ASTM D7374-21

(Practice)Standard Practice for Evaluating Elevated Temperature Performance of Adhesives Used in End-Jointed Lumber

Standard Practice for Evaluating Elevated Temperature Performance of Adhesives Used in End-Jointed Lumber

SIGNIFICANCE AND USE

5.1 End-jointed lumber studs used in fire resistance-rated assemblies shall be able to support the superimposed design load for the specified time under an elevated temperature exposure, when a wall assembly is exposed to a standard fire specified in Test Methods E119. Light-weight wood assemblies utilize gypsum wallboard or other types of membrane protection to accomplish a requisite fire resistance rating for the assembly. However, wood studs and the end joints in the studs shall resist the developed elevated temperature environment for the duration of the rating. This practice provides a method for evaluating the elevated temperature performance of an adhesive used in end-jointed lumber as compared with the elevated temperature performance of solid wood.

SCOPE

1.1 This practice is to be used to evaluate the elevated temperature performance of adhesives used in end-jointed lumber.

1.2 A symmetric wall assembly containing end-jointed lumber studs is exposed to a standard fire exposure specified in Test Methods E119.

1.3 The wall assembly shall sustain the applied load during a standard fire exposure specified in Test Methods E119 for a period of 60 min or more.

1.4 This practice is used to evaluate the performance of adhesives used in end-jointed lumber to heat and flame under controlled conditions, but it does not by itself incorporate all factors required for fire hazard or fire risk assessment under actual fire conditions.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7374 − 21

Standard Practice for

Evaluating Elevated Temperature Performance of Adhesives

1

Used in End-Jointed Lumber

This standard is issued under the fixed designation D7374; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This practice is to be used to evaluate the elevated 2.1 ASTM Standards:

temperature performance of adhesives used in end-jointed C1396/C1396MSpecification for Gypsum Board

lumber. D9Terminology Relating to Wood and Wood-Based Prod-

ucts

1.2 Asymmetricwallassemblycontainingend-jointedlum-

D4688Test Method for Evaluating StructuralAdhesives for

ber studs is exposed to a standard fire exposure specified in

Finger Jointing Lumber

Test Methods E119.

D6513Practice for Calculating the Superimposed Load on

1.3 The wall assembly shall sustain the applied load during

Wood-frame Walls for Standard Fire-Resistance Tests

a standard fire exposure specified in Test Methods E119 for a

E119Test Methods for Fire Tests of Building Construction

period of 60 min or more.

and Materials

F1667SpecificationforDrivenFasteners:Nails,Spikes,and

1.4 This practice is used to evaluate the performance of

adhesives used in end-jointed lumber to heat and flame under Staples

controlled conditions, but it does not by itself incorporate all

2.2 Other Standards:

factors required for fire hazard or fire risk assessment under

ANSI/AF&PANDSNationalDesignSpecificationforWood

3

actual fire conditions.

Construction

1.5 The values stated in inch-pound units are to be regarded

3. Terminology

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

3.1 Definitions:

and are not considered standard.

3.1.1 For general definitions of terms related to wood, refer

to Terminology D9.

1.6 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.2.1 end joint, n—joint formed by adhesive bonding of

responsibility of the user of this standard to establish appro-

machined, mated surfaces at the ends of two pieces of lumber.

priate safety, health, and environmental practices and deter-

3.2.1.1 Discussion—Typical end joint configurations in-

mine the applicability of regulatory limitations prior to use.

clude finger joints and scarf joints.

1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3.2.2 finger joint, n—endjointformedbymultipleinterlock-

ization established in the Decision on Principles for the

ing tapered profiles (“fingers”).

Development of International Standards, Guides and Recom-

3.2.3 scarf joint, n—end joint formed by a single tapered

mendations issued by the World Trade Organization Technical

profile.

Barriers to Trade (TBT) Committee.

1 2

This practice is under the jurisdiction ofASTM Committee D07 on Wood and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

is the direct responsibility of Subcommittee D07.02 on Lumber and Engineered contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Wood Products. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 15, 2021. Published August 2021. Originally the ASTM website.

3

approved in 2008. Last previous edition approved in 2015 as D7374 – 08 (2015). Available from American Forest and Paper Association (AF&PA), 1111 19th

DOI: 10.1520/D7374-21. St., NW, Suite 800, Washington, DC 20036, http://www.afandpa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7374 − 21

3.2.4 end-jointed lumber—lumber containing one or more sive used in end-jointed lumber as compared with the elevated

end joints. temperature performance of solid wood.

