ASTM E587-00(2005)

(Practice)Standard Practice for Ultrasonic Angle-Beam Examination by the Contact Method

Standard Practice for Ultrasonic Angle-Beam Examination by the Contact Method

SCOPE

1.1 This practice covers ultrasonic examination of materials by the pulse-echo technique, using continuous coupling of angular incident ultrasonic vibrations.

1.2 The values stated in inch-pound units are regarded as standard. The SI equivalents are in brackets and may be approximate.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E587–00 (Reapproved 2005)

Standard Practice for

1

Ultrasonic Angle-Beam Examination by the Contact Method

This standard is issued under the fixed designation E587; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

5

1. Scope 2.4 Aerospace Industries Association Document:

NAS 410 Certification and Qualification of Nondestructive

1.1 This practice covers ultrasonic examination of materials

Testing Personnel

by the pulse-echo technique, using continuous coupling of

angular incident ultrasonic vibrations.

3. Terminology

1.2 The values stated in inch-pound units are regarded as

3.1 Definitions—For definitions of terms used in this prac-

standard. The SI equivalents are in brackets and may be

tice, see Terminology E1316.

approximate.

1.3 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 An electrical pulse is applied to a piezoelectric trans-

responsibility of the user of this standard to establish appro-

ducer which converts electrical to mechanical energy. In the

priate safety and health practices and determine the applica-

angle-beam search unit, the piezoelectric element is generally

bility of regulatory limitations prior to use.

a thickness expander which creates compressions and rarefac-

tions.Thislongitudinal(compressional)wavetravelsthrougha

2. Referenced Documents

2

wedge (generally a plastic). The angle between transducer face

2.1 ASTM Standards:

and the examination face of the wedge is equal to the angle

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam Ex-

between the normal (perpendicular) to the examination surface

amination by the Contact Method

and the incident beam. Fig. 1 shows the incident angle f, and

i

E317 Practice for Evaluating Performance Characteristics

the refracted angle f , of the ultrasonic beam.

