ASTM D5413-93(2007)

(Test Method)Standard Test Methods for Measurement of Water Levels in Open-Water Bodies

Standard Test Methods for Measurement of Water Levels in Open-Water Bodies

SIGNIFICANCE AND USE

These test methods are used to determine the gauge height or elevation of a river or other body of water above a given datum.

Water level data can serve as an easily recorded parameter, and through use of a stage-discharge relation provide an indirect value of stream discharge, often at a gauging station.

These test methods can be used in conjunction with other determinations of biological, physical, or chemical properties of waters. TEST METHOD A—NONRECORDING WATER-LEVEL MEASUREMENT DEVICES Top

SCOPE

1.1 These test methods cover equipment and procedures used in obtaining water levels of rivers, lakes, and reservoirs or other water bodies. Three types of equipment are available as follows:Test Method A-Nonrecording water-level measurement devices Test Method B-Recording water-level measurement devices Test Method C-Remote-interrogation water-level measurement devices

1.2 The procedures detailed in these test methods are widely used by those responsible for investigations of streams, lakes, reservoirs, and estuaries, for example, the U.S. Agricultural Research Service, the U.S. Army Corp of Engineers, and the U.S. Geological Survey. The referenced ISO standard also furnishes useful information.

1.3 It is the responsibility of the user of these test methods to determine the acceptability of a specific device or procedure to meet operational requirements. Compatibility between sensors, recorders, retrieval equipment, and operational systems is necessary, and data requirements and environmental operating conditions must be considered in equipment selection.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5413 − 93 (Reapproved2007)

Standard Test Methods for

Measurement of Water Levels in Open-Water Bodies

This standard is issued under the fixed designation D5413; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 These test methods cover equipment and procedures

D1129 Terminology Relating to Water

used in obtaining water levels of rivers, lakes, and reservoirs or

D1941 Test Method for Open Channel Flow Measurement

other water bodies. Three types of equipment are available as

of Water with the Parshall Flume

follows:

D2777 Practice for Determination of Precision and Bias of

Test MethodA—Nonrecording water-level measurement devices

Applicable Test Methods of Committee D19 on Water

Test Method B—Recording water-level measurement devices

Test Method C—Remote-interrogation water-level measurement devices D5242 Test Method for Open-Channel Flow Measurement

of Water with Thin-Plate Weirs

1.2 Theproceduresdetailedinthesetestmethodsarewidely

2.2 ISO Standard:

used by those responsible for investigations of streams, lakes,

ISO 4373 Measurement of Liquid Flow in Open Channels—

reservoirs, and estuaries, for example, the U.S. Agricultural

Water Level Measuring Devices

Research Service, the U.S. Army Corp of Engineers, and the

U.S. Geological Survey. The referenced ISO standard also

3. Terminology

furnishes useful information.

3.1 Definitions—For definitions of terms used in these test

1.3 It is the responsibility of the user of these test methods methods, refer to Terminology

to determine the acceptability of a specific device or procedure

3.2 Definitions of Terms Specific to This Standard:

to meet operational requirements. Compatibility between

3.2.1 elevation—the vertical distance from a datum to a

sensors, recorders, retrieval equipment, and operational sys-

point.

tems is necessary, and data requirements and environmental

3.2.2 datum—a level plane that represents a zero or some

operating conditions must be considered in equipment selec-

defined elevation.

tion.

3.2.3 gauge—a generic term that includes water level mea-

1.4 The values stated in inch-pound units are to be regarded

suring devices.

as the standard. The values given in parentheses are for

3.2.4 gauge datum—a datum whose surface is at the zero

information only.

elevation of all the gauges at a gauging station; this datum is

1.5 This standard does not purport to address all of the often at a known elevation referenced to National Geodetic

safety concerns, if any, associated with its use. It is the Vertical Datum of 1929 (NGVD).

responsibility of the user of this standard to establish appro-

3.2.5 gauge height—the height of a water surface above an

priate safety and health practices and determine the applica-

established or arbitrary datum at a particular gauging station;

bility of regulatory limitations prior to use.

also termed stage.

