ASTM B366-10a

(Specification)Standard Specification for Factory-Made Wrought Nickel and Nickel Alloy Fittings

Standard Specification for Factory-Made Wrought Nickel and Nickel Alloy Fittings

ABSTRACT

This specification covers wrought welding fittings, including threaded fittings, for pressure piping, factory-made from nickel and nickel alloys. The term welding applies to butt-welding or socket-welding parts such as elbows, bends, caps, tees, reducers, lap-joint, and stub ends. This specification does not apply to cast welding fittings. Grades of nickel and nickel alloys included in this specification are designated with a prefix, WP or CR, based on dimensional and rating standards. WP grades have class designations (Class S, Class W, Class WX, and Class WU) to indicate whether seamless or welded construction is utilized and to indicate the nondestructive test method and extent of nondestructive examination (such as radiography and/or ultrasonic test). The material for wrought welding fittings may consist of forgings, rods, bars, plates, sheets, and seamless or welded pipe that conform to all the specified requirements. Forging or shaping operations may be performed by hammering, pressing, piercing, extruding, upsetting, rolling, bending, or fusion welding, or by a combination of two or more of these operations. Chemical and product analyses shall conform to the chemical composition prescribed. Requirements for tensile properties, heat treatment, tension test, and dimensions are detailed. Hydrostatic testing of wrought fittings is not required by this specification.

SCOPE

1.1 This specification covers wrought welding fittings for pressure piping, factory-made from nickel and nickel alloys. Threaded fittings as covered in ASME B16.11 are also covered by this specification. The term welding applies to butt-welding or socket-welding parts such as 45 and 90° elbows, 180° bends, caps, tees, reducers, lap-joint stub ends, and other types, as covered by ASME B16.9, ASME B16.11, MSS SP-43, MSS SP-95, and MSS SP-97.

1.1.1 Several grades of nickel and nickel alloys are included in this specification. Grades are designated with a prefix, WP or CR, based on the applicable ASME or MSS dimensional and rating standards.

