ASTM C1293-95

(Test Method)Standard Test Method for Determination of Length Change of Concrete Due to Alkali-Silica Reaction

Standard Test Method for Determination of Length Change of Concrete Due to Alkali-Silica Reaction

SCOPE

1.1 This specification covers uranium ore concentrate containing a minimum of 65 mass % uranium.

1.2 This specification does not include requirements for health and safety. Observance of this specification does not relieve the user of the obligation to be aware of and conform to all applicable international, national, state, and local regulations pertaining to possessing, shipping, or using source nuclear material (see 2.2).

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1293 – 95

Standard Test Method for

Concrete Aggregates by Determination of Length Change of

Concrete Due to Alkali-Silica Reaction

This standard is issued under the fixed designation C 1293; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 295 Guide for Petrographic Examination of Aggregates

for Concrete

1.1 This test method covers the determination, by measure-

C 490 Practice for Use of Apparatus for the Determination

ment of length change of concrete prisms, of the susceptibility

of Length Change of Hardened Cement Paste, Mortar, and

of a sample of an aggregate for participation in expansive

Concrete

alkali-silica reaction involving hydroxide ions associated with

C 511 Specification for Moist Cabinets, Moist Rooms, and

alkalies (sodium and potassium).

Water Storage Tanks Used in the Testing of Hydraulic

1.2 This standard does not purport to address all of the

Cements and Concretes

safety concerns, if any, associated with its use. It is the

C 702 Practice for Reducing Field Samples of Aggregate to

responsibility of the user of this standard to establish appro-

Testing Size

priate safety and health practices and determine the applica-

C 856 Practice for Petrographic Examination of Hardened

bility of regulatory limitations prior to use.

Concrete

1.3 The values stated in SI units are to be regarded as the

D 75 Practice for Sampling Aggregates

standard. The inch-pound values in parentheses are for infor-

D 1193 Specification for Reagent Water

mation only.

2.2 CSA Standards:

2. Referenced Documents CSA A23.1-M90 Concrete Materials and Methods of Con-

crete Construction, Appendix B

2.1 ASTM Standards:

CSA A23.2-14A-M90 Potential Expansivity of Aggregates

C 1260 Test Method for Potential Alkali Reactivity of

(Procedure for Length Change due to Alkali-Aggregate

Aggregates (Mortar Bar Method) (formerly Proposal

Reaction in Concrete Prisms)

P 214)

C 33 Specification for Concrete Aggregates

3. Terminology

C 125 Terminology Relating to Concrete and Concrete

3.1 Terminology used in this standard is as given in Termi-

Aggregates

nology C 125 or Descriptive Nomenclature C 294.

C 138 Test Method for Unit Weight, Yield, and Air Content

(Gravimetric) of Concrete

4. Significance and Use

C 143 Test Method for Slump of Hydraulic Cement Con-

4.1 Alkali-silica reaction is a chemical interaction between

crete

3 some siliceous constituents of concrete aggregates or particles

C 150 Specification for Portland Cement

of such constituents in fine aggregates and hydroxyl ions (1).

C 157 Test Method for Length Change of Hardened

2 The concentration of hydroxyl ion within the concrete is

Hydraulic-Cement Mortar and Concrete

predominantly controlled by the concentration of sodium and

C 192 Practice for Making and Curing Concrete Test Speci-

2 potassium (2).

mens in the Laboratory

4.2 This test method is intended to evaluate the potential of

C 227 Test Method for Potential Alkali Reaction of

2 an aggregate to expand deleteriously due to any form of

Cement-Aggregate Combinations (Mortar-Bar Method)

alkali-silica reactivity (3,4).

C 289 Test Method for Potential Reactivity of Aggregates

2 4.3 When selecting a sample or deciding on the number of

(Chemical Method)

samples for test, it is important to recognize the variability in

C 294 Descriptive Nomenclature of Constituents of Natural

2 lithography of material from a given source, whether a deposit

Mineral Aggregates

of sand, gravel, or a rock formation of any origin. For specific

This test method is under the jurisdiction of ASTM Committee C-9 on Concrete

and Concrete Aggregates and is the direct responsibility of Subcommittee C09.26 on Annual Book of ASTM Standards, Vol 11.01.

