ASTM F1724-96

(Test Method)Standard Test Method for Measuring Surface Metal Contamination of Polycrystalline Silicon by Acid Extraction-Atomic Absorption Spectroscopy

Standard Test Method for Measuring Surface Metal Contamination of Polycrystalline Silicon by Acid Extraction-Atomic Absorption Spectroscopy

SCOPE

1.1 This test method covers the quantitative determination of surface trace metal contamination on the surface of polycrystalline silicon using an acid to extract the metals from the surface. The metals content of the acid is then analyzed by graphite furnace atomic-absorption spectroscopy.

1.2 This test method can be used for various rod, chunk, granule and chip sizes, for polycrystalline or single crystal silicon, to determine surface metal contaminants. Since the area of irregularly-shaped chunks, chips, or granules is difficult to measure accurately, values are based on sample weight. Using a sample weight of 300 g allows detection limits at the 0.1 ppbw (parts per billion weight) level.

1.3 The strength, composition, temperature, and exposure time of the acid determine the depth of surface etching and the efficiency of the extraction of the contaminants from the surface. Less than 1 % of the sample weight is removed in this test method.

1.4 This test method is useful for determining the alkali elements, alkali earth, and first series transition elements, such as sodium, potassium, calcium, iron, chromium, nickel, copper, zinc, as well as other elements such as aluminum. The recovery of these elements from the silicon surface is measured as greater than 90 %, using control standards intentionally added to the polysilicon surface.

1.5 This test method suggests a particular sample size, acid composition, etch cycle, testing environment, and instrument protocol. Variations in these parameters may be used, but may effect the recovery efficiency or retention of metals during processing. In practice, this test method is used for sample weights of 25 to 5000 g. For referee purposes, this test method specifies a sample weight of 300 g. This test method includes guidelines to alert the analyst to the interferences and resultant variations in this test method, and includes standard methods for quantifying and reporting these variations.

1.6 This test method specifies the use of graphite furnace atomic-absorption spectroscopy to analyze trace metals content of the acid extract. Other instruments of equivalent sensitivity, such as inductively-coupled plasma/mass spectrometry, may be used.

1.7 The detection limit and method variation depend on the efficiency of the acid extraction procedure, sample size, the method interferences, the absorption spectrum of each element, and the instrumental sensitivity, background, and blank value.

1.8 This test method uses hot acid to etch away the surface of the silicon. The etchant is potentially harmful and must be handled in an acid exhaust fume hood, with utmost care at all times. Hydrofluoric acid solutions are particularly hazardous and should not be used by anyone who is not familiar with the specific preventive measures and first aid treatments given in the appropriate Material Safety Data Sheet.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1724 – 96

Standard Test Method for

Measuring Surface Metal Contamination of Polycrystalline

Silicon by Acid Extraction-Atomic Absorption

Spectroscopy

This standard is issued under the fixed designation F 1724; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope such as inductively-coupled plasma/mass spectrometry, may be

used.

1.1 This test method covers the quantitative determination

1.7 The detection limit and method variation depend on the

of surface trace metal contamination on the surface of poly-

efficiency of the acid extraction procedure, sample size, the

crystalline silicon using an acid to extract the metals from the

method interferences, the absorption spectrum of each element,

surface. The metals content of the acid is then analyzed by

and the instrumental sensitivity, background, and blank value.

graphite furnace atomic-absorption spectroscopy.

1.8 This test method uses hot acid to etch away the surface

1.2 This test method can be used for various rod, chunk,

of the silicon. The etchant is potentially harmful and must be

granule and chip sizes, for polycrystalline or single crystal

handled in an acid exhaust fume hood, with utmost care at all

silicon, to determine surface metal contaminants. Since the

times. Hydrofluoric acid solutions are particularly hazardous

area of irregularly-shaped chunks, chips, or granules is difficult

and should not be used by anyone who is not familiar with the

to measure accurately, values are based on sample weight.

specific preventive measures and first aid treatments given in

Using a sample weight of 300 g allows detection limits at the

the appropriate Material Safety Data Sheet.

0.1 ppbw (parts per billion weight) level.

1.9 This standard does not purport to address all of the

1.3 The strength, composition, temperature, and exposure

safety concerns, if any, associated with its use. It is the

time of the acid determine the depth of surface etching and the

responsibility of the user of this standard to establish appro-

efficiency of the extraction of the contaminants from the

priate safety and health practices and determine the applica-

surface. Less than 1 % of the sample weight is removed in this

bility of regulatory limitations prior to use. Specific precau-

test method.

tionary statements are given in Section 9.

