ASTM E2581-07

(Practice)Standard Practice for Shearography of Polymer Matrix Composites, Sandwich Core Materials and Filament-Wound Pressure Vessels in Aerospace Applications

Standard Practice for Shearography of Polymer Matrix Composites, Sandwich Core Materials and Filament-Wound Pressure Vessels in Aerospace Applications

SIGNIFICANCE AND USE

Shearography is commonly used during product process design and optimization, process control, post manufacture inspection, and in service inspection, and can be used to measure static and dynamic axial (tensile and compressive) strain, as well as shearing, Poisson, bending, and torsional strains. The general types of defects detected by shearography include delamination, deformation under load, disbond/unbond, microcracks, and thickness variation.

Factors that influence shearography and therefore shall be reported include but are not limited to the following: laminate (matrix and fiber) material, lay-up geometry, fiber volume fraction (flat panels); facing material, core material, facing stack sequence, core geometry (cell size); core density, facing void content, and facing volume percent reinforcement (sandwich core materials); processing and fabrication methods, overall thickness, specimen alignment, specimen conditioning, specimen geometry, and test environment (flat panels and sandwich core materials).

SCOPE

1.1 This practice describes procedures for shearography of polymer matrix composites, sandwich core materials, and filament-wound pressure vessels made entirely or in part from fiber-reinforced polymer matrix composites. The composite materials under consideration typically contain continuous high modulus (greater than 20 GPa (3106 psi)) fibers, but may also contain discontinuous fiber, fabric, or particulate reinforcement.

1.2 This practice describes established shearography procedures that are currently used by industry and federal agencies that have demonstrated utility in quality assurance of polymer matrix composites, sandwich core materials, and filament-wound pressure vessels during product process design and optimization, manufacturing process control, post manufacture inspection, and in service inspection.

1.3 This practice has utility for testing of polymer matrix composites, sandwich core materials, and filament-wound pressure vessels containing but not limited to bismaleimide, epoxy, phenolic, poly(amideimide), polybenzimidazole, polyester (thermosetting and thermoplastic), poly(ether ether ketone), poly(ether imide), polyimide (thermosetting and thermoplastic), poly(phenylene sulfide), or polysulfone matrices; and alumina, aramid, boron, carbon, glass, quartz, or silicon carbide fibers. Typical as-fabricated geometries include uniaxial, cross ply and angle ply laminates; as well as honeycomb and foam core sandwich materials and structures.

1.4 This practice does not specify accept-reject criteria and is not intended to be used as a means for approving polymer matrix composites, sandwich core materials, or filament-wound pressure vessels for service. (Please note that a flaw does not become a defect until rejected by acceptance/rejection criteria.)

1.5 To ensure proper use of the referenced standards, there are recognized nondestructive testing (NDT) specialists that are certified in accordance with industry and company NDT specifications. It is recommended that an NDT specialist be a part of any composite component design, quality assurance, in service maintenance, or damage examination activity.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2581 − 07

StandardPractice for

Shearography of Polymer Matrix Composites, Sandwich

Core Materials and Filament-Wound Pressure Vessels in

Aerospace Applications

This standard is issued under the fixed designation E2581; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.5 To ensure proper use of the referenced standards, there

are recognized nondestructive testing (NDT) specialists that

1.1 This practice describes procedures for shearography of

are certified in accordance with industry and company NDT

polymer matrix composites, sandwich core materials, and

specifications. It is recommended that an NDT specialist be a

filament-wound pressure vessels made entirely or in part from

part of any composite component design, quality assurance, in

fiber-reinforced polymer matrix composites. The composite

service maintenance, or damage examination activity.

materials under consideration typically contain continuous

1.6 This standard does not purport to address all of the

highmodulus(greaterthan20GPa(3×106psi))fibers,butmay

safety concerns, if any, associated with its use. It is the

also contain discontinuous fiber, fabric, or particulate rein-

responsibility of the user of this standard to establish appro-

forcement.

priate safety and health practices and determine the applica-

1.2 This practice describes established shearography proce-

bility of regulatory limitations prior to use.

dures that are currently used by industry and federal agencies

that have demonstrated utility in quality assurance of polymer

2. Referenced Documents

matrix composites, sandwich core materials, and filament-

2.1 ASTM Standards:

wound pressure vessels during product process design and

C274Terminology of Structural Sandwich Constructions

optimization, manufacturing process control, post manufacture

D3878Terminology for Composite Materials

inspection, and in service inspection.

