ASTM D4644-04

(Test Method)Standard Test Method for Slake Durability of Shales and Similar Weak Rocks

Standard Test Method for Slake Durability of Shales and Similar Weak Rocks

SIGNIFICANCE AND USE

The test method is used to estimate qualitatively the durability of weak rocks in the service environment.(1-7)3 .

This test method is used to assign quantitative durability values to weak rocks. A primary example is the Franklin Rating System (1).

Note 1—The quality of the result produced by this standard is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D 3740 are generally considered capable of competent and objective testing, sampling, inspection, and so forth. Users of this standard are cautioned that compliance with Practice D 3740 does not in itself assure reliable results. Reliable results depend on many factors; Practice D 3740 provides a means of evaluating some of those factors.

SCOPE

1.1 This test method covers the determination of the slake durability index of a shale or other similar rock after two drying and wetting cycles with abrasion.

1.2 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D 6026.

1.2.1 The method used to specify how data are collected, calculated, or recorded in this standard is not directly related to the accuracy to which the data can be applied in design or other uses, or both. How one applies the results obtained using this standard is beyond its scope.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4644–04

Standard Test Method for

1

Slake Durability of Shales and Similar Weak Rocks

This standard is issued under the fixed designation D 4644; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* E 11 Specification for Wire Cloth and Sieves for Testing

Purposes

1.1 This test method covers the determination of the slake

durability index of a shale or other similar rock after two

3. Terminology

drying and wetting cycles with abrasion.

3.1 For terminology used in this test method, refer to

1.2 All observed and calculated values shall conform to the

Terminology D 653

guidelines for significant digits and rounding established in

3.2 Definitions of Terms Specific to This Standard:

Practice D 6026.

