ASTM D25-99(2005)

(Specification)Standard Specification for Round Timber Piles

Standard Specification for Round Timber Piles

ABSTRACT

This specification deals with the standards for unused round timber piles to be used either treated or untreated. This specification, however, does not cover preused piles unless the piles have the quality and design stresses equal to or greater than those prescribed herein. The piles shall be made of sound wood, free of decay, insect attacks, marine borer attack, and Limnoria damage. The piles shall also be cut above the ground swell and have a tapered tip.

SCOPE

1.1 This specification covers the physical characteristics of unused round timber piles to be used either treated or untreated.

1.2 This specification is not intended for preused piles unless the piles have the quality specified by this specification and design stresses equal to or greater than those derived from Method D 2899.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 his standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D25 – 99 (Reapproved 2005)

Standard Specification for

Round Timber Piles

ThisstandardisissuedunderthefixeddesignationD25;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4.2 Method D2899 provides a basis for specifying the pile

size. This standard gives a procedure for estimating the design

1.1 This specification covers the physical characteristics of

stress at any location along the pile length. As design stress

unused round timber piles to be used either treated or un-

must always exceed that imposed under service conditions, the

treated.

quotient of the structural loads divided by the design stress

1.2 This specification is not intended for preused piles

gives an estimate of the minimum section property required at

unless the piles have the quality specified by this specification

any location.

and design stresses equal to or greater than those derived from

4.3 Under this specification, pile size requirements esti-

Method D2899.

mated at a critical location are extrapolated to either the tip or

1.3 The values stated in inch-pound units are to be regarded

buttendassumingalineartaper.Forthisspecification,pilesare

as standard. The values given in parentheses are mathematical

classified by nominal circumference and length.

conversions to SI units that are provided for information only

and are not considered standard.

5. Quality Requirement (All Piles)

1.4 This standard does not purport to address all of the

5.1 Piles shall be of sound wood, free of decay, insect

safety concerns, if any, associated with its use. It is the

attack, marine borer attack, and Limnoria damage, except as

responsibility of the user of this standard to establish appro-

herein allowed in 13.2 and 14.1.

priate safety and health practices and determine the applica-

5.2 Piles shall be cut above the ground swell and have a

bility of regulatory limitations prior to use.

taper from butt to tip.

2. Referenced Documents 5.3 Piles shall have an average rate of growth measured in

the outer 50 % of the radius at the pile tip of not less than 6

2.1 ASTM Standards:

rings per inch and shall have an average summerwood content

D9 Terminology Relating to Wood and Wood-Based Prod-

of not less than 33.3 % in the outer 50 % of the tip radius.

ucts

Exception: Piles with less than 6 rings per inch are acceptable

D2555 Practice for Establishing Clear Wood Strength Val-

if the average is 50 % or more summerwood present in the

ues

outer 50 % of the pile tip radius.

D2899 Practice for Establishing Allowable Stresses for

5.4 Piles that cannot be adequately inspected for the physi-

Round Timber Piles

cal requirements specified in this specification due to adhering

3. Species of Wood barnacles or other material shall not be permitted.

3.1 Piles shall be of any species of wood for which clear

6. Lengths

wood strength values are given in Test Methods D2555.

6.1 All piles shall be furnished in lengths specified, except

4. Classification

that tolerances shall be allowed as follows:

6.1.1 Piles 40 ft (12.2 m) and shorter—plus 1 ft (0.3 m),

4.1 Timber piles are commonly used to transfer structural

minus 6 in. (152 mm).

loads to sub surface soil bearing strata by way of friction or tip

6.1.2 Piles41ft(12.5m)orlonger—plus2ft(0.6m),minus

end bearing forces, or both.

6 in. (152 mm).

This specification is under the jurisdiction ofASTM Committee D07 on Wood

7. Sizes

and is under the jurisdiction of Subcommittee D07.04 on Pole and Pile Products.

Current edition approved Oct. 1, 2005. Published October 2005. Originally 7.1 Pile sizes are specified according to nominal circumfer-

´1

approved in 1915. Last previous edition approved in 1999 as D25 – 99 . DOI:

ence 3 ft from the butt or at the tip. Tables are provided in

10.1520/D0025-99R05.

Appendix X1.1 to facilitate the selection of pile dimensions.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.2 The out-of-round ratio (maximum to minimum diam-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on eter) at the butt or the tip shall not exceed 1.2.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D25 – 99 (2005)

7.3 All circumference measurements shall be taken under 10.1.3 Unpeeled piles require no bark removal.

the bark.

