ASTM D4595-86(2001)

(Test Method)Standard Test Method for Tensile Properties of Geotextiles by the Wide-Width Strip Method

Standard Test Method for Tensile Properties of Geotextiles by the Wide-Width Strip Method

SCOPE

1.1 This test method covers the measurement of tensile properties of geotextiles using a wide-width strip specimen tensile method. This test method is applicable to most geotextiles that include woven fabrics, nonwoven fabrics, layered fabrics, knit fabrics, and felts that are used for geotextile application.

1.2 This test method covers the measurement of tensile strength and elongation of geotextiles and includes directions for the calculation of initial modulus, offset modulus, secant modulus, and breaking toughness.

1.3 Procedures for measuring the tensile properties of both conditioned and wet geotextiles by the wide-width strip method are included.

1.4 The basic distinction between this test method and other methods for measuring strip tensile properties is the width of the specimen. This width, by contrast, is greater than the length of the specimen. Some fabrics used in geotextile applications have a tendency to contract (neck down) under a force in the gage length area. The greater width of the specimen specified in this test method minimizes the contraction effect of those fabrics and provides a closer relationship to expected geotextile behavior in the field and a standard comparison.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4595–86(Reapproved 2001)

Standard Test Method for

Tensile Properties of Geotextiles by the Wide-Width Strip

Method

This standard is issued under the fixed designation D4595; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D2905 Practice for Statements on Number of Specimens

for Textiles

1.1 This test method covers the measurement of tensile

D4439 Terminology for Geosynthetics

properties of geotextiles using a wide-width strip specimen

tensile method. This test method is applicable to most geotex-

3. Terminology

tiles that include woven fabrics, nonwoven fabrics, layered

3.1 atmosphere for testing geotextiles, n.—air maintained at

fabrics, knit fabrics, and felts that are used for geotextile

arelativehumidityof65 65%andatemperatureof21 62°C

application.

(70 6 4°F).

1.2 This test method covers the measurement of tensile

−1 −2

3.2 breaking toughness, T, (FL ), Jm , n.—for geotextiles,

strength and elongation of geotextiles and includes directions

the actual work-to-break per unit surface area of material.

for the calculation of initial modulus, offset modulus, secant

3.2.1 Discussion—Breaking toughness is proportional to

modulus, and breaking toughness.

the area under the force−elongation curve from the origin to

1.3 Procedures for measuring the tensile properties of both

the breaking point (see also work-to-break). Breaking tough-

conditioned and wet geotextiles by the wide-width strip

ness is calculated from work-to-break, gage length, and width

method are included.

of a specimen.

1.4 Thebasicdistinctionbetweenthistestmethodandother

3.3 corresponding force, F ,n.—the force associated with a

c

methods for measuring strip tensile properties is the width of

specific elongation on the force-per-unit-width strain curve.

thespecimen.Thiswidth,bycontrast,isgreaterthanthelength

(Syn. load at specified elongation, LASE.)

of the specimen. Some fabrics used in geotextile applications

3.4 geotechnical engineering, n.—the engineering applica-

have a tendency to contract (neck down) under a force in the

tion of geotechnics.

gage length area. The greater width of the specimen specified

3.5 geotechnics, n.—the application of scientific methods

in this test method minimizes the contraction effect of those

and engineering principles to the acquisition, interpretation,

fabricsandprovidesacloserrelationshiptoexpectedgeotextile

and use of knowledge of materials of the earth’s crust to the

behavior in the field and a standard comparison.

solution of engineering problems.

1.5 This standard does not purport to address all of the

3.5.1 Discussion—Geotechnics embraces the fields of soil

safety concerns, if any, associated with its use. It is the

mechanics, rock mechanics, and many of the engineering

responsibility of the user of this standard to establish appro-

aspects of geology, geophysics, hydrology, and related sci-

priate safety and health practices and determine the applica-

ences.

bility of regulatory limitations prior to use.

3.6 geotextile, n.—any permeable textile material used with

2. Referenced Documents foundation, soil, rock, earth, or any other geotechnical engi-

neering related material, as an integral part of a man-made

2.1 ASTM Standards:

project, structure, or system.

