ASTM D4185-96

(Practice)Standard Practice for Measurement of Metals in Workplace Atmosphere by Flame Atomic Absorption Spectrophotometry

Standard Practice for Measurement of Metals in Workplace Atmosphere by Flame Atomic Absorption Spectrophotometry

SCOPE

1.1 This practice covers the collection, dissolution, and determination of trace metals in workplace atmospheres, by atomic absorption spectrophotometry.

1.2 The sensitivity, detection limit, and optimum working concentration for 23 metals are given in Table 1.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Specific safety precautionary statements are given in Section 9.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4185 – 96 An American National Standard

Standard Practice for

Measurement of Metals in Workplace Atmosphere by Flame

Atomic Absorption Spectrophotometry

This standard is issued under the fixed designation D 4185; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

NOTE 1—Values for detection limit may vary from instrument to

1. Scope

instrument.

1.1 This practice covers the collection, dissolution, and

determination of trace metals in workplace atmospheres, by

4. Summary of Practice

atomic absorption spectrophotometry.

4.1 The samples are collected on membrane filters and

1.2 The sen

treated with nitric acid to destroy the organic matrix and to

sitivity, detection limit, and optimum working concentration

dissolve the metals present. The analysis is subsequently made

for 23 metals are given in Table 1.

by flame atomic absorption spectrophotometry (AAS).

1.3 This standard does not purport to address all of the

4.2 Samples and standards are aspirated into an appropriate

safety concerns, if any, associated with its use. It is the

AAS flame. A hollow cathode or electrodeless discharge lamp

responsibility of the user of this standard to establish appro-

for the metal being determined provides a source of character-

priate safety and health practices and determine the applica-

istic radiation energy for that particular metal. The absorption

bility of regulatory limitations prior to use. (Specific safety

of this characteristic energy by the atoms of interest in the

precautionary statements are given in Section 9.)

flame is related to the concentration of the metal in the

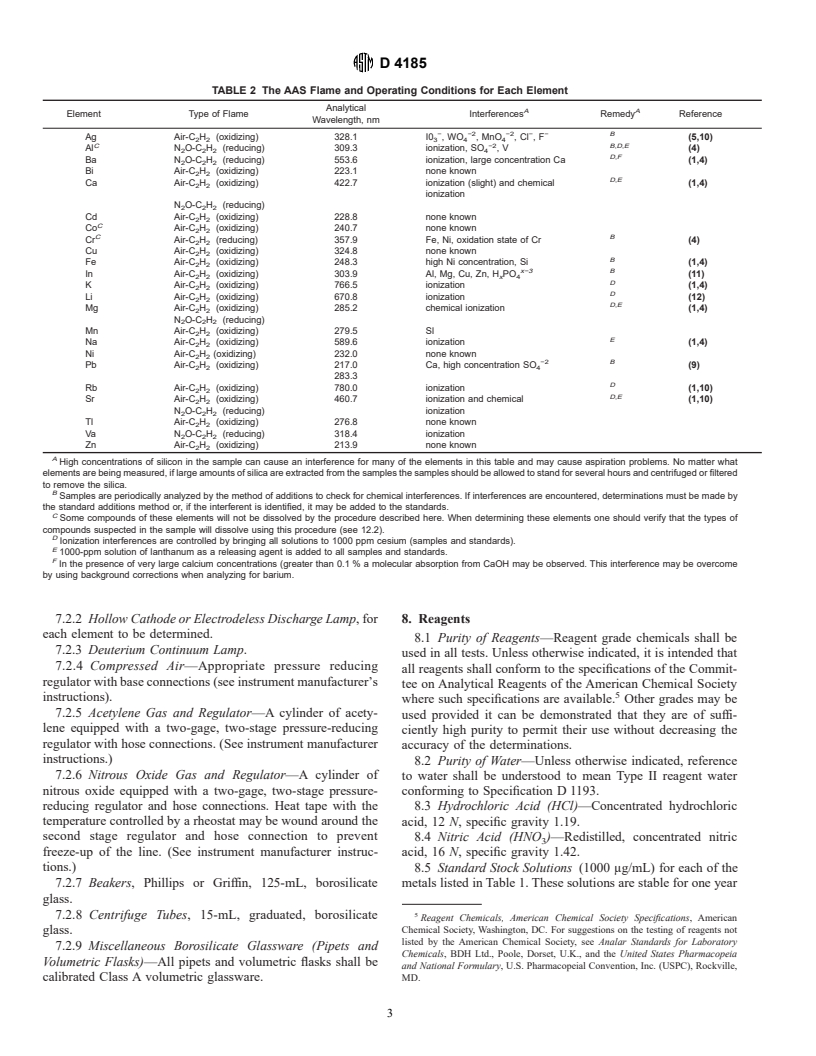

aspirated sample. The flame and operating conditions for each

2. Referenced Documents

element are listed in Table 2.