11. Straightness

7.4 Circumference at the butt shall not exceed circumfer-

ence 3 ft (0.9 m) from the butt by more than 8 in. (203 mm). 11.1 Astraight line from the center of the butt to the center

7.5 Circumferences given in Table X1.4 and Table X1.2 are

of the tip shall lie entirely within the body of the pile.

minimum values. No more than 10 % of piles in any shipment 11.2 Piles shall be free from short crooks that deviate more

shall have tip circumferences less than the tabulated values. Of than 2 ⁄2 in. (64 mm) from straightness in any 5-ft (1.5-m)

those that are below tabulated values, none shall vary from length (see Fig. 1).

tabulated values by more than 2 in. (51 mm).

12. Twist of Grain

8. Sapwood

12.1 Spiral grain shall not exceed 180 deg of twist when

8.1 Wood piles for preservative treatment shall have suffi- measured over any 20-ft (6.1-m) section of the pile.

cient sapwood to meet minimum penetration requirements.

13. Knots

9. Cutting and Trimming

13.1 Sound knots shall be no larger than one sixth the

9.1 Butts and tips of piles shall be sawed square with the

circumference of the pile located where the knot occurs.

axis of the piles and shall not be out of square by more than ⁄10 Cluster knots shall be considered as a single knot, and the

in./in. (100 mm/m) of diameter. entire cluster cannot be greater in size than permitted for a

9.2 All knots and limbs shall be cut flush with the surface of single knot. The sum of knot diameters in any 1-ft (304-mm)

the pile, except that knots may be hand-trimmed flush with the length of pile shall not exceed one third of the circumference

surface of the swell surrounding the knot. at the point where they occur. Knots shall be measured in

accordance with Terminology D9, and at a right angle to the

10. Peeling (Shaving)

length of the pile.

13.2 Piles may have unsound knots not exceeding half the

10.1 Piles are classified according to the extent of bark

removal as clean-peeled, rough-peeled, or unpeeled. permitted size of a sound knot, provided that the unsoundness

extends to not more than a 1 ⁄2-in. (38-mm) depth, and that the

10.1.1 Clean-peeled piles require the removal of all outer

bark. In addition, at least 80 % of the inner bark, well- adjacent areas of the trunk are not affected.

distributed over the surface of the pile, shall be removed. Piles

14. Holes and Scars

for preservative treatment shall have no strip of inner bark

larger than 1 by 6 in. (25 by 152 mm). 14.1 Holes less than ⁄2 in. (12.7 mm) in average diameter

10.1.2 Rough-peeled piles require the complete removal of shall be permitted in the external tangential surface of piles,

all outer bark. provided that the sum of the average diameters of all holes in

The three cases shown are typical, and are intended to establish the principle of measuring shorty crooks. There may be other cases not exactly like those illustrated.

NOTE—5 ft = 1.5 m

FIG. 1 Measurement of Short Crook

D25 – 99 (2005)

any square foot of pile surface does not exceed 1 ⁄2 in. (38 across the rings of normal growth, extending from the surface

mm), and the depth of any hole does not extend to more than toward the pith, but not extending through the piece.

1 ⁄2 in. (38 mm) and provided that the holes are not caused by 15.2 The length of any shake or combination of shakes in

decay, marine borer attack, or Limnoria damage. the outer one half of the radius of the butt of the pile, when

14.2 Internal holes or damage to the cross-section (bearing) measured along the curve of the annual ring, shall not exceed

surfaces caused by decay, marine borers (shipworms or one third of the circumference of the butt of the pile. A shake

pholads), or insects are not permitted. isdefinedasacircumferentialseparationoftheringsofnormal

14.3 Piles having sound turpentine scars undamaged by growth.

insects shall be permitted. 15.3 Splits shall not be longer than the butt diameter.Asplit

is defined as a lengthwise separation of the wood across the

15. Checks, Shakes, and Splits

rings of normal growth, extending from one surface through

15.1 A check shall not extend any deeper than to the pith.

the piece to the opposite surface.

