ASTM D6244-06(2011)

(Test Method)Standard Test Method for Vertical Compression of Geocomposite Pavement Panel Drains

Standard Test Method for Vertical Compression of Geocomposite Pavement Panel Drains

SIGNIFICANCE AND USE

The vertical compression test for geocomposite pavement panel drains is intended to simulate vertical, horizontal, and eccentric loading resulting from an applied vertical load. The results of the analyses, including vertical strain of the panels and core area change, may be used as an index test. The vertical compression test may be used to evaluate core area change for a given load.

The vertical compression test may be used to evaluate percent vertical strain for a given load.

This test method may be modified to evaluate core area change and vertical strain under various backfill conditions.

SCOPE

1.1 This test method covers vertical strain and core area change of geocomposite pavement drains, such as those included in Specification D7001, under vertical compression.

1.2 The values as stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6244 − 06 (Reapproved 2011)

Standard Test Method for

Vertical Compression of Geocomposite Pavement Panel

Drains

This standard is issued under the fixed designation D6244; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3.1 Discussion—In compression testing of

geosynthetics, gage length is the measured thickness of the test

1.1 This test method covers vertical strain and core area

specimen under specified compressional force, expressed in

change of geocomposite pavement drains, such as those

units of length.

included in Specification D7001, under vertical compression.

3.1.4 geosynthetic, n—a planar product manufactured from

1.2 The values as stated in SI units are to be regarded as the

polymeric material used with foundation, soil, rock, earth, or

standard. The values given in parentheses are for information

any other geotechnical engineering-related materials as an

only.

integral part of a manmade project, structure, or system (see

1.3 This standard does not purport to address all of the

Terminology D4439).

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1.5 index test, n—a test procedure, which may contain a

priate safety and health practices and determine the applica-

known bias but which may be used to order a set of specimens

bility of regulatory limitations prior to use.

with respect to the property of interest (see Terminology

D4439).

2. Referenced Documents

2.1 ASTM Standards:

4. Summary of Test Method

D1566 Terminology Relating to Rubber

4.1 Geocomposite pavement edge drains are placed into a

D4354 Practice for Sampling of Geosynthetics and Rolled

304.8-mm (12-in.) long, 106.7-mm (4.20-in.) wide, and

Erosion Control Products(RECPs) for Testing

610-mm (24-in.) tall glass and aluminum compression cham-

D4439 Terminology for Geosynthetics

ber. The geocomposites are placed against the wall of the

D7001 Specification for Geocomposites for Pavement Edge

chamber. The remainder of the chamber is then backfilled with

Drains and Other High-Flow Applications

a specified sand. A vertical load is applied at a constant rate.

3. Terminology

The vertical strains of the panels and change in core area and

height is recorded at 1112.5-N (250-lb) increments. The test is

3.1 Definitions of Terms Specific to This Standard:

3.1.1 compressive deformation, n—the decrease in gage discontinued at 4450 N (1 000 lb) or 156.5 kPa (22.7 psi). The

length produced in the test specimen by a compressive load, change in vertical strain, core height, and core area is deter-

expressed in units of length (new). mined.

3.1.2 compressive strain, n—the ratio of compressive defor-

5. Significance and Use

mation to the gage length of the test specimen, expressed as a

dimensionless ratio (new).

5.1 The vertical compression test for geocomposite pave-

3.1.3 gage length, n—the known distance between two

ment panel drains is intended to simulate vertical, horizontal,

bench marks (see Terminology D1566).

and eccentric loading resulting from an applied vertical load.

The results of the analyses, including vertical strain of the

panels and core area change, may be used as an index test. The

This test method is under the jurisdiction of ASTM Committee D35 on

Geosynthetics and is the direct responsibility of Subcommittee D35.01 on Mechani-

vertical compression test may be used to evaluate core area

cal Properties.

change for a given load.

Current edition approved Oct. 1, 2011. Published November 2011. Originally

approved in 1998. Last previous edition approved in 2006 as D6244 - 06. DOI:

5.2 The vertical compression test may be used to evaluate

10.1520/D6244-06R11.

