ASTM D5466-95

(Test Method)Standard Test Method for Determination of Volatile Organic Chemicals in Atmospheres (Canister Sampling Methodology)

Standard Test Method for Determination of Volatile Organic Chemicals in Atmospheres (Canister Sampling Methodology)

SCOPE

1.1 This test method describes a procedure for sampling and analysis of volatile organic compounds (VOCs) in ambient, indoor, or workplace atmospheres. The test method is based on the collection of air samples in stainless steel canisters with specially treated (passivated) interior surfaces. For sample analysis, a portion of the sample is subsequently removed from the canister and the collected VOCs are selectively concentrated by adsorption or condensation onto a trap, subsequently released by thermal desorption, separated by gas chromatography, and measured by a mass spectrometric detector or other detector(s). This test method describes procedures for sampling into canisters to final pressures both above and below atmospheric pressure (respectively referred to as pressurized and subatmospheric pressure sampling).

1.2 This test method is applicable to specific VOCs that have been tested and determined to be stable when stored in canisters. Numerous compounds, many of which are chlorinated VOCs, have been successfully tested for storage stability in pressurized canisters (1-4). Although not as extensive, documentation is also available demonstrating stability of VOCs in subatmospheric pressure canisters. While initial studies were concentrated on non-polar VOCs, information on storage stability has been extended to many polar compounds as well (5-7).

1.3 The procedure for collecting the sample involves the use of inlet lines and air filters, flow rate regulators for obtaining time-integrated samples, and in the case of pressurized samples, an air pump. Canister samplers have been designed to automatically start and stop the sample collection process using electronically actuated valves and timers (8-10). A weatherproof shelter is required if the sampler is to be used outside.

