ASTM E796-94

(Test Method)Standard Test Method for Ductility Testing of Metallic Foil

Standard Test Method for Ductility Testing of Metallic Foil

SCOPE

1.1 This test method covers the determination of ductility, that is, the ability to undergo plastic deformation in tension or bending before fracturing, of metallic foil in thicknesses up through 0.150 mm (0.0059 in.).

1.2 Values stated in SI units are to be regarded as the standard. Inch-pound units are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 796 – 94 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Ductility Testing of Metallic Foil

This standard is issued under the fixed designation E 796; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

true tensile strain at fracture. Elongation and reduction of area represent

1. Scope

the engineering tensile strain after fracture.

1.1 This test method covers the determination of ductility,

NOTE 3—For the purpose of this definition the fatigue ductility expo-

that is, the ability to undergo plastic deformation in tension or 4

nent, c, is defined as c 5 −0.60 (see equation in 9.1).

bending before fracturing, of metallic foil in thicknesses up

4. Summary of Test Method

through 0.150 mm (0.0059 in.).

1.2 Values stated in SI units are to be regarded as the

4.1 The specimen is subjected to a fatigue test which

standard. Inch-pound units are provided for information only.

employs precisely controlled, symmetric, cyclic, constant-

1.3 This standard does not purport to address all of the

amplitude, flexural strains of a magnitude that will cause

safety concerns, if any, associated with its use. It is the

fracture in the low-cycle fatigue regime.

responsibility of the user of this standard to establish appro-

4.2 The fatigue ductility is determined from an equation

priate safety and health practices and determine the applica-

derived from universal, empirical, relationships between ten-

bility of regulatory limitations prior to use.

sile properties and fatigue behavior which utilizes the strain

range employed and the fatigue life obtained in the fatigue test,

2. Referenced Documents

as well as the modulus of elasticity, the tensile strength and the

2.1 ASTM Standards:

fracture strength determined in accordance with Test Method

E 3 Methods of Preparation of Metallographic Specimens

E 111 and Test Methods E 8, with the provisions in Test

E 6 Terminology Relating to Methods of Mechanical Test-

Methods E 345 and in this standard.

ing

5. Significance and Use

E 8 Test Methods for Tension Testing of Metallic Materials

E 111 Test Method for Young’s Modulus, Tangent Modulus,

5.1 For bulk specimens, tension tests provide an adequate

and Chord Modulus

means to determine the ductility of materials either through the

E 345 Test Methods of Tension Testing of Metallic Foil

measurement of elongation or reduction of area. For foil

E 513 Definitions of Terms Relating to Constant-Amplitude

specimens, however, tension tests are not very useful for the

Low-Cycle Fatigue Testing

determination of ductility. This test method, employing low-

E 606 Practice for Strain Controlled Fatigue Testing

cycle fatigue, circumvents the difficulties arising from the

E 1150 Definitions of Terms Relating to Fatigue

continuous application of strain until fracture and determines

the ductility indirectly from empirical low-cycle fatigue rela-

3. Terminology

tionships for metals.

3.1 Definitions:

5.2 The results of ductility tests from selected portions of a

3.1.1 The definitions of terms appearing in Definitions E 6,

metallic foil may not totally represent the ductility of the entire

E 1150, E 513, and Practice E 606, shall be considered as

foil or its in-service behavior in different environments.

applying to the terms used in this test method.

5.3 This test method is considered satisfactory for accep-

3.1.2 fatigue ductility, D —the ability of a material to

f tance testing of commercial shipments, design purposes, ser-

deform plastically before fracturing, determined from a

vice evaluation, manufacturing control, and research and

constant-strain amplitude, low-cycle fatigue test.

development.

NOTE 1—Fatigue ductility is usually expressed in percent in direct

6. Apparatus

analogy with elongation and reduction of area ductility measures.

