ASTM F2118-14

(Test Method)Standard Test Method for Constant Amplitude of Force Controlled Fatigue Testing of Acrylic Bone Cement Materials

Standard Test Method for Constant Amplitude of Force Controlled Fatigue Testing of Acrylic Bone Cement Materials

SIGNIFICANCE AND USE

5.1 This test method describes a uniaxial, constant amplitude, fully reversed fatigue test to characterize the fatigue performance of a uniform cylindrical waisted specimen manufactured from acrylic bone cement.

5.2 This test method considers two approaches to evaluating the fatigue performance of bone cement:

5.2.1 Testing is conducted at three stress levels to characterize the general fatigue behavior of a cement over a range of stresses. The stress level and resultant cycles to failure of the specimens can plotted on an S-N diagram.

5.2.2 Another approach is to determine the fatigue life of a particular cement. The fatigue life for orthopaedic bone cement is to be determined up to 5 million (5 × 106) cycles.

5.3 This test method does not define or suggest required levels of performance of bone cement. This fatigue test method is not intended to represent the clinical use of orthopaedic bone cement, but rather to characterize the material using standard and well-established methods. The user is cautioned to consider the appropriateness of this test method in view of the material being tested and its potential application.

5.4 It is widely reported that multiple clinical factors affect the fatigue performance of orthopaedic bone cement; however, the actual mechanisms involves multiple factors. Clinical factors which may affect the performance of bone cement include: temperature and humidity, mixing method, time of application, surgical technique, bone preparation, implant design, anatomical site, and patient factors, among others. This test method does not specifically address all of these clinical factors. The test method can be used to compare different acrylic bone cement formulations and products and different mixing methods and environments (that is, mixing temperature, vacuum, centrifugation, and so forth).

SCOPE

1.1 This test method describes test procedures for evaluating the constant amplitude, uniaxial, tension-compression uniform fatigue performance of acrylic bone cement materials.

1.2 This test method is relevant to orthopedic bone cements based on acrylic resins, as specified in Specification F451 and ISO 16402. The procedures in this test method may or may not apply to other surgical cement materials.

1.3 It is not the intention of this test method to define levels of performance of these materials. It is not the intention of this test method to directly simulate the clinical use of these materials, but rather to allow for comparison between acrylic bone cements to evaluate fatigue behavior under specified conditions.

1.4 A rationale is given in Appendix X2.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2118 − 14

Standard Test Method for

Constant Amplitude of Force Controlled Fatigue Testing of

1

Acrylic Bone Cement Materials

This standard is issued under the fixed designation F2118; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F451Specification for Acrylic Bone Cement

2.2 ISO Standard:

1.1 This test method describes test procedures for evaluat-

ISO 16402Flexural Fatigue Testing of Acrylic Resin Ce-

ing the constant amplitude, uniaxial, tension-compression uni-

3

ments Used in Orthopedics

form fatigue performance of acrylic bone cement materials.

1.2 This test method is relevant to orthopedic bone cements

3. Terminology

based on acrylic resins, as specified in Specification F451 and

3.1 Unless otherwise given, the definitions for fatigue ter-

ISO16402.Theproceduresinthistestmethodmayormaynot

minology given in Terminology E1823 will be used.

apply to other surgical cement materials.

3.2 Definitions:

1.3 It is not the intention of this test method to define levels

3.2.1 mean fatigue life at N cycles—the average number of

of performance of these materials. It is not the intention of this

cycles to failure at the specified load level. For the purposes of

test method to directly simulate the clinical use of these

thistestmethod,thefatiguelifewillbedeterminedat5million

materials, but rather to allow for comparison between acrylic

load cycles. A rationale for this is provided in X2.4.

bone cements to evaluate fatigue behavior under specified

3.2.2 median fatigue life at a given stress level—thenumber

conditions.

of cycles to failure at which 50% of the tested samples failed

1.4 A rationale is given in Appendix X2.

at the specified stress level.

1.5 The values stated in SI units are to be regarded as

3.2.3 runout—a predetermined number of cycles at which

standard. No other units of measurement are included in this

the testing on a particular specimen will be stopped, and no

standard.

further testing on that specimen will be performed. For the

1.6 This standard does not purport to address all of the purposes of this test method, the runout will be 5 million load

safety concerns, if any, associated with its use. It is the cycles.

responsibility of the user of this standard to establish appro-

3.2.4 specimenfailure—theconditionatwhichthespecimen

priate safety and health practices and determine the applica-

completelybreaksorisdamagedtosuchanextentthattheload

bility of regulatory limitations prior to use.

frame is no longer able to apply the intended stress within the

required limits.

2. Referenced Documents

3.2.5 stress level—the value of stress at which a series of

2

2.1 ASTM Standards:

duplicate tests are performed. For the purposes of this test

E466Practice for Conducting Force Controlled Constant

method, the stress level is reported as the maximum stress

Amplitude Axial Fatigue Tests of Metallic Materials

applied to the specimen.