Chemical Reactions. Canadian Standards Association Standards for Concrete Construction, 173

Current edition approved May 15, 1995. Published July 1995. Rexdale Blvd., Rexdale, Ontario Canada, MaW1R3.

2 6

Annual Book of ASTM Standards, Vol 04.02. The boldface numbers in parentheses refer to the list of references at the end of

Annual Book of ASTM Standards, Vol 04.01. this test method.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C 1293

advice, see Guide C 295. bottom. Fill the container with water to a depth of 20 6 5mm

4.4 This test method is intended for evaluating the behavior above the bottom. A significant moisture loss is defined as a

of aggregates in an alkaline environment. This test method loss greater than 3 % of the original amount of water placed at

assesses the potential for deleterious expansion of concrete the bottom of the pail. Place a wick of absorbent material

caused by alkali-silica reaction, of either coarse or fine aggre- consisting of polypropylene fibers around the inside wall of the

gates, from tests performed under prescribed laboratory curing container from the top so that the bottom of the wick extends

conditions that will probably differ from field conditions. Thus, into the reagent water.

actual field performance will not be duplicated due to differ- 5.2.2 Alternative Containers—Alternative storage contain-

ences in wetting and drying, temperature, other factors, or ers may be used. Confirm the efficiency of the alternative

combinations of these (5). storage container with an alkali-reactive aggregate of known

4.5 Results of tests conducted as described herein should expansion characteristics. The expansion efficiency is con-

form a part of the basis for a decision as to whether precautions firmed when expansions at one year obtained using the

should be taken against excessive expansion due to alkali-silica alternative container are within 10 % of those obtained using

reaction. This decision should be made before a particular the recommended container. Alternative storage containers

aggregate is used in concrete construction. Criteria to deter- must contain the required depth of reagent water. When

mine the potential deleteriousness of expansions measured in reporting results, note the use of an alternative container, if one

this test are given in Appendix X1. is utilized, together with documentation proving compliance

4.6 The basic intent of this test method is to develop with the above.

information on a particular aggregate at a specific alkali level 5.3 The storage environment necessary to maintain the

3 3

of 5.25 kg/m (8.85 lb/yd ). It has been found that this high 38.0°C (100.4°F) reaction accelerating storage temperature

alkali level is required to identify certain deleteriously reactive consistently and homogeneously is described in 5.3.1.

aggregates (3). 5.3.1 Recommended Environment—The recommended stor-

4.7 When the expansions in this test method are greater than age environment is a sealed space insulated so as to minimize

the limit shown in X1.2, the aggregate is potentially alkali- heat loss. Provide a fan for air circulation so the maximum

reactive. Supplemental information should be developed to variation in temperature measured within 250 mm (9.8 in.) of

confirm that the expansion is actually due to alkali-silica the top and bottom of the space does not exceed 2.0°C (3.6°F).

reaction. Petrographic examination of the concrete prisms Provide an insulated entry door with adequate seals so as to

should be conducted after the test using Practice C 856 to minimize heat loss. Racks for storing containers within the

confirm that known reactive constituents are present and to space are not to be closer than 30 mm (1.2 in.) to the sides of

identify the products of alkali-silica reactivity. Confirmation of the enclosure and are to be perforated so as to provide air flow.

alkali-silica reaction is also derived from the results of the test Provide an automatically controlled heat source to maintain the

methods this procedure supplements (see Appendix X1). temperature at 38.0 6 2.0°C (100.4 6 3.6°F) (see Note 1).

4.8 If the supplemental tests show that a given aggregate is Record the ambient temperature and its variation within the

potentially deleteriously reactive, additional studies may be space to ensure compliance.

appropriate to evaluate preventive measures in order to allow

NOTE 1—It has been found to be good practice to monitor the efficiency

safe use of the aggregate. Preventive measures are mentioned

of the storage environment by placing thermocouples inside dummy

in Specification C 33.

concrete specimens inside a dummy container within the storage area. The

storage room described in Test Method C 227 generally will be satisfac-

5. Apparatus

tory.

