ASTM E28-99(2009)

(Test Method)Standard Test Methods for Softening Point of Resins Derived from Naval Stores by Ring-and-Ball Apparatus

Standard Test Methods for Softening Point of Resins Derived from Naval Stores by Ring-and-Ball Apparatus

SIGNIFICANCE AND USE

In general, with materials of these types, softening does not take place at a definite temperature. As the temperature rises, these materials gradually change from brittle or exceedingly thick and slow-flowing materials to softer and less viscous liquids. For this reason, the determination of the softening point must be made by a fixed, arbitrary, and closely defined method if the results obtained are to be comparable.

In these test methods, the softening point is defined as the temperature at which a disk of the sample held within a horizontal ring is forced downward a distance of 25.4 mm (1 in.) under the weight of a steel ball as the sample is heated at 5°C/min in a water, glycerin, silicone oil, ethylene glycol/water or glycerin/water bath.

SCOPE

1.1 These test methods are intended for determining the softening point of resins (including rosin and terpene resins) and similar materials by means of the ring-and-ball apparatus.

Note 1—For testing asphalts, tars, and pitches, see Test Method D 36.

1.1.1 Test method using the manual ring and ball softening point apparatus, and

1.1.2 Test method using an automated ring and ball softening point apparatus.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E28 − 99 (Reapproved2009)

Standard Test Methods for

Softening Point of Resins Derived from Naval Stores by

Ring-and-Ball Apparatus

ThisstandardisissuedunderthefixeddesignationE28;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope rises, these materials gradually change from brittle or exceed-

ingly thick and slow-flowing materials to softer and less

1.1 These test methods are intended for determining the

viscous liquids. For this reason, the determination of the

softening point of resins (including rosin and terpene resins)

softening point must be made by a fixed, arbitrary, and closely

and similar materials by means of the ring-and-ball apparatus.

defined method if the results obtained are to be comparable.

NOTE 1—For testing asphalts, tars, and pitches, see Test Method D36.

3.2 In these test methods, the softening point is defined as

1.1.1 Test method using the manual ring and ball softening

the temperature at which a disk of the sample held within a

point apparatus, and

horizontal ring is forced downward a distance of 25.4 mm(1

1.1.2 Test method using an automated ring and ball soften-

in.) under the weight of a steel ball as the sample is heated at

ing point apparatus.

5°C/mininawater,glycerin,siliconeoil,ethyleneglycol/water

1.2 The values stated in SI units are to be regarded as the

or glycerin/water bath.

standard. The values given in parentheses are for information

4. Sample Preparation

only.

1.3 This standard does not purport to address all of the 4.1 Preparation of Sample by the Pour Method:

safety concerns, if any, associated with its use. It is the

4.1.1 This procedure is suitable for materials that can be

responsibility of the user of this standard to establish appro- heated and poured without adverse effects on the softening

priate safety and health practices and determine the applica-

point.

bility of regulatory limitations prior to use. 4.1.2 Select a sample representative of the material to be

tested.Thesampleshouldconsistofflakes,pastilles,orfreshly

2. Referenced Documents

broken lumps free of oxidized surfaces. Avoid inclusion of

2.1 ASTM Standards:

finely divided material or dust.

D36TestMethodforSofteningPointofBitumen(Ring-and-

4.1.3 Selectaquantityatleasttwicethatnecessarytofillthe

Ball Apparatus)

desired number of rings, and melt it immediately in a clean

E1Specification for ASTM Liquid-in-Glass Thermometers

container, using an oven, hot plate, sand bath or oil bath to

E177Practice for Use of the Terms Precision and Bias in

prevent local overheating. Take care to avoid incorporating air

ASTM Test Methods

bubbles in the sample. Melt the sample completely, but do not

E691Practice for Conducting an Interlaboratory Study to

heat it above a temperature necessary to pour the material

Determine the Precision of a Test Method

readily. The time from the beginning of heating to the pouring

of the sample should not exceed 15 min.

3. Significance and Use

NOTE 2—For materials that may be heat sensitive, continuously inert

3.1 In general, with materials of these types, softening does

the flask containing the test specimen with nitrogen (N ) during the

not take place at a definite temperature. As the temperature 2

remelting procedure.

