ASTM C747-93(1998)

(Test Method)Standard Test Method for Moduli of Elasticity and Fundamental Frequencies of Carbon and Graphite Materials by Sonic Resonance

Standard Test Method for Moduli of Elasticity and Fundamental Frequencies of Carbon and Graphite Materials by Sonic Resonance

SCOPE

1.1 This test method covers the measurement of the fundamental transverse, longitudinal, and torsional frequencies of isotropic and anisotropic carbon and graphite materials. These measured resonant frequencies are used to calculate dynamic elastic moduli for any grain orientations.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: C 747 – 93 (Reapproved 1998)

Standard Test Method for

Moduli of Elasticity and Fundamental Frequencies of

Carbon and Graphite Materials by Sonic Resonance

This standard is issued under the fixed designation C 747; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the measurement of the funda-

mental transverse, longitudinal, and torsional frequencies of

isotropic and anisotropic carbon and graphite materials. These

measured resonant frequencies are used to calculate dynamic

elastic moduli for any grain orientations.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C215 Test Method for Fundamental Transverse, Longitu-

dinal, and Torsional Frequencies of Concrete Specimens

C559 Test Method for Bulk Density by Physical Measure-

ment of Manufactured Carbon and Graphite Articles

C885 Test Method for Young’s Modulus of Refractory

Shapes by Sonic Resonance

E111 TestMethodforYoung’sModulus,TangentModulus,

and Chord Modulus

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

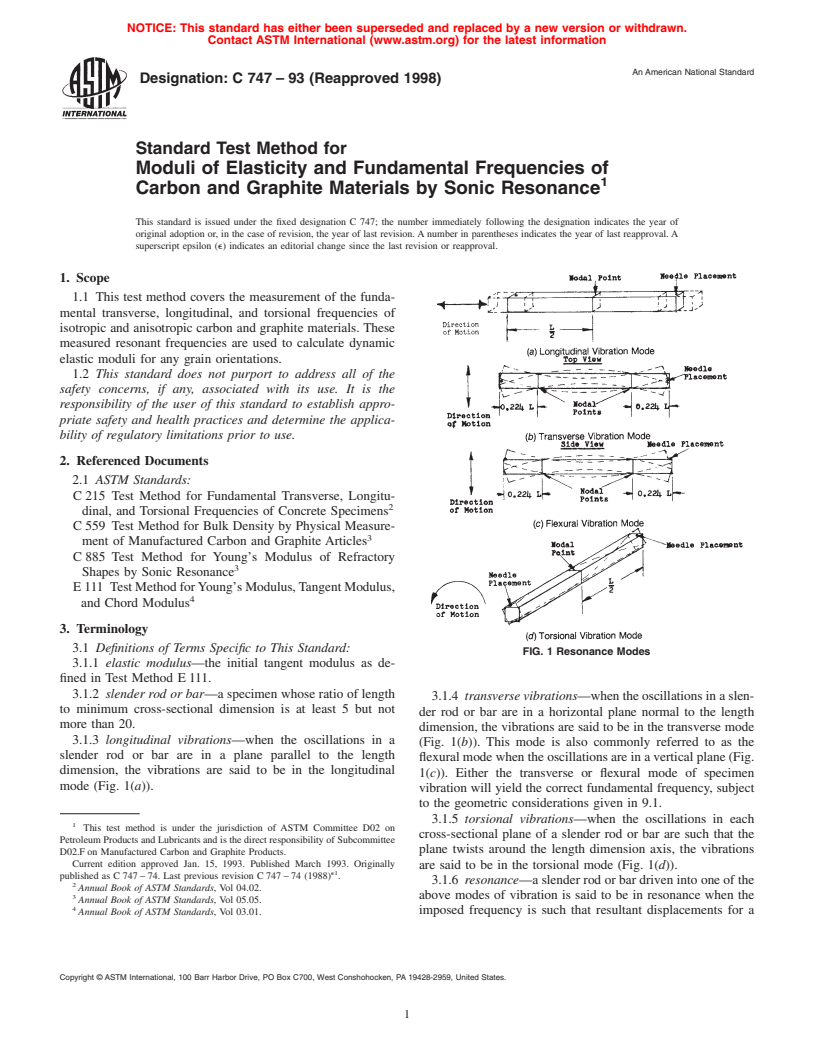

FIG. 1 Resonance Modes

3.1.1 elastic modulus—the initial tangent modulus as de-

fined in Test Method E111.