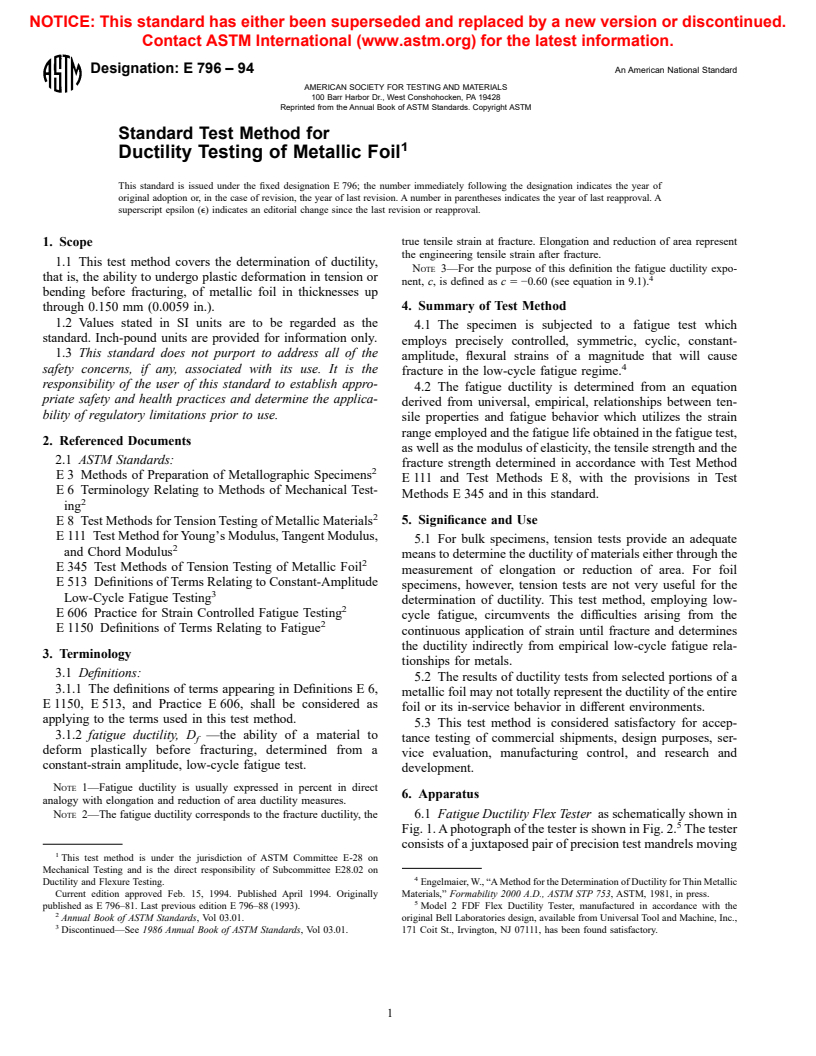

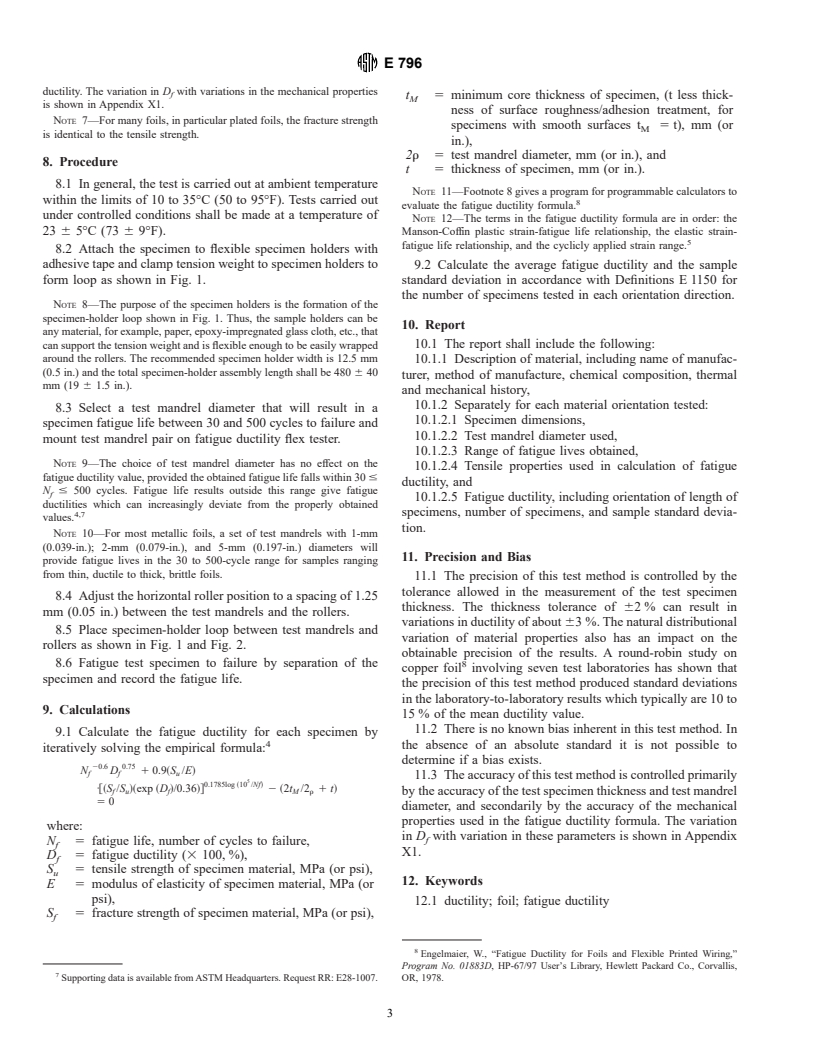

NOTE 2—The fatigue ductility corresponds to the fracture ductility, the 6.1 Fatigue Ductility Flex Tester as schematically shown in