3.2.6 gauging station—a particular site on a stream, canal,

lake, or reservoir where systematic observations of hydrologic

These test methods are under the jurisdiction of ASTM Committee D19 on

data are obtained.

Water and is the direct responsibility of Subcommittee D19.07 on Sediments,

Geomorphology, and Open-Channel Flow.

Current edition approved June 15, 2007. Published July 2007. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1993. Last previous edition approved in 2002 as D5413 – 93 (2002). contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

DOI: 10.1520/D5413-93R07. Standards volume information, refer to the standard’s Document Summary page on

Buchanan, T. J., and Somers, W. P., “Stage Measurement at Gauging Stations,” the ASTM website.

Techniques of Water Resources Investigations, Book 3, ChapterA-7, U.S. Geologi- Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

cal Survey, 1968. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

D5413 − 93 (Reapproved2007)

3.2.7 National Geodetic Vertical Datum of 1929 (NGVD)

—prior to 1973 known as mean sea level datum; a spheroidal

datum in the conterminous United States and Canada that

approximates mean sea level but does not necessarily agree

with sea level at a specific location.

4. Significance and Use

4.1 These test methods are used to determine the gauge

height or elevation of a river or other body of water above a

given datum.

D5413 − 93 (2007)

4.2 Water level data can serve as an easily recorded param-

eter, and through use of a stage-discharge relation provide an

indirect value of stream discharge, often at a gauging station.

4.3 These test methods can be used in conjunction with

other determinations of biological, physical, or chemical prop-

erties of waters.

TEST METHOD A—NONRECORDING WATER-

LEVEL MEASUREMENT DEVICES

5. Summary of Test Method

5.1 These test methods are usually applicable to conditions

where continuous records of water level or discharge are not

required. However, in some situations, daily or twice daily

observations from a nonrecording water-level device can

provide a satisfactory record of daily water levels or discharge.

Water levels obtained by the nonrecording devices described in

these test methods can be used to calibrate recording water-

level devices described in Test Methods B and C.

5.2 Devices included in these test methods are of two

generaltypes:thosethatarereaddirectly,suchasastaffgauge;

and those that are read by measurement to the water surface

from a fixed point, such as wire-weight, float-tape, electric-

tape, point and hook gauges.