D5687/D5687MGuide for Preparation of Flat Composite

1.3 This practice has utility for testing of polymer matrix

Panels with Processing Guidelines for Specimen Prepara-

composites, sandwich core materials, and filament-wound

tion

pressure vessels containing but not limited to bismaleimide,

E543Specification forAgencies Performing Nondestructive

epoxy, phenolic, poly(amideimide), polybenzimidazole, poly-

Testing

ester (thermosetting and thermoplastic), poly(ether ether

E1309 Guide for Identification of Fiber-Reinforced

ketone), poly(ether imide), polyimide (thermosetting and

Polymer-Matrix Composite Materials in Databases

thermoplastic), poly(phenylene sulfide), or polysulfone matri-

E1316Terminology for Nondestructive Examinations

ces; and alumina, aramid, boron, carbon, glass, quartz, or

E1434Guide for Recording Mechanical Test Data of Fiber-

silicon carbide fibers.Typical as-fabricated geometries include

Reinforced Composite Materials in Databases

uniaxial, cross ply and angle ply laminates; as well as honey-

E1471Guide for Identification of Fibers, Fillers, and Core

comb and foam core sandwich materials and structures.

Materials in Computerized Material Property Databases

E1736 Practice for Acousto-Ultrasonic Assessment of

1.4 This practice does not specify accept-reject criteria and

Filament-Wound Pressure Vessels

is not intended to be used as a means for approving polymer

2.2 Federal Standards:

matrix composites, sandwich core materials, or filament-

21 CFR 1040.10Laser products

wound pressure vessels for service. (Please note that a flaw

21 CFR 1040.11Specific purpose laser products

doesnotbecomeadefectuntilrejectedbyacceptance/rejection

criteria.)

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This practice is under the jurisdiction of ASTM Committee E07 on Nonde- Standards volume information, refer to the standard’s Document Summary page on

structive Testing and is the direct responsibility of Subcommittee E07.10 on the ASTM website.

Specialized NDT Methods. AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Current edition approved Sept. 1, 2007. Published October 2007. DOI: 10.1520/ 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

E2581-07. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2581 − 07

29 CFR 1910.95Occupational Noise Exposure number of layers, fiber orientation, and composite shell thick-

2.3 ANSI Standard: ness may vary from point to point.

Z136.1-2000Safe Use of Lasers

3.2.9 composite over-wrapped pressure vessel, (COPV)—

2.4 ASNT Standards:

see filament-wound pressure vessel.

SNT-TC-1ARecommended Practice for Personnel Qualifi-

3.2.10 core crush—a collapse, distortion, or compression of

cation and Certification in Nondestructive Testing

core material in a sandwich structure.

ANSI/ASNTCP-189Standard for Qualification and Certifi-

3.2.11 core separation—a partial or complete breaking of

cation of Nondestructive Testing Personnel

honeycomb core node bonds.

2.5 AIA Document:

NAS-410Certification and Qualification of Nondestructive 3.2.12 disbond, unbond —see Terminology D3878.

Test Personnel

3.2.13 de-correlation—loss of shearography phase data

2.6 ISO Standard:

causedbytestpartdeformationexceedingtheresolutionofthe

EN 60825-1Safety of Laser Products - Part 1: Equipment

shearing interferometer or motion occurs between the test

Classification, Requirements, and User’s Guide

object and shearing interferometer during data acquisition.

3.2.14 delamination—see Terminology D3878.

3. Terminology

3.2.15 displacement derivatives (∂w/∂x)— rate of spatial

3.1 Definitions—Definition of terms related to structural

displacement change, where w is the surface displacement and

sandwich constructions, NDT, and composites appearing in

x is the surface coordinates.

Terminologies C274, E1316, and D3878, respectively, shall

apply to the terms used in this practice. 3.2.16 excitation method—applied stress to a test object

usedinlaserholographicorlasershearographicexaminationto

3.2 Definitions:

affect motion at the surface of the test object.

3.2.1 aerospace—any component that will be installed on a

system that flies. 3.2.17 filament-wound pressure vessel—an inner shell over

wrapped with composite layers that form a composite shell.

3.2.2 beam splitter—an optical element capable of splitting

The inner shell or liner may consist of an impervious metallic

a single beam of coherent laser light into two beams. Beam

or nonmetallic material. The vessel may be cylindrical or

splitters are key elements of Michelson Type Image Shearing

spherical and will have at least one penetration with valve

Interferometers.

attachments for introducing and holding pressurized liquids or

3.2.3 cognizant engineering organization—seeTerminology

gases.AlsoreferredtoasaCompositeOver-WrappedPressure

E1316.

