ASTM D849-09

(Test Method)Standard Test Method for Copper Strip Corrosion by Industrial Aromatic Hydrocarbons

Standard Test Method for Copper Strip Corrosion by Industrial Aromatic Hydrocarbons

SIGNIFICANCE AND USE

This test method is suitable for setting specifications, for use as an internal quality control tool, and for use in development or research work on industrial aromatic hydrocarbons and related materials. It also gives an indication of the presence of certain corrosive substances which may corrode equipment, such as acidic compounds or sulfur compounds.

SCOPE

1.1 This test method covers the corrosiveness of industrial aromatic hydrocarbons to a copper strip.

Note 1—For a similar copper strip test applicable to other petroleum products, see Test Method D130 and Test Method D1838.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 8.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D849 – 09

Standard Test Method for

Copper Strip Corrosion by Industrial Aromatic

1

Hydrocarbons

This standard is issued under the fixed designation D849; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

3

1. Scope* 2.2 Other Documents:

OSHA Regulations, 29 CFR paragraphs 1910.1000 and

1.1 This test method covers the corrosiveness of industrial

1910.1200

aromatic hydrocarbons to a copper strip.

2.3 ASTM Adjuncts:

NOTE 1—For a similar copper strip test applicable to other petroleum

ASTM Copper Strip Corrosion Standards (13 photo litho-

products, see Test Method D130 and Test Method D1838.

4

graphed aluminum strips; includes Test Method D130)

1.2 The values stated in SI units are to be regarded as

3. Terminology

standard. No other units of measurement are included in this

standard.

3.1 See Terminology D4790 for definition of terms used in

1.3 This standard does not purport to address all of the

this test method.

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

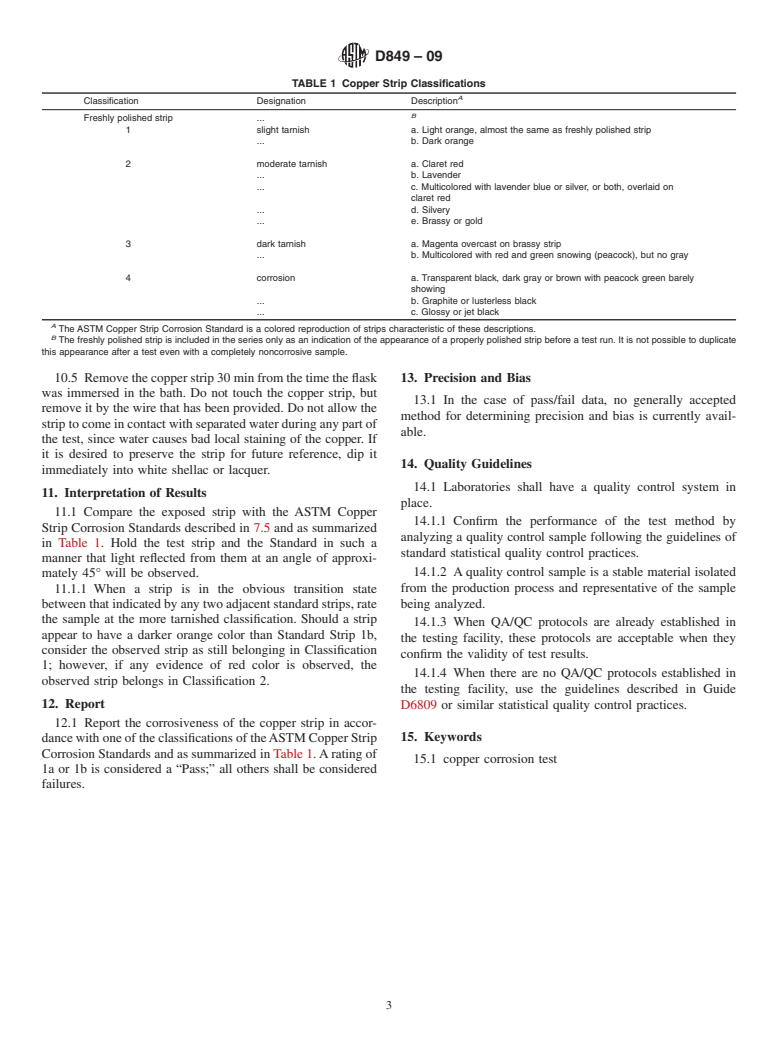

4.1 A polished copper strip is immersed in 200 mL of

bility of regulatory limitations prior to use. For specific hazard specimen in a flask with a condenser and placed in boiling

statements, see Section 8.

water for 30 min. At the end of this period, the copper strip is

removed and compared with the ASTM Copper Strip Corro-

2. Referenced Documents

sion Standards.

