ASTM D1552-01

(Test Method)Standard Test Method for Sulfur in Petroleum Products (High-Temperature Method)

Standard Test Method for Sulfur in Petroleum Products (High-Temperature Method)

SCOPE

1.1 This test method covers three procedures for the determination of total sulfur in petroleum products including lubricating oils containing additives, and in additive concentrates. This test method is applicable to samples boiling above 177°C (350°F) and containing not less than 0.06 mass % sulfur. Two of the three procedures use iodate detection; one employing an induction furnace for pyrolysis, the other a resistance furnace. The third procedure uses IR detection following pyrolysis in a resistance furnace.

1.2 Petroleum coke containing up to 8 mass % sulfur can be analyzed.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 1552 – 01

Standard Test Method for

1

Sulfur in Petroleum Products (High-Temperature Method)

This standard is issued under the fixed designation D 1552; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * factor is employed to obtain accurate results. The combustion

products are passed into an absorber containing an acid

1.1 This test method covers three procedures for the deter-

solution of potassium iodide and starch indicator. A faint blue

mination of total sulfur in petroleum products including

color is developed in the absorber solution by the addition of

lubricating oils containing additives, and in additive concen-

standard potassium iodate solution. As combustion proceeds,

trates. This test method is applicable to samples boiling above

bleaching the blue color, more iodate is added. The amount of

177°C (350°F) and containing not less than 0.06 mass % sulfur.

standard iodate consumed during the combustion is a measure

Two of the three procedures use iodate detection; one employ-

of the sulfur content of the sample.

ing an induction furnace for pyrolysis, the other a resistance

3.2 IR Detection System—The sample is weighed into a

furnace. The third procedure uses IR detection following

special ceramic boat which is then placed into a combustion

pyrolysis in a resistance furnace.

furnace at 1371°C (2500°F) in an oxygen atmosphere. Most

1.2 Petroleum coke containing up to 8 mass % sulfur can be

sulfur present is combusted to SO which is then measured

2

analyzed.

with an infrared detector after moisture and dust are removed

1.3 This standard does not purport to address all of the

by traps. A microprocessor calculates the mass percent sulfur

safety concerns, if any, associated with its use. It is the

from the sample weight, the integrated detector signal and a

responsibility of the user of this standard to establish appro-

predetermined calibration factor. Both the sample identification

priate safety and health practices and determine the applica-

number and mass percent sulfur are then printed out. The

bility of regulatory limitations prior to use.

calibration factor is determined using standards approximating

2. Referenced Documents the material to be analyzed.

2.1 ASTM Standards:

4. Significance and Use

2

D 1193 Specification for Reagent Water

4.1 This test method provides a means of monitoring the

D 1266 Test Method for Sulfur in Petroleum Products

3

sulfur level of various petroleum products and additives. This

(Lamp Method)

knowledge can be used to predict performance, handling, or

D 4057 Practice for Manual Sampling of Petroleum and

4

processing properties. In some cases the presence of sulfur

Petroleum Products

compounds is beneficial to the product and monitoring the

D 6299 Practice for Applying Statistical Quality Assurance

depletion of sulfur can provide useful information. In other

Techniques to Evaluate Analytical Measurement System

5

cases the presence of sulfur compounds is detrimental to the

Performance

processing or use of the product.