2.1 ASTM Standards:

D 1193 Specification for Reagent Water

5. Significance and Use

D 1356 Terminology Relating to Sampling and Analysis of

5.1 Exposure to some metal-containing particulates has

Atmospheres

been demonstrated to cause dermatitis, skin ulcers, eye prob-

D 1357 Practice for Planning the Sampling of the Ambient

lems, chemical pneumonitis, and other physical disorders (1).

Atmosphere

5.2 AAS is capable of quantitatively determining most

D 3195 Practice for Rotameter Calibration

metals in air samples at the levels required by federal, state,

and local occupational health and air pollution regulations.

3. Terminology

3.1 Definitions:

6. Interferences

3.1.1 For definitions of terms used in this practice, refer to

6.1 In AAS the occurrence of interferences is less common

Terminology D 1356.

than in many other analytical techniques. Interferences can

3.2 Definitions of Terms Specific to This Standard:

occur, however, and when encountered are corrected for as

3.2.1 blank signal—that signal which results from all added

indicated in the following sections. The known interferences

reagents and a clean membrane filter ashed exactly as the

and correction methods for each metal are indicated in Table 2.

samples.

The methods of standard additions and background monitoring

3.2.2 detection limit—that concentration of a given element

and correction (2-5) are used to identify the presence of an

which produces a signal three times the standard deviation of

interference. Insofar as possible, the matrix of sample and

the blank signal.

standard are matched to minimize the possible interference.

3.2.3 working range for an analytical precision better than

6.2 Background or nonspecific absorption can occur from

3%—the range of sample concentrations that will absorb 10 to

particles produced in the flame which can scatter light and

70 % of the incident radiation (0.05 to 0.52 absorbance unit).

produce an apparent absorption signal. Light scattering may be

encountered when solutions of high salt content are being

1 analyzed. They are most severe when measurements are made

This practice is under the jurisdiction of ASTM Committee D-22 on Sampling

and Analysis of Atmospheres and are the direct responsibility of Subcommittee at shorter wavelengths (for example, below about 250 nm).

D22.04 on Workplace Atmospheres.

Current edition approved Dec. 10, 1996. Published February 1997. Originally

published as D 4185 – 90. Last previous edition D 4185 – 90.

2 4

Annual Book of ASTM Standards, Vol 11.01. Boldface numbers in parentheses refer to the list of references appended to

Annual Book of ASTM Standards, Vol 11.03. these methods.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 4185

TABLE 1 Detection Limits and Optimum Working Concentration for 23 Metals

Detection Limit, μg/mL Optimum Linear Range

3 B

Element (approximately three times Upper Limit, TLV, mg/m (elements, compound classes, and oxides)

A

standard deviation) μg/mL

Ag 0.001 5 0.1 (metal) 0.01 (soluble compounds as Ag)

Al 0.04 50 2.0 (soluble salts and alkyls not otherwise classified) 10 (metal dust and oxide)

5 (pyro powder and welding fume)

Ba 0.01 10 0.5 (soluble compounds)

Bi 0.03 10 No Limit expressed for this element

Ca 0.002 1 2 (oxide as CaO)

Cd 0.0008 1 0.01 (elemental and compounds—total dust)

0.002 (elemental compounds—respirable fraction)

Co 0.009 5 0.02 (elemental and inorganic) 0.1 (carbonyl and hydrocarbonyl)

Cr 0.003 5 0.5 (metal and Cr III compounds) 0.05 (water soluble Cr VI compounds)

0.01 (insoluble Cr VI compounds)

Cu 0.002 5 0.2 (fume) 1 (dust and mists as Cu)

Fe 0.005 5 5 (iron oxide fume) 5 (soluble salts as Fe)

In 0.03 50 0.1 (metal and compounds)

K 0.003 1 No Limit expressed for this element

Li 0.0008 1 No Limit expressed for this element

Mg 0.0002 0.5 10 (as MgO fume)

Mn 0.002 5 0.2 (elemental and inorganic compounds)

Na 0.0003 0.5 No Limit expressed for this element

Ni 0.006 5 0.05 (elemental, soluble and insoluble compounds)

Pb 0.02 10 0.15 (inorganic compounds, fume, dust)

Rb 0.003 5 No Limit expressed for this element

Sr 0.003 5 No Limit expressed for this element

Tl 0.02 50 0.1 (soluble compounds)

V 0.06 100 0.05 (pentoxide, respirable dust or fume, as V O )

2 5

Zn 0.002 1 10 (oxide dust as ZnO) 5 (oxide fume as ZnO)

A

Detection limit data and precision information supplied by Perkin-Elmer Corp., Norwalk, CT.