1 4.1.4 Formaterialsthattendtocrackorshrinkintheringon

These test methods are under the jurisdiction of ASTM Committee D01 on

Paint and Related Coatings, Materials, and Applications and are the direct

cooling, immediately before filling the ring, preheat the ring to

responsibility of Subcommittee D01.34 on Pine Chemicals and Hydrocarbon

approximately the temperature at which the material is to be

Resins.

poured. The ring, while being filled, should rest bottom down

Current edition approved June 1, 2009. Published June 2009. Originally

on a suitable metal surface. Pour the sample into the ring so as

approvedin1936.Lastpreviouseditionapprovedin2004asE28–99(2004).DOI:

10.1520/E0028-99R09.

to leave an excess on cooling.After cooling a minimum of 30

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

min, trim off the excess resin on the periphery of the ring. To

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

remove excess resin from the top, cut the excess material off

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. cleanlywithaslightlyheatedknifeorspatula,orgraspthering

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E28 − 99 (2009)

in a pair of tongs and draw the top surface quickly and firmly MANUAL RING AND BALL SOFTENING POINT

over the surface of a heated metal plate. In case the test is METHOD

repeated, use a clean container and fresh sample.

6. Apparatus

4.2 Preparation of Sample by the Molding Method:

6.1 Ring and Ball Apparatus, consisting of the following:

4.2.1 See Appendix X1, Alternate Sample Preparation Pro-

cedures. 6.1.1 Ring—A brass, shouldered ring conforming to the

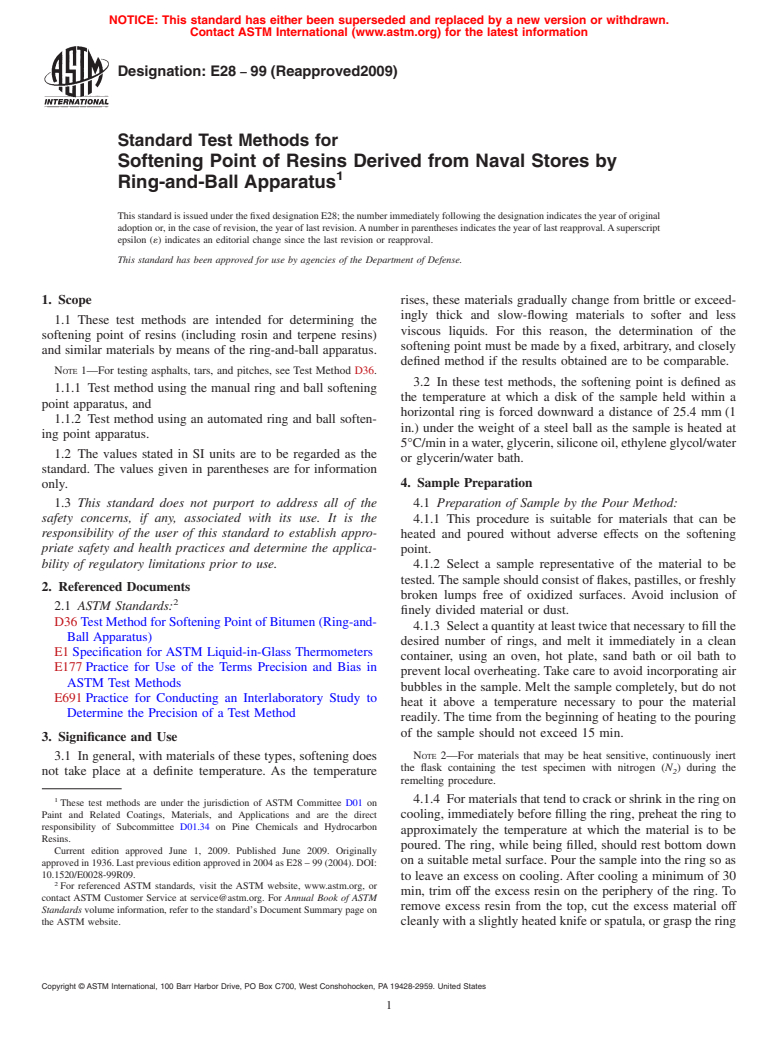

dimensions shown in Fig. 1(a).

