ASTM D7217-11

(Test Method)Standard Test Method for Determining Extreme Pressure Properties of Solid Bonded Films Using a High-Frequency, Linear-Oscillation (SRV) Test Machine

Standard Test Method for Determining Extreme Pressure Properties of Solid Bonded Films Using a High-Frequency, Linear-Oscillation (SRV) Test Machine

SIGNIFICANCE AND USE

This laboratory test method can be used to quickly determine extreme pressure properties of parts coated with solid bonded films at selected temperatures specified for use in unlubricated applications where high-speed vibrational or start-stop motions are present with high Hertzian point contact. This test method has found wide application in qualifying solid bonded films used in automotive door lock mechanisms, hinge joints, bolts, and in aerospace. This test method is a material and application oriented approach for characterizing the tribological behaviour using random, discrete and constant parameter combinations Users of this test method should determine whether results correlate with field performance or other applications.

SCOPE

1.1 This test method covers a procedure for determining extreme pressure properties of solid bonded films under high-frequency linear-oscillation motion using the SRV test machine.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7217 − 11

Standard Test Method for

Determining Extreme Pressure Properties of Solid Bonded

Films Using a High-Frequency, Linear-Oscillation (SRV) Test

1

Machine

This standard is issued under the fixed designation D7217; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.2 Other Standards:

DIN EN ISO 683-17 Heat-treated Steels, Alloy Steels and

1.1 This test method covers a procedure for determining

Free-Cutting Steels—Part 17: Ball and Roller Bearing

extreme pressure properties of solid bonded films under

3

Steels

high-frequency linear-oscillation motion using the SRV test

DIN EN ISO 13565-2:1998 Geometrical Product Specifica-

machine.

tions (GPS)—Surface Texture: Profile Method; Surfaces

1.2 The values stated in SI units are to be regarded as

Having Stratified Functional Properties—Part 2: Height

standard. No other units of measurement are included in this

Characterization Using Linear Material Ratio Curve [Re-

standard.

placement of DIN 4776:1990: Measurement of Surface

1.3 This standard does not purport to address all of the Roughness; Parameters R ,R ,R ,M ,M for the

K PK VK r1 r2

3

safety concerns, if any, associated with its use. It is the

Description of the Material Portion]

responsibility of the user of this standard to establish appro- SAE AS5272 Lubricant, Solid Film, Heat Cured, Corrosion

4

priate safety and health practices and determine the applica-

Inhibiting Procurement Specification

5

bility of regulatory limitations prior to use. AMS 2562B

3. Terminology

2. Referenced Documents

2

3.1 Definitions:

2.1 ASTM Standards:

3.1.1 break-in, n—in tribology, an initial transition process

A295/A295M Specification for High-Carbon Anti-Friction

occurring in newly established wearing contacts, often accom-

Bearing Steel

panied by transients in coefficient of friction or wear rate, or

D2510 Test Method for Adhesion of Solid Film Lubricants

both, which are uncharacteristic of the given tribological

D4175 Terminology Relating to Petroleum, Petroleum

system’s long-term behavior. G40

Products, and Lubricants

D5706 Test Method for Determining Extreme Pressure

3.1.2 coeffıcient of friction, µ or ƒ, n—in tribology, the

Properties of Lubricating Greases Using a High-

dimensionlessratioofthefrictionforce(F)betweentwobodies

Frequency, Linear-Oscillation (SRV) Test Machine to the normal force (N) pressing these bodies together. G40

D7421 Test Method for Determining Extreme Pressure

3.1.3 Hertzian contact area, n—the apparent area of contact

Properties of Lubricating Oils Using High-Frequency,

between two nonconforming solid bodies pressed against each

Linear-Oscillation (SRV) Test Machine

other, as calculated from Hertz’s equations of elastic

E45 Test Methods for Determining the Inclusion Content of

deformation. G40

Steel

3.1.4 Hertzian contact pressure, n—magnitude of the pres-

G40 Terminology Relating to Wear and Erosion

sure at any specified location in a Hertzian contact area, as

calculated from Hertz’s equations of elastic deformation. The

Hertzian contact pressure can also be calculated and reported

1

This test method is under the jurisdiction of ASTM Committee D02 on

as maximum value P in the centre of the contact or as

max

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

P as average over the total contact area.

Subcommittee D02.L0.05 on Solid Lubricants. average

Current edition approved Dec. 1, 2011. Published March 2012. Originally

ε1

approved in 2005. Last previous edition approved in 2010 as D7217–05(2010) .

3

DOI: 10.1520/D7217-11. Available from Beuth Verlag GmbH, Burggrafenstrasse 6, D-10787 Berlin,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Germany.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Society of Automotive Engineers (SAE), 400 Commonwealth

Standards volume information, refer to the standard’s Document Summary page on Dr., Warrendale, PA 15096-0001.

5

the ASTM website. Aerospace Material Specifications.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