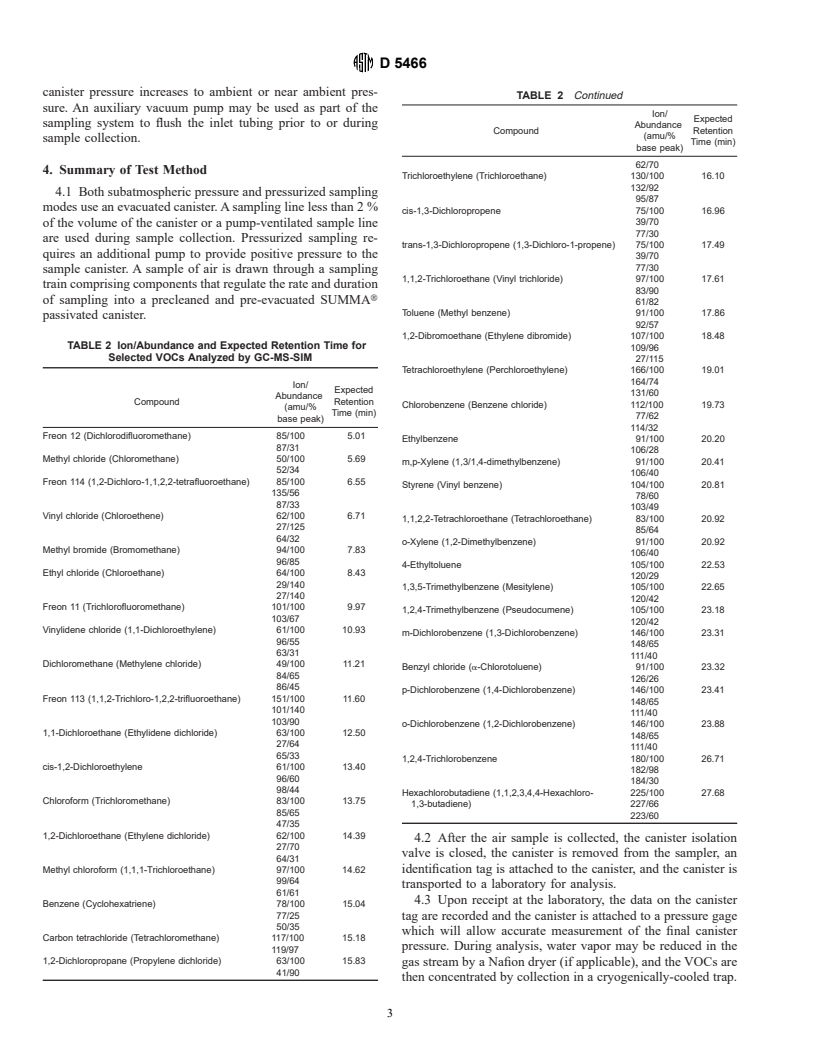

1.4 The organic compounds that have been successfully measured at single-digit parts-per-billion by volume (ppbv) levels with this test method are listed in . This test method is applicable to VOC concentrations ranging from the detection limit to 300 ppbv. Above this concentration, samples require dilution with dry ultra-high-purity nitrogen or air.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Safety practices should be part of the user's SOP manual.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5466 – 95 An American National Standard

Standard Test Method for

Determination of Volatile Organic Chemicals in

Atmospheres (Canister Sampling Methodology)

This standard is issued under the fixed designation D 5466; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method describes a procedure for sampling and 2.1 ASTM Standards:

analysis of volatile organic compounds (VOCs) in ambient, D 1356 Terminology Relating to Sampling and Analysis of

indoor, or workplace atmospheres. The test method is based on Atmospheres

the collection of air samples in passivated stainless steel D 1357 Practice for Planning and Sampling of the Ambient

canisters. The VOCs are subsequently removed from the Atmosphere

canisters, separated by gas chromatography, and measured by E 260 Practice for Packed Column Gas Chromatography

a mass spectrometric detector. This test method describes E 355 Practice for Gas Chromatography Terms and Rela-

procedures for sampling into canisters to final pressures both tionships

above and below atmospheric pressure (respectively referred to 2.2 Other Documents:

as pressurized and subatmospheric pressure sampling). U.S. Environmental Protection Agency Technical Assistance

1.2 This test method is applicable to specific VOCs that Document for Sampling and Analysis of Toxic Organic

have been tested and determined to be stable when stored in Compounds in Ambient Air (3)

pressurized and subatmospheric pressure canisters. Numerous Laboratory and Ambient Air Studies (4-20)

compounds, many of which are chlorinated VOCs, have been

3. Terminology

successfully tested for storage stability in pressurized canisters

3.1 Definitions—For definitions of terms used in this test

(1, 2). While not as extensive, documentation is currently also

available demonstrating stability of VOCs in subatmospheric method, refer to Terminology D 1356. Other pertinent abbre-

viations and symbols are defined within this practice at point of

pressure canisters.

1.3 The organic compounds that have been successfully use.

3.2 Definitions of Terms Specific to This Standard:

collected in pressurized canisters by this test method are listed

in Table 1. These compounds have been successfully measured 3.2.1 absolute canister pressure—Pg+Pa, where Pg

= gage pressure in the canister. (KPa, psi) and Pa = barometric

at the parts per billion by volume (ppbv) level. This test method

is applicable to concentrations of VOC from the detection limit pressure (see 5.2).

3.2.2 absolute pressure—pressure measured with reference

to 300 ppb by volume. Above this concentration samples

require dilution with dry ultra high purity nitrogen or air. to absolute zero pressure (as opposed to atmospheric pressure),

usually expressed as kPa, mm Hg, or psia.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.2.3 certification—the process of demonstrating with hu-

responsibility of the user of this standard to establish appro- mid zero air and humid calibration gases that the sampling

systems components and the canister will not change the

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Safety practices concentrations of sampled and stored atmospheres.

3.2.4 cryogen—a refrigerant used to obtain very low tem-

should be part of the user’s SOP manual.

peratures in the cryogenic trap of the analytical system. A

typical cryogen is liquid argon (bp −185.7°C) or liquid nitro-

gen (bp −195°C).

This test method is under the jurisdiction of ASTM Committee D-22 on

3.2.5 dynamic calibration—calibration of an analytical sys-

Sampling and Analysis of Atmospheres and is the direct responsibility of Subcom-

tem using calibration gas standard concentrations generated by

mittee D22.05 on Indoor Air.

diluting known concentration compressed gas standards with

Current edition approved Dec. 10, 1995. Published February 1996. Originally

published as D 5466 – 93. Last previous edition D 5466 – 93.

purified, humidified inert gas.