Thereshallnotbeanytwoormorechecksextendingtothepith

16. Keywords

which become contiguous at the pith, except as modified by

15.3.Acheck is defined as a lengthwise separation of the wood 16.1 piles; round timber piles; timber

APPENDIX

(Nonmandatory Information)

X1. PILE SIZE OPTIONS

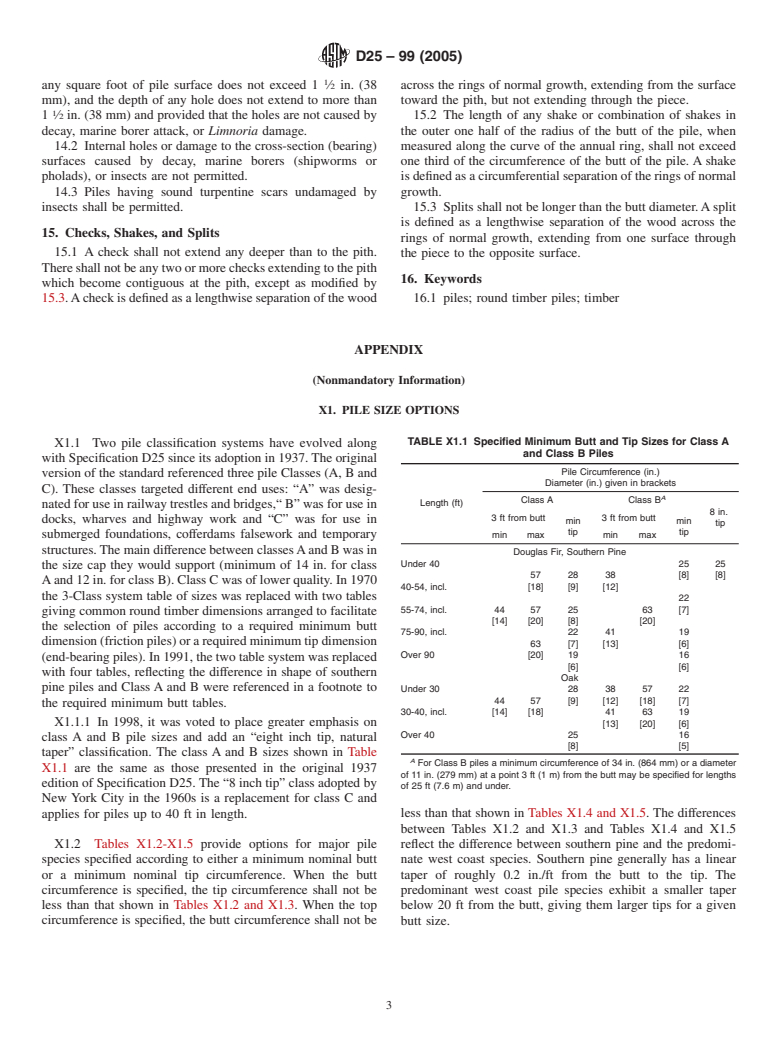

TABLE X1.1 Specified Minimum Butt and Tip Sizes for Class A

X1.1 Two pile classification systems have evolved along

and Class B Piles

with Specification D25 since its adoption in 1937.The original

Pile Circumference (in.)

version of the standard referenced three pile Classes (A, B and

Diameter (in.) given in brackets

C). These classes targeted different end uses: “A” was desig-

A

Class A Class B

Length (ft)

nated for use in railway trestles and bridges,“ B” was for use in

8in.

3 ft from butt 3 ft from butt

docks, wharves and highway work and “C” was for use in

min min

tip

tip tip

submerged foundations, cofferdams falsework and temporary min max min max

structures.ThemaindifferencebetweenclassesAandBwasin

Douglas Fir, Southern Pine

Under 40 25 25

the size cap they would support (minimum of 14 in. for class

57 28 38 [8] [8]

Aand 12 in. for class B). Class C was of lower quality. In 1970

40-54, incl. [18] [9] [12]

the 3-Class system table of sizes was replaced with two tables

55-74, incl. 44 57 25 63 [7]

giving common round timber dimensions arranged to facilitate

[14] [20] [8] [20]

the selection of piles according to a required minimum butt

75-90, incl. 22 41 19

dimension(frictionpiles)orarequiredminimumtipdimension

63 [7] [13] [6]

Over 90 [20] 19 16

(end-bearing piles). In 1991, the two table system was replaced

[6] [6]

with four tables, reflecting the difference in shape of southern

Oak

pine piles and Class A and B were referenced in a footnote to Under 30 28 38 57 22

44 57 [9] [12] [18] [7]

the required minimum butt tables.

30-40, incl. [14] [18] 41 63 19

X1.1.1 In 1998, it was voted to place greater emphasis on [13] [20] [6]

Over 40 25 16

class A and B pile sizes and add an “eight inch tip, natural

[8] [5]

taper” classification. The class A and B sizes shown in Table

A

For Class B piles a minimum circumference of 34 in. (864 mm) or a diameter

X1.1 are the same as those presented in the original 1937

of 11 in. (279 mm) at a point 3 ft (1 m) from the butt may be specified for lengths

edition of Specification D25. The “8 inch tip” class adopted by

of 25 ft (7.6 m) and under.

