ASTM D1389-97a(2004)

(Test Method)Standard Test Method for Proof-Voltage Testing of Thin Solid Electrical Insulating Materials

Standard Test Method for Proof-Voltage Testing of Thin Solid Electrical Insulating Materials

SCOPE

1.1 This test method covers a general procedure for proof-voltage testing of thin solid electrical insulating materials at commercial power frequencies. It is intended to apply principally to flat materials but is applicable, with modification, to any form that permits continuously passing the material between suitable electrodes.

1.2 On extremely thin materials (usually less than 0.05 mm (0.002 in.)) the test results may be influenced more by mechanical damage caused by conditions of test than by dielectric defects. Consequently, this test method is not recommended for use with extremely thin materials, unless prior determination has established that the test results are not influenced by mechanical damage.

1.3 While the equipment and procedures described in this test method relate specifically to tests made with power frequency ac voltages, similar equipment and procedures are used for proof-voltage tests using dc voltages. To the extent that it applies to dc tests, this test method can serve as a guide for persons making such tests. However, only tests made with power frequency ac voltages can be said to be in accordance with this test method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D1389–97a (Reapproved 2004)

Standard Test Method for

Proof-Voltage Testing of Thin Solid Electrical Insulating

Materials

This standard is issued under the fixed designation D 1389; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers a general procedure for proof- 2.1 ASTM Standards:

voltage testing of thin solid electrical insulating materials at D 149 Test Method for Dielectric Breakdown Voltage and

commercial power frequencies. It is intended to apply princi- Dielectric Strength of Solid Electrical Insulating Materials

pally to flat materials but is applicable, with modification, to at Commercial Power Frequencies

any form that permits continuously passing the material

2,3 3. Terminology

between suitable electrodes.

1.2 On extremely thin materials (usually less than 0.05 mm 3.1 Definitions:

3.1.1 proof voltage test, n—a test during which a specified

(0.002 in.)), the test results may be influenced more by

mechanical damage caused by conditions of test than by voltage is applied to a specimen to determine whether break-

down will occur at that voltage. Fixed electrodes may be used,

dielectric defects. Consequently, this test method is not recom-

mended for use with extremely thin materials, unless prior in which case the voltage is held for a specified time; or large

area specimens may pass between roller, brush, or blade

determination has established that the test results are not

influenced by mechanical damage. electrodes, in which case the speed is specified.