This test method is based on EPA Compendium Method TO-14, “The

3.2.5.1 Discussion—Such standards are in a form identical

Determination of Volatile Organic Compounds (VOCs) in Ambient Air Using

or very similar to the samples to be analyzed. Calibration

SUMMA Passivated Canister Sampling and Gas Chromatographic Analysis,” May

1988.

The boldface numbers in parentheses refer to the list of references at the end

Annual Book of ASTM Standards, Vol 11.03.

of the standard.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5466

TABLE 1 Volatile Organic Compounds Known to Have Been Analyzed by the Canister Method

Molecular

Compound (Synonym) Formula Boiling Point (°C) Melting Point (°C) Cas Number

Weight

Freon 12 (Dichlorodifluoromethane) Cl CF 120.91 −29.8 −158.0

2 2

Methyl chloride (Chloromethane) CH Cl 50.49 −24.2 −97.1 74-87-3

Freon 114 (1,2-Dichloro-1,1,2,2-tetrafluoroethane) ClCF CClF 170.93 4.1 −94.0

2 2

—

Vinyl chloride (Chloroethylene) CH —CHCl 62.50 −13.4 −1538.0 75-01-4

Methyl bromide (Bromomethane) CH Br 94.94 3.6 −93.6 74-83-9

Ethyl chloride (Chloroethane) CH CH Cl 64.52 12.3 −136.4 75-00-3

3 2

Freon 11 (Trichlorofluoromethane) CCl F 137.38 23.7 −111.0

Vinylidene chloride (1,1-Dichloroethene) C H Cl 96.95 31.7 −122.5 75-35-4

2 2 2

Dichloromethane (Methylene chloride) CH Cl 84.94 39.8 −95.1 75-09-2

2 2

Freon 113 (1,1,2-Trichloro-1,2,2-trifluoroethane) CF ClCCl F 187.38 47.7 −36.4

2 2

1,1-Dichloroethane (Ethylidene chloride) CH CHCl 98.96 57.3 −97.0 74-34-3

3 2

—

cis-1,2-Dichloroethylene CHCl—CHCl 96.94 60.3 −80.5

Chloroform (Trichloromethane) CHCl 119.38 61.7 −63.5 67-66-3

1,2-Dichloroethane (Ethylene dichloride) ClCH CH Cl 98.96 83.5 −35.3 107-06-2

2 2

Methyl chloroform (1,1,1,-Trichloroethane) CH CCl 133.41 74.1 −30.4 71-55-6

3 3

Benzene (Cyclohexatriene) C H 78.12 80.1 5.5 71-43-2

6 6

Carbon tetrachloride (Tetrachloromethane) CCl 153.82 76.5 −23.0 56-23-5

1,2-Dichloropropane (Propylene dichloride) CH CHClCH Cl 112.99 96.4 −100.4 78-87-5