3.1.2 slender rod or bar—a specimen whose ratio of length

3.1.4 transverse vibrations—whentheoscillationsinaslen-

to minimum cross-sectional dimension is at least 5 but not

der rod or bar are in a horizontal plane normal to the length

more than 20.

dimension, the vibrations are said to be in the transverse mode

3.1.3 longitudinal vibrations—when the oscillations in a

(Fig. 1(b)). This mode is also commonly referred to as the

slender rod or bar are in a plane parallel to the length

flexuralmodewhentheoscillationsareinaverticalplane(Fig.

dimension, the vibrations are said to be in the longitudinal

1(c)). Either the transverse or flexural mode of specimen

mode (Fig. 1(a)).

vibration will yield the correct fundamental frequency, subject

to the geometric considerations given in 9.1.

3.1.5 torsional vibrations—when the oscillations in each

This test method is under the jurisdiction of ASTM Committee D02 on

cross-sectional plane of a slender rod or bar are such that the

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee

plane twists around the length dimension axis, the vibrations

D02.Fon Manufactured Carbon and Graphite Products.

Current edition approved Jan. 15, 1993. Published March 1993. Originally

are said to be in the torsional mode (Fig. 1(d)).

e1

published as C747–74. Last previous revision C747–74 (1988) .

3.1.6 resonance—a slender rod or bar driven into one of the

Annual Book of ASTM Standards, Vol 04.02.

above modes of vibration is said to be in resonance when the

Annual Book of ASTM Standards, Vol 05.05.

Annual Book of ASTM Standards, Vol 03.01. imposed frequency is such that resultant displacements for a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 747

givenamountofdrivingforce(voltage)areatamaximum.The

L = length of the specimen, m, and

resonant frequency is a natural vibration frequency which is

r = density of the specimen as determined by Test Method

determined by the elastic moduli, density, and dimensions of

C559, kg/m .

the test specimen.

3.1.7 nodal points—a slender rod or bar in resonance 5. Significance and Use

contains one or more points having zero displacement, called

5.1 This test method is primarily concerned with the room

nodal points. In the longitudinal and torsional fundamental

temperature determination of the dynamic moduli of elasticity

resonances of a uniform rod or bar, the mid-length point is the

and rigidity of slender rods or bars composed of homoge-

nodal point (Fig. 1(a) and Fig. 1(d)). For the fundamental

neously distributed carbon or graphite particles.

transverse or flexural resonance, the nodal points are located at

5.2 This test method can be adapted for other materials that

0.224 L from each end, where L is the length of the specimen

are elastic in their initial stress-strain behavior, as defined in

(Fig. 1(b) and Fig. 1(c)).

Test Method E111.

5.3 This basic test method can be modified to determine

4. Summary of Test Method

elastic moduli behavior at temperatures from −75°C to

4.1 The dynamic methods of determining the elastic moduli

+2500°C. Thin graphite rods may be used to project the

are based on the measurement of the fundamental resonant

specimen extremities into ambient temperature conditions to

frequencies of a slender rod of circular or rectangular cross

provide resonant frequency detection by the use of transducers

section. The resonant frequencies are related to the specimen

as described in 6.1.

dimensions and material properties as follows:

4.1.1 Transverse or Flexural Mode—The equation for the

6. Apparatus

fundamental resonant frequency of the transverse or flexural

6.1 The fundamental resonant frequencies for the different

mode of vibration is as follows:

modes of vibration of a test specimen can be determined by

E 5 CMf (1) severalestablishedtestingprocedures.Theapparatusdescribed

herein uses phonograph record pickup cartridges as a conve-

where:

nient method of generating and detecting these frequencies.A

E = elastic modulus, Pa,

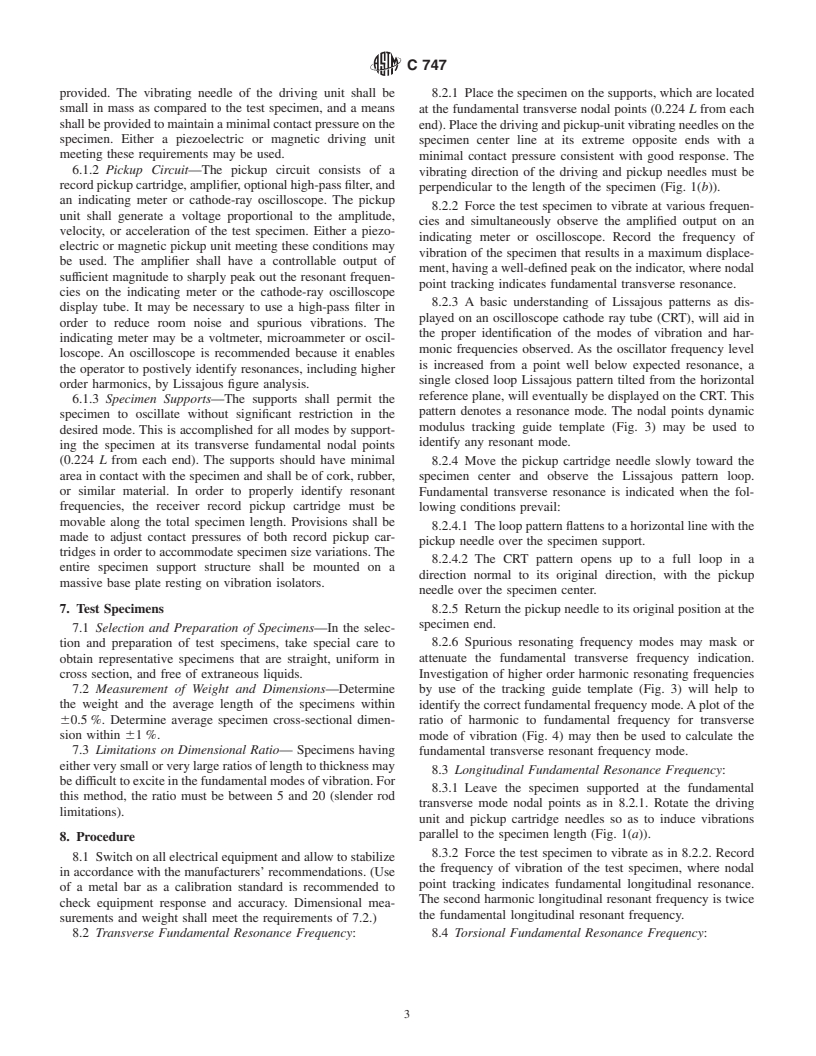

typical testing apparatus is shown schematically in Fig. 2.

C = a dimensional constant that depends upon the shape

6.1.1 Driving Circuit—The driving circuit consists of a

and size of the specimen, and Poisson’s ratio. The

variable-frequency oscillator and a record pickup cartridge

units of C are to be consistent with those of E, M, and

assembly. It is recommended that a variable-frequency oscil-

f,

lator be used in conjunction with a digital-frequency counter.

M = mass of the specimen, kg, and

The oscillator shall have sufficient power output to induce

f = frequency of fundamental transverse or flexural mode

detectable vibrations in the test specimen at frequencies above

of vibration, Hz.

and below the fundamental frequency under consideration.