D76 Specification for Tensile Testing Machines for Tex-

−1 −1

3.7 initial tensile modulus, J , (FL ), Nm , n.—for geo-

i

tiles

textiles, the ratio of the change in tensile force per unit width

D123 Terminology Relating to Textiles

to a change in strain (slope) of the initial portion of a force per

D579 Specification for Greige Woven Glass Fabrics

unit width strain curve.

D1776 Practice for Conditioning Textiles for Testing

−1 −1

3.8 offset tensile modulus, J , (FL ), Nm , n.—for geo-

o

textiles, the ratio of the change in force per unit width to a

1 change in strain (slope) below the proportional limit point and

This test method is under the jurisdiction of ASTM Committee D35 on

GeosyntheticsandisthedirectresponsibilityofSubcommitteeD35.01onMechani- above the tangent point on the force−elongation curve.

cal Properties.

Current edition approved Sept. 24, 1986. Published November 1986.

2 3

Annual Book of ASTM Standards, Vol 07.01. Annual Book of ASTM Standards, Vol 04.13.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4595–86 (2001)

3.9 proportional limit, n.—the greatest stress which a ma- design of reinforced embankments over soft subgrades, rein-

terial is capable of sustaining without any deviation from forced soil retaining walls, and reinforcement of slopes. When

proportionality of stress to strain (Hooke’s law).

strength is not necessarily a design consideration, an alterna-

−1 −1

3.10 secant tensile modulus, J (FL ), Nm , n.—for tive test method may be used for acceptance testing. Test

sec

geotextiles, the ratio of change in force per unit width to a

Method D4595 for the determination of the wide-width strip

change in strain (slope) between two points on a force per unit

tensilepropertiesofgeotextilesmaybeusedfortheacceptance

width strain curve.

testing of commercial shipments of geotextiles but caution is

3.11 tangent point, n.—for geotextiles, the first point of the

advised since information about between-laboratory precision

force−elongation curve at which a major decrease in slope

is incomplete (Note 6). Comparative tests as directed in 5.1.1

occurs.

may be advisable.

3.11.1 Discussion—The tangent point is determined by

5.1.1 In cases of a dispute arising from differences in

drawing a tangent line passing through the zero axis and the

reported test results when using Test Method D4595 for

proportional elastic limit. The point from the zero force axis

acceptancetestingofcommercialshipments,thepurchaserand

that the force−elongation curve first touches that tangent line

the supplier should conduct comparative tests to determine if

is the tangent point.

there is a statistical bias between their laboratories. Competent

−1 −1

3.12 tensile modulus, J, (FL ), Nm , n.—for geotextiles,

statistical assistance is recommended for the investigation of

the ratio of the change in tensile force per unit width to a

bias.Asaminimum,thetwopartiesshouldtakeagroupoftest

corresponding change in strain (slope).

specimens which are as homogeneous as possible and which

3.13 tensile strength, n.—for geotextiles, the maximum

are from a lot of material of the type in question. The test

resistance to deformation developed for a specific material

specimensshouldthenberandomlyassignedinequalnumbers

when subjected to tension by an external force.

toeachlaboratoryfortesting.Theaverageresultsfromthetwo

3.13.1 Discussion—Tensile strength of geotextiles is the

laboratories should be compared using Student’s t-test for

characteristic of a sample as distinct from a specimen and is

unpaireddataandanacceptableprobabilitylevelchosenbythe

expressed in force per unit width.

twopartiesbeforethetestingbegan.Ifabiasisfound,eitherits

3.14 tensile test, n.—in textiles, a test in which a textile

cause must be found and corrected or the purchaser and the

material is stretched in one direction to determine the

suppliermustagreetointerpretfuturetestresultsinthelightof

force−elongation characteristics, the breaking force, or the

the known bias.

breaking elongation.