3 2

—

Trichloroethylene (Trichloroethene) ClCH—CCl 131.29 87 −73.0 79-01-6

—

cis-1,3-Dichloropropene (cis-1,3-dichloropropylene) CH CC—CHCl 110.97 76

—

trans-1,3-Dichloropropene (cis-1,3-Dichloropropylene) 110.97 112.0

ClCH CH—CHCl

1,1,2-Trichloroethane (Vinyl trichloride) CH ClCHCl 133.41 113.8 −36.5 79-00-5

2 2

Toluene (Methyl benzene) C H CH 92.15 110.6 −95.0 108-88-3

6 5 3

1,2-Dibromoethane (Ethylene dibromide) BrCH CH Br 187.88 131.3 9.8 106-93-4

2 2

—

Tetrachloroethylene (Perchloroethylene) Cl C—CCl 165.83 121.1 −19.0 127-18-4

2 2

Chlorobenzene (Phenyl chloride) C H Cl 112.56 132.0 −45.6 108-90-7

6 5

Ethylbenzene C H C H 106.17 136.2 −95.0 100-41-4

6 5 2 5

m-Xylene (1,3-Dimethylbenzene) 1,3-(CH ) C H 106.17 139.1 −47.9

3 2 6 4

p-Xylene (1,4-Dimethylxylene) 1,4-(CH ) C H 106.17 138.3 13.3

3 2 6 4

—

Styrene (Vinyl benzene) C H CH—CH 104.16 145.2 −30.6 100-42-5

6 5 2

1,1,2,2-Tetrachloroethane CHCl CHCl 167.85 146.2 −36.0 79-34-5

2 2

o-Xylene (1,2-Dimethylbenzene) 1,2-(CH ) C H 106.17 144.4 −25.2

3 2 6 4

1,3,5-Trimethylbenzene (Mesitylene) 1,3,5-(CH ) C H 120.20 164.7 −44.7 108-67-8

3 3 6 6

1,2,4-Trimethylbenzene (Pseudocumene) 1,2,4-(CH ) C H 120.20 169.3 −43.8 95-63-6

3 3 6 6

m-Dichlorobenzene (1,3-Dichlorobenzene) 1,3-Cl C H 147.01 173.0 −24.7 541-73-1

2 6 4

Benzyl chloride (a-Chlorotoluene) C H CH Cl 126.59 179.3 −39.0 100-44-7

6 5 2

o-Dichlorobenzene (1,2-Dichlorobenzene) 1,2-Cl C H 147.01 180.5 −17.0 95-50-1

2 6 4

p-Dichlorobenzene (1,4-Dichlorobenzene) 1,4-Cl C H 147.01 174.0 53.1 106-46-7

2 6 4

1,2,4-Trichlorobenzene Hexachlorobutadiene (1,1,2,3,4,4- 1,2,4-Cl C H 181.45 213.5 17.0 120-82-1

3 6 3

Hexachloro-1,3-butadiene)

standards are introduced into the inlet of the sampling or for selected constituents of the sample gas as programmed by

analytical system in the same manner as authentic field the user.

samples. 3.2.10 pressurized sampling—collection of an air sample in

3.2.6 gage pressure—pressure measured above ambient at- a canister with a (final) canister pressure above atmospheric

mospheric pressure (as opposed to absolute pressure). Zero pressure, using a sample pump.

gage pressure is equal to ambient atmospheric (barometric)

3.2.11 qualitative accuracy—the ability of an analytical

pressure. system to correctly identify compounds.

3.2.7 megabore column—chromatographic column having

3.2.12 quantitative accuracy—the ability of an analytical

an internal diameter (I.D.) greater than 0.50 mm. system to correctly measure the concentration of an identified

3.2.7.1 Discussion—The Megabore column is a trademark compound.

of the J & W Scientific Co. For purposes of this test method, 3.2.13 static calibration—calibration of an analytical sys-

Megabore refers to chromatographic columns with 0.53 mm

tem using standards in a form different than the samples to be

I.D. analyzed.

3.2.8 MS-SCAN—the GC is coupled to a Mass Spectrom- 3.2.13.1 Discussion—An example of a static calibration

eter (MS) programmed to scan all ions over a preset range would be injecting a small volume of a high concentration

repeatedly during the GC run.

standard directly onto a GC column, bypassing the sample

3.2.8.1 Discussion—As used in the current context, this extraction and preconcentration portion of the analytical sys-

tem.

procedure serves as a qualitative identification and character-

ization of the sample. 3.2.14 subatmospheric sampling—collection of an air

3.2.9 MS-SIM—the GC is coupled to a MS programmed to sample in an evacuated canister to a (final) canister pressure

acquire data for only specified ions and to disregard all others. below atmospheric pressure, with or without the assistance of

a sampling pump.

This is performed using SIM coupled to retention time dis-

criminators. The GC-SIM analysis provides quantitative results 3.2.14.1 Discussion—The canister is filled as the internal

D 5466

canister pressure increases to ambient or near ambient pres-

TABLE 2 Continued

sure. An auxiliary vacuum pump may be used as part of the

Ion/

Expected

sampling system to flush the inlet tubing prior to or during

Abundance

Compound Retention

(amu/%

sample collection.