Vessel or COPV.

3.2.4 coherent light source—a light source that converts

3.2.18 flaw, n—animperfectionordiscontinuitythatmaybe

electrical energy to a monochromatic beam of light having

detectable by nondestructive testing and is not necessarily

uniform phase over a minimum specified length known as the

rejectable.

coherent length.

3.2.19 fringe pattern—a set of lines in a subtraction or

3.2.5 component—the part(s) or element(s) of a system

wrapped phase shearogram that represents the locus of equal

described, assembled, or processed to the extent specified by

out-of-plane deformation derivative.

the drawing.

3.2.20 impact damage—fracturing of epoxy matrix, fiber

3.2.6 composite material—see Terminology D3878.

breakage, inter-laminar delamination of monolithic

3.2.7 composite component—a finished part containing

composites, composite sandwich structure face sheets or

compositematerial(s)thatisinitsenduseapplicationconfigu-

filament-wound composite pressure vessels due to impact,

ration and which has undergone processing, fabrication, and

characterized by visible dimple surface compression, or fiber

assembly to the extent specified by the drawing, purchase

breakage caused by impact strike and non-visible subsurface

order, or contract.

matrix cracking and delamination.

3.2.8 composite shell—a multilayer filament winding that

3.2.21 inclusion—foreign objects or material including but

comprises a second shell that reinforces the inner shell. The

not limited to particles, chips, backing films, razor blades, or

compositeshellconsistsofcontinuousfibers,impregnatedwith

tools of varying sizes which are inadvertently left in a

a matrix material, wound around the inner shell, and cured in

composite lay-up.

place. An example is the Kevlar epoxy filament wound

3.2.22 indication—the observation or evidence of a condi-

spherical shell shown in Figure 1 in Practice E1736. The

tionresultingfromtheshearographicexaminationthatrequires

interpretation to determine its significance, characterized by

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., dimensions, area, s/n ratio, or other quantitative measurement.

4th Floor, New York, NY 10036, http://www.ansi.org.

5 3.2.23 laser shearography inspection, shearography

AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

inspection, shearography —inspection method utilizing inter-

28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1000

ferometric imaging of deformation derivatives compared be-

WilsonBlvd.,Suite1700,Arlington,VA22209-3928,http://www.aia-aerospace.org.

tween different strain states and designed to reveal non-

homogeneities, material changes and structural defects

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. throughout the volume of the material.

E2581 − 07

3.2.24 out-of-plane displacement—the local deformation of testing, usually including features for adjustment of focus, iris,

a test part, normal to the surface, caused by the application of zoom, shear vector, and projection and adjustment of coherent

an engineered force acting on a non-homogeneity or defect in light onto the test object area to be inspected.

a composite material.