4.3 Preparation of Samples Having a Low Softening Point

6.1.2 Ball—Asteelball,9.53 60.1mm( ⁄8in.)indiameter,

(up to 35°C (95°F)):

weighing between 3.45 and 3.55 g.

4.3.1 Place a ring on a piece of aluminum foil. Pour the

6.1.3 Ball-CenteringGuide—Abrassguideforcenteringthe

material to be tested into the ring, then place the foil and filled

ball conforming to the general shape and dimensions shown in

ring on dry ice or in a freezer to cool. The material in the ring

Fig. 1(c), the use of which is optional.

must be free of bubbles.

6.2 Support for Ring and Thermometer—Any convenient

4.3.2 After cooling, cut and scrape off any excess material

method for supporting the ring and thermometer may be used,

using a slightly heated spatula, then slide the ring gently from

provided it meets the following requirements:

the foil. Place the ring in the supporting apparatus, and

immediately perform the softening point analysis according to 6.2.1 The ring must be supported in a substantially horizon-

Section 11.

tal position.

6.2.2 When using the apparatus shown in Fig. 1(d): The

5. Reagents and Materials

bottom of the ring must be 25.4 6 0.2 mm (1.0 in.) above the

horizontal plate below it; the bottom surface of the horizontal

5.1 Bath Liquids:

plate must be 12.7 to 19.05 mm (0.5 to 0.75 in.) above the

5.1.1 Distilled or Deionized Water, Freshly Boiled—For

bottom of the beaker.

softening points between 35°C (95°F) and 80°C (176°F).

6.2.3 Suspend a thermometer so that the bottom of the bulb

5.1.1.1 Usedistilledordeionizedwaterthathasbeencooled

is level with the bottom of ring and within 12.7 mm (0.5 in.)

to at least 27°C (81°F) below the anticipated softening point,

but not touching the ring or the ring holder.

but in no case lower than 5°C (41°F).

6.3 Bath—A heat-resistant glass beaker, at least 85 mm

5.1.2 USP Glycerin—For softening points between 80°C

(3.34 in.) in diameter and 127 mm (5 in.) in depth from the

(176°F) and 150°C (302°F). Repeated use of glycerin will

bottom of the flare, for example, an 800-mL low-form Griffin

increase the moisture content over time and may affect results.

beaker.

Replace with fresh glycerin if any change in appearance is

noted.

6.4 TemperatureMeasuringDevice—Athermometerhaving

a range described below and conforming to the requirements

NOTE 3—Glycerin should not be used for softening points greater than

prescribed in Specification E1, or an electronic temperature

150°C (302°F) due to the 160°C (320°F) flash point of glycerin.

measuring device, such as a resistance thermometer or ther-

5.1.3 Silicone Oil (Polydimethylsiloxane)—For softening

mocouple. The device must exhibit the same temperature

points above 80°C (176°F). The silicone oil must have a

responseasthethermometersspecifiedinSpecificationE1and

temperature range of 200°C+(392°F), remain clear within the

must be accurately calibrated.

temperature range, have no apparent reactivity with the test

6.4.1 An ASTM Thermometer, having a range from−38 to

specimen, have a high water repellency, and maintain a

+50°C (−36 to+120°F), ASTM 5C, 5F, or equivalent.

uniform viscosity and stirring rate within the temperature

3 6.4.2 AnASTMLow-Softening-PointThermometer,having

range.

a range from−2 to 80°C (30 to 180°F), ASTM 15C, 15F or

NOTE 4—Replace with fresh silicone oil if any change in appearance is

equivalent.

noted. Do not use silicone oil that contains any gels; gels are an indicator

6.4.3 An ASTM Medium-Softening Point Thermometer,

that degradation has occurred.

having a range from 30 to 200°C (85 to 392°F), ASTM 16C,

5.1.4 Ethylene Glycol—For softening points up to 35°C

16F or equivalent.

(95°F).

