ASTM D5495-03(2011)

(Practice)Standard Practice for Sampling With a Composite Liquid Waste Sampler (COLIWASA)

Standard Practice for Sampling With a Composite Liquid Waste Sampler (COLIWASA)

SIGNIFICANCE AND USE

This practice is applicable to sampling liquid wastes and other stratified liquids. The COLIWASA is used to obtain a vertical column of liquid representing an accurate cross-section of the sampled material. To obtain a representative sample of stratified liquids, the COLIWASA should be open at both ends so that material flows through it as it is slowly lowered to the desired sampling depth. The COLIWASA must not be lowered with the stopper in place. Opening the stopper after the tube is submerged will cause material to flow in from the bottom layer only, resulting in gross over-representation of that layer.

This practice is to be used by personnel acquiring samples.

This practice should be used in conjunction with Guide D4687 which covers sampling plans, safety, QA, preservation, decontamination, labeling and chain-of-custody procedures; Practice D5088 which covers decontamination of field equipment used at waste sites; Practice D5283 which covers project specifications and practices for environmental field operations, and Practice D5743 which covers drum sampling..

SCOPE

1.1 This practice describes the procedure for sampling liquids with the composite liquid waste sampler, or “COLIWASA.” The COLIWASA is an appropriate device for obtaining a representative sample from stratified or unstratified liquids. Its most common use is for sampling containerized liquids, such as tanks, barrels, and drums. It may also be used for pools and other open bodies of stagnant liquid.

Note 1—A limitation of the COLIWASA is that the stopper mechanism may not allow collection of approximately the bottom inch of material, depending on construction of the stopper.

1.2 The COLIWASA should not be used to sample flowing or moving liquids.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5495 − 03(Reapproved 2011)

Standard Practice for

Sampling With a Composite Liquid Waste Sampler

1

(COLIWASA)

This standard is issued under the fixed designation D5495; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope and Quality Control Planning and Implementation

D5743 Practice for Sampling Single or Multilayered

1.1 This practice describes the procedure for sampling

Liquids, With or Without Solids, in Drums or Similar

liquids with the composite liquid waste sampler, or “COLI-

Containers

WASA.” The COLIWASAis an appropriate device for obtain-

D6232 Guide for Selection of Sampling Equipment for

ing a representative sample from stratified or unstratified

WasteandContaminatedMediaDataCollectionActivities

liquids. Its most common use is for sampling containerized

liquids, such as tanks, barrels, and drums. It may also be used

3. Summary of Practice

for pools and other open bodies of stagnant liquid.

3.1 A clean device is slowly lowered into the liquid to be

NOTE 1—Alimitation of the COLIWASAis that the stopper mechanism

sampled.After it has filled, the bottom of the sampling tube is

may not allow collection of approximately the bottom inch of material,

closed and the device is retrieved. The contents are subse-

depending on construction of the stopper.

quently discharged into a sample container.

1.2 The COLIWASA should not be used to sample flowing

or moving liquids. 4. Significance and Use

1.3 The values stated in SI units are to be regarded as 4.1 Thispracticeisapplicabletosamplingliquidwastesand

standard. No other units of measurement are included in this other stratified liquids. The COLIWASA is used to obtain a

standard. verticalcolumnofliquidrepresentinganaccuratecross-section

of the sampled material. To obtain a representative sample of

1.4 This standard does not purport to address all of the

stratified liquids, the COLIWASAshould be open at both ends

safety problems, if any, associated with its use. It is the

so that material flows through it as it is slowly lowered to the

responsibility of the user of this standard to establish appro-

desired sampling depth. The COLIWASAmust not be lowered

priate safety and health practices and determine the applica-

with the stopper in place. Opening the stopper after the tube is

bility of regulatory limitations prior to use.

submerged will cause material to flow in from the bottom layer

2. Referenced Documents

only, resulting in gross over-representation of that layer.

2

2.1 ASTM Standards:

4.2 This practice is to be used by personnel acquiring

D4687 Guide for General Planning of Waste Sampling

samples.

D5088 Practice for Decontamination of Field Equipment

4.3 This practice should be used in conjunction with Guide

Used at Waste Sites

D4687 which covers sampling plans, safety, QA, preservation,

D5283 Practice for Generation of Environmental Data Re-

decontamination, labeling and chain-of-custody procedures;

lated to Waste ManagementActivities: QualityAssurance

Practice D5088 which covers decontamination of field equip-

ment used at waste sites; Practice D5283 which covers project

1

This practice is under the jurisdiction of ASTM Committee D34 on Waste specifications and practices for environmental field operations,

Management and is the direct responsibility of Subcommittee D34.01.03 on

and Practice D5743 which covers drum sampling.

Sampling Equipment.

Current edition approved July 1, 2011. Published September 2011. Originally

5. Sampling Equipment

approved in 1994. Last previous edition approved in 2007 as D5495-03 (2007).

DOI: 10.1520/D5495-03R11.

