ASTM D4047-13

(Test Method)Standard Test Method for Phosphorus in Lubricating Oils and Additives by Quinoline Phosphomolybdate Method

Standard Test Method for Phosphorus in Lubricating Oils and Additives by Quinoline Phosphomolybdate Method

SIGNIFICANCE AND USE

4.1 Knowledge of the phosphorus content, and thus the phosphorus-containing additives, in a lubricating oil or additive can be used to predict performance characteristics.

SCOPE

1.1 This test method covers the determination of 0.005 to 10.0 mass % phosphorus in unused lubricating oil and additive concentrates. There is no reason to doubt its applicability to filtered, used lubricating oils, but no systematic study of this application has been made.

1.2 The test method is applicable to samples containing any of the phosphorus compounds in normal use. Note 1—This test method extends the scope of the previous version of IP 149 and replaces IP 148 and the previous version of IP 149 as a referee method.

1.3 This test method is free from most interferences because the high insolubility of the quinoline phosphomolybdate precipitate leads to constant composition and freedom from most adsorbed or occluded impurities, especially from cations which would otherwise interfere in the subsequent titration of the precipitate.

1.4 Barium, calcium, magnesium, zinc, iron, aluminum, alkali salts, citric acid and citrates, chromium up to 18 times the phosphorus content, and titanium up to 3.5 times do not interfere with the test method.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 6.9.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4047 − 13

Designation: 149/93

Standard Test Method for

Phosphorus in Lubricating Oils and Additives by Quinoline

1

Phosphomolybdate Method

This standard is issued under the fixed designation D4047; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method covers the determination of 0.005 to

D1193 Specification for Reagent Water

10.0 mass % phosphorus in unused lubricating oil and additive

D6299 Practice for Applying Statistical Quality Assurance

concentrates. There is no reason to doubt its applicability to

and Control Charting Techniques to Evaluate Analytical

filtered, used lubricating oils, but no systematic study of this

Measurement System Performance

application has been made.

2.2 IP Standard:

1.2 The test method is applicable to samples containing any

IP 148 Test Method for Phosphorous in Lubricating Oils

of the phosphorus compounds in normal use.

3

and Additives

NOTE 1—This test method extends the scope of the previous version of

3. Summary of Test Method

IP149 and replaces IP148 and the previous version of IP149 as a referee

method.

3.1 Additive concentrates are diluted with phosphorus-free

white oil to produce a working blend.

1.3 Thistestmethodisfreefrommostinterferencesbecause

the high insolubility of the quinoline phosphomolybdate pre-

3.2 Thesampleisignitedwithexcessofzincoxidewhereby

cipitate leads to constant composition and freedom from most

phosphorus is converted to phosphate.The residue is dissolved

adsorbedoroccludedimpurities,especiallyfromcationswhich

in hydrochloric acid and any sulfide formed is oxidized with

would otherwise interfere in the subsequent titration of the

potassium bromate. Phosphorus is then precipitated as quino-

precipitate.

line phosphomolybdate and determined volumetrically by

addition of excess standard alkali and back titration with

1.4 Barium, calcium, magnesium, zinc, iron, aluminum,

standard acid.

alkali salts, citric acid and citrates, chromium up to 18 times

the phosphorus content, and titanium up to 3.5 times do not

4. Significance and Use

interfere with the test method.

4.1 Knowledge of the phosphorus content, and thus the

1.5 The values stated in SI units are to be regarded as

phosphorus-containing additives, in a lubricating oil or addi-

standard. No other units of measurement are included in this

tive can be used to predict performance characteristics.

standard.

5. Apparatus

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 5.1 Silica Crucibles, 40-mm internal diameter at the top and

40 mm in height. The internal surface should be smooth and

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- free from pitting.

bility of regulatory limitations prior to use. For specific hazard

5.2 Muffle Furnace,capableofmaintainingatemperatureof

statements, see 6.9.

approximately 700°C, and fitted with ports to allow air

circulation.

1 2

This test method is under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

D02.03 on Elemental Analysis. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved June 15, 2013. Published August 2013. Originally the ASTM website.

