ASTM F110-00a

(Test Method)Standard Test Method for Thickness of Epitaxial or Diffused Layers in Silicon by the Angle Lapping and Staining Technique (Withdrawn 2003)

Standard Test Method for Thickness of Epitaxial or Diffused Layers in Silicon by the Angle Lapping and Staining Technique (Withdrawn 2003)

SCOPE

This standard was transferred to SEMI (www.semi.org) May 2003

1.1 This test method covers a procedure suitable for interlaboratory comparisons of layer thickness. This test method is applicable for layers of any resistivity so long as the layer differs from the silicon substrate under it either in conductivity type or in resistivity by at least one order of magnitude. The method described is destructive in nature but is more widely applicable than the alternate infrared method, Test Method F95.

1.2 For layers with thicknesses between 1 and 25 µm, an interlaboratory precision as defined in Practice E177, of +(0.15 T + 0.5 µm) (3S) can be achieved where T represents thickness expressed in micrometres.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 8.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 110 – 00a

Standard Test Method for

Thickness of Epitaxial or Diffused Layers in Silicon by the

Angle Lapping and Staining Technique

This standard is issued under the fixed designation F 110; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers a procedure suitable for inter- 3.1 Definitions:

laboratory comparisons of layer thickness. This test method is 3.1.1 diffused layer—a region of opposite conductivity type

applicable for layers of any resistivity so long as the layer formed near the surface of a silicon crystal as a result of the

differs from the silicon substrate under it either in conductivity introduction of impurities into the silicon crystal by means of

type or in resistivity by at least one order of magnitude. The solid state diffusion.

method described is destructive in nature but is more widely 3.1.2 epitaxial layer—in semiconductor technology, a layer

applicable than the alternate infrared method, Test Method of semiconducting material having the same crystalline spacing

F 95. as the host substrate on which it is grown.

1.2 For layers with thicknesses between 1 and 25 μm, an 3.1.3 layer boundary—for the purpose of this test method,

interlaboratory precision as defined in Practice E 177, of the interface between the layer and substrate as revealed by this

6(0.15 T + 0.5 μm) (3S) can be achieved where T represents test method.

thickness expressed in micrometres.

4. Summary of Test Method

1.3 This standard does not purport to address all of the

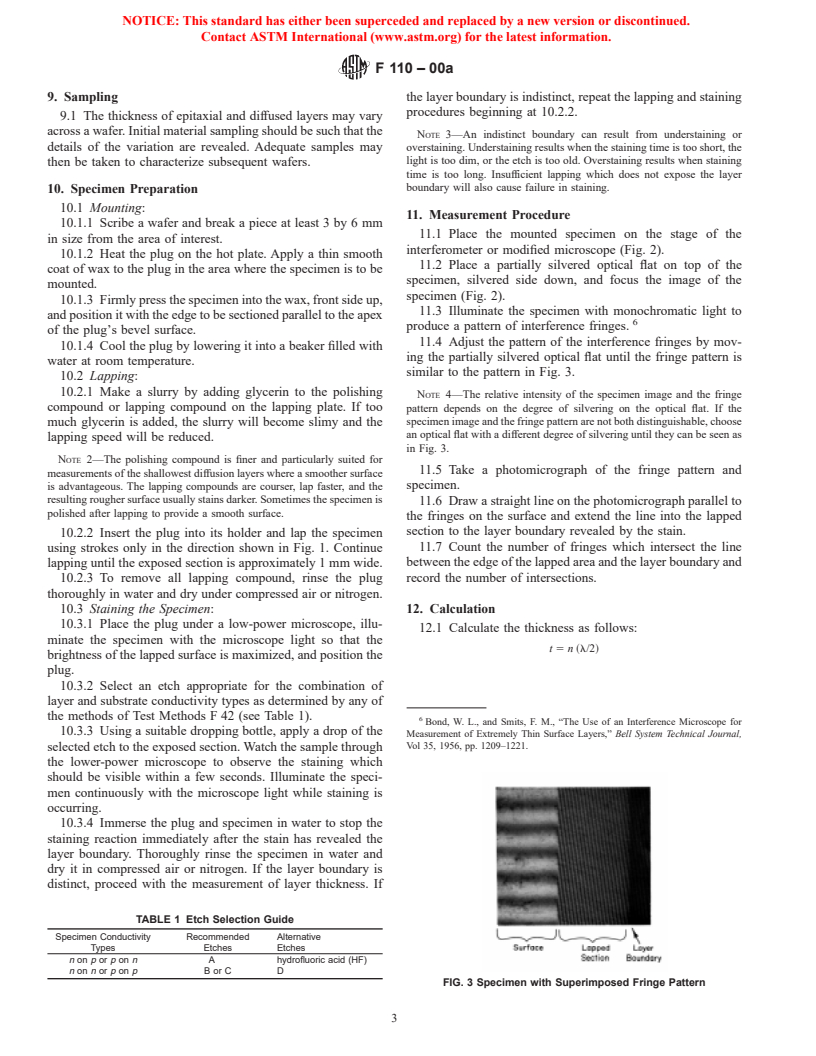

safety concerns, if any, associated with its use. It is the 4.1 The specimen is lapped to obtain a section inclined at a

small angle to the original surface. The boundary of the layer

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- is revealed by a chemical stain and illuminated with mono-

chromatic light through a partially silvered optical flat to

bility of regulatory limitations prior to use. Specific hazard

statements are given in Section 8. produce interference fringes. A photomicrograph of the fringe

pattern and specimen is taken and the thickness is determined

2. Referenced Documents

from the number of fringes.