1.4 This test method is useful for determining the alkali

elements, alkali earth, and first series transition elements, such

2. Referenced Documents

as sodium, potassium, calcium, iron, chromium, nickel, copper,

2.1 ASTM Standards:

zinc, as well as other elements such as aluminum. The recovery

D 5127 Guide for Electronic Grade Water

of these elements from the silicon surface is measured as

E 122 Practice for Choice of Sample Size to Estimate a

greater than 90 %, using control standards intentionally added

Measure of Quality of a Lot or Process

to the polysilicon surface.

2.2 SEMI Standards:

1.5 This test method suggests a particular sample size, acid

C 7 Specification for Reagents

composition, etch cycle, testing environment, and instrument

2.3 Federal Standard:

protocol. Variations in these parameters may be used, but may

209E Airborne Particulate Cleanliness Classes in Clean-

effect the recovery efficiency or retention of metals during

rooms and Clean Zones

processing. In practice, this test method is used for sample

weights of 25 to 5000 g. For referee purposes, this test method

3. Terminology

specifies a sample weight of 300 g. This test method includes

3.1 Definitions of Terms Specific to This Standard:

guidelines to alert the analyst to the interferences and resultant

3.1.1 acid blank—a sample of acid used to establish the

variations in this test method, and includes standard methods

background spectrum and trace metal contamination of the

for quantifying and reporting these variations.

extraction acid used in the procedure.

1.6 This test method specifies the use of graphite furnace

3.1.2 carrousel protocol—the order and function of

atomic-absorption spectroscopy to analyze trace metals content

of the acid extract. Other instruments of equivalent sensitivity,

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 14.02.

1 4

This test method is under the jurisdiction of ASTM Committee F-1 on Available from Semiconductor Equipment and Materials International, 805 E.

Electronics and is the direct responsibility of Subcommittee F01.06 on Silicon Middlefield Road, Mountain View, CA 94043.

Materials and Process Control. Available from Superintendent of Documents, U.S. Government Printing

Current edition approved July 10, 1996. Published September 1996. Office, Washington, DC 20402.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1724

samples, standards, and blanks loaded into the sampling tray of bound form usually found on the polysilicon surface, after one

the atomic absorption spectrograph (AAS). etch cycle. By measuring the analytes after a second etch cycle,

3.1.3 digestion—holding the polysilicon chunks in the acid the recovery efficiency of the first cycle is determined. Recov-

mixture at temperature until the surface metal contaminants are ery efficiencies above 90 % are required to verify the accuracy

dissolved into solution. of the analysis. Recovery efficiency was confirmed by neutron

3.1.4 digested blank—samples of acid, with no analytes activation analyses. To ensure that no analytes are lost through

added, taken through the digestion process and analyzed to chemical reaction or evaporation processes, digested control

provide a monitor of the analytical process that includes acid standards are prepared and monitored for each analyses.

purity, digestion bottles cleanliness, and environment purity. 4.7 Contamination from the room environment, apparatus,

3.1.5 digested control standard—samples prepared to reagents, sampling techniques, and handling techniques is

known concentrations of the analytes to provide calibration monitored statistically by the absorption values for the digested

checks on the instrument and the digestion procedure. blanks and digested control standards.

3.1.6 GFAAS—graphite furnace atomic absorption spectro- 4.8 The detection limit depends on the dilution factor,

photometer. instrument sensitivity, spectral response of the analyte, acid

3.1.7 PTFE, polytetrafluoroethylene—an HF-resistant ma- recovery efficiency, blank value, and method interferences.

terial for sample bottles, lids, and tongs. Instrument and method variations are given in Section 15.

3.1.8 standard samples—samples prepared to known con-

5. Significance and Use

centrations of the analytes, typically 5 ppbw and 10 ppbw, to

5.1 This test method can measure the elemental, particularly

provide a calibration standard and set absorption values for the

metal, surface contamination on polysilicon chunks. Values are

GFAAS instrument.

related to sample weight rather than area due to the irregular

4. Summary of Test Method

size and form of the sample.

4.1 A standard weight and volume of chunk sample is

5.2 This surface measurement of metal contamination is

chosen in order to provide a consistent basis for the analysis used for monitoring polysilicon production processes, devel-

and provide a basis for interlaboratory correlation of analytical

opment of new processes, and materials acceptance purposes.

values. For referee purposes, a total sample weight of 300 g, 5.3 This test method is used as a standard for defining

taken as six chunks, each approximately 3 by 3 by 3 cm, at 50

detection limits, and quantifying variations and method inter-

g each, is recommended. A minimum of three of the six pieces ferences to allow interlaboratory correlations (Section 11, 15).

should have an outside surface. The outside surface, or skin of

6. Interferences

the polysilicon rod, is thought to be the most susceptible to

contamination during the rod removal and chunk processing 6.1 The common interferences of absorption spectroscopy

are present in this test method, including overlap of absorption

steps. Choosing a minimum of half of the chunk samples to

peaks, nonlinearity of absorption peaks, matrix effects, back-

have an outside surface is assumed to be representative of the

lot characteristics. ground noise, interelement interferences, and instrument drift.

