ASTM C1374-03

(Test Method)Standard Test Method for Determination of Installed Thickness of Pneumatically Applied Loose-Fill Building Insulation

Standard Test Method for Determination of Installed Thickness of Pneumatically Applied Loose-Fill Building Insulation

SIGNIFICANCE AND USE

This test method was designed to give the manufacturer of loose-fill insulation products a way of determining what the initial installed thickness should be in a horizontal open attic for pneumatic applications.

The installed thickness value developed by this test method is intended to provide guidance to the installer in order to achieve a minimum mass/unit area for a given R-value.

For the purpose of product design, testing should be done at a variety of R-values. At least three R-values should be used: the lowest R-value on the product label, the highest R-value on the product label, and an R-value near the midpoint of the R-value range.

Note 1—For quality control purposes, testing may be done at one R-value of R-19 (h×ft2×°F/Btu) or higher.

Specimens are blown in a manner consistent with the intended installation procedure. Blowing machine settings should be representative of those typically used for field application with that machine.

The material blown for a given R-value as part of the installed thickness test equals the installed mass/unit area times the test chamber area. This mass can be calculated from information provided on the package label at the R-value prescribed.

SCOPE

1.1 This test method covers determination of the installed thickness of pneumatically applied loose-fill building insulations prior to settling by simulating an open attic with horizontal blown applications.

1.2 This test method is a laboratory procedure for use by manufacturers of loose-fill insulation for product design, label development, and quality control testing. The apparatus used produces installed thickness results at a given mass/unit area.

1.3 This test method is not the same as the design density procedures described in Test Methods C 520 or Specifications C 739 or C 764.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.5 responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:C1374–03

Standard Test Method for

Determination of Installed Thickness of Pneumatically

1

Applied Loose-Fill Building Insulation

This standard is issued under the fixed designation C1374; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers determination of the installed

thickness of pneumatically applied loose-fill building insula-

3. Terminology

tions prior to settling by simulating an open attic with

3.1 Definitions—Unless otherwise stated, the definitions

horizontal blown applications.

listed in Terminology C168 are applicable herein.

1.2 This test method is a laboratory procedure for use by

3.2 Definitions of Terms Specific to This Standard:

manufacturers of loose-fill insulation for product design, label

3.2.1 installed thickness, n—the average thickness, as mea-

development, and quality control testing. The apparatus used

sured immediately after application of blown insulation mate-

produces installed thickness results at a given mass/unit area.

rial when applied at a given mass/unit area.

1.3 This test method is not the same as the design density

procedures described in Test Methods C520 or Specifications

4. Summary of Test Method

C739 or C764.

2 2

4.1 Astandardized test chamber of 80 ft (7.4 m ) is used as

1.4 The values stated in inch-pound units are to be regarded

a receptacle to receive a calculated mass/unit area of pneumati-

as the standard. The values given in parentheses are provided

cally applied insulation.

for information only.

4.2 Themassofinsulationtobeblownintothetestchamber

1.5 This standard does not purport to address all of the

is calculated from the bag label information.

safety concerns, if any, associated with its use. It is the

4.3 The mass of insulation prescribed in 4.2 is uniformly

responsibility of the user of this standard to establish appro-

blown into the test chamber.

priate safety and health practices and determine the applica-

4.4 The thickness of the blown insulation is determined at

bility of regulatory limitations prior to use.

13 predetermined locations.

2. Referenced Documents 4.5 The thickness average of three tests is the installed

2 thickness for the mass/unit area being tested.

2.1 ASTM Standards:

C168 Terminology Relating to Thermal Insulation

5. Significance and Use

C520 Test Methods for Density of Granular Loose Fill

5.1 This test method was designed to give the manufacturer

Insulations

of loose-fill insulation products a way of determining what the

C739 Specification for Cellulosic Fiber Loose-Fill Thermal

initial installed thickness should be in a horizontal open attic

Insulation

for pneumatic applications.

