ASTM D3955-04

(Specification)Standard Specification for Electrical Insulating Varnishes

Standard Specification for Electrical Insulating Varnishes

ABSTRACT

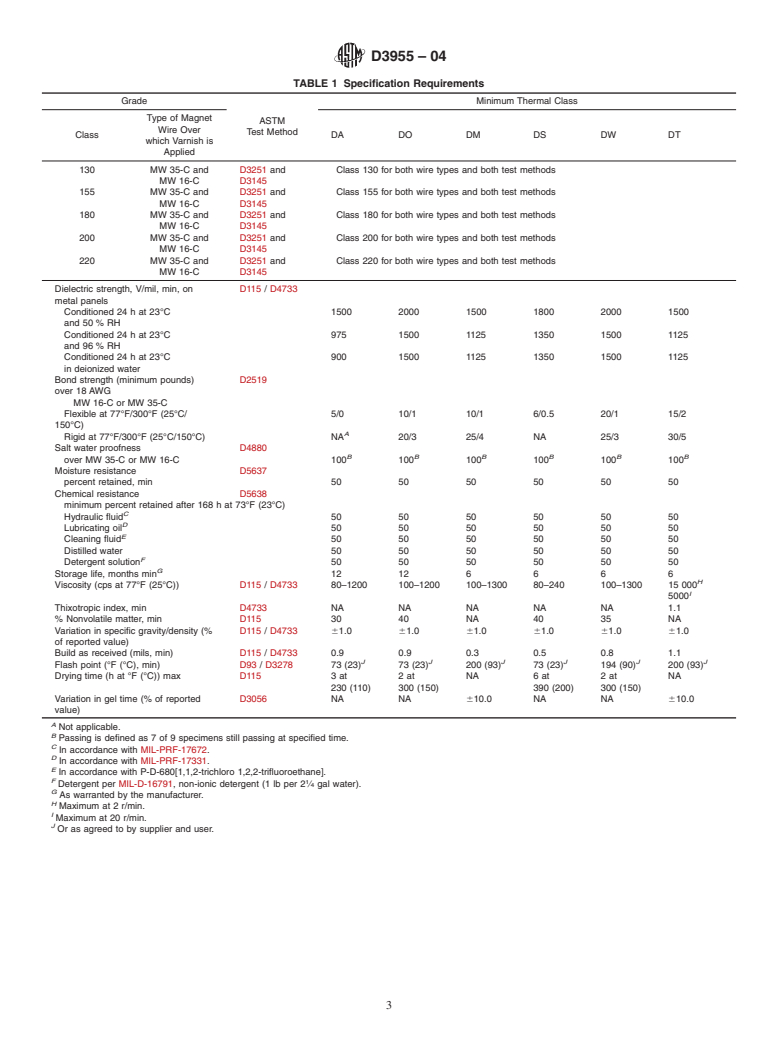

This specification covers the tests and values for electrical insulating varnishes, as supplied, which are suitable for the impregnation and treatment of electrical coils and windings applied by dip process. The varnishes are classified according to grades: Grade DA; Grade DO; Grade DM; Grade DS; Grade DW; and Grade DT. This specification covers both flexible and rigid, solvent and solventless insulating varnishes. The insulating varnishes are classified according to thermal classes: Class 130; Class 155; Class 180; Class 200; and Class 220. Quality conformance tests shall be performed to conform to the specified requirements.

SCOPE

1.1 This specification covers the tests and values for electrical insulating varnishes, as supplied, which are suitable for the impregnation and treatment of electrical coils and windings applied by dip process.

1.2 Varnishes, flexible or rigid, included in this specification are:

Grade DA-Air-dry

Grade DO-Organic solvent containing, baking,

Grade DM-Reactive diluent containing,

Grade DS-Silicone,

Grade DW-Water containing, and

Grade DT-Thixotropic.