1.3 While the equipment and procedures described in this

4. Summary of Test Method

test method relate specifically to tests made with power

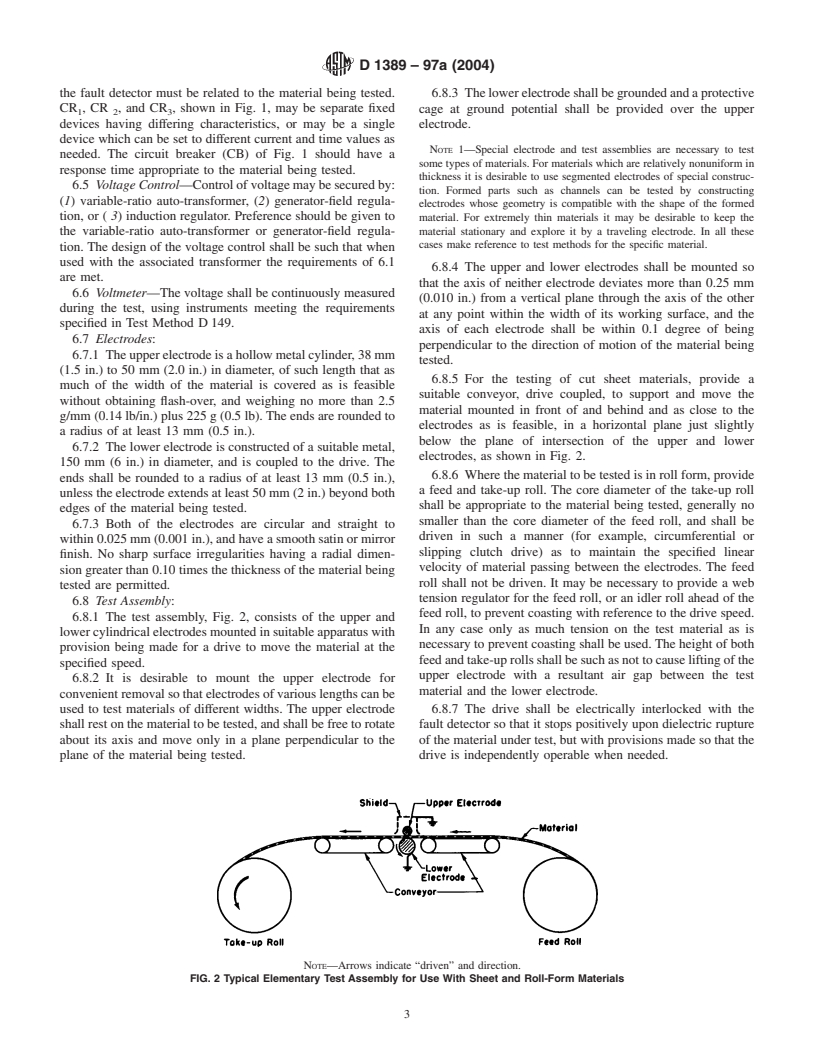

4.1 In this test method, sheet insulating material is passed at

frequency ac voltages, similar equipment and procedures are

a specified speed between roller electrodes with a specified ac

used for proof-voltage tests using dc voltages. To the extent

voltage applied, so that all, or nearly all, of the area of the

that it applies to dc tests, this test method can serve as a guide

material is subjected to the specified voltage. The number of

for persons making such tests. However, only tests made with

electrical breakdowns and their locations are determined.

power frequency ac voltages can be said to be in accordance

4.2 The applied proof voltage may be selected as a percent-

with this test method.

age of the dielectric breakdown voltage, as determined in

1.4 This standard does not purport to address all of the

accordance with Test Method D 149, or as a multiple of the

safety concerns, if any, associated with its use. It is the

breakdown voltage for an air gap of equal thickness.

responsibility of the user of this standard to establish appro-

4.3 Unless the material being tested is known to have high

priate safety and health practices and determine the applica-

resistance to partial discharges, the proof voltage is ordinarily

bility of regulatory limitations prior to use. For specific hazard

selected to be below the visible corona level. If it is necessary

statements, see Section 7.

to test at a voltage at which visible corona will be present, the

degradation of the material resulting from exposure to corona

This test method is under the jurisdiction of ASTM Committee D09 on

should be weighed against the advantages of testing at the high

Electrical and Electronic Insulating Materials and is the direct responsibility of

voltage level.

Subcommittee D09.12 on Electrical Tests.

Current edition approved March 1, 2004. Published March 2004. Originally 4.4 Two values for the rate of movement of the material

approved in 1956. Last previous edition approved in 1997 as D 1389 – 97a.

between the electrodes are given to facilitate handling of

Bartnikas, R., Chapter 3, “High Voltage Measurements,” Electrical Properties

of Solid Insulating Materials, Measurement Techniques, Vol. IIB, Engineering

Dielectrics, R. Bartnikas, Editor, ASTM STP 926, ASTM, Philadelphia, 1987.

3 4

Nelson, J. K., Chapter 5, “Dielectric Breakdown of Solids,” Electrical For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Properties of Solid Insulating Materials: Molecular Structure and Electrical contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Behavior, Vol. IIA, Engineering Dielectrics, R. Bartnikas and R. M. Eichorn, Standards volume information, refer to the standard’s Document Summary page on

Editors, ASTM STP 783, ASTM, Philadelphia, 1983. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1389–97a (2004)

different types of materials. The results obtained with the considered, and if more than one set of apparatus is to be used,

different speeds are not equivalent. that comparable results are obtained from them.

5. Significance and Use 6. Apparatus

5.1 Occasional dielectric defects may be found in commer- 6.1 General Requirements—The test voltage must conform

cially available and acceptable thin electric insulating materi- to the requirements of Test Method D 149, relative to its

als. More often than not, these materials are used in multiple variation from nominal value, wave-shape, and accuracy and

layers. The probability that occasional dielectric weak spots methodofmeasurement.Asrelatedtothisspecifictestmethod,

will coincide from layer to layer is very small but increases somedesigndetailsthatareusefularedescribedin6.2-6.5,and