Means for controlling the output of the oscillator shall be

4.1.2 Longitudinal Mode—The equation for the fundamen-

tal resonant frequency of the longitudinal mode of variation is

as follows:

2 2

E 5 Df L r (2)

where:

E = elastic modulus, Pa,

D = a constant consistent with the units of E, f, and L,

f = frequency of fundamental longitudinal mode of vibra-

tion, Hz,

L = length of the specimen, m, and

r = density of the specimen as determined by Test Method

C559, kg/m .

4.1.3 Torsional Mode—The equation for the fundamental

resonant frequency of the torsional mode of vibration is as

follows:

2 2

G 5RBf L r (3)

where:

G = modulus of rigidity, Pa,

R = ratio of the polar moment of inertia to the shape factor

for torsional rigidity,

B = a constant consistent with the units of G, R, f, L, and r,

FIG. 2 Schematic Diagram of Typical Dynamic Elastic Modulus

f = frequency of fundamental torsional mode of vibration,

Detection Apparatus

Hz,

C 747

provided. The vibrating needle of the driving unit shall be 8.2.1 Place the specimen on the supports, which are located

small in mass as compared to the test specimen, and a means at the fundamental transverse nodal points (0.224 L from each

shallbeprovidedtomaintainaminimalcontactpressureonthe

end).Placethedrivingandpickup-unitvibratingneedlesonthe

specimen. Either a piezoelectric or magnetic driving unit

specimen center line at its extreme opposite ends with a

meeting these requirements may be used.

minimal contact pressure consistent with good response. The

6.1.2 Pickup Circuit—The pickup circuit consists of a

vibrating direction of the driving and pickup needles must be

recordpickupcartridge,amplifier,optionalhigh-passfilter,and

perpendicular to the length of the specimen (Fig. 1(b)).

an indicating meter or cathode-ray oscilloscope. The pickup

8.2.2 Force the test specimen to vibrate at various frequen-

unit shall generate a voltage proportional to the amplitude,

cies and simultaneously observe the amplified output on an

velocity, or acceleration of the test specimen. Either a piezo-

indicating meter or oscilloscope. Record the frequency of

electric or magnetic pickup unit meeting these conditions may

vibration of the specimen that results in a maximum displace-

be used. The amplifier shall have a controllable output of

ment,havingawell-definedpeakontheindicator,wherenodal

sufficient magnitude to sharply peak out the resonant frequen-

point tracking indicates fundamental transverse resonance.

cies on the indicating meter or the cathode-ray oscilloscope

8.2.3 A basic understanding of Lissajous patterns as dis-

display tube. It may be necessary to use a high-pass filter in

played on an oscilloscope cathode ray tube (CRT), will aid in

order to reduce room noise and spurious vibrations. The

the proper identification of the modes of vibration and har-

indicating meter may be a voltmeter, microammeter or oscil-

monic frequencies observed. As the oscillator frequency level

loscope. An oscilloscope is recommended because it enables

is increased from a point well below expected resonance, a

the operator to postively identify resonances, including higher

single closed loop Lissajous pattern tilted from the horizontal

order harmonics, by Lissajous figure analysis.

reference plane, will eventually be displayed on the CRT. This

6.1.3 Specimen Supports—The supports shall permit the

pattern denotes a resonance mode. The nodal points dynamic

specimen to oscillate without significant restriction in the

modulus tracking guide template (Fig. 3) may be used to

desired mode. This is accomplished for all modes by support-

identify any resonant mode.

ing the specimen at its transverse fundamental nodal points

(0.224 L from each end). The supports should have minimal 8.2.4 Move the pickup cartridge needle slowly toward the

area in contact with the specimen and shall be of cork, rubber,

specimen center and observe the Lissajous pattern loop.

or similar material. In order to properly identify resonant Fundamental transverse resonance is indicated when the fol-

frequencies, the receiver record pickup cartridge must be

lowing conditions prevail:

movable along the total specimen length. Provisions shall be

8.2.4.1 Thelooppatternflattenstoahorizontallinewiththe

made to adjust contact pressures of both record pickup car-

pickup needle over the specimen support.

tridges in order to accommodate specimen size variations. The

8.2.4.2 The CRT pattern opens up to a full loop in a

entire specimen support structure shall be mounted on a

direction normal to its original direction, with the pickup

massive base plate resting on vibration isolators.

needle over the specimen center.