C764 Specification for Mineral Fiber Loose-Fill Thermal

5.2 The installed thickness value developed by this test

Insulation

method is intended to provide guidance to the installer in order

to achieve a minimum mass/unit area for a given R-value.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC16onThermal

5.3 For the purpose of product design, testing should be

Insulation and is the direct responsibility of Subcommittee C16.32 on Mechanical

done at a variety of R-values.At least three R-values should be

Properties.

used: the lowest R-value on the product label, the highest

Current edition approved April 10, 2003. Published May 2003.Originally

approved in 1997. Last previous edition approved in 1997 as C1374–97. DOI: R-value on the product label, and an R-value near the midpoint

10.1520/C1374-03.

of the R-value range.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

NOTE 1—For quality control purposes, testing may be done at one

2

Standards volume information, refer to the standard’s Document Summary page on

R-value of R-19 (h3ft 3°F/Btu) or higher.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1374–03

FIG. 1 Installed Thickness Test Chamber

5.4 Specimens are blown in a manner consistent with the

intended installation procedure. Blowing machine settings

should be representative of those typically used for field

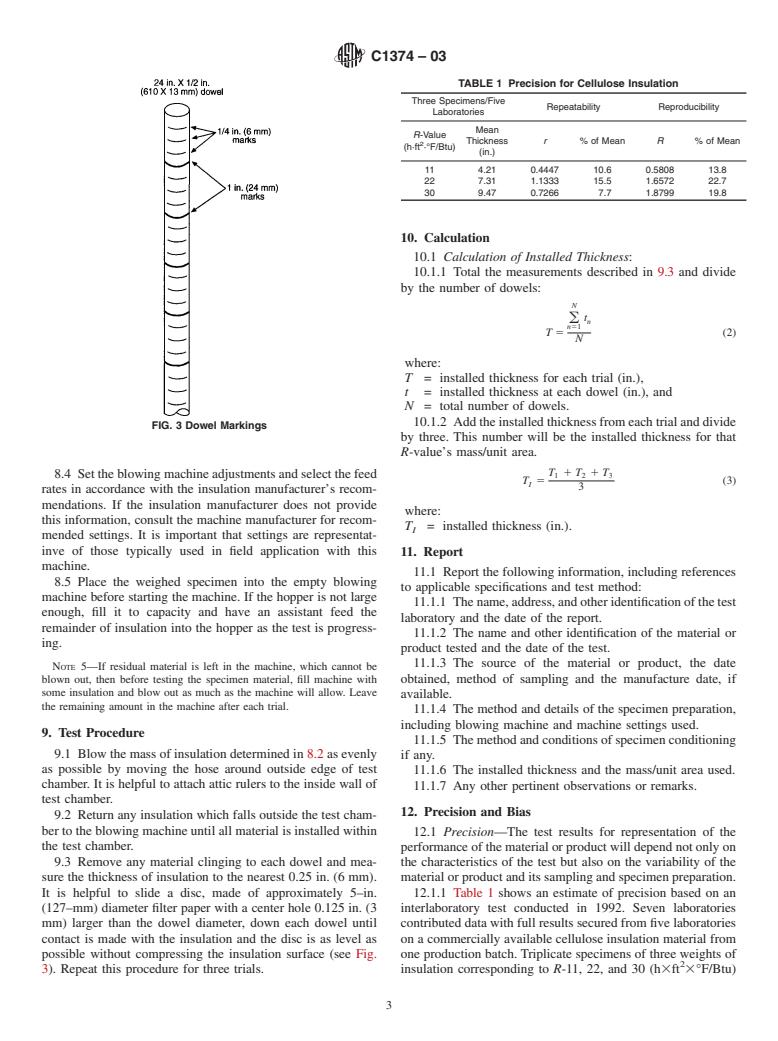

FIG. 2 Dowel Placement in Chamber Floor

application with that machine.

5.5 The material blown for a given R-value as part of the

air currents. Room geometry should not influence the blowing

installedthicknesstestequalstheinstalledmass/unitareatimes

stream from

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.