6.2 Interferences from contamination due to reagent purity,

4.2 The six chunks are loaded into clean PTFE bottles,

covered with acid etchant, heated in a fume hood and the cleanliness of apparatus, cleanliness of the room, and handling

techniques during sampling and processing are critical con-

surface of the chunks dissolved. The chunks are removed from

the etchant, and the etchant heated to dryness on a hotplate. cerns. This test method describes a series of blanks and

controls to monitor and quantify these interferences.

4.3 The dried etchant residue is dissolved by adding 2 mL of

5 % HNO and8mL ofH O to make a total of 10 mL. This 6.3 The recovery efficiency of the acid mixture and extrac-

3 2

tion process must be measured in order to monitor any

extract is then analyzed by GFAAS for trace metals.

4.4 The sample carrousel tray of the GFAAS instrument is interference from this source. Metal contaminants chemically

bound to the surface by various treatments or in the bulk of the

loaded with a series of blanks, calibration standards, and

monitor standards, along with the acid extract samples. The polysilicon may not be recovered by this acid mixture. Recov-

ery efficiency can be confirmed by neutron activation analyses,

temperature program for the graphite furnace is optimized for

maximum sensitivity and the absorption spectral lines chosen or by another test method.

6.4 This test method specifies a sample size of 300 g to be

for maximum sensitivity and minimum interferences for each

element. representative of the lot sample. Since surface contamination is

not distributed evenly upon a surface, sample size and volume

4.5 Data from the GFAAS instrument is collected and the

value for each analyte in the lot sample calculated. For each must be chosen to be representative of the lot. If the sample

size is too small, the sample may not be representative of the

analyte, the two digested blanks are averaged to provide a zero

lot, resulting in excessive variation in duplicate samples.

reference. This average value is subtracted from the lot sample

value, and the remaining value multiplied by the dilution factor

7. Apparatus

to obtain the reported result. The dilution factor is the final

7.1 GFAAS Instrument, graphite furnace atomic absorption

volume of the acid extract, 10 mL, divided by the starting

weight of the polysilicon sample, 300 g.

4.6 This acid mixture has a measured recovery efficiency of

Maurits, J. E. A., Dawson, H. J., and Barker, T. H., “The Analysis of Surface

95 % or greater for iron, chromium, nickel, sodium, zinc,

Metals in Polycrystalline Silicon,” Abstract No. 401, Extended Abstracts, Vol 94-2,

aluminum, copper, calcium, and potassium, in the chemically- Fall Meeting of the Electrochemical Society, October 9–14, 1994, Miami Beach, FL.

F 1724

spectrometer, with sufficient resolving power to perform el- from commercially-available atomic-absorption elemental

emental analysis at the sub-ppb level. A sample tray with calibration standards, at 1000 ppm, traceable to NIST Refer-

selective sampling capability is integral to the instrument. A ence Standards.

computerized data system calculates peak absorbance values, 11.2 Prepare a series of calibration and control standards for

provides the instrument calibration curve, and reports sample each analyte to determine the instrument calibration curve,