2 percent vertical strain for a given load.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.3 This test method may be modified to evaluate core area

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. change and vertical strain under various backfill conditions.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6244 − 06 (2011)

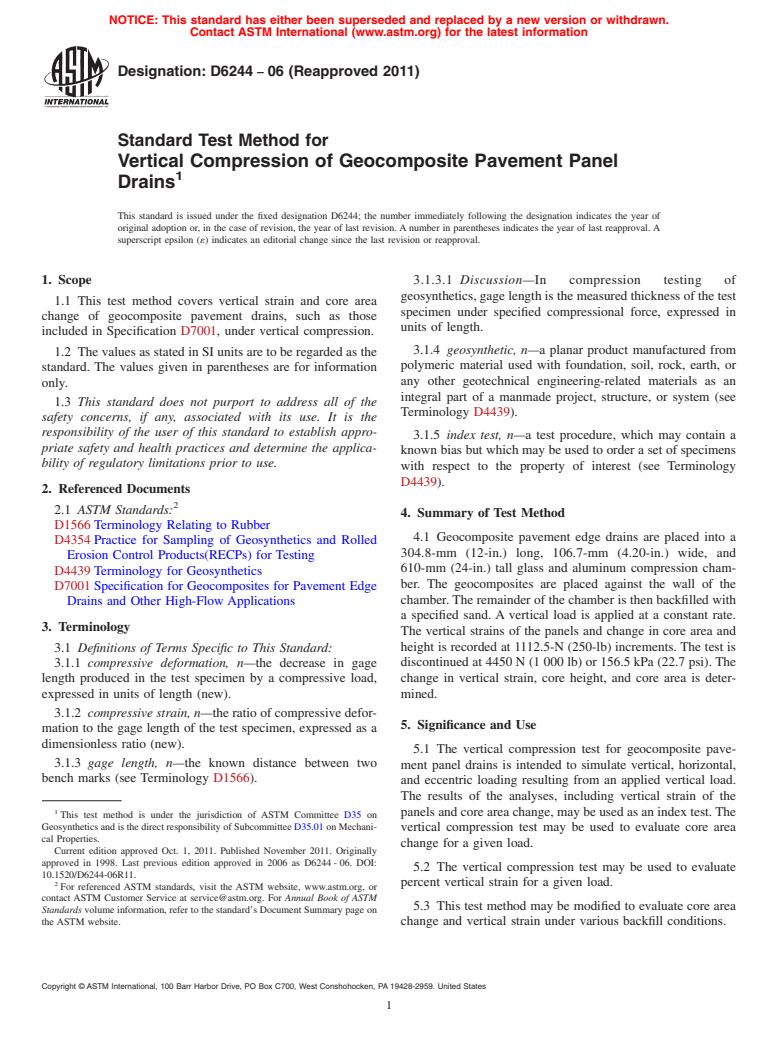

6. Apparatus 6.2 Compression Box—The box must be capable of holding

the specimen and the backfill material, and it must be capable

6.1 Compression Machine—A compression machine that is

of supporting a minimum vertical load of 4450 N (1 000 lb).

capable of producing at least 4450 N (1 000 lb) of load. The

The design of the box and the loading plate shall conform to

machine must be capable of loading at a rate of 445 N (100

the attached Fig. 1. The box shall be rigid enough to resist

lbs)/min, and maintaining a constant load for an indefinite

deformation.

period.

FIG. 1 Edge Drain Compression Chamber

D6244 − 06 (2011)