Fig. 1. A photograph of the tester is shown in Fig. 2. The tester

consists of a juxtaposed pair of precision test mandrels moving

This test method is under the jurisdiction of ASTM Committee E-28 on

Mechanical Testing and is the direct responsibility of Subcommittee E28.02 on

Ductility and Flexure Testing. Engelmaier, W., “A Method for the Determination of Ductility for Thin Metallic

Current edition approved Feb. 15, 1994. Published April 1994. Originally Materials,” Formability 2000 A.D., ASTM STP 753, ASTM, 1981, in press.

published as E 796–81. Last previous edition E 796–88 (1993). Model 2 FDF Flex Ductility Tester, manufactured in accordance with the

Annual Book of ASTM Standards, Vol 03.01. original Bell Laboratories design, available from Universal Tool and Machine, Inc.,

Discontinued—See 1986 Annual Book of ASTM Standards, Vol 03.01. 171 Coit St., Irvington, NJ 07111, has been found satisfactory.

E 796

of the yield strength (0.2 % offset, determined in accordance

with Test Methods E 8 with the provisions in Test Methods

E 345) of the material. A 100-g (3-oz) tension weight is

suitable for most specimens; however, for very thin foil

specimens it might be necessary to use a lighter tension weight.

6.2 Double-Bladed Specimen Cutter, as required in Test

Methods E 345, but capable of cutting specimens to the width

required herein (Section 7).

7. Test Specimens

7.1 Specimen Preparation—Test specimens shall be pre-

pared in accordance with Test Methods E 345, Type B speci-

mens, with the dimensions as specified herein. The specimens

may be prepared individually by use of a double-bladed cutter.

The cutting edges of the blades should be lubricated with a

material such as stearic acid in alcohol or other suitable

material. The finished specimens shall be examined under

about 20 3 magnification to ascertain that the edges are

smooth and that there are no surface scratches or creases.

FIG. 1 Schematic of Fatigue Ductility Flex Tester Showing

Specimens showing discernible surface scratches, creases, or

Principle of Operation

edge discontinuities shall be rejected.

7.2 Specimen Thickness—Specimen thickness shall be de-

termined in accordance with Test Methods E 345. The thick-

ness of each specimen may be determined by any suitable

means, provided that the thickness of each specimen is

measured to an accuracy of 2 %.

NOTE 4—For specimens for which the density is not known, for

example, plated foil, the thickness of the specimens will have to be

measured directly even for soft materials or materials thinner than 0.025

mm (0.001 in.).

NOTE 5—For specimens with rough surfaces, it is necessary to deter-

mine the minimum core thickness, that is, the specimen thickness without

the rough surface features, from a metallographic cross section, prepared

in accordance with Methods E 3.

7.3 Specimen Dimensions—The test specimens shall have

the following dimensions:

7.3.1 Width—2.5 to 7.5 mm (0.1 to 0.3 in.) with 3.2 mm

(0.125 in.) the preferred width.

7.3.2 Length—30 mm (1.2 in.) minimum.

7.4 Number of Specimens—It is recommended that at least

three specimens in both the main orientation direction (direc-

tion of rolling for wrought foil, direction of plating solution

FIG. 2 Fatigue Ductility Flex Tester, Model 2 FDF

agitation for plated foil) and the orthogonal direction be tested.

7.5 Mechanical Properties—For purposes of performing the

1 1

vertically a total of 38 63mm(1 ⁄2 6 ⁄8 in.) at 50 cycles/min.

test and calculating the fatigue ductility, it is desirable to have

The specimen, held in a horizontal position by six rollers and

available in both the main orientation direction and the

positioned between the two test mandrels, is subjected to cyclic

orthogonal direction the following mechanical properties, ob-

flexural strains by being bent alternately around the two test

tained in accordance with the applicable standards such as Test

mandrels. The precision test mandrels shall have uniform

Methods E 8, Test Method E 111, and Methods E 345: tensile

roundness, a maximum surface roughness height of 0.25 μm

yield strength, tensile strength, tensile fracture strength, and

(10 μin.), and a minimum surface hardness of 60 HRC. The

modulus of elasticity.

diamet

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.