2.1 ASTM Standards:

5. Significance and Use

E 177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods 5.1 Epitaxial growth and dopant diffusion processes are

used extensively in the manufacture of silicon electron devices.

F 42 Test Methods for Conductivity Type of Extrinsic

Measurement of the resulting layer thickness is a key factor in

Semiconducting Materials

F 95 Test Method for Thickness of Lightly Doped Silicon the control of these processes. Epitaxial and diffusion layer

thickness measurements are also used to determine the suit-

Epitaxial Layers on Heavily Doped Silicon Substrates

Using a Dispersive Infrared Spectrophotometer ability of silicon wafers for subsequent steps in electron-device

manufacture.

2.2 SEMI Standard:

C 28 Specifications for Hydrofluoric Acid 5.2 The thickness as determined by various methods de-

pends on the impurity profile in the layer. Therefore, the layer

C 30 Specification for Hydrogen Peroxide

C 35 Specification for Nitric Acid thickness determined by this test method may not be equal to

the layer thickness determined in accordance with Test Method

F 95 or to the depth of the electrical junction below the surface.

This test method is under the jurisdiction of ASTM Committee F1 on

5.3 The test method is suitable for process control, research

Electronics and is the direct responsibility of Subcommittee F01.06 on Silicon

and development, and materials acceptance purposes.

Materials and Process Control.

Current edition approved Dec. 10, 2000. Published February 2001. Originally

published as F110 – 69 T. Last previous edition F 110 – 00.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 10.05.

Available from the Semiconductor Equipment and Materials International,

3081 Zanker Road, San Jose, CA 95135 (www. semi.org).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 110 – 00a

6. Apparatus

6.1 Angle Lapping— A plug and plug holder which hold the

specimen at an angle of 1 to 5° (Fig. 1), flat frosted-glass

lapping plate, a hot plate, a diamond scriber, and tweezers are

required.

6.2 Etching—Containers of polyethylene or polypropylene

suitable for use with hydrofluoric acid. A low-power micro-

scope is required for checking the progress of the etch in

staining the specimen.

NOTE 1—Special consideration is necessary in choosing a microscope

used in the staining procedure. The etches used contain hydrofluoric acid,

the vapors of which will fog glass lenses. An objective lens with a long

working distance is recommended to retard this effect.

6.3 Optical Measurements:

6.3.1 A research microscope adapted for use in this proce-

dure or a special purpose two-beam interferometer is required.

Several partially silvered optical flats or microscope slides of

FIG. 2 Interference Microscope

different transmission values, and a source of monochromatic

light such as a mercury or sodium-vapor lamp are required if a

microscope is to be adapted (Fig. 2).

the reagent is of sufficiently high purity to permit its use

6.3.2 A camera for photomicrography of the fringe pattern.

without lessening the accuracy of the determination.

7.2 Purity of Water— Reference to water shall be under-

7. Reagents and Materials

stood to mean either distilled water, or deionized water, having

7.1 Purity of Reagents—All chemicals for which specifica-

a resistivity greater than 2 MV·cm.

tions exist shall conform to Grade 1, SEMI specifications for

7.3 Compressed Air or Nitrogen—Oil free and suitable for

those specific chemicals. Reagents for which SEMI specifica-

drying.

tions have not been developed shall conform to the specifica-

7.4 Etch A—Add 8 drops of nitric acid (HNO )to50mLof

tions of the Committee on Analytical Reagents of the American

hydrofluoric acid (HF).

Chemical Society, where such specifications are available.

7.5 Etch B—Mix 30 mL of hydrofluoric acid (HF) and 15

Other grades may be used provided it is first ascertained that

mL of hydrogen peroxide (H O ).

2 2

7.6 Etch C—Add to 10 mL of hydrofluoric acid (HF), 4

drops of nitric acid (HNO ) and 2 drops of silver nitrate

solution.

Reagent Chemicals, American Chemical Society Specifications, American

7.7 Etch D—Add 1 to 3 drops of nitric acid (HNO )to20

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

mL of hydrofluoric acid (HF).

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia 7.8 Glycerin.

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

7.9 Lapping Compound— Alumina or silicon carbide hav-

MD.

ing particle sizes in the range from 6 to 12 μm.

7.10 Mounting Wax— Glycol phthalate or a suitable wax

can be prepared from a mixture of 500 parts carnauba wax, 225

parts cherry-bark rosin, and 25 parts bee’s wax, by weight.

7.11 Polishing Compound—Alpha-phase alumina having

an average particle size of 0.3 μm.

7.12 Silver Nitrate Solution—Dissolve 2.0 g silver nitrate

(AgNO ) in water and dilute to 100 mL with water.

7.13

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.