1.1.2 Class WP fittings are those manufactured to the requirements of ASME B16.9, B16.11.

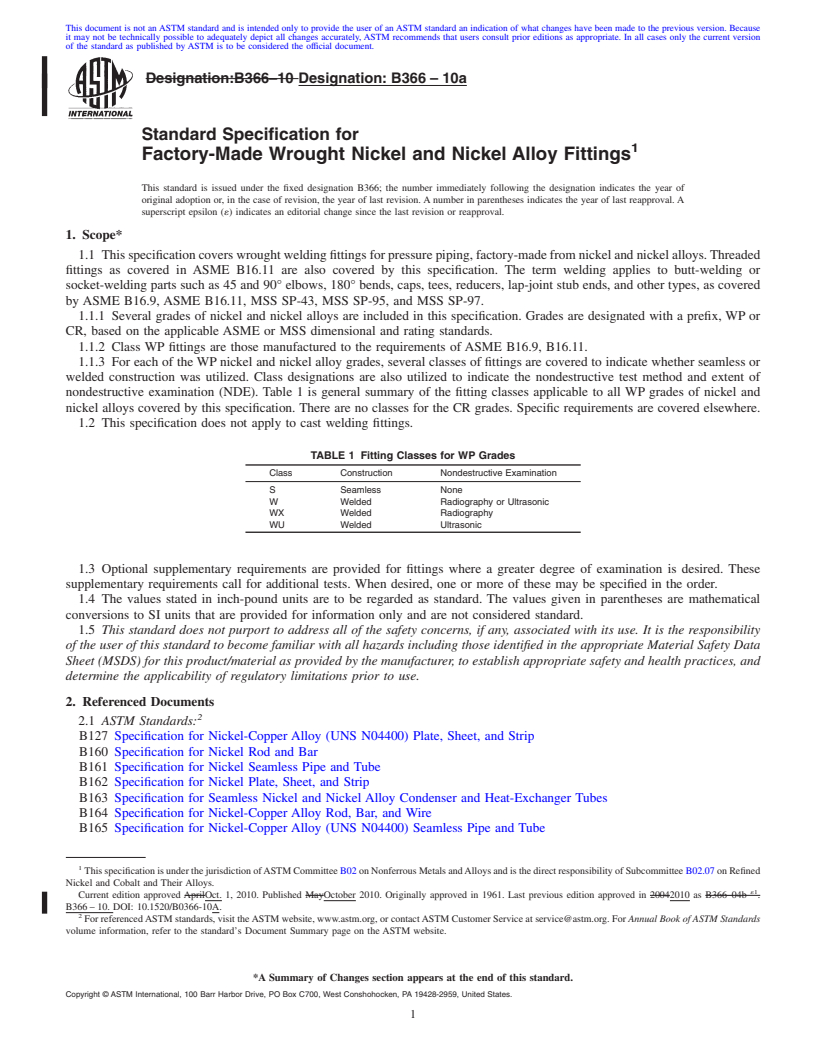

1.1.3 For each of the WP nickel and nickel alloy grades, several classes of fittings are covered to indicate whether seamless or welded construction was utilized. Class designations are also utilized to indicate the nondestructive test method and extent of nondestructive examination (NDE). Table 1 is general summary of the fitting classes applicable to all WP grades of nickel and nickel alloys covered by this specification. There are no classes for the CR grades. Specific requirements are covered elsewhere.

1.2 This specification does not apply to cast welding fittings.

1.3 Optional supplementary requirements are provided for fittings where a greater degree of examination is desired. These supplementary requirements call for additional tests. When desired, one or more of these may be specified in the order.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B366 −10a

StandardSpecification for

1

Factory-Made Wrought Nickel and Nickel Alloy Fittings

This standard is issued under the fixed designation B366; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* responsibility of the user of this standard to become familiar

with all hazards including those identified in the appropriate

1.1 This specification covers wrought welding fittings for

Material Safety Data Sheet (MSDS) for this product/material

pressure piping, factory-made from nickel and nickel alloys.

as provided by the manufacturer, to establish appropriate

Threaded fittings as covered inASME B16.11 are also covered

safety and health practices, and determine the applicability of

by this specification. The term welding applies to butt-welding

regulatory limitations prior to use.

orsocket-weldingpartssuchas45and90°elbows,180°bends,

caps, tees, reducers, lap-joint stub ends, and other types, as

2. Referenced Documents

covered by ASME B16.9, ASME B16.11, MSS SP-43, MSS

2

2.1 ASTM Standards:

SP-95, and MSS SP-97.

B127 Specification for Nickel-CopperAlloy (UNS N04400)

1.1.1 Severalgradesofnickelandnickelalloysareincluded

Plate, Sheet, and Strip

inthisspecification.Gradesaredesignatedwithaprefix,WPor

B160 Specification for Nickel Rod and Bar

CR, based on the applicable ASME or MSS dimensional and

B161 Specification for Nickel Seamless Pipe and Tube

rating standards.

B162 Specification for Nickel Plate, Sheet, and Strip

1.1.2 Class WP fittings are those manufactured to the

B163 Specification for Seamless Nickel and Nickel Alloy

requirements of ASME B16.9, B16.11.

(UNS N06845) Condenser and Heat-Exchanger Tubes

1.1.3 For each of the WP nickel and nickel alloy grades,

B164 Specification for Nickel-Copper Alloy Rod, Bar, and

several classes of fittings are covered to indicate whether

Wire

seamless or welded construction was utilized. Class designa-

B165 Specification for Nickel-CopperAlloy (UNS N04400)

tionsarealsoutilizedtoindicatethenondestructivetestmethod

Seamless Pipe and Tube

and extent of nondestructive examination (NDE). Table 1 is

B166 Specification for Nickel-Chromium-IronAlloys (UNS

general summary of the fitting classes applicable to all WP

N06600, N06601, N06603, N06690, N06693, N06025,

gradesofnickelandnickelalloyscoveredbythisspecification.

N06045, and N06696), Nickel-Chromium-Cobalt-

There are no classes for the CR grades. Specific requirements

Molybdenum Alloy (UNS N06617), and Nickel-Iron-

are covered elsewhere.

Chromium-Tungsten Alloy (UNS N06674) Rod, Bar, and

1.2 This specification does not apply to cast welding fit-

Wire

tings.