Note—These detection limits represent ideal laboratory conditions; variability due to sampling, digestion, reagents, and sample handling has not been taken into account.

B

Threshold Limit Values of Airborne Contaminants and Physical Agents adopted by ACGIH for 1994–1995. Values are elemental concentration except as noted.

Background absorption may also occur as the result of the thus cause erroneous results. Sample dilution or the method of

formation of various molecular species which can absorb light. standard additions, or both, are used to correct such interfer-

The background absorption can be accounted for by the use of ences. High concentrations of silica in the sample can cause

background correction techniques (2). aspiration problems. No matter what elements are being

6.3 Spectral interferences are those interferences which determined, if large amounts of silica are extracted from the

result from an atom different from the one being measured that samples they shall be allowed to stand for several hours and

absorbs a portion of the radiation. Such interferences are centrifuged or filtered to remove the silica.

extremely rare in AAS. In some cases multielement hollow 6.7 This procedure describes a generalized method for

cathode lamps may cause a spectral interference by having sample preparation which is applicable to the majority of

closely adjacent emission lines from two different elements. In samples. There are some relatively rare chemical forms of a

general, the use of multielement hollow cathode lamps is few of the elements listed in Table 1 that will not be dissolved

discouraged. by this procedure. If such chemical forms are suspected, results

6.4 Ionization interference occurs when easily ionized at- obtained using this procedure shall be compared with those

oms are being measured. The degree to which such atoms are obtained using an appropriately altered dissolution procedure.

ionized is dependent upon the atomic concentration and the Alternatively, the results may be compared with values ob-

presence of other easily ionized atoms. This interference can be tained using a technique that does not require dissolving the

controlled by the addition of a high concentration of another sample (for example, X-ray fluorescence or activation analy-

easily ionized element which will buffer the electron concen- sis).

tration in the flame.

7. Apparatus

6.5 Chemical interferences occur in AAS when species

present in the sample cause variations in the degree to which 7.1 Sampling Apparatus:

7.1.1 Cellulose Ester or Cellulose Nitrate Membrane Fil-

atoms are formed in the flame, or when different valence states

of a single element have different absorption characteristics. ters, with a pore size of 0.8 μm mounted in a 37-mm diameter

Such interferences may be controlled by adjusting the sample two- or three-piece filter cassette.

matrix or by the method of standard additions (3). Also, the use 7.1.2 Portable, Battery-Operated Personal Sampling

of lanthanum as a releasing element minimizes the interference Pumps, equipped with a flow-monitoring device (rotameter,

from the formation of involatile compounds in the flame. critical orifice) or a constant-flow device and capable of

Lanthanum forms involatile compounds preferentially with the drawing 2 L/min of air through the 0.8-μm filter membranes for

interferent so that the analyte stays free. a period of 8 h.

6.6 Physical interferences may result if the physical prop- 7.2 Analytical Apparatus:

erties of the samples vary significantly. Changes in viscosity 7.2.1 Atomic Absorption Spectrophotometer, equipped with

and surface tension can affect the sample aspiration rate and air/acetylene and nitrous oxide/acetylene burner heads.

D 4185

TABLE 2 The AAS Flame and Operating Conditions for Each Element

Analytical

A A

Element Type of Flame Interferences Remedy Reference

Wavelength, nm

− −2 −2 − − B

Ag Air-C H (oxidizing) 328.1 I0 ,WO , MnO ,Cl ,F (5,10)

2 2 3 4 4

C −2 B,D,E

Al N O-C H (reducing) 309.3 ionization, SO ,V (4)

2 2 2 4

D,F

Ba N O-C H (reducing) 553.6 ionization, large concentration Ca (1,4)

2 2 2

Bi Air-C H (oxidizing) 223.1 none known

2 2

D,E

Ca Air-C H (oxidizing) 422.7 ionization (slight) and chemical (1,4)

2 2

ionization

N O-C H (reducing)