values. monitor recovery efficiency of the acid etchant, and monitor

7.2 Class 1000 Air Environment—The area for sample reagent purity and purity of the environment. Purpose of the

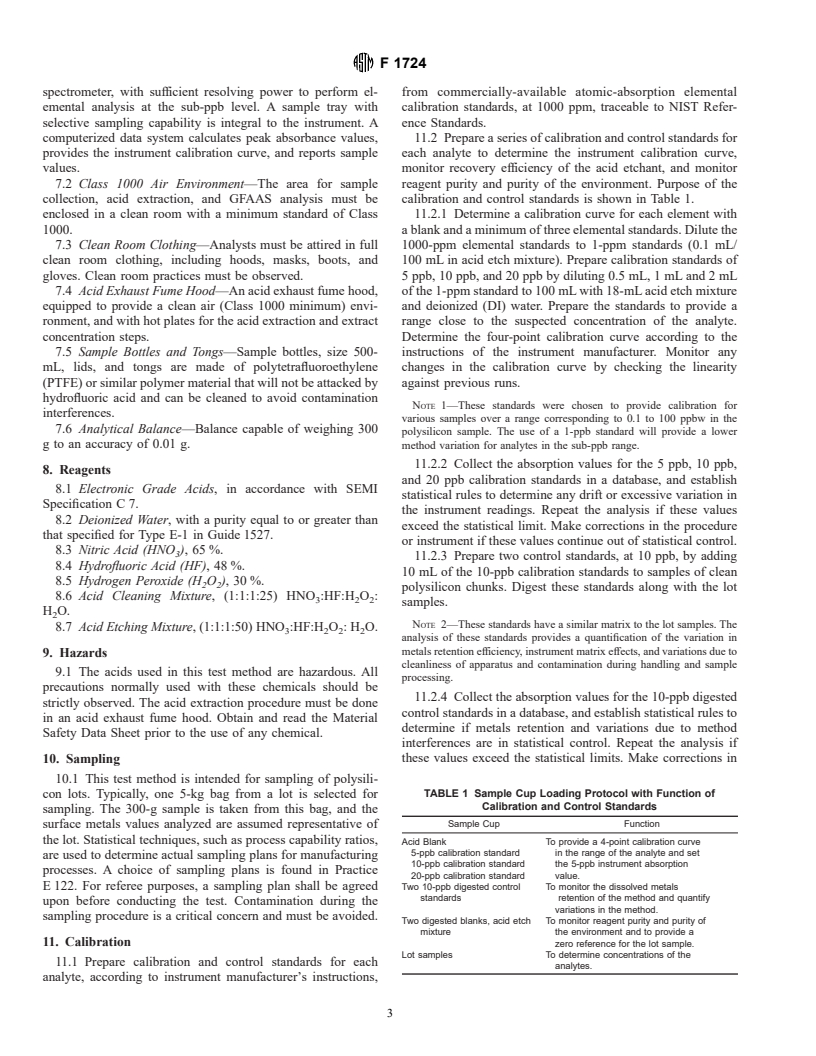

collection, acid extraction, and GFAAS analysis must be calibration and control standards is shown in Table 1.

enclosed in a clean room with a minimum standard of Class 11.2.1 Determine a calibration curve for each element with

1000. a blank and a minimum of three elemental standards. Dilute the

7.3 Clean Room Clothing—Analysts must be attired in full 1000-ppm elemental standards to 1-ppm standards (0.1 mL/

clean room clothing, including hoods, masks, boots, and 100 mL in acid etch mixture). Prepare calibration standards of

gloves. Clean room practices must be observed. 5 ppb, 10 ppb, and 20 ppb by diluting 0.5 mL, 1 mL and 2 mL

7.4 Acid Exhaust Fume Hood—An acid exhaust fume hood, of the 1-ppm standard to 100 mL with 18-mL acid etch mixture

equipped to provide a clean air (Class 1000 minimum) envi- and deionized (DI) water. Prepare the standards to provide a

ronment, and with hot plates for the acid extraction and extract range close to the suspected concentration of the analyte.

concentration steps. Determine the four-point calibration curve according to the

7.5 Sample Bottles and Tongs—Sample bottles, size 500- instructions of the instrument manufacturer. Monitor any

mL, lids, and tongs are made of polytetrafluoroethylene changes in the calibration curve by checking the linearity

(PTFE) or similar polymer material that will not be attacked by against previous runs.

hydrofluoric acid and can be cleaned to avoid contamination

NOTE 1—These standards were chosen to provide calibration for

interferences.

various samples over a range corresponding to 0.1 to 100 ppbw in the

7.6 Analytical Balance—Balance capable of weighing 300

polysilicon sample. The use of a 1-ppb standard will provide a lower

g to an accuracy of 0.01 g.

method variation for analytes in the sub-ppb range.

11.2.2 Collect the absorption values for the 5 ppb, 10 ppb,

8. Reagents

and 20 ppb calibration standards in a database, and establish

8.1 Electronic Grade Acids, in accordance with SEMI

statistical rules to determine any drift or excessive variation in

Specification C 7.

the instrument readings. Repeat the analysis if these values

8.2 Deionized Water, with a purity equal to or greater than

exceed the statistical limit. Make corrections in the procedure

that specified for Type E-1 in Guide 1527.

or instrument if these values continue out of statistical control.

8.3 Nitric Acid (HNO ),65%.

11.2.3 Prepare two control standards, at 10 ppb, by adding

8.4 Hydrofluoric Acid (HF),48%.

10 mL of the 10-ppb calibration standards to samples of clean

8.5 Hydrogen Peroxide (H O ),30%.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.