r

of Ultrasonic Pulse-Echo Testing Instruments and Systems

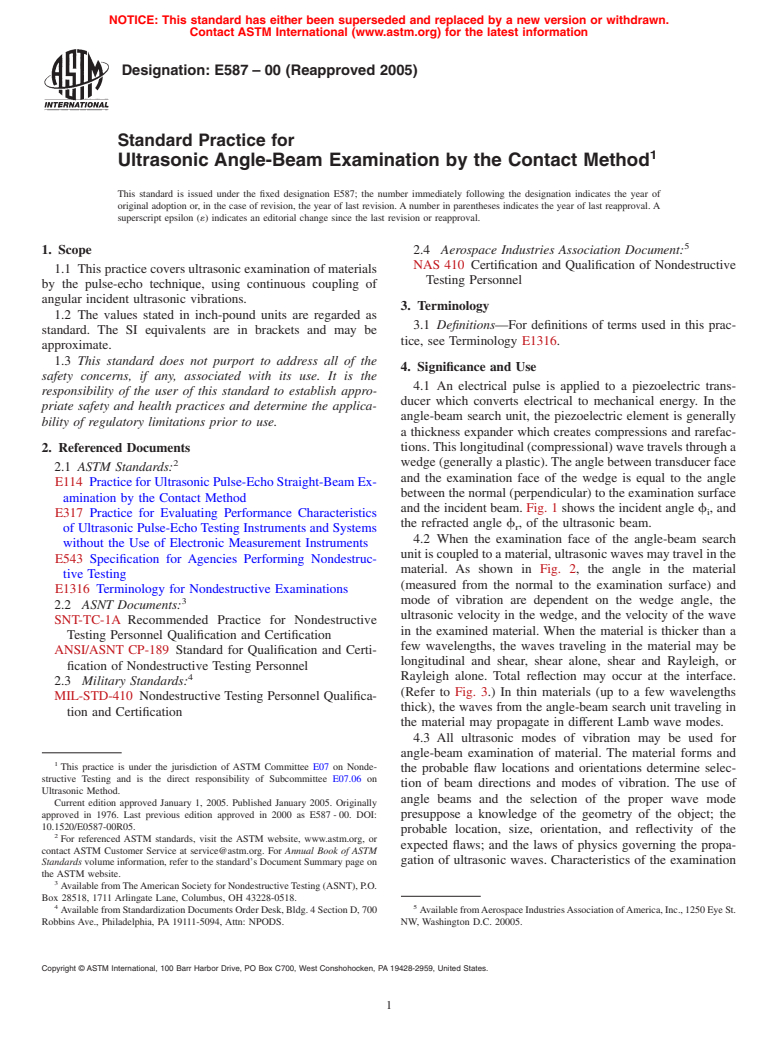

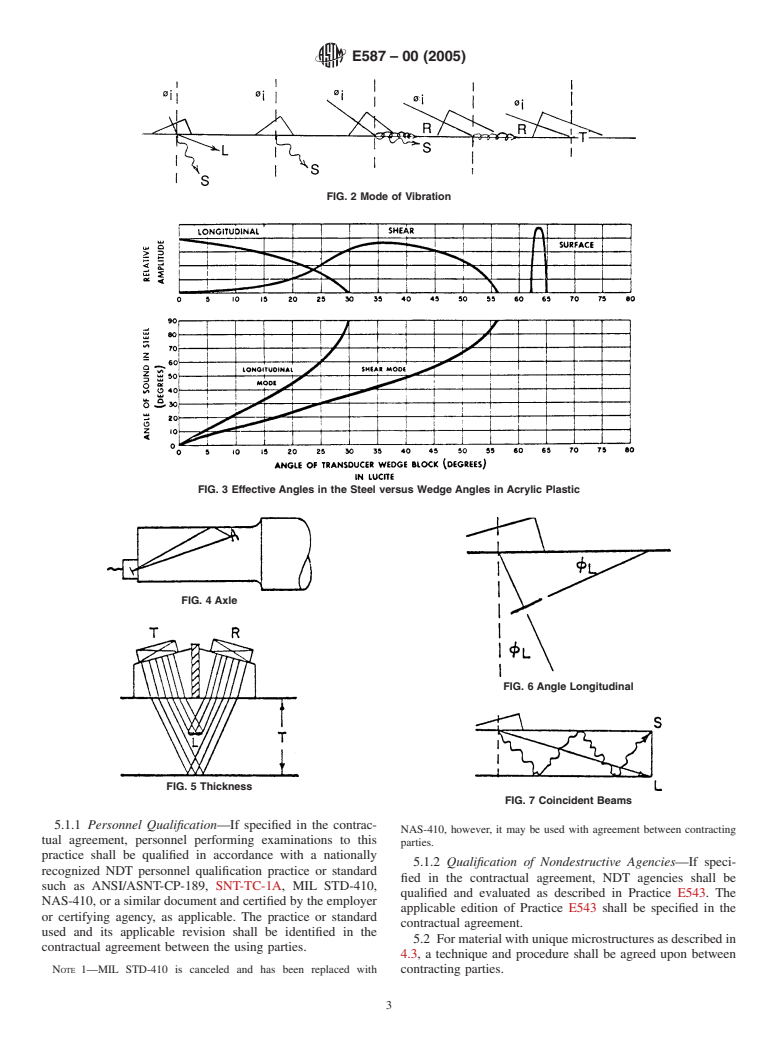

4.2 When the examination face of the angle-beam search

without the Use of Electronic Measurement Instruments

unit is coupled to a material, ultrasonic waves may travel in the

E543 Specification for Agencies Performing Nondestruc-

material. As shown in Fig. 2, the angle in the material

tive Testing

(measured from the normal to the examination surface) and

E1316 Terminology for Nondestructive Examinations

3 mode of vibration are dependent on the wedge angle, the

2.2 ASNT Documents:

ultrasonic velocity in the wedge, and the velocity of the wave

SNT-TC-1A Recommended Practice for Nondestructive

in the examined material. When the material is thicker than a

Testing Personnel Qualification and Certification

few wavelengths, the waves traveling in the material may be

ANSI/ASNT CP-189 Standard for Qualification and Certi-

longitudinal and shear, shear alone, shear and Rayleigh, or

fication of Nondestructive Testing Personnel

4 Rayleigh alone. Total reflection may occur at the interface.

2.3 Military Standards:

(Refer to Fig. 3.) In thin materials (up to a few wavelengths

MIL-STD-410 Nondestructive Testing Personnel Qualifica-

thick), the waves from the angle-beam search unit traveling in

tion and Certification

the material may propagate in different Lamb wave modes.

4.3 All ultrasonic modes of vibration may be used for

angle-beam examination of material. The material forms and

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

the probable flaw locations and orientations determine selec-

structive Testing and is the direct responsibility of Subcommittee E07.06 on

tion of beam directions and modes of vibration. The use of

Ultrasonic Method.

angle beams and the selection of the proper wave mode

Current edition approved January 1, 2005. Published January 2005. Originally

approved in 1976. Last previous edition approved in 2000 as E587 - 00. DOI:

presuppose a knowledge of the geometry of the object; the

10.1520/E0587-00R05.

probable location, size, orientation, and reflectivity of the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

expected flaws; and the laws of physics governing the propa-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

gation of ultrasonic waves. Characteristics of the examination

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

Available fromTheAmerican Society for NondestructiveTesting (ASNT), P.O.

Box 28518, 1711 Arlingate Lane, Columbus, OH 43228-0518.

4 5

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700 AvailablefromAerospaceIndustriesAssociationofAmerica,Inc.,1250EyeSt.

Robbins Ave.,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.