ASTM D4688-99(2005)

(Test Method)Standard Test Method for Evaluating Structural Adhesives for Finger Jointing Lumber

Standard Test Method for Evaluating Structural Adhesives for Finger Jointing Lumber

SIGNIFICANCE AND USE

This test method is specifically designed to measure the performance of adhesives in finger joints manufactured under production line conditions.

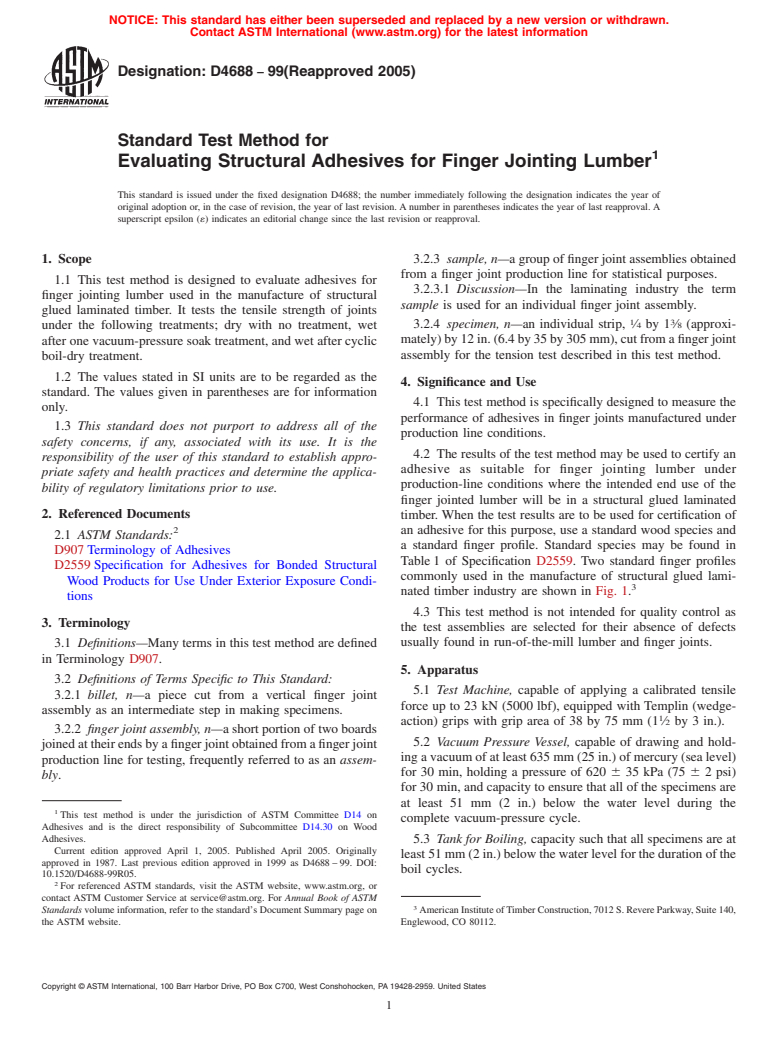

The results of the test method may be used to certify an adhesive as suitable for finger jointing lumber under production-line conditions where the intended end use of the finger jointed lumber will be in a structural glued laminated timber. When the test results are to be used for certification of an adhesive for this purpose, use a standard wood species and a standard finger profile. Standard species may be found in Table 1 of Specification D 2559. Two standard finger profiles commonly used in the manufacture of structural glued laminated timber industry are shown in Fig. 1.3

This test method is not intended for quality control as the test assemblies are selected for their absence of defects usually found in run-of-the-mill lumber and finger joints.

Note—Recommended by American Institute of Timber Construction.3 FIG. 1 Standard Joint Profiles for Certification Tests

SCOPE

1.1 This test method is designed to evaluate adhesives for finger jointing lumber used in the manufacture of structural glued laminated timber. It tests the tensile strength of joints under the following treatments; dry with no treatment, wet after one vacuum-pressure soak treatment, and wet after cyclic boil-dry treatment.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4688 −99(Reapproved 2005)

Standard Test Method for

Evaluating Structural Adhesives for Finger Jointing Lumber

This standard is issued under the fixed designation D4688; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.3 sample, n—agroupoffingerjointassembliesobtained

from a finger joint production line for statistical purposes.