New York City in the 1960s is a replacement for class C and

applies for piles up to 40 ft in length. less than that shown in Tables X1.4 and X1.5. The differences

between Tables X1.2 and X1.3 and Tables X1.4 and X1.5

X1.2 Tables X1.2-X1.5 provide options for major pile reflect the difference between southern pine and the predomi-

species specified according to either a minimum nominal butt nate west coast species. Southern pine generally has a linear

or a minimum nominal tip circumference. When the butt taper of roughly 0.2 in./ft from the butt to the tip. The

circumference is specified, the tip circumference shall not be predominant west coast pile species exhibit a smaller taper

less than that shown in Tables X1.2 and X1.3. When the top below 20 ft from the butt, giving them larger tips for a given

circumference is specified, the butt circumference shall not be

butt size.

D25 – 99 (2005)

TABLE X1.2 Specified Butt Circumferences with Corresponding Minimum Tip Circumferences for Coast Douglas Fir Piles and Other

A,B

Species, Except Southern Yellow Pine

[Approximate Diameters in Brackets]

Required Minimum 22 25 28 31 35 38 41 44 47 50 57

Circumference, in. [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [18]

3 ft from Butts

Length (ft) Minimum Tip Circumferences, in.

20 16.0 16.0 16.0 18.0 22.0 25.0 28.0 . . . .

[5.1] [5.1] [5.1] [5.7] [7.0] [8.0] [8.9]

25 16.0 16.0 16.0 17.0 20.5 23.5 26.5 29.5 . . .

[5.1] [5.1] [5.1] [5.4] [6.5] [7.5] [8.4] [9.4]

30 16.0 16.0 16.0 16.0 19.0 22.0 25.0 28.0 . . .

[5.1] [5.1] [5.1] [5.1] [6.0] [7.0] [8.0] [8.9]

35 . . . 16.0 18.0 21.0 24.0 27.0 30.0 . .

[5.1] [5.7] [6.7] [7.6] [8.6] [9.5]

40 . . . 16.0 17.0 20.0 23.0 26.0 29.0 . .

[5.1] [5.4] [6.4] [7.3] [8.3] [9.2]

45 . . . . 16.5 18.5 21.0 24.0 27.0 30.0 .

[5.3] [5.9] [6.7] [7.6] [8.6] [9.5]

50 . . . . 16.0 17.0 19.0 22.0 25.0 28.0 .

[5.1] [5.4] [6.0] [7.0] [8.0] [8.9]

55 . . . . . 16.5 17.5 20.3 23.3 26.3 31.3

[5.3] [5.6] [6.5] [7.4] [8.4] [10.0]

60 . . . . . 16.0 16.0 18.6 21.6 24.6 31.6

[5.1] [5.1] [5.9] [6.9] [7.8] [10.0]

65 . . . . . 16.0 16.0 17.3 18.9 21.9 28.9

[5.1] [5.1] [5.5] [6.0] [7.0] [9.2]

70 . . . . . 16.0 16.0 16.0 16.2 19.2 26.2

[5.1] [5.1] [5.1] [5.2] [6.1] [8.3]

75 . . . . . . 16.0 16.0 16.1 17.6 24.0

[5.1] [5.1] [5.1] [5.6] [7.6]

80 . . . . . . 16.0 16.0 16.0 16.0 21.8

[5.1] [5.1] [5.1] [5.1] [6.9]

85 . . . . . . 16.0 16.0 16.0 16.0 20.6

[5.1] [5.1] [5.1] [5.1] [6.6]

90 . . . . . . 16.0 16.0 16.0 16.0 19.5

[5.1] [5.1] [5.1] [5.1] [6.2]

95 . . . . . . 16.0 16.0 16.0 16.0 18.8

[5.1] [5.1] [5.1] [5.1] [6.0]

100 . . . . . . 16.0 16.0 16.0 16.0 18.0

[5.1] [5.1] [5.1] [5.1] [5.7]

105 . . . . . . . . . 16.0 17.0

[5.1] [5.4]

110 . . . . . . . . . 16.0 16.0

[5.1] [5.1]

115 . . . . . . . . . . 16.0

[5.1]

120 . . . . . . . . . . 16.0

[5.1]

A

Where the taper applied to the butt circumferences calculate to a circumference at the tip of less than 16 in., the individual values have been increasedto16in.to

ensure a minimum of 5-in. tip for purposes of driving.

B

To convert to metric dimensions, 1 in. = 25.4 mm.

D25 – 99 (2005)

A,B,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.