6.4.4 An ASTM High-Softening-Point Thermometer, hav-

5.1.4.1 Prepareafresh50/50(v/v)mixtureofdistilledwater ing a range from−2 to 300°C (30 to 580°F),ASTM 7C, 7F or

and ethylene glycol prior to sample analysis. For softening

equivalent.

pointsbetween0°Cand35°C,a50/50(v/v)mixtureofglycerin

6.5 Stirrer—The heating bath must be stirred at a speed

and water may be used.

sufficient to ensure uniform heat distribution without causing

significant sideways displacement of the resin as it softens in

the ring. A stirring rate of 500 to 700 r/min is typical. A

The sole source of supply of silicone oil, 200 fluid, 50 cSt viscosity known to

mechanical motor-driven stirrer, mounted so that any vibra-

the committee at this time is Dow Corning Corp., Midland, MI 48686. If you are

tions created by its rotation are not conveyed directly to the

aware of alternative suppliers, please provide this information to ASTM Interna-

samplesupport,oramagneticstirrerplacedunderthebathmay

tional Headquarters.Your comments will receive careful consideration at a meeting

of the responsible technical committee, which you may attend. be used.

E28 − 99 (2009)

FIG. 1 Shouldered Ring, Ring Holder, Ball-Centering Guide, and Assembly of Apparatus Showing Two Rings

6.6 Heat Source—Aheat source capable of maintaining the the water for 15 min. Start stirring, and continue stirring until

proper heating rate, such as a temperature controller with completion of the determination.

immersion heating coil, an electric heater or a bunsen burner.

7.2 Heating—Heat the bath so that the temperature of the

water is raised uniformly at a rate of 5°C (10°F)/min. Protect

7. Procedure for Materials Having a Softening Point

thebathfromdrafts,usingshieldsifnecessary.Donotaverage

Between 35 and <80°C (95 and 176°F)

the rate of rise over the test period. The maximum permissible

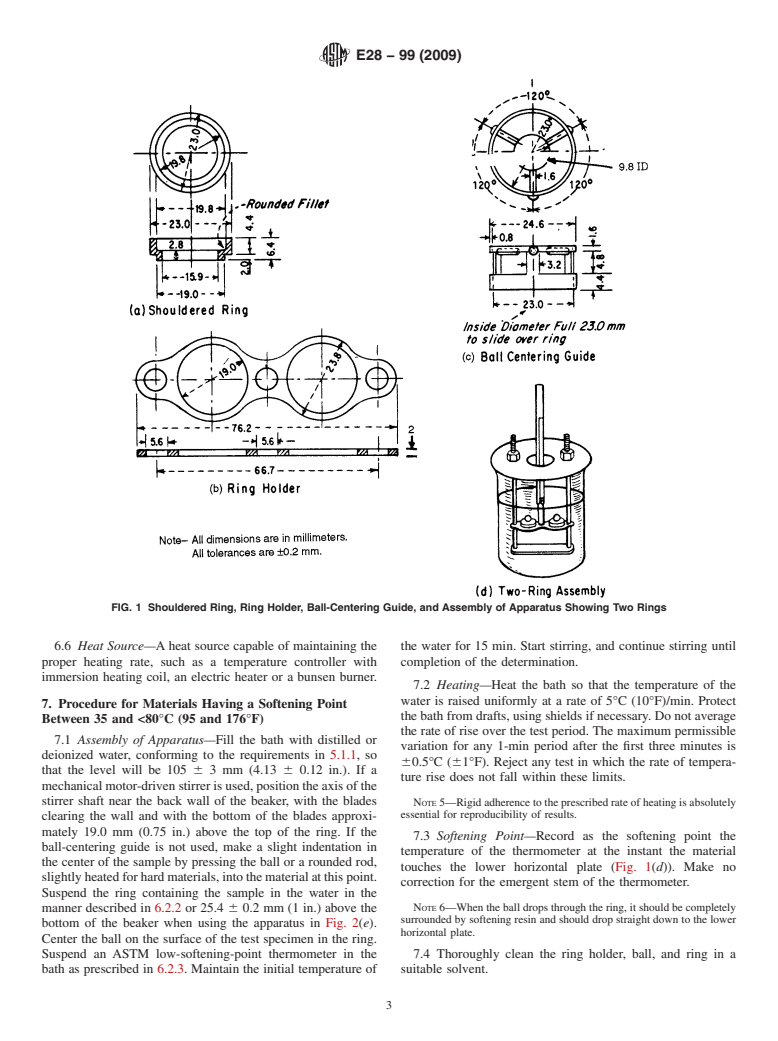

7.1 Assembly of Apparatus—Fill the bath with distilled or

variation for any 1-min period after the first three minutes is

deionized water, conforming to the requirements in 5.1.1,so

60.5°C (61°F). Reject any test in which the rate of tempera-

that the level will be 105 6 3 mm (4.13 6 0.12 in.). If a

ture rise does not fall within these limits.