B167 Specification for Nickel-Chromium-IronAlloys (UNS

N06600, N06601, N06603, N06690, N06693, N06025,

1.3 Optional supplementary requirements are provided for

N06045, and N06696), Nickel-Chromium-Cobalt-

fittingswhereagreaterdegreeofexaminationisdesired.These

Molybdenum Alloy (UNS N06617), and Nickel-Iron-

supplementary requirements call for additional tests. When

Chromium-TungstenAlloy (UNS N06674) Seamless Pipe

desired, one or more of these may be specified in the order.

and Tube

1.4 The values stated in inch-pound units are to be regarded

B168 Specification for Nickel-Chromium-IronAlloys (UNS

as standard. The values given in parentheses are mathematical

N06600, N06601, N06603, N06690, N06693, N06025,

conversions to SI units that are provided for information only

N06045, and N06696), Nickel-Chromium-Cobalt-

and are not considered standard.

Molybdenum Alloy (UNS N06617), and Nickel-Iron-

1.5 This standard does not purport to address all of the

Chromium-Tungsten Alloy (UNS N06674) Plate, Sheet,

safety concerns, if any, associated with its use. It is the

and Strip

B333 Specification for Nickel-Molybdenum Alloy Plate,

Sheet, and Strip

1

This specification is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

2

B02.07 on Refined Nickel and Cobalt and Their Alloys. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2010. Published October 2010. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1961. Last previous edition approved in 2010 as B366 – 10. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0366-10A. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 -------------------

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B366–10 Designation: B366 – 10a

Standard Specification for

1

Factory-Made Wrought Nickel and Nickel Alloy Fittings

This standard is issued under the fixed designation B366; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 Thisspecificationcoverswroughtweldingfittingsforpressurepiping,factory-madefromnickelandnickelalloys.Threaded

fittings as covered in ASME B16.11 are also covered by this specification. The term welding applies to butt-welding or

socket-welding parts such as 45 and 90° elbows, 180° bends, caps, tees, reducers, lap-joint stub ends, and other types, as covered

by ASME B16.9, ASME B16.11, MSS SP-43, MSS SP-95, and MSS SP-97.

1.1.1 Several grades of nickel and nickel alloys are included in this specification. Grades are designated with a prefix, WP or

CR, based on the applicable ASME or MSS dimensional and rating standards.

1.1.2 Class WP fittings are those manufactured to the requirements of ASME B16.9, B16.11.

1.1.3 For each of the WP nickel and nickel alloy grades, several classes of fittings are covered to indicate whether seamless or

welded construction was utilized. Class designations are also utilized to indicate the nondestructive test method and extent of

nondestructive examination (NDE). Table 1 is general summary of the fitting classes applicable to all WP grades of nickel and

nickel alloys covered by this specification. There are no classes for the CR grades. Specific requirements are covered elsewhere.

1.2 This specification does not apply to cast welding fittings.

TABLE 1 Fitting Classes for WP Grades

Class Construction Nondestructive Examination

S Seamless None

W Welded Radiography or Ultrasonic

WX Welded Radiography

WU Welded Ultrasonic

1.3 Optional supplementary requirements are provided for fittings where a greater degree of examination is desired. These

supplementary requirements call for additional tests. When desired, one or more of these may be specified in the order.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data

Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and

determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B127 Specification for Nickel-Copper Alloy (UNS N04400) Plate, Sheet, and Strip

B160 Specification for Nickel Rod and Bar

B161 Specification for Nickel Seamless Pipe and Tube

B162 Specification for Nickel Plate, Sheet, and Strip

B163 Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes

B164 Specification for Nickel-Copper Alloy Rod, Bar, and Wire

B165 Specification for Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB02onNonferrousMetalsandAlloysandisthedirectresponsibilityofSubcommitteeB02.07onRefined

Nickel and Cobalt and Their Alloys.

´1

Current edition approved AprilOct. 1, 2010. Published MayOctober 2010. Originally approved in 1961. Last previous edition approved in 20042010 as B366–04b .

B366 – 10. DOI: 10.1520/B0366-10A.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B366 – 10a

B166 Specification for Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045,

and N06696) and Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617) Rod, Bar, and Wire

B167 Specification for Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.