5.2 Mostgeotextilescanbetestedbythistestmethod.Some

3.15 wide-width strip tensile test, n.—for geotextiles,a

modification of clamping techniques may be necessary for a

uniaxial tensile test in which the entire width of a 200-mm

given geotextile depending upon its structure. Special clamp-

(8.0-in.) wide specimen is gripped in the clamps and the gage

ing adaptions may be necessary with strong geotextiles or

length is 100 mm (4.0 in.).

geotextiles made from glass fibers to prevent them from

3.16 work-to-break, W, (LF), n.—in tensile testing, the total

slipping in the clamps or being damaged as a result of being

energy required to rupture a specimen.

3.16.1 Discussion—For geotextiles, work-to-break is pro- gripped in the clamps. Specimen clamping may be modified as

requiredatthediscretionoftheindividuallaboratoryproviding

portional to the area under the force−elongation curve from

the origin to the breaking point, and is commonly expressed in a representative tensile strength is obtained. In any event, the

joules (inch-pound-force). procedure described in Section 10 of this test method for

3.17 yield point, n.—thefirstpointoftheforce−elongation obtainingwide-widthstriptensilestrengthmustbemaintained.

curve above the proportional (linear) section at which an

5.3 This test method is applicable for testing geotextiles

increase in elongation occurs without a corresponding increase

either dry or wet. It is used with a constant rate of extension

in force.

type tension apparatus.

3.18 For terminology of other terms used in this test

5.4 The use of tensile strength test methods that restrict the

method, refer toTerminology D123 andTerminology D4439.

clamped width dimension to 50 mm (2 in.) or less, such as the

ravel, cut strip, and grab test procedures, have been found less

4. Summary of Method

suitable than this test method for determining design strength

4.1 A relatively wide specimen is gripped across its entire

parameters for some geotextiles. This is particularly the case

width in the clamps of a constant rate of extension (CRE) type

for nonwoven geotextiles. The wide-width strip technique has

tensile testing machine operated at a prescribed rate of exten-

been explored by the industry and is recommended in these

sion, applying a longitudinal force to the specimen until the

cases for geotextile applications.

specimen ruptures. Tensile strength, elongation, initial and

5.4.1 This test method may not be suited for some woven

secant modulus, and breaking toughness of the test specimen

fabrics used in geotextile applications that exhibit strengths

can be calculated from machine scales, dials, recording charts,

approximately 100 kN/m or 600 lbf/in. due to clamping and

or an interfaced computer.

equipment limitations. In those cases, 100-mm (4-in.) width

5. Significance and Use

specimens may be substituted for 200-mm (8-in.) width speci-

5.1 The determination of the wide-width strip mens. On those fabrics, the contraction effect cited in 1.4 is

minimal and, consequently, the standard comparison can con-

force−elongation properties of geotextiles provides design

parameters for reinforcement type applications, for example tinue to be made.

D4595–86 (2001)

6. Apparatus and Reagents 6.4 Distilled Water and Nonionic Wetting Agent, for wet

specimens only.

6.1 Tensile Testing Machine—A constant rate of extension

(CRE) type of testing machine described in Specification D76

7. Sampling

shall be used. When using the CRE type tensile tester, the

recorder must have adequate pen response to properly record

7.1 Lot Sample—Forthelotsample,takerollsofgeotextiles

the force—elongation curve as specified in Specification D76. as directed in an applicable material specification, or as agreed

6.2 Clamps—The clamps shall be sufficiently wide to grip

upon between the purchaser and the supplier.

the entire width of the sample and with appropriate clamping

NOTE 1—The extent of the sampling for wide-width strip tensile

power to prevent slipping or crushing (damage).