E467Practice for Verification of Constant Amplitude Dy-

namic Forces in an Axial Fatigue Testing System

4. Summary of Test Method

E1823TerminologyRelatingtoFatigueandFractureTesting

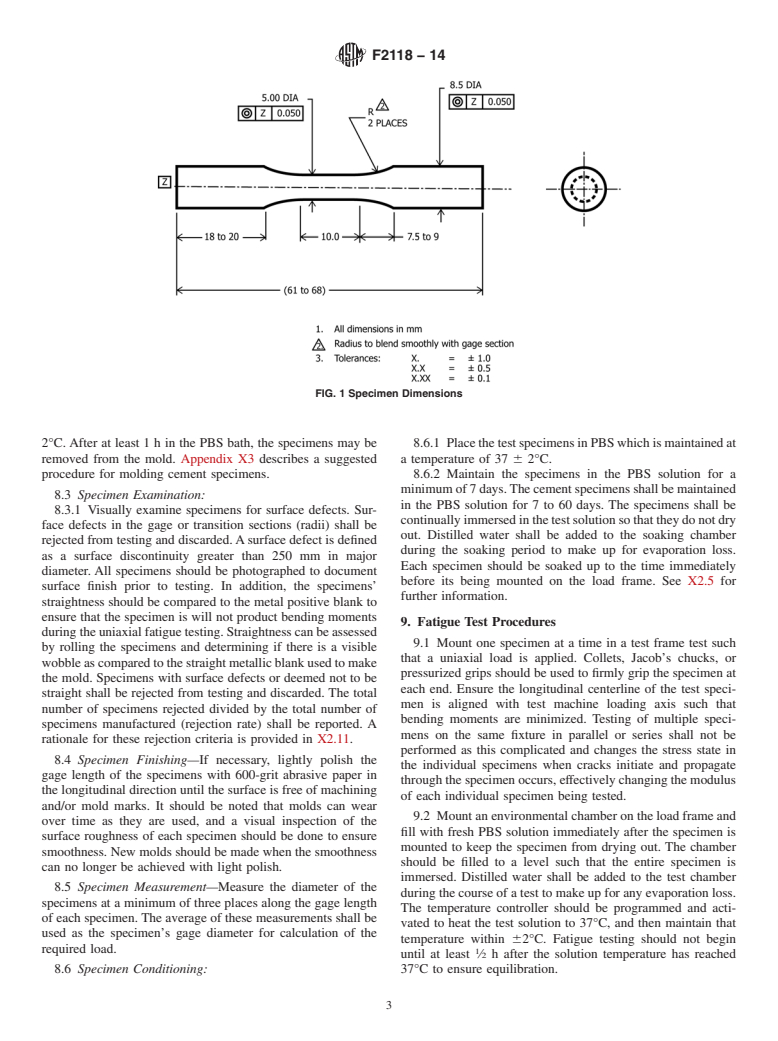

4.1 Uniformcylindricalreducedgagesectiontestspecimens

are manufactured from acrylic bone cement and mounted in a

uniaxial fatigue frame. The specimen is subjected to fully

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF04onMedical

andSurgicalMaterialsandDevicesandisthedirectresponsibilityofSubcommittee reversed tensile and compressive loading in a sinusoidal cyclic

F04.15 on Material Test Methods.

manner at a specified frequency in phosphate buffered saline

Current edition approved Dec. 1, 2014. Published February 2015. Originally

(PBS).Thefatigueloadingiscontinueduntilthespecimenfails

approved in 2001. Last previous edition approved in 2010 as F2118-10.

orapredeterminednumberofcycles(run-outlimit)isreached.

DOI:10.1520/F2118-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2118 − 14

5. Significance and Use 7. Test Specimen

5.1 This test method describes a uniaxial, constant 7.1 Test specimens shall be fabricated from cement that is

amplitude,fullyreversedfatiguetesttocharacterizethef

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2118 − 10 F2118 − 14

Standard Test Method for

Constant Amplitude of Force Controlled Fatigue Testing of

1

Acrylic Bone Cement Materials

This standard is issued under the fixed designation F2118; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