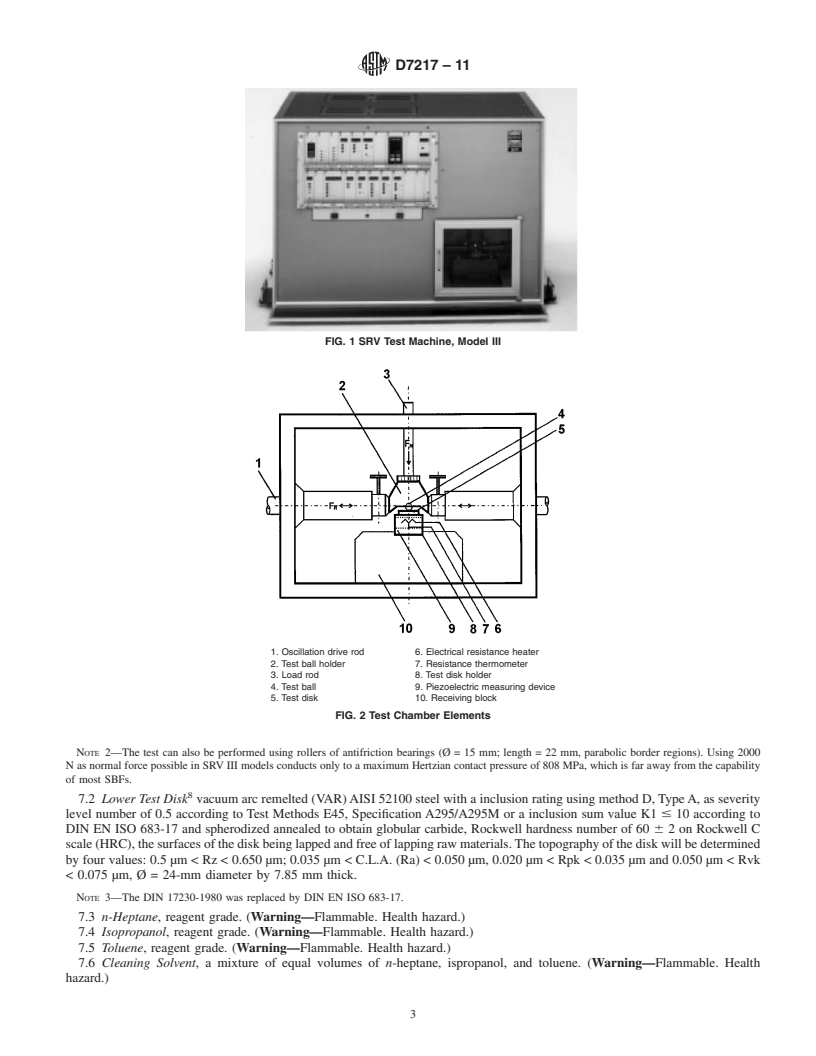

D7217 − 11

3.1.5 lubricant, n—any material interposed between two

surfaces that reduces the friction or wear, or both between

them. D4175

3.1.6 solid bonded film (sbf), n—consists of physically dried

orchemicallyhardened(cured)bondedsolidfilmsaswellasof

inorganic matrices containing embedded organic or inorganic,

or both, so

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D7217–05 (Reapproved 2010) Designation:D7217–11

Standard Test Method for

Determining Extreme Pressure Properties of Solid Bonded

Films Using a High-Frequency, Linear-Oscillation (SRV) Test

1

Machine

This standard is issued under the fixed designation D7217; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Updated Section 7 to include HRC editorially in October 2010.

1. Scope*

1.1 Thistestmethodcoversaprocedurefordeterminingextremepressurepropertiesofsolidbondedfilmsunderhigh-frequency

linear-oscillation motion using the SRV test machine.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A295/A295M Specification for High-Carbon Anti-Friction Bearing Steel

D2510 Test Method for Adhesion of Solid Film Lubricants

D4175 Terminology Relating to Petroleum, Petroleum Products, and Lubricants

D5706 Test Method for Determining Extreme Pressure Properties of Lubricating Greases Using a High-Frequency,

Linear-Oscillation (SRV) Test Machine

D7421 Test Method for Determining Extreme Pressure Properties of Lubricating Oils Using High-Frequency, Linear-

Oscillation (SRV) Test Machine

E45 Test Methods for Determining the Inclusion Content of Steel

G40 Terminology Relating to Wear and Erosion

2.2 Other Standards:

3

DIN EN ISO 683-17 Heat-treated Steels, Alloy Steels and Free-Cutting Steels—Part 17: Ball and Roller Bearing Steels

DIN EN ISO 13565-2:1998 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method; Surfaces Having

Stratified Functional Properties—Part 2: Height Characterization Using Linear Material Ratio Curve [Replacement of DIN

4776:1990: Measurement of Surface Roughness; Parameters R ,R ,R ,M ,M for the Description of the Material

K PK VK r1 r2

3

Portion]

4

SAE AS5272 Lubricant, Solid Film, Heat Cured, Corrosion Inhibiting Procurement Specification

5

AMS 2562B

3. Terminology

3.1 Definitions:

3.1.1 break-in, n—in tribology,aninitialtransitionprocessoccurringinnewlyestablishedwearingcontacts,oftenaccompanied

by transients in coefficient of friction or wear rate, or both, which are uncharacteristic of the given tribological system’s long-term

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.L0.05

on Solid Lubricants.

Current edition approved Oct. 1, 2010. Published December 2010. Originally approved in 2005. Last previous edition approved in 2005 as D7217–05. DOI:

10.1520/D7217-10.

´1

Current edition approved Dec. 1, 2011. Published March 2012. Originally approved in 2005. Last previous edition approved in 2010 as D7217–05(2010) . DOI:

10.1520/D7217-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Beuth Verlag GmbH, Burggrafenstrasse 6, D-10787 Berlin, Germany.

4

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001.

5

Aerospace Material Specifications.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D7217–11

behavior. G40

3.1.2 coeffıcient of friction, µ or ƒ, n—in tribology, the dimensionless ratio of the friction force (F) between two bodies to the

normal force (N) pressing these bodies together. G40

3.1.3 Hertzian contact area, n—the apparent area of contact between two nonconforming solid bodies pressed against each

other, as calculated from Hertz’s equations of elastic deformation. G40

3.1.4 Hertzian contact pressure, n—the magnitude of the pressure at any specified location in a Hertzian contact area, as

calculated from Hertz’s equations of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.