5.2.1 Staff, wire-weight, and chain gauges are commonly

used as both outside auxiliary and reference gauges. Vertical-

and inclined-staff, float-tape, electric-tape, hook and point

gauges are commonly used as inside auxiliary and reference

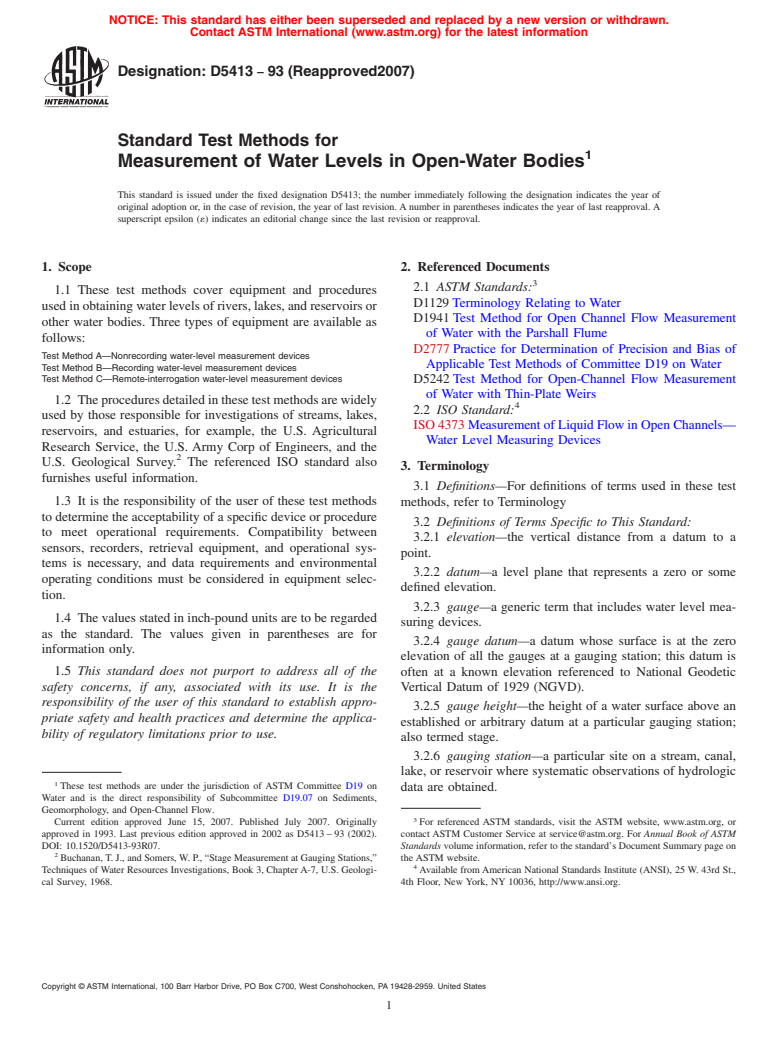

FIG. 1 Staff Gauges

gauges.

5.3 Documentation of observations must be manually re-

corded.

6. Apparatus

6.1 Staff Gauges:

6.1.1 Vertical Staff Gauges—Staff gauges are usually gradu-

ated porcelain-enameled plates attached to wooden piers or

pilings, bridge piers, or other hydraulic structures. They may

also be installed on the inside of gauging station stilling wells

as inside reference gauges. They are precisely graduated,

usually to 0.02 ft or 2 mm, although other markings may be

used for specific applications (see Fig. 1).