3

approved in 1981. Last previous edition approved in 2011 as D4047– 00 (2011). Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

DOI: 10.1520/D4047-13. U.K., http://www.energyinst.org.uk.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

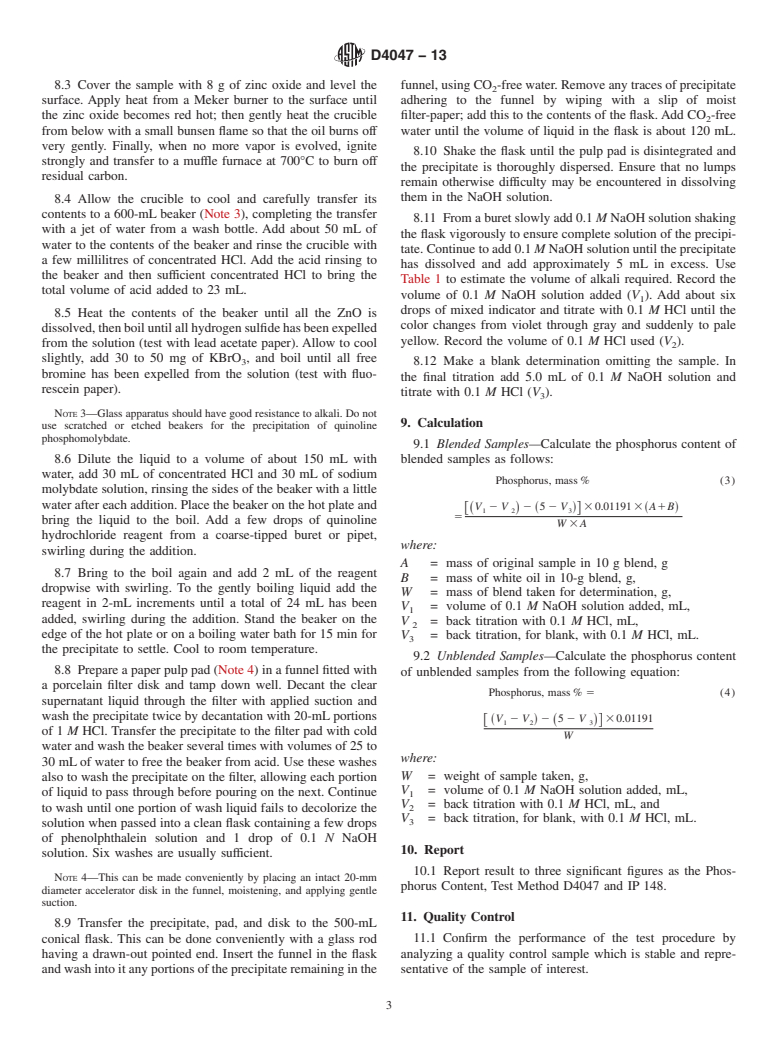

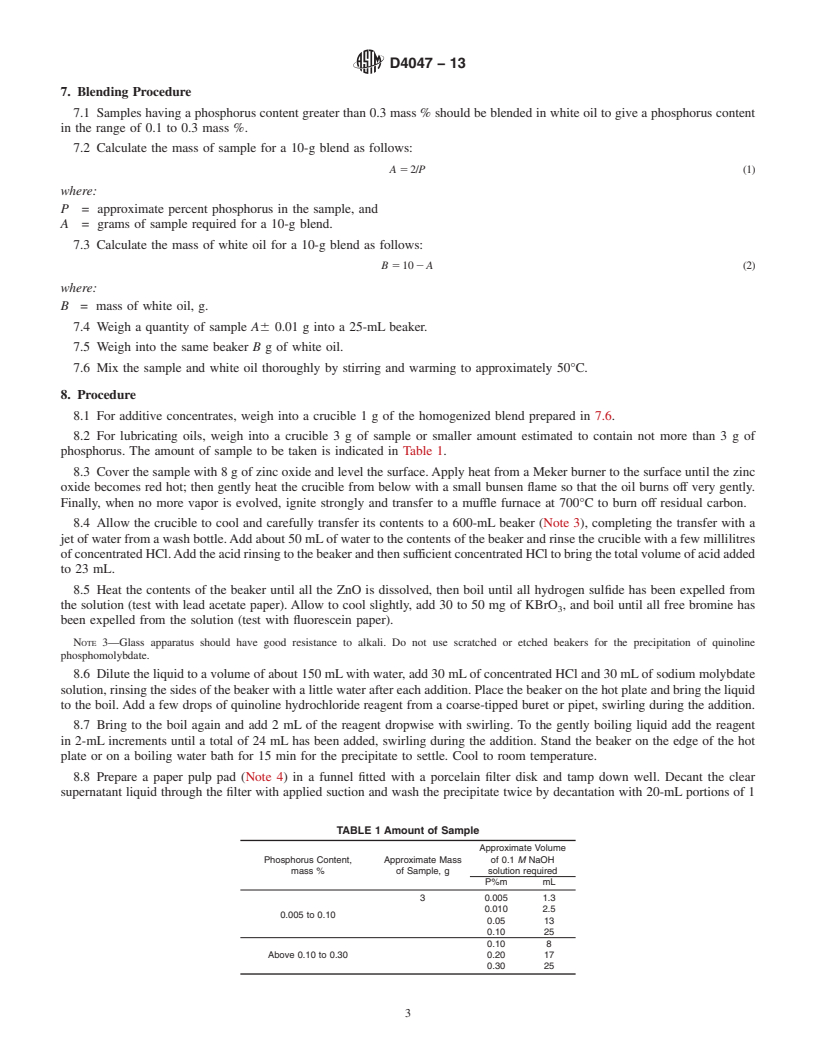

D4047 − 13

alkalinereagents,includingsodiummolybdatesolution,storeinpolythene

5.3 Beakers, 25-mL capacity.

containers.

5.4 Filtering Apparatus, a filter flask of capacity 500 mL,

6.13 Thymol Blue Solution (1 g/L) in 95 % volume ethanol.

provided with a glass crucible adapter fitted in a rubber bung

together with a rubber sleeve. 6.14 Zinc Oxide (ZnO), finely divided.

5.5 Gooch Crucible, porcelain, 35 mm diameter at the top, 6.15 Lead Acetate Test Paper.

or a filter funnel fitted with a porcelain filter disk

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4047 − 00 (Reapproved 2011) D4047 − 13

Designation: 149/93

Standard Test Method for

Phosphorus in Lubricating Oils and Additives by Quinoline

1

Phosphomolybdate Method

This standard is issued under the fixed designation D4047; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Scope*

1.1 This test method covers the determination of 0.005 to 10.0 mass % phosphorus in unused lubricating oil and additive

concentrates. There is no reason to doubt its applicability to filtered, used lubricating oils, but no systematic study of this

application has been made.

1.2 The test method is applicable to samples containing any of the phosphorus compounds in normal use.

NOTE 1—This test method extends the scope of the previous version of IP 149 and replaces IP 148 and the previous version of IP 149 as a referee

method.

1.3 This test method is free from most interferences because the high insolubility of the quinoline phosphomolybdate precipitate

leads to constant composition and freedom from most adsorbed or occluded impurities, especially from cations which would

otherwise interfere in the subsequent titration of the precipitate.