4. Summary of Practice

6. Wall Assembly

4.1 This practice shall be used to evaluate end-jointed

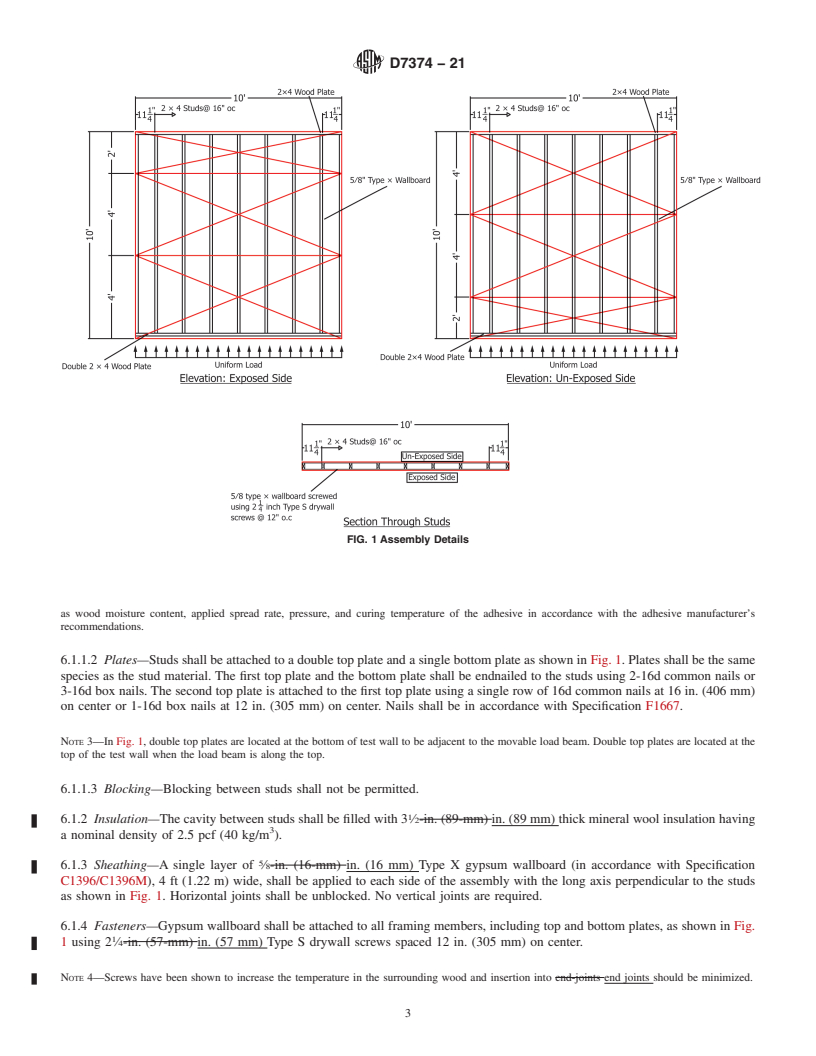

6.1 A load-bearing wall meeting the following assembly

lumberadhesivesintendedforuseinend-jointedlumberbyfire

description shall be used.

testing a wall assembly under a vertical load associated with

6.1.1 Framing Elements:

the highest visual grade for the species group of Douglas

6.1.1.1 Studs—Nine pieces of 2×4 (nominal) end-jointed

Fir–Larch or Southern Pine.The results are deemed applicable

lumber shall be

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7374 − 08 (Reapproved 2015) D7374 − 21

Standard Practice for

Evaluating Elevated Temperature Performance of Adhesives

1

Used in End-Jointed Lumber

This standard is issued under the fixed designation D7374; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This standard practice is to be used to evaluate the elevated temperature performance of adhesives used in end-jointed lumber.

1.2 A symmetric wall assembly containing end-jointed lumber studs is exposed to a standard fire exposure specified in Test

Methods E119.

1.3 The wall assembly shall sustain the applied load during a standard fire exposure specified in Test Methods E119 for a period

of 60 min or more.

1.4 This practice is used to evaluate the performance of adhesives used in end-jointed lumber to heat and flame under controlled

conditions, but it does not by itself incorporate all factors required for fire hazard or fire risk assessment under actual fire

conditions.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C1396/C1396M Specification for Gypsum Board

D9 Terminology Relating to Wood and Wood-Based Products

D4688 Test Method for Evaluating Structural Adhesives for Finger Jointing Lumber

D6513 Practice for Calculating the Superimposed Load on Wood-frame Walls for Standard Fire-Resistance Tests

E119 Test Methods for Fire Tests of Building Construction and Materials

1

This practice is under the jurisdiction of ASTM Committee D07 on Wood and is the direct responsibility of Subcommittee D07.02 on Lumber and Engineered Wood

Products.

Current edition approved May 1, 2015July 15, 2021. Published June 2015August 2021. Originally approved in 2008. Last previous edition approved in 20082015 as D7374

– 08. 08 (2015). DOI: 10.1520/D7374-08R15.10.1520/D7374-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7374 − 21

F1667 Specification for Driven Fasteners: Nails, Spikes, and Staples

2.2 Other Standards:

3

ANSI/AF&PA NDS National Design Specification for Wood Construction

3. Terminology

3.1 Definitions:

3.1.1 For general definitions of terms related to wood, refer to Terminology D9.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 end-jointed lumber—end joint, n—lumber containing one or more end-joints.joint formed by adhesive bonding of machined,

mated surfaces at the ends of two pieces of lumber.

3.2.1.1 Discussion—

Typical end joint configurations include finger joints and scarf joints.

3.2.2 end-joints—finger joint, n—aend joint formed by bonding two pieces of lumber end-to-end, often by machining a set of

interlocking “fingers” (finger-joint) into each end of adjoining pieces, using an adhesive to form an adhesive bonded joint.multiple

interlocking tapered profiles (“fingers”).

3.2.3 scarf joint, n—end joint formed by a single tapered profile.

3.2.4 end-jointed lumber—lumber containing one or more end joints.

4. Summary of Practice

4.1 This practice shall be used to evaluate end-jointed lumber adhesives intended for use in end-jointed lumber by fire testing a

wall assembly under a vertical load associated with the highest visual grade for the species gro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.