1.3 The values given in parentheses are for information only.

Note 1—This specification resembles IEC 60455 in title only. The content is significantly different.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D3955 – 04

Standard Specification for

1

Electrical Insulating Varnishes

This standard is issued under the fixed designation D3955; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3251 Test Method for Thermal Endurance Characteristics

of Electrical Insulating Varnishes Applied Over Film-

1.1 This specification covers the tests and values for elec-

Insulated Magnet Wire

trical insulating varnishes, as supplied, which are suitable for

D3278 Test Methods for Flash Point of Liquids by Small

the impregnation and treatment of electrical coils and windings

Scale Closed-Cup Apparatus

applied by dip process.

D4733 Test Methods for Solventless Electrical Insulating

1.2 Varnishes, flexible or rigid, included in this specification

Varnishes

are:

D4880 Test Method for Salt Water Proofness of Insulating

Grade DA—Air-dry

Varnishes Over Enamelled Magnet Wire

Grade DO—Organic solvent containing, baking,

D5637 Test Method for Moisture Resistance of Electrical

Grade DM—Reactive diluent containing,

Insulating Varnishes

Grade DS—Silicone,

D5638 Test Method for Chemical Resistance of Electrical

Grade DW—Water containing, and

Insulating Varnishes

Grade DT—Thixotropic.

3

2.2 Military Specifications:

1.3 The values stated in inch-pound units are to be regarded

MIL-PRF-17672 Hydraulic Fluid, Petroleum, Inhibited

as standard. The values given in parentheses are mathematical

MIL-PRF-17331 Lubricating Oil, Synthetic Base P-D-680,

conversions to SI units that are provided for information only

Dry Cleaning Solvent

and are not considered standard.

MIL-D-16791 Detergent, General Purpose, (Liquid, Non-

NOTE 1—This specification resembles IEC 60455 in title only. The

Ionic)

content is significantly different.

3

2.3 Other Standards:

NEMA MW1000 Magnet Wire

2. Referenced Documents

IEC 60455 Resin Based Reactive Compounds Used for

2

2.1 ASTM Standards:

Electrical Insulation

D93 Test Methods for Flash Point by Pensky-Martens

Closed Cup Tester

3. Terminology

D115 Test Methods for Testing Solvent Containing Var-

3.1 Definitions—For definitions of terms used in this speci-

nishes Used for Electrical Insulation

fication refer to Terminology D1711.

D1711 Terminology Relating to Electrical Insulation

D2519 Test Method for Bond Strength of Electrical Insu-

4. Flexible or Rigid Classification

lating Varnishes by the Helical Coil Test

4.1 This specification covers both flexible and rigid, solvent

D3056 Test Method for Gel Time of Solventless Varnishes

(including water) and solventless insulating varnishes.

D3145 Test Method for Thermal Endurance of Electrical

Insulating Varnishes by the Helical Coil Method

5. Thermal Classification

5.1 The thermal classification of insulating varnishes cov-

1

ered by this specification is determined by using Test Methods

This specification is under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and is the direct responsibility of

D3145 and D3251 in conjunction with 18 AWG magnet wire

Subcommittee D09.01 on Electrical Insulating Varnishes, Powders and Encapsulat-

conforming to MW 35-C and MW 16-C in accordance with

ing Compounds.

NEMA MW1000. Determine the temperature index at 20 000

Current edition approved March 1, 2004. Published March 2004. Originally

approved in 1980. Last previous edition approved in 1999 as D3955–99. DOI: h.

10.1520/D3955-04.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from Global Engineering Documents, 15 Inverness Way, East

the ASTM website. Englewood, CO 80112.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3955 – 04

5.2 The thermal class is determined from the temperature 7. Hazards

index range as follows:

7.1 It is unsafe to use varnish at temperatures above the

Thermal Class Temperature Index Range

flash point without adequate ventilation, especially if the

130 130.0 to 154.9

155 155.0 to 179.9 possibility exists that flames or sparks are present. Store

180 180.0 to 199.9

varnish in sealed containers.

200 200.0 to 219.9

220 220.0 and above

8. Sampling

6. General Specifications and Qualification Requirements

8.1 Obtain varnish samples and appropriate thinner either

6.1 All varnishes supplied under this specification must

from the manufacturer or directly from shipping containers

conform to th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.