2

2.1 ASTM Standards:

5. Significance and Use

B152/B152M Specification for Copper Sheet, Strip, Plate,

and Rolled Bar 5.1 Thistestmethodissuitableforsettingspecifications,for

D130 Test Method for Corrosiveness to Copper from Pe-

use as an internal quality control tool, and for use in develop-

troleum Products by Copper Strip Test mentorresearchworkonindustrialaromatichydrocarbonsand

D1838 Test Method for Copper Strip Corrosion by Lique-

related materials. It also gives an indication of the presence of

fied Petroleum (LP) Gases certain corrosive substances which may corrode equipment,

D4790 TerminologyofAromaticHydrocarbonsandRelated

such as acidic compounds or sulfur compounds.

Chemicals

6. Apparatus

D6809 Guide for Quality Control and Quality Assurance

Procedures for Aromatic Hydrocarbons and Related Ma- 6.1 Flask, of sufficient size to allow for refluxing 200 mL

terials specimen, of chemically resistant glass with flat bottom and

vial mouth.

6.2 Glass Condenser, length may vary, with the inside

diameter of the condenser tube not less than 10 mm.Acork is

used to connect the flask with the condenser. A condenser and

1

This test method is under the jurisdiction of ASTM Committee D16 on

flask with ground-glass joints may also be used.

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

Subcommittee D16.01 on Benzene, Toluene, Xylenes, Cyclohexane and Their

Derivatives.

Current edition approved Dec. 1, 2009. Published January 2010. Originally

3

approved in 1945. Last previous edition approved in 2005 as D849 – 05. DOI: AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

10.1520/D0849-09. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.access.gpo.gov.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from ASTM International Headquarters. Request Adjunct No.

Standards volume information, refer to the standard’s Document Summary page on ADJD0130. Names of suppliers in the United Kingdom can be obtained from the

the ASTM website. Institute of Petroleum. Two master standards are held by the IP for reference.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D849 – 09

6.3 Strip Polishing Vise, (optional), to hold the copper strip results efficiently. Finish with 65-µm (240-grit) silicon-carbide

firmlywithoutmarringtheedges.ForconvenientvisesseeTest paperorcloth,removingallmarksthatmayhavebeenmadeby

Method D130. other grades of paper used previously. Ensure the prepared

6.4 Water Bath, of convenient design, able to maintain copper strip is protected from oxidation prior to final prepara-

boiling water such that the contents of the flask are submerged tion, such as by immersing the strip in

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D849–05 Designation: D849 – 09

Standard Test Method for

Copper Strip Corrosion by Industrial Aromatic

1

Hydrocarbons

This standard is issued under the fixed designation D849; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This test method covers the corrosiveness of industrial aromatic hydrocarbons to a copper strip.

NOTE 1—For a similar copper strip test applicable to other petroleum products, see Test Method D130 and Test Method D1838.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Section 8.

2. Referenced Documents

2

2.1 ASTM Standards:

B152/B152M Specification for Copper Sheet, Strip, Plate, and Rolled Bar

D130 Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test

D1838 Test Method for Copper Strip Corrosion by Liquefied Petroleum (LP) Gases

D4790 Terminology of Aromatic Hydrocarbons and Related Chemicals Terminology of Aromatic Hydrocarbons and Related

Chemicals

D6809 Guide for Quality Control and Quality Assurance Procedures for Aromatic Hydrocarbons and Related Materials

3

2.2 Other Documents:

OSHA Regulations, 29 CFRCFR, paragraphs paragraphs 1910.1000 and 1910.1200

2.3 ASTM Adjuncts:

4

ASTM Copper Strip Corrosion Standards (13 photo lithographed aluminum strips; includes Test Method D130)