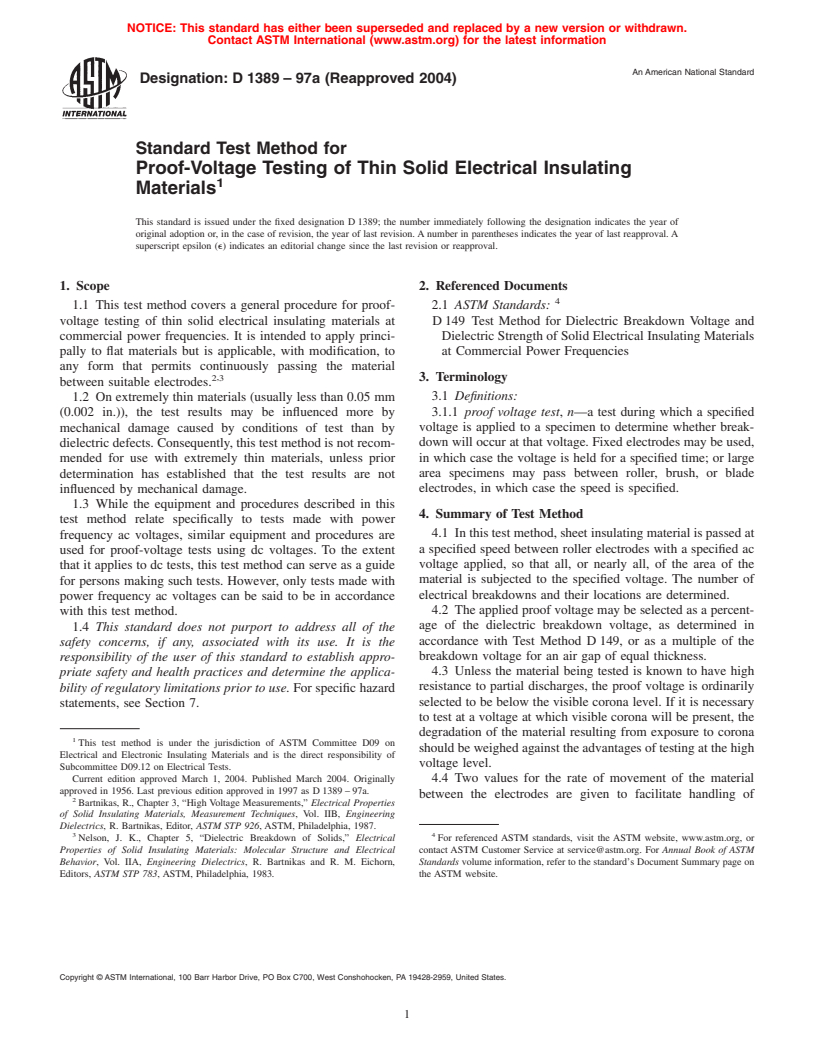

with the frequency of occurrence of these defects. The proof- in Fig. 1.

voltage test serves to indicate the frequency of occurrence of 6.2 System Considerations—Departure from a sinusoidal

dielectricdefectsandfacilitatestheisolationofareaswherethe wave form may arise either at the voltage source or in the load

defects are excessive. circuit. Excessive distortion due to load current can usually be

5.2 Some uses of thin electrical insulating materials require avoided if the overall impedance drop through the apparatus at

the complete absence of any dielectric defects. The proof- rated current and voltage is less than 10 % of the rated voltage,

voltage test serves to locate dielectric defects, making possible and provided the ratio of test voltage to rated voltage is not too

repair or replacement of the area involved as may be desirable. small; the lower limit of this ratio can be determined by test.

5.3 In the absence of detected faults, this test method is The apparatus should be of such size and design that fault

nondestructive to the material being evaluated, except as currents at breakdown produce visually observable ruptures.

discussed in 1.2 and 4.3. The magnitude of the fault current required will depend on the

5.4 A critical part of the apparatus and procedure is the material being tested.

sensitivity and speed of response of the fault detection device, 6.3 Transformer—The desired test voltage is readily ob-

usually a circuit breaker. The results obtained using different tained from a step-up transformer energized from an adjustable

sets of apparatus may differ greatly, depending upon the voltage source. The transformer must be of such size and

characteristics of this component. design that its continuous duty rating is consistent with the

5.5 It is essential that the fault detector respond only to fault requirements as specified in 6.1. Standard 5 kVA or larger

currents, and that fault currents above a pre-defined value distribution transformers 14400/13200 to 120/240 or 240/480

should always make the fault detector respond. The design, V with less than 5 % impedance drop are readily available and

adjustment, and operation of the apparatus should be such as to their use is suggested.

avoid both erroneous functioning and erroneous nonfunction- 6.4 Fault Detector—Fault detection shall be provided by an

ing of the detector resulting from charging currents, magnetiz- automatic circuit-breaking device with non-automatic reset. In

ing currents, corona currents, imbalance of circuit impedences, order to provide detection of the smallest defects, to prevent

or component malfunction. pittingoftheelectrodes,andtoprovidemaximumprotectionof

5.6 The proof-voltage test may be used as a manufacturing the other electrical elements, the fault detector should be as

control test and as an acceptance test to guarantee a minimum sensitive and as fast-acting as possible. On the other hand, the

level of dielectric defects. task of visually locating dielectric punctures in some types of

5.7 If this test method is used as an acceptance test, take materials may be difficult if the fault current is interrupted too

care that the factors discussed in 5.4 and 5.5 have been quickly. Therefore, the current setting and the response time of

Symbols: CB-Circuit Breaker: CR-Current Relay; VR-Voltage Relay.

FIG. 1 Elementary Schematic Diagram of Typical Electrical Test Apparatus

-----------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.