes Channels Ventilation Vane, available from Commander,

Current edition approved July 15, 199 1. Published September 199 I. Originally Portsmouth Naval S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.