TABLE 1 Backfill Gradation

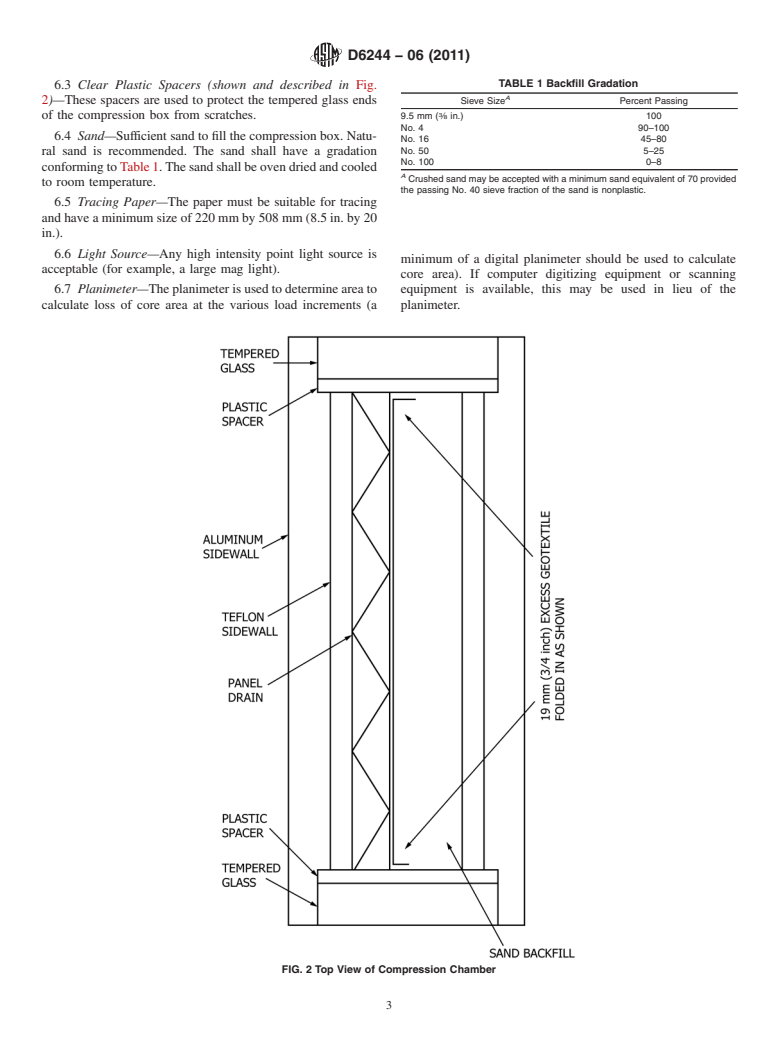

6.3 Clear Plastic Spacers (shown and described in Fig.

A

2)—These spacers are used to protect the tempered glass ends Sieve Size Percent Passing

of the compression box from scratches. 9.5mm( ⁄8 in.) 100

No. 4 90–100

6.4 Sand—Sufficient sand to fill the compression box. Natu-

No. 16 45–80

No. 50 5–25

ral sand is recommended. The sand shall have a gradation

No. 100 0–8

conformingtoTable1.Thesandshallbeovendriedandcooled

A

Crushed sand may be accepted with a minimum sand equivalent of 70 provided

to room temperature.

the passing No. 40 sieve fraction of the sand is nonplastic.

6.5 Tracing Paper—The paper must be suitable for tracing

and have a minimum size of 220 mm by 508 mm (8.5 in. by 20

in.).

6.6 Light Source—Any high intensity point light source is

minimum of a digital planimeter should be used to calculate

acceptable (for example, a large mag light).

core area). If computer digitizing equipment or scanning

6.7 Planimeter—Theplanimeterisusedtodetermineareato equipment is available, this may be used in lieu of the

calculate loss of core area at the various load increments (a planimeter.

FIG. 2 Top View of Compression Chamber

D6244 − 06 (2011)

6.8 Scale (Length Measuring Device)—A minimum range thetrench.Thesampleshallbeplacedintothechamberinsuch

of 450 mm (18 in.), and an accuracy of 1 mm ( ⁄16 in.). a way that the maximum core area of the panel is visible

through the ends of the box. If necessary, the samples shall be

7. Sampling

snugged into place with thin panes of plexiglass, 3.2 mm

(0.125 in.) and 6.4 mm (0.25 in.) are recommended, to ensure

7.1 Lot Sample—Divide the product into lots and take the

proper tightness on the walls of the chamber.

lot sample as directed in Practice D4354.

NOTE 5—The panes shall not be forced into place. This could cause

7.2 Laboratory Sample—Consider the units in the lot

compression or misalignment in the sample.

sample as the units in the laboratory sample for the lot to be

tested.Takeforalaboratorysampleasampleextendingthefull

9.3 The 19 mm ( ⁄4 in.) excess geotextile at the ends of the

width of the geocomposite edge drain, of sufficient length so

core shall be lapped as shown in Fig. 2. This helps to prevent

that the requirements in 7.3 are met.

sand from flowing between the end of the core and the glass

endwall and reduces end effects.

NOTE 1—This test method only addresses products with uniform

(parallel and perpendicular) geometry. This procedure does not address

9.4 Pour the oven-dried sand into the compression box to a

products with other geometry.

height of at least 101.6 mm (4 in.) above the top of the core of

7.3 The height of the geocomposite edge drain sample

the panel. The sand shall be poured into the chamber from a

testedshallbeequaltotheheightofthedraininthefieldunless

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.