properties is generally defined in an applicable order or contract. Among

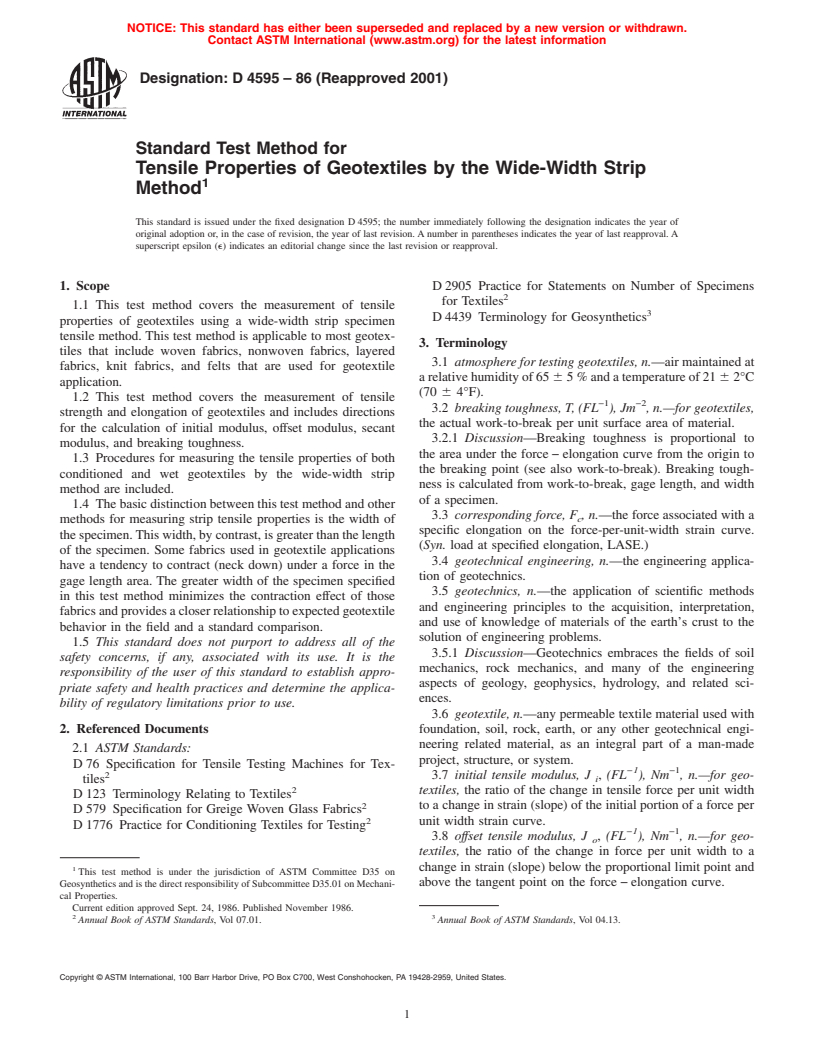

6.2.1 Two basic clamp designs are shown in Fig. 1, Fig. 2,

the options available to the purchaser and the supplier is for the purchaser

Fig. 3, and Fig. 4. These designs have been used in the

to accept certification by the manufacturer that the material in question

meetstherequirementsagreeduponbythetwoparties,andwhatthebasis

laboratory and have provided reproducible tensile strengths.

for the certification is, such as, historical data generated from material

These clamps may be modified to provide greater ease and

manufactured under the same conditions.

speed of clamping. In any event, caution must be taken to

ensure the type material and dimensions of the clamp are 7.2 Laboratory Sample—For the laboratory sample, take a

adequate for the user’s expected fabric strength. full-width swatch approximately 1 m (40 in.) long in the

6.2.2 Size of Jaw Faces—Each clamp shall have jaw faces machine direction from each roll in the lot sample.The sample

measuring wider than the width of the specimen, 200 mm (8 may be taken from the end portion of a roll provided there is

in.),andaminimumof50-mm(2-in.)lengthinthedirectionof no evidence it is distorted or different from other portions of

the applied force. the roll. In cases of dispute, take a sample that will exclude

6.3 Area-Measuring Device—Use an integrating accessory fabric from the outer wrap of the roll or the inner wrap around

to the tensile testing machine or a planimeter. the core.