5.1 The molds, the associated items for molding test speci-

5.3.2 Alternative Storage Environment—Use of an alterna-

mens, and the length comparator for measuring length change

tive storage environment is permitted. Confirm the efficiency

conform to the applicable requirements of Test Method C 157

of the alternative storage container with an alkali-reactive

and Practice C 490, and shall have square cross sections of 8

aggregate of known expansion characteristics. The expansion

75.0 6 0.7 mm (3.00 6 0.03 in.).

efficiency is confirmed when expansions at one year obtained

5.2 The storage container options required to maintain the

using the alternative storage environment are within 10 % of

prisms at a high relative humidity are described in 5.2.1.

those obtained using the recommended environment. When

5.2.1 Recommended Container—The recommended con-

reporting the results, note the use of an alternative storage

tainers are 22-litre (5-gal) polyethylene pails with airtight lids

environment, if one is utilized, together with documentation

and approximate dimensions of 250- to 270-mm (9.8- to

proving compliance with the above.

10.6-in.) diameter at bottom, 290 to 310 mm (11.4 to 12.2 in.)

at top, by 450 to 480 mm (17.7 to 18.9 in.) high. Prevent

6. Reagents

significant loss of enclosed moisture due to evaporation with

6.1 Sodium Hydroxide (NaOH)—USP or technical grade

airtight lid seal. Place a perforated rack in the bottom of the

may be used.

storage container so that the prisms are 30 to 40 mm above the

7 8

Polyethylene pails used in the food industry have been found to be suitable. Non-reactive aggregates and alkali-silica reactive aggregates of known expan-

Twenty two-litre pails (Model Nos.: pail, 5251; lid, 63493), are available from IPL sion characteristics (6) are available from The Petrographer, Engineering Materials

Products Ltd., 348 Park Street, Suite 201, East Building, North Reading, Mass. Office, Ministry of Transportation, 1201 Wilson Ave., Downsview, Ontario, Canada,

01864. M3M1J8.

C 1293

NOTE 2—Precaution: Before using NaOH, review: (1) the safety

sieve is of such a composition and lithology that no difference

precautions for using NaOH; (2) first aid for burns; and (3) the emergency

should be expected compared with the smaller size material,

response to spills as described in the manufacturers Material Safety Data

then no further attention need be paid to the larger sizes. If

Sheet or other reliable safety literature. NaOH can cause severe burns and

petrographic examination suggests the larger size material to

injury to unprotected skin and eyes. Always use suitable personal

be more reactive, the material should be studied for its effect in

protective equipment including: full-face shields, rubber aprons, and

concrete according to one or the other alternative procedures

gloves impervious to NaOH (Check periodically for pinholes.).

described herein:

6.2 Water:

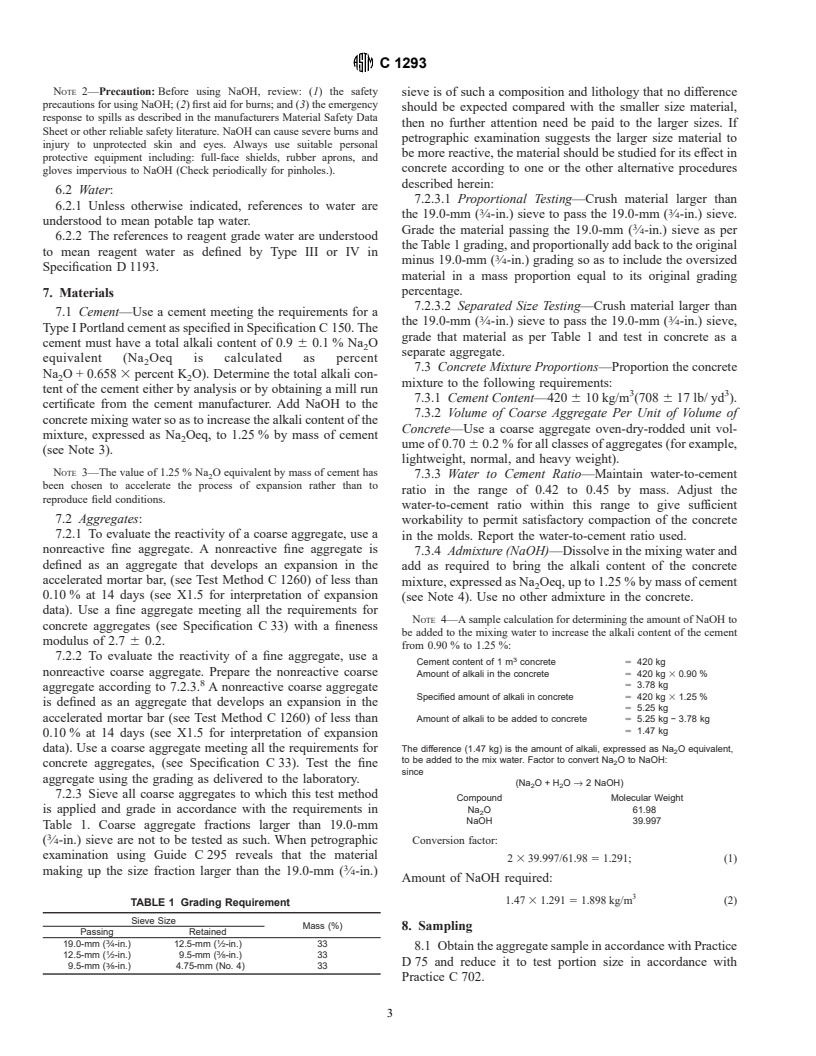

7.2.3.1 Proportional Testing—Crush material larger than

6.2.1 Unless otherwise indicated, references to water are

3 3

the 19.0-mm ( ⁄4-in.) sieve to pass the 19.0-mm ( ⁄4-in.) sieve.

understood to mean potable tap water.

Grade the material passing the 19.0-mm ( ⁄4-in.) sieve as per

6.2.2 The references to reagent grade water are understood

the Table 1 grading, and proportionally add back to the original

to mean reagent water as defined by Type III or IV in

minus 19.0-mm ( ⁄4-in.) grading so as to include the oversized

Specification D 1193.

material in a mass proportion equal to its original grading

percentage.

7. Materials

7.2.3.2 Separated Size Testing—Crush material larger than

7.1 Cement—Use a cement meeting the requirements for a

3 3

the 19.0-mm ( ⁄4-in.) sieve to pass the 19.0-mm ( ⁄4-in.) sieve,

Type I Portland cement as specified in Specification C 150. The

grade that material as per Table 1 and test in concrete as a

cement must have a total alkali content of 0.9 6 0.1 % Na O

separate aggregate.

equivalent (Na Oeq is calculated as percent

7.3 Concrete Mixture Proportions—Proportion the concrete

Na O + 0.658 3 percent K O). Determine the total alkali con-

2 2

mixture to the following requirements:

tent of the cement either by analysis or by obtaining a mill run

3 3

7.3.1 Cement Content—420 6 10 kg/m (708 6 17 lb/ yd ).

certificate from the cement manufacturer. Add NaOH to the

7.3.2 Volume of Coarse Aggregate Per Unit of Volume of

concrete mixing water so as to increase the alkali content of the

Concrete—Use a coarse aggregate oven-dry-rodded unit vol-

mixture, expressed as Na Oeq, to 1.25 % by mass of cement

ume of 0.70 6 0.2 % for all classes of aggregates (for example,

(see Note 3).

lightweight, normal, and heavy weight).

NOTE 3—The value of 1.25 % Na O equivalent by mass of cement has

7.3.3 Water to Cement Ratio—Maintain water-to-cement

been chosen to accelerate the process of expansion rather than to

ratio in the range of 0.42 to 0.45 by mass. Adjust the

reproduce field conditions.

water-to-cement ratio within this range to give sufficient

7.2 Aggregates:

workability to permit satisfactory compaction of the concrete

7.2.1 To evaluate the reactivity of a coarse aggregate, use a

in the molds. Report the water-to-cement ratio used.

nonreactive fine aggregate. A nonreactive fine aggregate is

7.3.4 Admixture (NaOH)—Dissolve in the mixing water and

defined as an aggregate that develops an expansion in the

add as required to bring the alkali content of the concrete

accelerated mortar bar, (see Test Method C 1260) of less than

mixture, expressed as Na Oeq, up to 1.25 % by mass of cement

0.10 % at 14 days (see X1.5 for interpretation of expansion

(see Note 4). Use no other admixture in the concrete.

data). Use a fine aggregate meeting all the requirements for

NOTE 4—A sample calculation for determining the amount of NaOH to

concrete aggregates (see Specification C 33) with a fineness

be added to the mixing water to increase the alkali content of the ce

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.