6.1.2 Inclined Staff Gauges—Inclined staff gauges usually

consist of markings on heavy timbers, steel beams, or occa-

sionally concrete beams built partially embedded into the

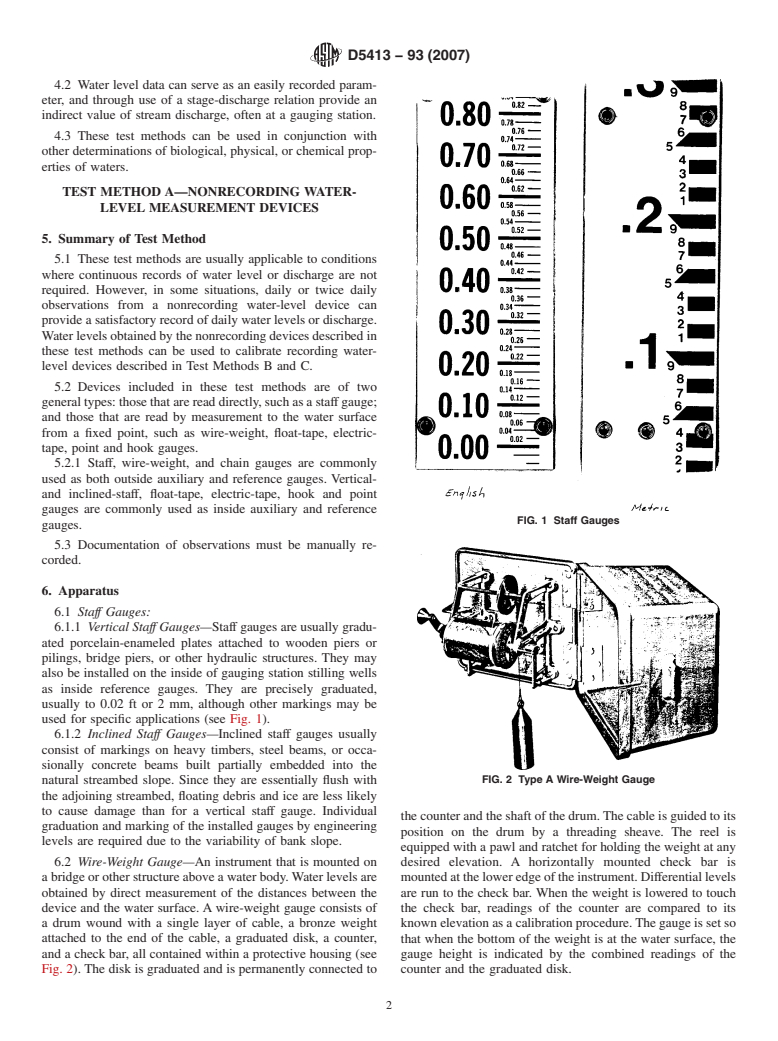

FIG. 2 Type A Wire-Weight Gauge

natural streambed slope. Since they are essentially flush with

the adjoining streambed, floating debris and ice are less likely

to cause damage than for a vertical staff gauge. Individual

the counter and the shaft of the drum.The cable is guided to its

graduation and marking of the installed gauges by engineering

position on the drum by a threading sheave. The reel is

levels are required due to the variability of bank slope.

equipped with a pawl and ratchet for holding the weight at any

6.2 Wire-Weight Gauge—An instrument that is mounted on desired elevation. A horizontally mounted check bar is

a bridge or other structure above a water body.Water levels are mountedattheloweredgeoftheinstrument.Differentiallevels

obtained by direct measurement of the distances between the are run to the check bar. When the weight is lowered to touch

device and the water surface. A wire-weight gauge consists of the check bar, readings of the counter are compared to its

a drum wound with a single layer of cable, a bronze weight known elevation as a calibration procedure.The gauge is set so

attached to the end of the cable, a graduated disk, a counter, that when the bottom of the weight is at the water surface, the

and a check bar, all contained within a protective housing (see gauge height is indicated by the combined readings of the

Fig. 2). The disk is graduated and is permanently connected to counter and the graduated disk.

D5413 − 93 (2007)

6.3 Needle Gauges—Frequently referred to as point or hook

gauges. A needle gauge consists of a vertically-mounted

pointed metallic, small-diameter rod, which can be lowered

until an exact contact is made with the water surface.Avernier

or graduated scale is read to indicate a gauge height. A

needle-type gauge offers high measurement accuracy, but

requires some skill and good visibility (light conditions) in

lowering and raising the device to a position where the point

just pierces the water surface. These gauges are most com-

monly used in applications where the water surface is calm.

6.3.1 PointGauge—Aformofneedlegaugewherethetipor

point approaches the water surface from above.

6.3.2 Hook Gauge—A form of needle gauge made in the

shape of a hook, where the tip or point approaches the water

surface from below (see Fig. 3). The hook gauge is easier to

use in a stilling well application. As the point contacts the

water surface, overhead light will reflect from a dimple on the

water surface.

6.4 Float-Tape Gauge—Consists of a float attached to a

stainless steel graduated tape that passes over a suitable pulley

with a counterweight to maintain tension. A pointer or other

index is frequently fabricated as an integral part of the pulley

assembly (see Fig. 4). Float-tape gauges frequently are com-

bined with water-level recorders in a manner whereby the

pulley is the stage drive wheel for the recorder.

FIG. 4 Float-Type Gauge

6.5 Electric-Tape Gauge—Consists of a graduated steel tape

and weight attached to a combined tape reel, voltmeter, datum

index and electrical circuit, powered by a 4 ⁄2 to 6 volt battery

(see Fig. 5). The gauge frame is mounted on a shelf or bracket

over the water surface, usually in a stilling well. The weight is

lowered until the weight touches the water surface closing the

FIG. 3 Hook Gauge FIG. 5 Electric-Type Gauge

D5413 − 93 (2007)

electrical circuit that is indicated by the voltmeter. The gauge Procedures described in Test Method A are usually used to set

height is read on the tape at the index. these recording devices to the correct datum.