3. Terminology

3.1 See Terminology D4790 for definition of terms used in this test method.

4. Summary of Test Method

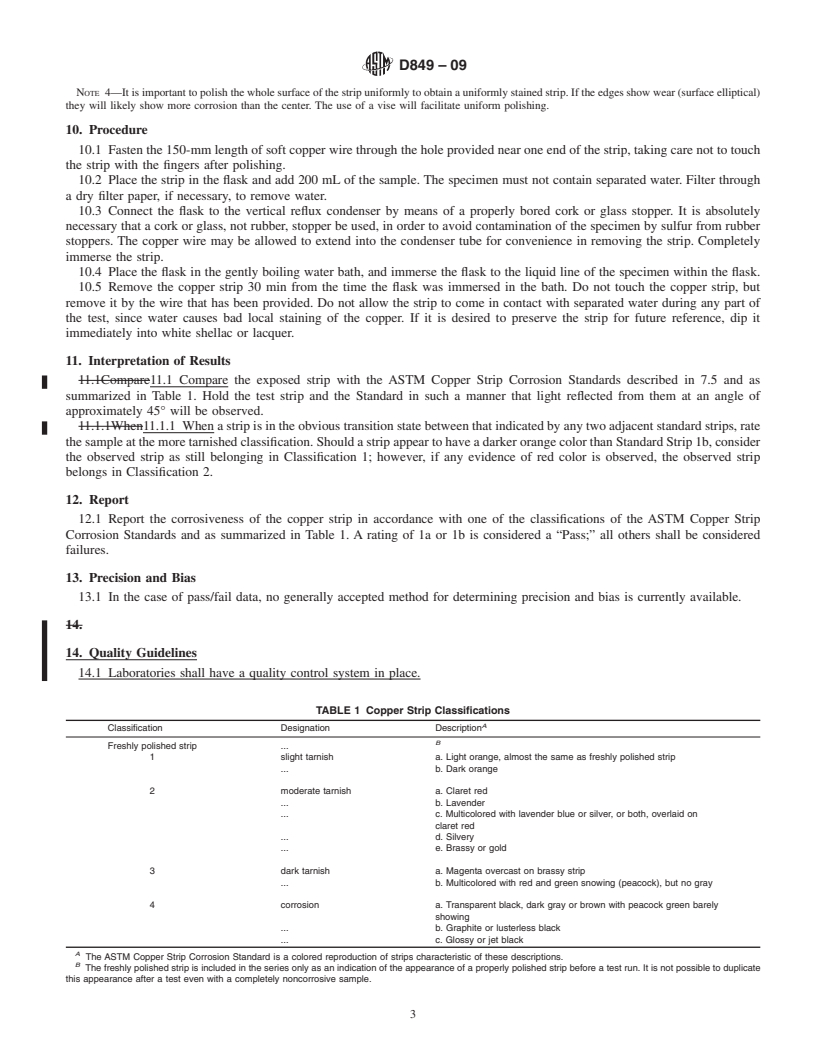

4.1 Apolished copper strip is immersed in 200 mL of specimen in a flask with a condenser and placed in boiling water for 30

min. At the end of this period, the copper strip is removed and compared with the ASTM Copper Strip Corrosion Standards.

5. Significance and Use

5.1 This test method is suitable for setting specifications, for use as an internal quality control tool, and for use in development

or research work on industrial aromatic hydrocarbons and related materials. It also gives an indication of the presence of certain

corrosive substances which may corrode equipment, such as acidic compounds or sulfur compounds.

1

This test method is under the jurisdiction ofASTM Committee D16 onAromatic Hydrocarbons and Related Chemicals and is the direct responsibility of Subcommittee

D16.01 on Benzene, Toluene, Xylenes, Cyclohexane, and Their Derivatives.

Current edition approved JulyDec. 1, 2005.2009. Published July 2005.January 2010. Originally approved in 1945. Last previous edition approved in 20032005 as

D849 – 035. DOI: 10.1520/D0849-059.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

4

Available from ASTM International Headquarters. Request Adjunct No. ADJD0130. Names of suppliers in the United Kingdom can be obtained from the Institute of

Petroleum. Two master standards are held by the IP for reference.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D849 – 09

6. Apparatus

6.1 Flask, of sufficient size to allow for refluxing 200 mL specimen, of chemically resistant glass with flat bottom and vial

mouth.

6.2 Glass Condenser, length may vary, with the inside diameter of the condenser tube not less than 10 mm. A cork is used to

connect the flask with the condenser. A condenser and flask with ground-glass joints may also be used.

6.3 Strip Polishing Vise, (optional), to hold the copper strip firmly without marring the edges. For convenient vises see Te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.