FIG. 1 Wide Width Test Clamps

D4595–86 (2001)

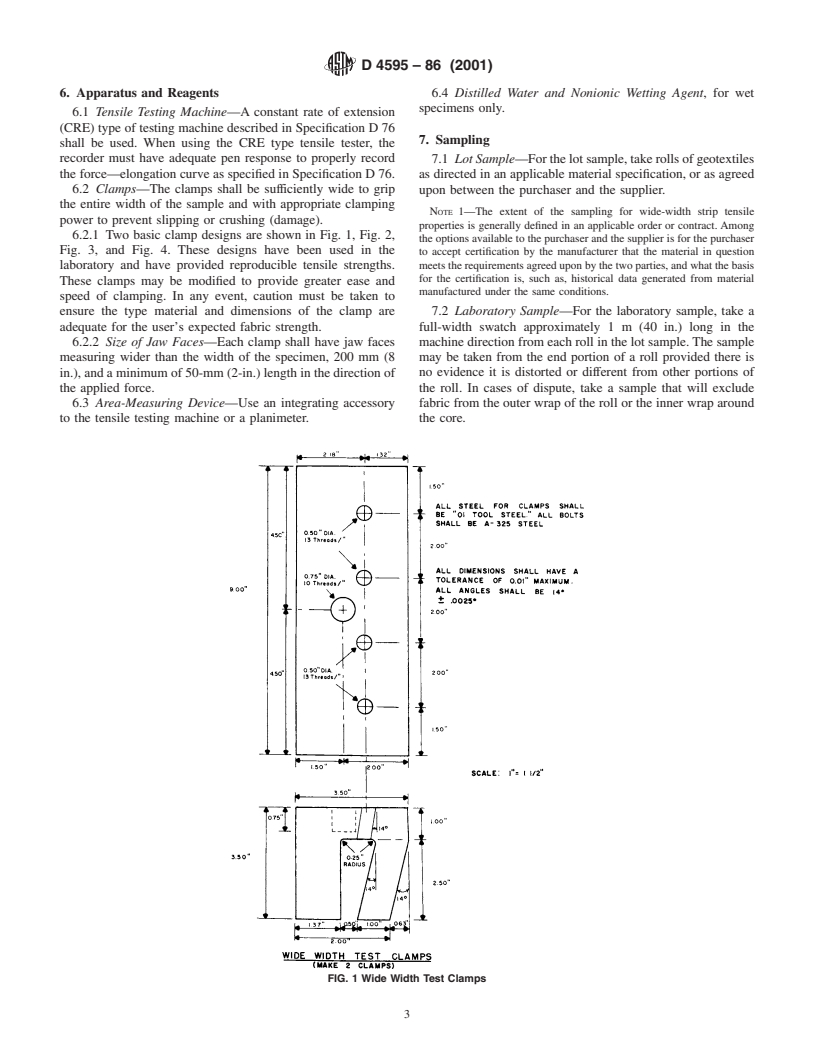

FIG. 2 Inserts for Wide Width Clamps

7.3 Test Specimens—For tests in the machine direction and

where:

the cross-machine direction, respectively, take from each

n = number of specimens (rounded upward to a whole

swatch in the laboratory sample the number of specimens

number),

directed in Section 8. Take specimens at random from the

v = reliable estimate of the coefficient of variation of

laboratory sample, with those for the measurement of the individual observations on similar materials in the

machine direction tensile properties from different positions

user’s laboratory under conditions of single-operator

across the geotextile width, and the specimens for the mea- precision, %,

surementofthecross-machinedirectiontensilepropertiesfrom t = thevalueofStudent’s tforone-sidedlimits(seeTable

different positions along the length of the geotextile. Take no 1), a 95% probability level, and the degrees of

specimens nearer the selvage or edge of the geotextile than freedom associated with the estimate of v, and

A = 5.0% of the average, the value of the allowable

1/10 the width of the geotextile (see 8.2).

variation.

8. Test Specimen Preparation

8.1.1.2 No Reliable Estimate of v—When there is no reli-

8.1 Number of Specimens:

able estimate of v for the user’s laboratory, Eq 1 should not be

8.1.1 Unlessotherwiseagreedupon,aswhenspecifiedinan used directly. Instead, specify the fixed number of six speci-

applicable material specification, take a number of specimens

mens for each the machine direction and the cross-machin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.