1.1 This test method is designed to evaluate adhesives for

3.2.3.1 Discussion—In the laminating industry the term

finger jointing lumber used in the manufacture of structural

sample is used for an individual finger joint assembly.

glued laminated timber. It tests the tensile strength of joints

1 3

3.2.4 specimen, n—an individual strip, ⁄4 by 1 ⁄8 (approxi-

under the following treatments; dry with no treatment, wet

mately)by12in.(6.4by35by305mm),cutfromafingerjoint

after one vacuum-pressure soak treatment, and wet after cyclic

assembly for the tension test described in this test method.

boil-dry treatment.

1.2 The values stated in SI units are to be regarded as the

4. Significance and Use

standard. The values given in parentheses are for information

4.1 This test method is specifically designed to measure the

only.

performance of adhesives in finger joints manufactured under

1.3 This standard does not purport to address all of the

production line conditions.

safety concerns, if any, associated with its use. It is the

4.2 The results of the test method may be used to certify an

responsibility of the user of this standard to establish appro-

adhesive as suitable for finger jointing lumber under

priate safety and health practices and determine the applica-

production-line conditions where the intended end use of the

bility of regulatory limitations prior to use.

finger jointed lumber will be in a structural glued laminated

2. Referenced Documents timber. When the test results are to be used for certification of

an adhesive for this purpose, use a standard wood species and

2.1 ASTM Standards:

a standard finger profile. Standard species may be found in

D907Terminology of Adhesives

Table1 of Specification D2559. Two standard finger profiles

D2559Specification for Adhesives for Bonded Structural

commonly used in the manufacture of structural glued lami-

Wood Products for Use Under Exterior Exposure Condi-

nated timber industry are shown in Fig. 1.

tions

4.3 This test method is not intended for quality control as

3. Terminology

the test assemblies are selected for their absence of defects

usually found in run-of-the-mill lumber and finger joints.

3.1 Definitions—Many terms in this test method are defined

in Terminology D907.

5. Apparatus

3.2 Definitions of Terms Specific to This Standard:

5.1 Test Machine, capable of applying a calibrated tensile

3.2.1 billet, n—a piece cut from a vertical finger joint

force up to 23 kN (5000 lbf), equipped with Templin (wedge-

assembly as an intermediate step in making specimens.

action) grips with grip area of 38 by 75 mm (1 ⁄2 by 3 in.).

3.2.2 finger joint assembly, n—ashortportionoftwoboards

5.2 Vacuum Pressure Vessel, capable of drawing and hold-

joinedattheirendsbyafingerjointobtainedfromafingerjoint

ingavacuumofatleast635mm(25in.)ofmercury(sealevel)

production line for testing, frequently referred to as an assem-

for 30 min, holding a pressure of 620 6 35 kPa (75 6 2 psi)

bly.

for 30 min, and capacity to ensure that all of the specimens are

at least 51 mm (2 in.) below the water level during the

This test method is under the jurisdiction of ASTM Committee D14 on

complete vacuum-pressure cycle.

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood

Adhesives.

5.3 Tank for Boiling, capacity such that all specimens are at

Current edition approved April 1, 2005. Published April 2005. Originally

least51mm(2in.)belowthewaterlevelforthedurationofthe

approved in 1987. Last previous edition approved in 1999 as D4688–99. DOI:

boil cycles.

10.1520/D4688-99R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on AmericanInstituteofTimberConstruction,7012S.RevereParkway,Suite140,

the ASTM website. Englewood, CO 80112.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4688−99 (2005)