7. Test Specimens 8.2.5 Return the pickup needle to its original position at the

specimen end.

7.1 Selection and Preparation of Specimens—In the selec-

8.2.6 Spurious resonating frequency modes may mask or

tion and preparation of test specimens, take special care to

obtain representative specimens that are straight, uniform in attenuate the fundamental transverse frequency indication.

cross section, and free of extraneous liquids. Investigation of higher order harmonic resonating frequencies

7.2 Measurement of Weight and Dimensions—Determine by use of the tracking guide template (Fig. 3) will help to

the weight and the average length of the specimens within identify the correct fundamental frequency mode.Aplot of the

60.5%. Determine average specimen cross-sectional dimen-

ratio of harmonic to fundamental frequency for transverse

sion within 61%. mode of vibration (Fig. 4) may then be used to calculate the

7.3 Limitations on Dimensional Ratio— Specimens having

fundamental transverse resonant frequency mode.

eitherverysmallorverylargeratiosoflengthtothicknessmay

8.3 Longitudinal Fundamental Resonance Frequency:

bedifficulttoexciteinthefundamentalmodesofvibration.For

8.3.1 Leave the specimen supported at the fundamental

this method, the ratio must be between 5 and 20 (slender rod

transverse mode nodal points as in 8.2.1. Rotate the driving

limitations).

unit and pickup cartridge needles so as to induce vibrations

parallel to the specimen length (Fig. 1(a)).

8. Procedure

8.3.2 Force the test specimen to vibrate as in 8.2.2. Record

8.1 Switch on all electrical equipment and allow to stabilize

the frequency of vibration of the test specimen, where nodal

in accordance with the manufacturers’ recommendations. (Use

point tracking indicates fundamental longitudinal resonance.

of a metal bar as a calibration standard is recommended to

The second harmonic longitudinal resonant frequency is twice

check equipment response and accuracy. Dimensional mea-

the fundamental longitudinal resonant frequency.

surements and weight shall meet the requirements of 7.2.)

8.2 Transverse Fundamental Resonance Frequency: 8.4 Torsional Fundamental Resonance Frequency:

C 747

FIG. 3 Nodal Points Dynamic Modulus Tracking Guide Template

8.4.2 Force the specimen to vibrate as in 8.2.2. Record the

frequency of vibration of the test specimen, where nodal point

tracking indicates fundamental torsional resonance. The sec-

ond harmonic torsional resonant frequency is twice the funda-

mental torsional resonant frequency.

9. Calculation

9.1 Calculate the dynamic modulus of elasticity for the

transverse or flexural mode of vibration from the fundamental

transverse frequency, weight, and dimensions of the test

specimen as follows:

Dynamic E 5 CMf (4)

where units are as defined in 3.1.1. The evaluation of the

constant C, because of the complexity of its determination, is

in tabular form. Eq 4 may be rewritten in the forms:

Dynamic E ~pascals!5 A Mf /dforrodswith

c

circularcrosssections (5)

where d is the diameter of the rod in metres, and

Dynamic E ~pascals!5 A Mf /wforbarswith

R

squareorrectangularcrosssections (6)

where w is the width dimension of the bar in metres.

9.1.1 Values of A and A are shown in Annex A1 under

c R

Table A1.1 and Table A1.2. The value of A is given as a

c

function of the diameter-to-length ratio of the sample. The

NOTE—Taken from Pickett, Gerald, “Equations for Computing Elastic

Constants from Flexural andTorsional R

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.