1.4 Barium, calcium, magnesium, zinc, iron, aluminum, alkali salts, citric acid and citrates, chromium up to 18 times the

phosphorus content, and titanium up to 3.5 times do not interfere with the test method.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see 6.9.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

2.2 IP Standard:

3

IP 148 Test Method for Phosphorous in Lubricating Oils and Additives

3. Summary of Test Method

3.1 Additive concentrates are diluted with phosphorus-free white oil to produce a working blend.

3.2 The sample is ignited with excess of zinc oxide whereby phosphorus is converted to phosphate. The residue is dissolved

in hydrochloric acid and any sulfide formed is oxidized with potassium bromate. Phosphorus is then precipitated as quinoline

phosphomolybdate and determined volumetrically by addition of excess standard alkali and back titration with standard acid.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.03 on

Elemental Analysis.

Current edition approved May 1, 2011June 15, 2013. Published May 2011August 2013. Originally approved in 1981. Last previous edition approved in 20052011 as

D4047– 00 (2005).(2011). DOI: 10.1520/D4047-00R11.10.1520/D4047-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR, U.K., http://www.energyinst.org.uk.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4047 − 13

4. Significance and Use

4.1 Knowledge of the phosphorus content, and thus the phosphorus-containing additives, in a lubricating oil or additive can be

used to predict performance characteristics.

5. Apparatus

5.1 Silica Crucibles, 40-mm internal diameter at the top and 40 mm in height. The internal surface should be smooth and free

from pitting.

5.2 Muffle Furnace, capable of maintaining a temperature of approximately 700°C, and fitted with ports to allow air circulation.

5.3 Beakers, 25-mL capacity.

5.4 Filtering Apparatus, a filter flask of capacity 500 mL, provided with a g

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.