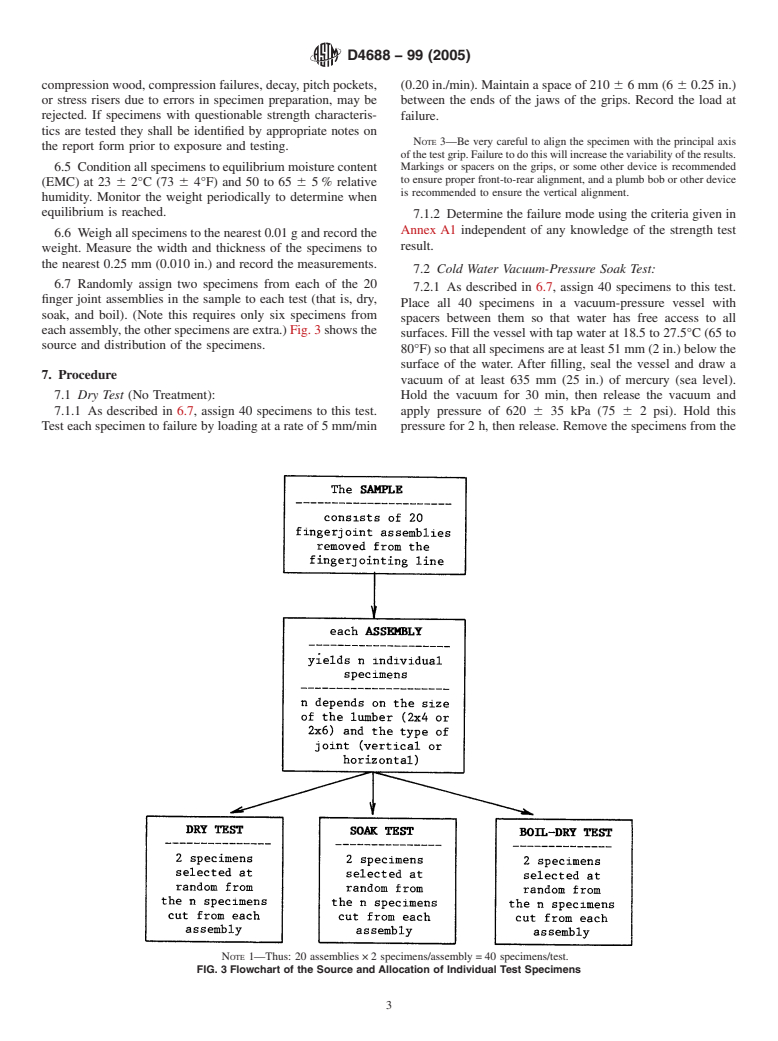

FIG. 2 Finger Joint Assembly and Specimen Descriptions

6.2.3 Plane the second face of the assembly until the finger

on the surface is feathered maintaining 35-mm (1 ⁄8-in.)

assembly thickness or nearly so.

NOTE 1—It is more important to feather the finger than to maintain the

35-mm (1 ⁄8-in.) thickness.

6.2.4 Cuttheassemblytoa305-mm(12-in.)lengthwiththe

finger jointed area at the center.

6.2.5 Rip individual specimens 6.4-mm ( ⁄4-in.) thick (Fig.

1) from the assembly starting with the jointed edge of the

assembly (see 6.2.2) against the saw guide. A thin hollow-

ground rip saw blade is preferred but the important criteria is

the straightness of the cut. Check cut specimens for uniform

thickness throughout. Thickness shall not vary by more than

NOTE 1—Recommended by American Institute of Timber Construc-

3 0.5 mm (0.02 in.). Number the specimens in order from one

tion.

side of the assembly to the other.

FIG. 1Standard Joint Profiles for Certification Tests

6.3 Vertical Joint (Fig. 2(b)):

6.3.1 Joint one edge of the finger joint assembly.

6.3.2 Joint one face of the finger joint assembly.

5.4 Oven, capable of operating continuously for 20 h at 63 6.3.3 Withthejointededgeagainstthesawguide,ripbillets

6 2°C (145 6 5°F) with sufficient air circulation to lower the 40 mm (1 ⁄16 in.) wide from the assembly.

moisturecontentofthegroupofspecimensto8%within20h.

NOTE 2—The 40-mm (1 ⁄16-in.) dimension is not critical but this

5.4.1 Timer, to shut the oven off automatically is desirable.

dimension must be enough to allow feathering the fingers in following

steps.