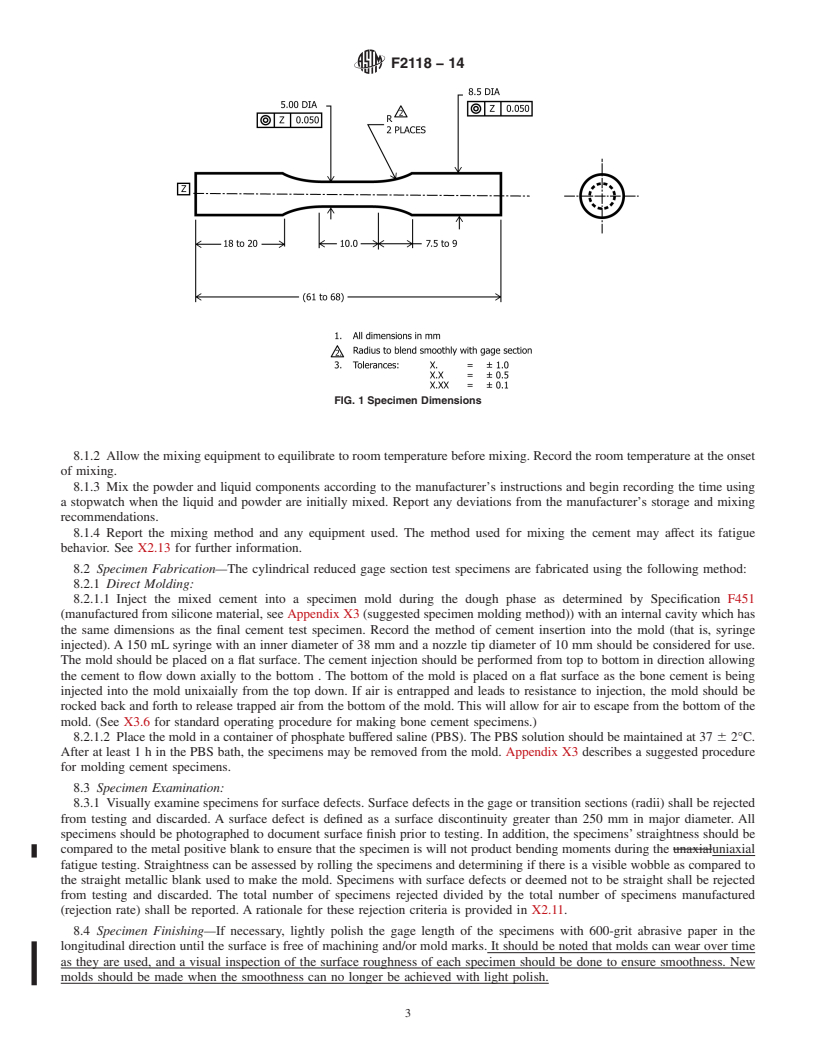

1.1 This test method describes test procedures for evaluating the constant amplitude, uniaxial, tension-compression uniform

fatigue performance of acrylic bone cement materials.

1.2 This test method is relevant to orthopedic bone cements based on acrylic resins, as specified in Specification F451 and ISO

16402. The procedures in this test method may or may not apply to other surgical cement materials.

1.3 It is not the intention of this test method to define levels of performance of these materials. It is not the intention of this

test method to directly simulate the clinical use of these materials, but rather to allow for comparison between acrylic bone cements

to evaluate fatigue behavior under specified conditions.

1.4 A rationale is given in Appendix X2.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E466 Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials

E467 Practice for Verification of Constant Amplitude Dynamic Forces in an Axial Fatigue Testing System

E1823 Terminology Relating to Fatigue and Fracture Testing

F451 Specification for Acrylic Bone Cement

2.2 ISO Standard:

3

ISO 16402 Flexural Fatigue Testing of Acrylic Resin Cements Used in Orthopedics

3. Terminology

3.1 Unless otherwise given, the definitions for fatigue terminology given in Terminology E1823 will be used.

3.2 Definitions:

3.2.1 mean fatigue life at N cycles—the average number of cycles to failure at the specified load level. For the purposes of this

test method, the fatigue life will be determined at 5 million load cycles. A rationale for this is provided in X2.4.

3.2.2 median fatigue life at a given stress level—the number of cycles to failure at which 50 % of the tested samples failed at

the specified stress level.

3.2.3 runout—a predetermined number of cycles at which the testing on a particular specimen will be stopped, and no further

testing on that specimen will be performed. For the purposes of this test method, the runout will be 5 million load cycles.

1

This test method is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.15 on Material Test Methods.

Current edition approved Dec. 1, 2010Dec. 1, 2014. Published January 2011February 2015. Originally approved in 2001. Last previous edition approved in 20092010 as

F2118F 2118 – 03 (2009). -10. DOI:10.1520/F2118-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2118 − 14

3.2.4 specimen failure—the condition at which the specimen completely breaks or is damaged to such an extent that the load

frame is no longer able to apply the intended stress within the required limits.

3.2.5 stress level—the value of stress at which a series of duplicate tests are performed. For the purposes of this test method,

the stress level is reported as the maximum stress applied to the specimen.

4. Summary of Test Method

4.1 Uniform cylindrical reduced gage section test specimens are manufactured from acrylic bone cement and mounted in a

uniaxial fatigue frame. The specimen is subjected to fully reversed tensile and compress

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.