3. Summary of Test Method

5. Interferences

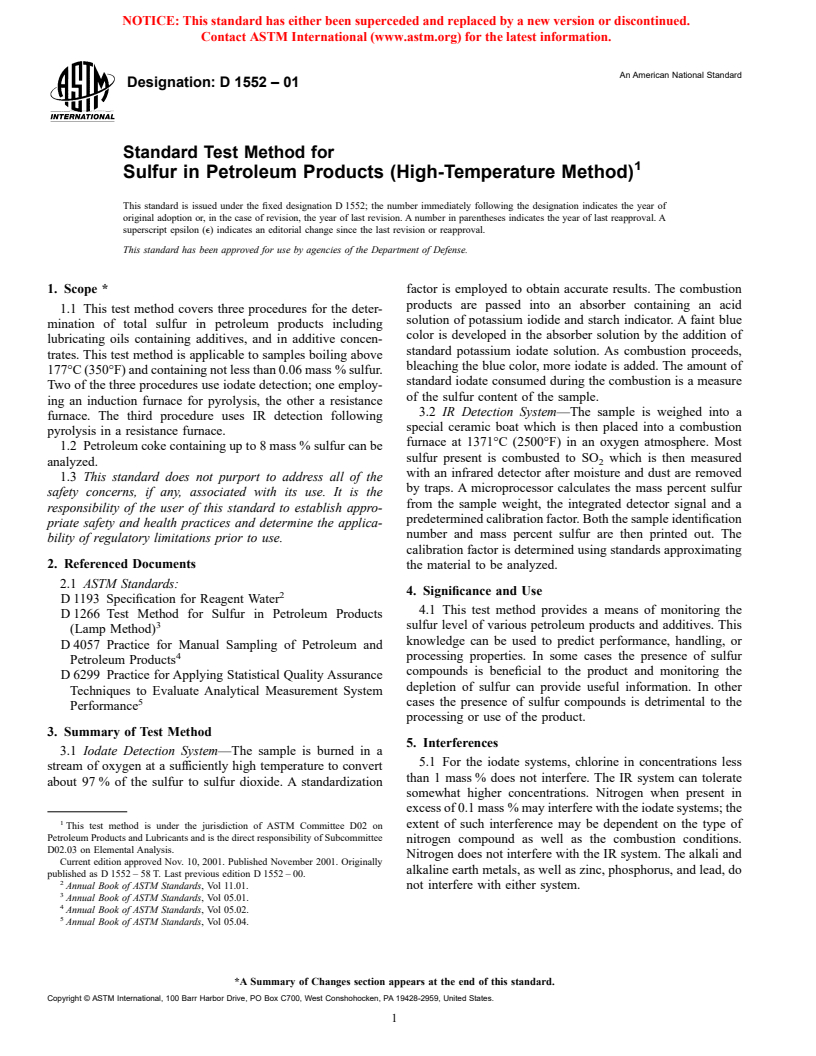

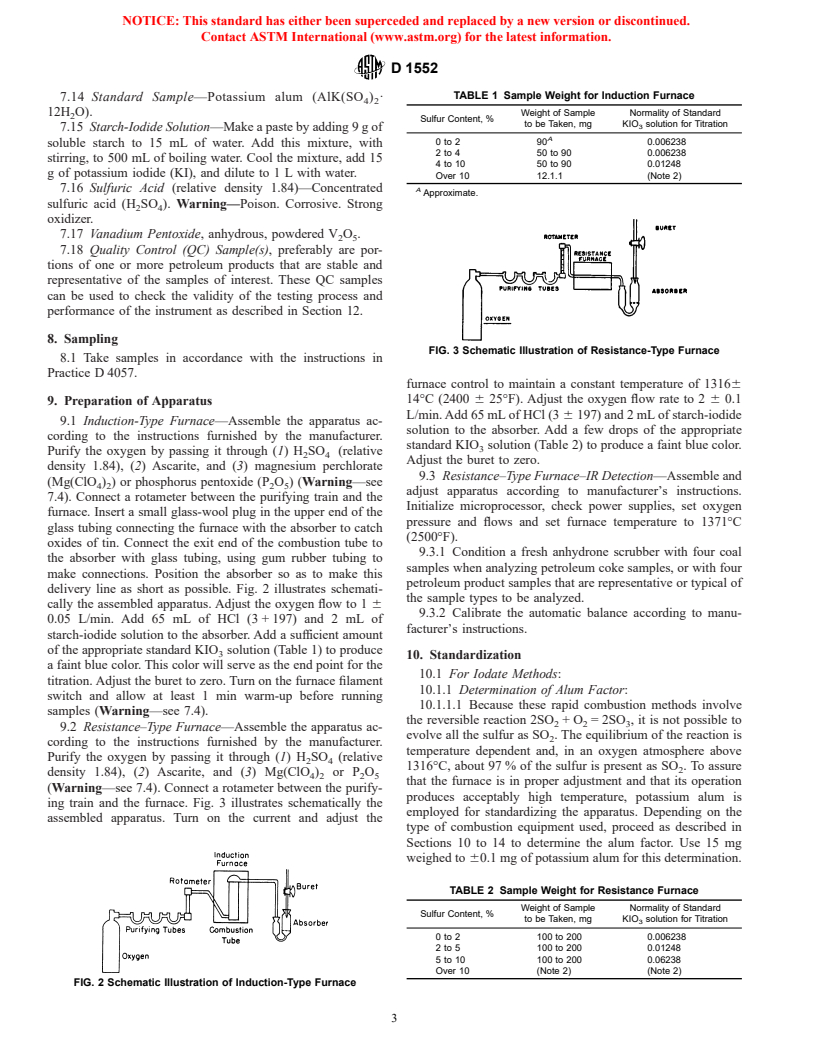

3.1 Iodate Detection System—The sample is burned in a

5.1 For the iodate systems, chlorine in concentrations less

stream of oxygen at a sufficiently high temperature to convert

than 1 mass % does not interfere. The IR system can tolerate

about 97 % of the sulfur to sulfur dioxide. A standardization

somewhat higher concentrations. Nitrogen when present in

excess of 0.1 mass % may interfere with the iodate systems; the

1

extent of such interference may be dependent on the type of

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

nitrogen compound as well as the combustion conditions.

D02.03 on Elemental Analysis.

Nitrogen does not interfere with the IR system. The alkali and

Current edition approved Nov. 10, 2001. Published November 2001. Originally

alkaline earth metals, as well as zinc, phosphorus, and lead, do

published as D 1552 – 58 T. Last previous edition D 1552 – 00.

2

Annual Book of ASTM Standards, Vol 11.01. not interfere with either system.

3

Annual Book of ASTM Standards, Vol 05.01.

4

Annual Book of ASTM Standards, Vol 05.02.

5

Annual Book of ASTM Standards, Vol 05.04.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

----------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.