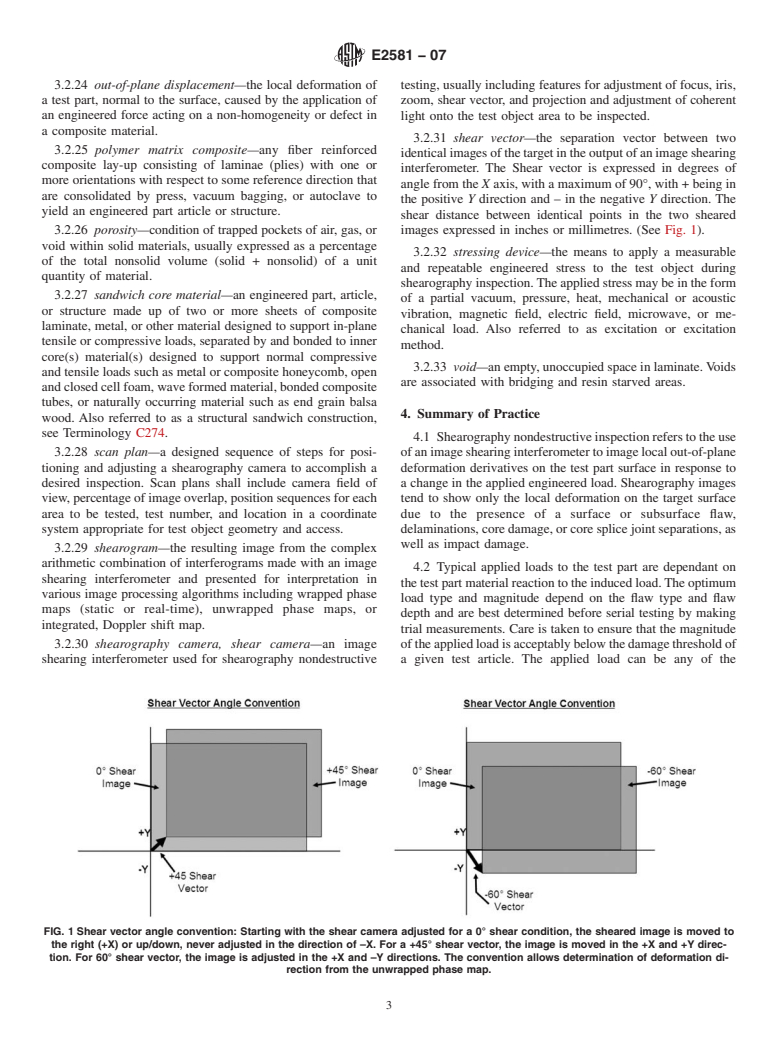

3.2.31 shear vector—the separation vector between two

3.2.25 polymer matrix composite—any fiber reinforced

identicalimagesofthetargetintheoutputofanimageshearing

composite lay-up consisting of laminae (plies) with one or

interferometer. The Shear vector is expressed in degrees of

more orientations with respect to some reference direction that

anglefromthe Xaxis,withamaximumof90°,with+beingin

are consolidated by press, vacuum bagging, or autoclave to

the positive Y direction and – in the negative Y direction. The

yield an engineered part article or structure.

shear distance between identical points in the two sheared

images expressed in inches or millimetres. (See Fig. 1).

3.2.26 porosity—condition of trapped pockets of air, gas, or

void within solid materials, usually expressed as a percentage

3.2.32 stressing device—the means to apply a measurable

of the total nonsolid volume (solid + nonsolid) of a unit

and repeatable engineered stress to the test object during

quantity of material.

shearographyinspection.Theappliedstressmaybeintheform

3.2.27 sandwich core material—an engineered part, article,

of a partial vacuum, pressure, heat, mechanical or acoustic

or structure made up of two or more sheets of composite

vibration, magnetic field, electric field, microwave, or me-

laminate, metal, or other material designed to support in-plane

chanical load. Also referred to as excitation or excitation

tensile or compressive loads, separated by and bonded to inner

method.

core(s) material(s) designed to support normal compressive

3.2.33 void—anempty,unoccupiedspaceinlaminate.Voids

and tensileloadssuch as metal or composite honeycomb,open

are associated with bridging and resin starved areas.

andclosedcellfoam,waveformedmaterial,bondedcomposite

tubes, or naturally occurring material such as end grain balsa

4. Summary of Practice

wood. Also referred to as a structural sandwich construction,

see Terminology C274.

4.1 Shearographynondestructiveinspectionreferstotheuse

3.2.28 scan plan—a designed sequence of steps for posi- ofanimageshearinginterferometertoimagelocalout-of-plane

tioning and adjusting a shearography camera to accomplish a deformation derivatives on the test part surface in response to

desired inspection. Scan plans shall include camera field of a change in the applied engineered load. Shearography images

view,percentageofimageoverlap,positionsequencesforeach tend to show only the local deformation on the target surface

area to be tested, test number, and location in a coordinate due to the presence of a surface or subsurface flaw,

system appropriate for test object geometry and access. delaminations,coredamage,orcoresplicejointseparations,as

well as impact damage.

3.2.29 shearogram—the resulting image from the complex

arithmetic combination of interferograms made with an image

4.2 Typical applied loads to the test part are dependant on

shearing interferometer and presented for interpretation in

thetestpartmaterialreactiontotheinducedload.Theoptimum

various image processing algorithms including wrapped phase

load type and magnitude depend on the flaw type and flaw

maps (static or real-time), unwrapped phase maps, or

depth and are best determined before serial testing by making

integrated, Doppler shift map.

trial measurements. Care is taken to ensure that the magnitude

3.2.30 shearography camera, shear camera—an image oftheappliedloadisacceptablybelowthedamagethresholdof

shearing interferometer used for shearography nondestructive a given test article. The applied load can be any of the

FIG. 1 Shear vector angle convention: Starting with the shear camera adjusted for a 0° shear condition, the sheared image is moved to

the right (+X) or up/down, never adjusted in the direction of –X. For a +45° shear vector, the image is moved in the +X and +Y direc-

tion. For 60° shear vector, the image is adjusted in the +X and –Y directions. The convention allows determination of deformation di-

rection from the unwrapped phase map.

E2581 − 07

following: heat, mechanical vibration, acoustic vibration, pres-

sure and vacuum, electric fields, magnetic fields,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.