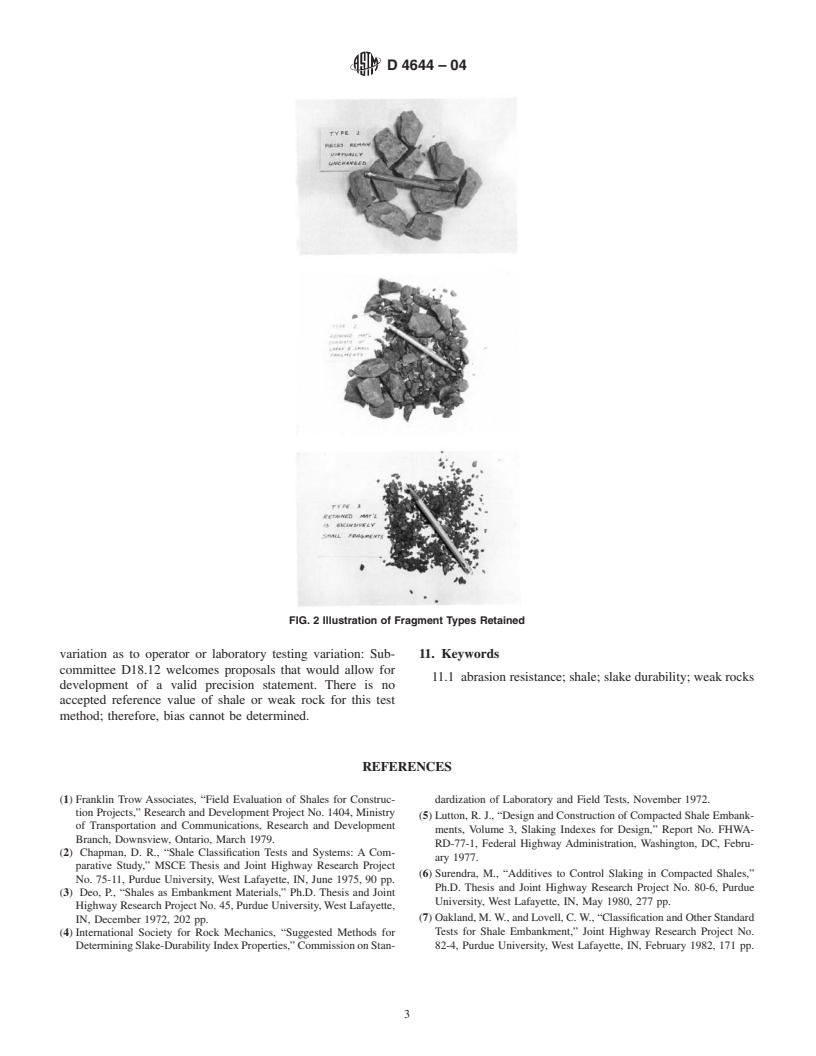

3.2.1 slake durability index—the percentage by dry mass

1.2.1 The method used to specify how data are collected,

retained of a collection of shale pieces on a 2.00 mm (No. 10)

calculated, or recorded in this standard is not directly related to

sieve after two cycles of oven drying and 10 min of soaking in

theaccuracytowhichthedatacanbeappliedindesignorother

water with a standard tumbling and abrasion action.

uses, or both. How one applies the results obtained using this

standard is beyond its scope.

4. Significance and Use

1.3 The values stated in SI units are to be regarded as the

4.1 The test method is used to estimate qualitatively the

standard. The values given in parentheses are provided for

3

durability of weak rocks in the service environment.(1-7) .

information only.

4.2 This test method is used to assign quantitative durability

1.4 This standard does not purport to address all of the

valuestoweakrocks.AprimaryexampleistheFranklinRating

safety concerns, if any, associated with its use. It is the

System (1).

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

NOTE 1—The quality of the result produced by this standard is

bility of regulatory limitations prior to use. dependent on the competence of the personnel performing it, and the

suitability of the equipment and facilities used. Agencies that meet the

2. Referenced Documents criteria of Practice D 3740 are generally considered capable of competent

2 and objective testing, sampling, inspection, and so forth. Users of this

2.1 ASTM Standards:

standard are cautioned that compliance with Practice D 3740 does not in

D 653 Terminology Relating to Soil, Rock, and Contained

itself assure reliable results. Reliable results depend on many factors;

Fluids

Practice D 3740 provides a means of evaluating some of those factors.

D 2113 Practice for Diamond Core Drilling for Site Inves-

5. Apparatus

tigation

D 2216 TestMethodforLaboratoryDeterminationofWater

5.1 Slake Durability Device—The drum (Fig. 1) shall be

(Moisture) Content of Rock and Soil

made of 2.00 mm (No. 10) square-mesh, woven-wire cloth,

D 3740 Practice for Minimum Requirements for Agencies

conforming to the requirements of Specification E 11. It shall

Engaged in Testing and/or Inspection of Soil and Rock as

becylindricalinshape,withadiameterof140mm(5.5in.)and

Used in Engineering Design and Construction

a length of 100 mm (3.9 in.). The ends shall be rigid plates,

D 5079 Practices for Preserving and Transporting Rock

with one removable end. It must be sufficiently strong to retain

Core Samples

itsshapeduringuse,butneithertheexteriorofthemeshnorthe

D 6026 Practice for Using Significant Digits in Geotechni-

interior of the drum shall be obstructed by a support.The drum

cal Data

shall be able to withstand a temperature of 110 6 5°C (230 6

9°F). A trough shall support the drum in a horizontal manner

such that the drum is free to rotate about its axis. The trough

1

shallbecapableofbeingfilledwithslakingfluidto20mm(0.8

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

Rock and is the direct responsibility of Subcommittee D18.12 on Rock Mechanics.

in.) below the drum axis, and shall allow at least 40 mm (1.6

Current edition approved Feb. 1, 2004. Published February 2004. Originally

in.) unobstructed clearance between the trough and the bottom

approved in 1987. Last previous edition approved in 1998 as D 4644 – 87 (1998).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to the list of references at the end of

the ASTM website. this standard.

*A Summary of Changes section appears at the end of th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.