6. Specimen Preparation

6.3.4 Joint and plane the sides of each billet so the exposed

6.1 Obtain a sample consisting of either 20 horizontal or sides of the fingers are feathered as described in 6.2.1 and

vertical finger joint assemblies from a finger joint production 6.2.3.

line.Theboardsmustbenominal2by4-in.or2by6-in.Reject 6.3.5 Rip four individual specimens of 6.4-mm ( ⁄4-in.)

any assembly with obvious defects in the lumber or joint. thickness from each billet of the assembly as in 6.2.5. Number

the specimens in order from one side of the assembly to the

6.2 Horizontal Joint (Fig. 2(a)):

other. Use the same order for each assembly.

6.2.1 Joint one face of each assembly until the finger on the

surface is feathered as shown in Fig. 2(c). 6.4 Inspect specimens for defects. Assemblies yielding

6.2.2 Joint one edge of the assembly for end cutting and specimens that have obvious strength-reducing characteristics

ripping at a later stage. such as: low visual density, knots, steep slope of grain,

D4688−99 (2005)

compression wood, compression failures, decay, pitch pockets, (0.20 in./min). Maintain a space of 210 66mm(6 6 0.25 in.)

or stress risers due to errors in specimen preparation, may be between the ends of the jaws of the grips. Record the load at

rejected. If specimens with questionable strength characteris-

failure.

tics are tested they shall be identified by appropriate notes on

NOTE 3—Be very careful to align the specimen with the principal axis

the report form prior to exposure and testing.

ofthetestgrip.Failuretodothiswillincreasethevariabilityoftheresults.

6.5 Conditionallspecimenstoequilibriummoisturecontent Markings or spacers on the grips, or some other device is recommended

to ensure proper front-to-rear alignment, and a plumb bob or other device

(EMC) at 23 6 2°C (73 6 4°F) and 50 to 65 6 5% relative

is recommended to ensure the vertical alignment.

humidity. Monitor the weight periodically to determine when

equilibrium is reached.

7.1.2 Determine the failure mode using the criteria given in

Annex A1 independent of any knowledge of the strength test

6.6 Weighallspecimenstothenearest0.01gandrecordthe

result.

weight. Measure the width and thickness of the specimens to

the nearest 0.25 mm (0.010 in.) and record the measurements.

7.2 Cold Water Vacuum-Pressure Soak Test:

6.7 Randomly assign two specimens from each of the 20

7.2.1 As described in 6.7, assign 40 specimens to this test.

finger joint assemblies in the sample to each test (that is, dry,

Place all 40 specimens in a vacuum-pressure vessel with

soak, and boil). (Note this requires only six specimens from

spacers between them so that water has free access to all

eachassembly,theotherspecimensareextra.)Fig.3showsthe

surfaces. Fill the vessel with tap water at 18.5 to 27.5°C (65 to

source and distribution of the specimens.

80°F)sothatallspecimensareatleast51mm(2in.)belowthe

surface of the water. After filling, seal the vessel and draw a

7. Procedure

vacuum of at least 635 mm (25 in.) of mercury (sea level).

7.1 Dry Test (No Treatment): Hold the vacuum for 30 min, then release the vacuum and

7.1.1 As described in 6.7, assign 40 specimens to this test. apply pressure of 620 6 35 kPa (75 6 2 psi). Hold this

Test each specimen to failure by loading at a rate of 5 mm/min pressure for 2 h, then release. Remove the specimens from the

NOTE 1—Thus: 20 assemblies×2 specimens/assembly=40 specimens/test.

FIG. 3Flowchart of the Source and Allocation of Individual Test Specimens

D4688−99 (2005)

pressure vessel and place them submerged in water at room outliers (test values outside the range expressed by the upper

temperature until tested. and lower adjacent values).

7.2.2 Wipe the surface of each specimen with a dry cotton

25th percentile = Q1 = the value below which 25 % of the observations

fall.

cloth or paper towel and test wet as described in 7.1.1. Record

50th percentile = Q2 = the value below which 50 % of the observations

the load at failure.

fall.

7.2.3 After the specimens have dried, determine the failure

75th percentile = Q3 = the value below which 75 % of the observations

fall.

mode as described in 7.1.2. Record the failure mode.