6.6 A reference point is frequently selected on a stable 9.2 Devices,genericallyreferredtoaswater-levelrecorders,

memberofabridge,stillingwell,orotherstructurefromwhich or recorders, included in these test methods must be capable of

distance vertical measurements to the water surface are made recording stage and the time and date at which the stage

by steel tape and weight. The reference point is a clearly occurred.

defined location, frequently a file mark or paint mark to ensure

9.3 Recorders may sense water level by direct mechanical

that all readings are from the same location.

connection, usually by float-counterweight and tape or cable,

by gas purge manometer systems (bubble gauges), or by

7. Calibration

electronic water level sensors (pressure transducer or acoustic

7.1 Establish a datum. The datum may be a recognized

devices).

datum such as National Geodetic Vertical Datum of 1929

9.4 Recorders may retain data in graphical, analog, digital,

(NGVD), a datum referenced to a recognized datum such as

or other format.

580.00 ft NGVD 1929, a local datum, or an arbitrary datum.A

datum is usually selected that will give readings of small 9.5 Recorders are available that can remain unattended for

positive numbers. periods from one week to longer than six months.

7.2 Establish at least three reference marks (RMs). Refer-

10. Apparatus

ence marks must be located on independent permanent struc-

tures that have a good probability of surviving a major flood or

10.1 Types of Sensing Systems:

other event that may destroy the gauge. Reference marks

10.1.1 Direct Reading Systems:

should be close enough to the water-level measuring device

10.1.1.1 Crest Stage Gauge—Acreststagegaugeisasimple

that the leveling circuit not require more than two or three

sensing-recording device that is installed near a water body to

instrument setups to complete elevation verification. If the

recordthehighestwaterlevelthatoccursbetweenvisitsoffield

NGVD datum is used, determine the elevation of the reference

personnel. A wooden rod is encased in a steel or plastic pipe

marks by differential leveling from the nearest NGVD bench-

with holes for water to enter and rise to the outside water level.

mark.

Arecoverablehigh-watermarkisleftonthedevicebyparticles

of ground cork that float to the highest water level (Fig. 6).

7.3 Set the gauges to correct datum by differential leveling

10.1.1.2 Tape Gauge Maximum-Minimum Indicators—

fromthereferencemarks.Uselevelingproceduresdescribedin

These indicators include magnetic or mechanical accessories

a surveying text or “Levels at Streamflow Gauging Stations.”

that record maximum or minimum travel of float-drive tape

7.4 Run levels to gauges from RMs annually for the first 3

gauges or recorder-drive tapes.

to 5 years, then if stability is evident, a level frequency of 3 to

10.1.2 Mechanical Sensing Systems :

5 years is acceptable. Rerun levels at any time that a gauge has

10.1.2.1 Float Tape—Consists of a float that floats on the

been disturbed or has unresolved gauge reading inconsisten-

watersurface,usuallyinastillingwell,andasteeltapeorcable

cies. Run levels to all RMs, reference points, index points, and

which passes over a recorder drive pulley. A weight on the

to each staff gauge, and to the water surface. Read the water

opposite end of the tape maintains tension in the tape or cable.

surface at each gauge at the time levels are run. Document

The rise and fall of the water surface is thus directly transmit-

differences found and changes made in a permanent record.

ted to the recorder.

10.1.2.2 Shaft Encoders— These devices consist of a float-

8. Procedure

tape driven shaft and pulley assembly that converts the angular

8.1 Read direct reading gauges by observing the water

shaftpositiontoanelectronicsignalcompatiblewithelectronic

surface on the gauge scale. Manually record this value on an

recorders. Analog output potentiometers and several digital

appropriate form.

format output encoding systems are available.

8.2 Gauges that require measurement from a fixed point to

10.1.3 Gas-Purge System— This system is commonly

the water surface must follow procedures

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.