2 2 2

Cd Air-C H (oxidizing) 228.8 none known

2 2

C

Co Air-C H (oxidizing) 240.7 none known

2 2

C B

Cr Air-C H (reducing) 357.9 Fe, Ni, oxidation state of Cr (4)

2 2

Cu Air-C H (oxidizing) 324.8 none known

2 2

B

Fe Air-C H (oxidizing) 248.3 high Ni concentration, Si (1,4)

2 2

x−3 B

In Air-C H (oxidizing) 303.9 Al, Mg, Cu, Zn, H PO (11)

2 2 x 4

D

K Air-C H (oxidizing) 766.5 ionization (1,4)

2 2

D

Li Air-C H (oxidizing) 670.8 ionization (12)

2 2

D,E

Mg Air-C H (oxidizing) 285.2 chemical ionization (1,4)

2 2

N O-C H (reducing)

2 2 2

Mn Air-C H (oxidizing) 279.5 Sl

2 2

E

Na Air-C H (oxidizing) 589.6 ionization (1,4)

2 2

Ni Air-C H (oxidizing) 232.0 none known

2 2

−2 B

Pb Air-C H (oxidizing) 217.0 Ca, high concentration SO (9)

2 2 4

283.3

D

Rb Air-C H (oxidizing) 780.0 ionization (1,10)

2 2

D,E

Sr Air-C H (oxidizing) 460.7 ionization and chemical (1,10)

2 2

N O-C H (reducing) ionization

2 2 2

Tl Air-C H (oxidizing) 276.8 none known

2 2

Va N O-C H (reducing) 318.4 ionization

2 2 2

Zn Air-C H (oxidizing) 213.9 none known

2 2

A

High concentrations of silicon in the sample can cause an interference for many of the elements in this table and may cause aspiration problems. No matter what

elements are being measured, if large amounts of silica are extracted from the samples the samples should be allowed to stand for several hours and centrifuged or filtered

to remove the silica.

B

Samples are periodically analyzed by the method of additions to check for chemical interferences. If interferences are encountered, determinations must be made by

the standard additions method or, if the interferent is identified, it may be added to the standards.

C

Some compounds of these elements will not be dissolved by the procedure described here. When determining these elements one should verify that the types of

compounds suspected in the sample will dissolve using this procedure (see 12.2).

D

Ionization interferences are controlled by bringing all solutions to 1000 ppm cesium (samples and standards).

E

1000-ppm solution of lanthanum as a releasing agent is added to all samples and standards.

F

In the presence of very large calcium concentrations (greater than 0.1 % a molecular absorption from CaOH may be observed. This interference may be overcome

by using background corrections when analyzing for barium.

7.2.2 Hollow Cathode or Electrodeless Discharge Lamp, for 8. Reagents

each element to be determined.

8.1 Purity of Reagents—Reagent grade chemicals shall be

7.2.3 Deuterium Continuum Lamp.

used in all tests. Unless otherwise indicated, it is intended that

7.2.4 Compressed Air—Appropriate pressure reducing

all reagents shall conform to the specifications of the Commit-

regulator with base connections (see instrument manufacturer’s

tee on Analytical Reagents of the American Chemical Society

instructions).

where such specifications are available. Other grades may be

7.2.5 Acetylene Gas and Regulator—A cylinder of acety-

used provided it can be demonstrated that they are of suffi-

lene equipped with a two-gage, two-stage pressure-reducing

ciently high purity to permit their use without decreasing the

regulator with hose connections. (See instrument manufacturer

accuracy of the determinations.

instructions.)

8.2 Purity of Water—Unless otherwise indicated, reference

7.2.6 Nitrous Oxide Gas and Regulator—A cylinder of to water shall be understood to mean Type II reagent water

nitrous oxide equipped with a two-gage, two-stage pressure-

conforming to Specification D 1193.

reducing regulator and hose connections. Heat tape with the 8.3 Hydrochloric Acid (HCl)—Concentrated hydrochloric

temperature controlled by a rheostat may be wound around the

acid, 12 N, specific gravity 1.19.

second stage regulator and hose connection to prevent 8.4 Nitric Acid (HNO )—Redistilled, concentrated nitric

freeze-up of the line. (See instrument manufacturer instruc-

acid, 16 N, specific gravity 1.42.

tions.) 8.5 Standard Stock Solutions (1000 μg/mL) for each of the

7.2.7 Beakers, Phillips or Griffin, 125-mL, borosilicate metals listed in Table 1. These solutions ar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.