Upper adjacent value = the largest observation equal to or less than

7.3 Cyclic Boil Test:

the quantity Q3+1.5(Q3− Q1).

7.3.1 As described in 6.7, assign 40 specimens to this test.

Lower adjacent value = the smallest observation greater than or equal

to the quantity Q1−1.5(Q3− Q1).

Place all 40 specimens in the boil tank with spacers so that

Outliers = observations greater than the upper adjacent

water has free access to all surfaces. Fill with water such that

value or less than the lower adjacent value.

the specimens are at least 51 mm (2 in.) below the water level.

8.4 Calculate the mean and standard deviation. Specimens

Boil specimens for 4 h, then dry them in an oven at 63 6 2°C

exhibiting failure mode 6 may be excluded from the calcula-

(145 65°F)withsufficientaircirculationtolowerthemoisture

tion. Include specimens with failure modes 1, 2, 3, 4, and 5 in

content to 8% (ovendry basis) in no more than 20 h.

the calculation unless the strength value is an outlier or the

NOTE 4—The rate of air circulation, the size of the load of specimens

wood is of poor quality (such as compression wood, etc.).

in the oven, and the spacing of the specimens greatly affect drying time

and the steepness of the moisture gradient in the specimen. Variation of

9. Report

these factors strongly affects the repeatability of the test method. If

repeatability (within-laboratory variability) or reproducibility (between

9.1 Include the following general information in the report:

laboratories) is important, the drying variables must be maintained as

9.1.1 Complete identification of the adhesive tested includ-

constant as possible from one series of tests to the next. If this is not

ing type, source, manufacturers’ code numbers, form, and any

possible, the drying should be conducted so that the specimens reach 8%

other pertinent information,

moisture content within the same drying period in every test. One way to

9.1.2 Adhesive application and bonding conditions used to

dothisistomonitortheweightofthespecimensandadjusttheovenvents

so the specimens reach the target 8% moisture in 15 to 20 h.As an aid in

prepare the finger jointed boards,

following moisture content, the weight of specimens at 8% moisture

9.1.3 Conditioning procedure used before testing,

contentisabout96%oftheirweightat12%moisturecontent.Thedrying

9.1.4 Temperature and relative humidity of the test room,

time required can be established with some of the extra specimens cut

9.1.5 Number of finger joint assemblies represented in the

from the 20 assemblies.

test, and

7.3.2 Repeat the boil-dry cycle five more times; except

9.1.6 Number of specimens per assembly tested in each test

during the final cycle do not dry the specimens. Cool the

(dry, soaked, and boiled),

specimens to room temperature submerged in water and keep

9.2 Include the following statistical information in the

them there until they are tested.

report:

7.3.3 Test wet in tension as described in 7.2.2. Record the

9.2.1 The range of test values,

load at failure.

9.2.2 The 25th, 50th, and 75th percentile values,

7.3.4 After the specimens have dried, determine the failure

9.2.3 The upper and lower adjacent values,

mode as described in 7.1.2. Record the failure mode.

9.2.4 Outliers identified by finger joint assembly and speci-

NOTE 5—Nonmandatory guidelines for joint performance follow:

men number,

Mode 1 — An unacceptable failure.

9.2.5 Failure mode 6 specimens identified by finger joint

Modes 2 and 3 — Unconditionally acceptable failure.

assembly and specimen number,

Modes 4, 5, and 6 — Conditionally acceptable failure if strength is

acceptable.

9.2.6 Specimenswithdefectsofmaterialorbondingdiscov-

ered after testing identified by finger joint assembly and

8. Calculation of Results

specimen number,

8.1 Calculate the tensile stress at failure in megapascals

9.2.7 The mean and standard deviation, and

(pounds-forcepersquareinch)astheloadatfailureinnewtons

9.2.8 The statistical mode (most frequent value) of the

(pounds-force) divided by the cross-sectional area of the

observed failure modes.

2 2

specimen expressed to the nearest mm (0.01 in. ).

8.2 Estimate the 25th, 50th, and 75th percentiles for the 10. Precision and Bias

group of specimens in the following manner:

10.1 Ameasureoftheprecisionofthistestmethodcovering

8.2.1 Arrange

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.