5.1 COLIWASAs are available commercially with different

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

types of stoppers and locking mechanisms, but they all operate

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

using the same principle. They can also be constructed from

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. materials such as polyvinylchloride (PVC), glass, metal, or

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5495 − 03 (2011)

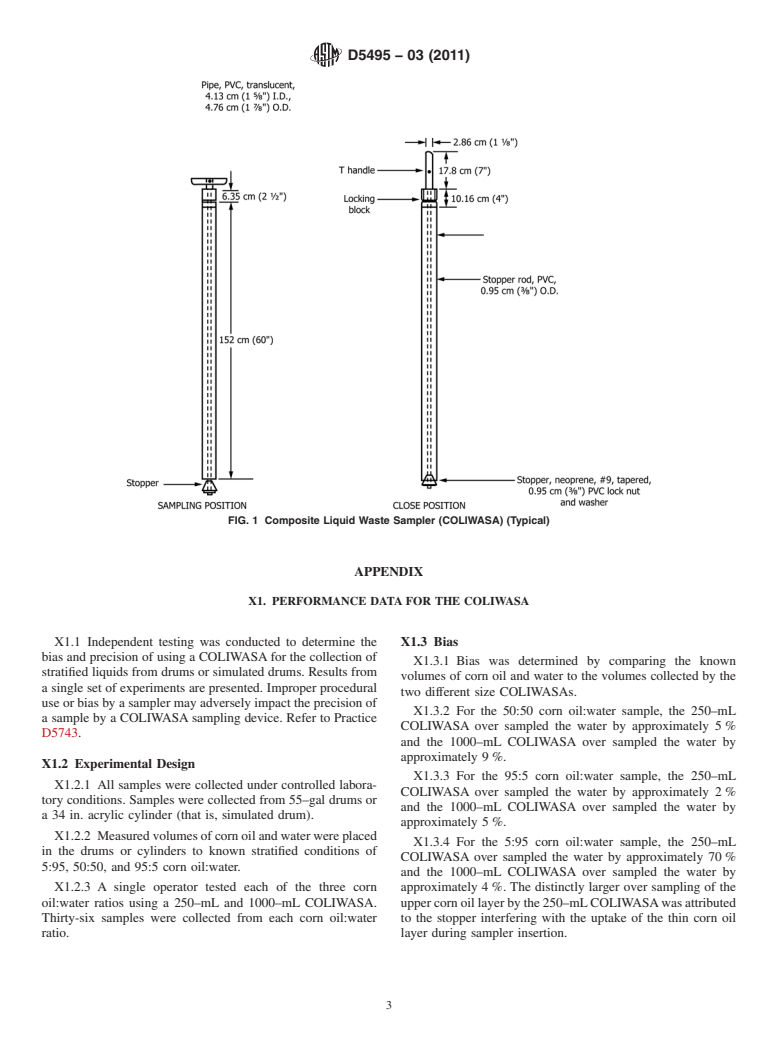

polytetrafluoroethylene (PTFE). A traditional model of the 7.2 Open the COLIWASA by placing the stopper mecha-

3,4

COLIWASAis shown in Fig. 1 [deVera et al.] ; however, the nism in the open position.

design can be modified or adapted, or both, to meet the needs

7.3 Lower the COLIWASAinto the liquid slowly so that the

of the sampler. COLIW

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5495 − 03 (Reapproved 2011) D5495 − 03 (Reapproved 2011)

Standard Practice for

Sampling With a Composite Liquid Waste Sampler

1

(COLIWASA)

This standard is issued under the fixed designation D5495; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes the procedure for sampling liquids with the composite liquid waste sampler, or “COLIWASA.” The

COLIWASA is an appropriate device for obtaining a representative sample from stratified or unstratified liquids. Its most common

use is for sampling containerized liquids, such as tanks, barrels, and drums. It may also be used for pools and other open bodies

of stagnant liquid.

NOTE 1—A limitation of the COLIWASA is that the stopper mechanism may not allow collection of approximately the bottom inch of material,

depending on construction of the stopper.

1.2 The COLIWASA should not be used to sample flowing or moving liquids.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D4687 Guide for General Planning of Waste Sampling

D5088 Practice for Decontamination of Field Equipment Used at Waste Sites

D5283 Practice for Generation of Environmental Data Related to Waste Management Activities: Quality Assurance and Quality

Control Planning and Implementation

D5743 Practice for Sampling Single or Multilayered Liquids, With or Without Solids, in Drums or Similar Containers

D6232 Guide for Selection of Sampling Equipment for Waste and Contaminated Media Data Collection Activities

3. Summary of Practice

3.1 A clean device is slowly lowered into the liquid to be sampled. After it has filled, the bottom of the sampling tube is closed

and the device is retrieved. The contents are subsequently discharged into a sample container.

4. Significance and Use

4.1 This practice is applicable to sampling liquid wastes and other stratified liquids. The COLIWASA is used to obtain a vertical

column of liquid representing an accurate cross-section of the sampled material. To obtain a representative sample of stratified

liquids, the COLIWASA should be open at both ends so that material flows through it as it is slowly lowered to the desired

sampling depth. The COLIWASA must not be lowered with the stopper in place. Opening the stopper after the tube is submerged

will cause material to flow in from the bottom layer only, resulting in gross over-representation of that layer.

4.2 This practice is to be used by personnel acquiring samples.

4.3 This practice should be used in conjunction with Guide D4687 which covers sampling plans, safety, QA, preservation,

decontamination, labeling and chain-of-custody procedures; Practice D5088 which covers decontamination of field equipment

1

This practice is under the jurisdiction of ASTM Committee D34 on Waste Management and is the direct responsibility of Subcommittee D34.01.03 on Sampling

Equipment.

Current edition approved July 1, 2011. Published September 2011. Originally approved in 1994. Last previous edition approved in 2007 as D5495-03 (2007). DOI:

10.1520/D5495-03R11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5495 − 03 (2011)

used at waste sites; Practice D5283 which covers project specifications and practices for environmental field operations, and

Practice D5743 which covers drum sampling.

5. Sampling Equipment

5.1 COLIWASAs are available commercially with different types of stoppers and locking mechanisms, but they all operate

using the same principle. They can also be constructed from materials such as polyvinylchloride (PVC), glass, metal, or

3,4

polytetrafl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.