mechanicalmotor-drivenstirrerisused,positiontheaxisofthe

stirrer shaft near the back wall of the beaker, with the blades NOTE5—Rigidadherencetotheprescribedrateofheatingisabsolutely

essential for reproducibility of results.

clearing the wall and with the bottom of the blades approxi-

mately 19.0 mm (0.75 in.) above the top of the ring. If the

7.3 Softening Point—Record as the softening point the

ball-centering guide is not used, make a slight indentation in

temperature of the thermometer at the instant the material

the center of the sample by pressing the ball or a rounded rod,

touches the lower horizontal plate (Fig. 1(d)). Make no

slightlyheatedforhardmaterials,intothematerialatthispoint.

correction for the emergent stem of the thermometer.

Suspend the ring containing the sample in the water in the

NOTE 6—When the ball drops through the ring, it should be completely

manner described in 6.2.2 or 25.4 6 0.2 mm (1 in.) above the

surrounded by softening resin and should drop straight down to the lower

bottom of the beaker when using the apparatus in Fig. 2(e).

horizontal plate.

Center the ball on the surface of the test specimen in the ring.

Suspend an ASTM low-softening-point thermometer in the 7.4 Thoroughly clean the ring holder, ball, and ring in a

bath as prescribed in 6.2.3. Maintain the initial temperature of suitable solvent.

E28 − 99 (2009)

FIG. 2 Assembly of Apparatus Showing Stirrer and Single Shouldered Ring

8. Calibration 11. Procedure for Materials Having Softening Points

Below 35°C (95°F)

8.1 Acalibration check of any temperature controllers used

in the manual ring and ball softening point apparatus must be

11.1 Apparatus:

performedonaregularbasissinceaccuratetemperaturecontrol

11.1.1 Isopropyl Alcohol Dry-Ice Bath.

is required.

11.2 Procedure:

9. Procedure for Materials Having Softening Points

11.2.1 Coolthebath,describedin5.1.4.1,to−25°C(−13°F)

Between 80°C (176°F) and 150°C (302°F)

in an isopropyl alcohol dry-ice bath.

11.2.2 UsethesameprocedureasinSection9exceptforthe

9.1 Use the same procedure as described in Section 8,

bathliquid,andimmediatelybeginheatingasdirectedoncethe

except fill the bath with glycerin or silicone oil (Note 3) and

test specimen in the ring has been placed in the bath.

use an ASTM medium-softening-point thermometer. The

maximum allowable starting temperature of the bath is the

AUTOMATED RING AND BALL SOFTENING POINT

lower of: (a) 27°C (81°F) below the anticipated softening

METHOD

point, or (b) 32°C (90°F).

NOTE 7—For materials softening around 80°C (176°F) report the bath

12. Apparatus

liquidsinceaglycerinorsiliconeoilbathwillyieldaslightlyhigherresult

than a water bath.

12.1 Automated Ring and Ball-Softening Point Instrument

NOTE 8—Repeated use of glycerin will increase the moisture content

with Control Unit, test units, and test inserts.

overtimeandmayaffectresults.Replacewithfreshglycerinifanychange

in appearance is noted. 12.2 Ring—A brass, shouldered ring conforming to the

dimensions shown in Fig. 1(a).

10. Procedure for Materials Having Softening Points

12.3 Ball—Asteel ball, 9.53 6 0.1 mm ( ⁄8 in.) in diameter,

Above 150°C (302°F)

weighing between 3.45 and 3.55 g.

10.1 Use the same procedure as described in Section 9,

exceptfillthebathwithsiliconeoil(Note4)anduseanASTM 12.4 Beaker, 600 mL. Ensure that the dimensions will

high-softening-point thermometer. properly fit the heating unit.

E28 − 99 (2009)

12.5 Stir Bar—The dimensions must be such that

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.