Time (min)

base peak)

62/70

4. Summary of Test Method

Trichloroethylene (Trichloroethane) 130/100 16.10

132/92

4.1 Both subatmospheric pressure and pressurized sampling

95/87

modes use an evacuated canister. A sampling line less than 2 %

cis-1,3-Dichloropropene 75/100 16.96

39/70

of the volume of the canister or a pump-ventilated sample line

77/30

are used during sample collection. Pressurized sampling re-

trans-1,3-Dichloropropene (1,3-Dichloro-1-propene) 75/100 17.49

quires an additional pump to provide positive pressure to the

39/70

77/30

sample canister. A sample of air is drawn through a sampling

1,1,2-Trichloroethane (Vinyl trichloride) 97/100 17.61

train comprising components that regulate the rate and duration

83/90

of sampling into a precleaned and pre-evacuated SUMMAt

61/82

Toluene (Methyl benzene) 91/100 17.86

passivated canister.

92/57

1,2-Dibromoethane (Ethylene dibromide) 107/100 18.48

TABLE 2 Ion/Abundance and Expected Retention Time for

109/96

Selected VOCs Analyzed by GC-MS-SIM 27/115

Tetrachloroethylene (Perchloroethylene) 166/100 19.01

164/74

Ion/

Expected

131/60

Abundance

Compound Retention

Chlorobenzene (Benzene chloride) 112/100 19.73

(amu/%

Time (min)

77/62

base peak)

114/32

Freon 12 (Dichlorodifluoromethane) 85/100 5.01

Ethylbenzene 91/100 20.20

87/31

106/28

Methyl chloride (Chloromethane) 50/100 5.69

m,p-Xylene (1,3/1,4-dimethylbenzene) 91/100 20.41

52/34

106/40

Freon 114 (1,2-Dichloro-1,1,2,2-tetrafluoroethane) 85/100 6.55

Styrene (Vinyl benzene) 104/100 20.81

135/56

78/60

87/33

103/49

Vinyl chloride (Chloroethene) 62/100 6.71

1,1,2,2-Tetrachloroethane (Tetrachloroethane) 83/100 20.92

27/125

85/64

64/32

o-Xylene (1,2-Dimethylbenzene) 91/100 20.92

Methyl bromide (Bromomethane) 94/100 7.83

106/40

96/85

4-Ethyltoluene 105/100 22.53

Ethyl chloride (Chloroethane) 64/100 8.43

120/29

29/140

1,3,5-Trimethylbenzene (Mesitylene) 105/100 22.65

27/140

120/42

Freon 11 (Trichlorofluoromethane) 101/100 9.97

1,2,4-Trimethylbenzene (Pseudocumene) 105/100 23.18

103/67

120/42

Vinylidene chloride (1,1-Dichloroethylene) 61/100 10.93

m-Dichlorobenzene (1,3-Dichlorobenzene) 146/100 23.31

96/55

148/65

63/31

111/40

Dichloromethane (Methylene chloride) 49/100 11.21

Benzyl chloride (a-Chlorotoluene) 91/100 23.32

84/65

126/26

86/45

p-Dichlorobenzene (1,4-Dichlorobenzene) 146/100 23.41

Freon 113 (1,1,2-Trichloro-1,2,2-trifluoroethane) 151/100 11.60

148/65

101/140

111/40

103/90

o-Dichlorobenzene (1,2-Dichlorobenzene) 146/100 23.88

1,1-Dichloroethane (Ethylidene dichloride) 63/100 12.50

148/65

27/64

111/40

65/33

1,2,4-Trichlorobenzene 180/100 26.71

cis-1,2-Dichloroethylene 61/100 13.40

182/98

96/60

184/30

98/44

Hexachlorobutadiene (1,1,2,3,4,4-Hexachloro- 225/100 27.68

Chloroform (Trichloromethane) 83/100 13.75

1,3-butadiene) 227/66

85/65

223/60

47/35

1,2-Dichloroethane (Ethylene dichloride) 62/100 14.39

4.2 After the air sample is collected, the canister isolation

27/70

valve is closed, the canister is removed from the sampler, an

64/31

Methyl chloroform (1,1,1-Trichloroethane) 97/100 14.62 identification tag is attached to the canister, and the canister is

99/64

transported to a laboratory for analysis.

61/61

4.3 Upon receipt at the laboratory, the data on the canister

Benzene (Cyclohexatriene) 78/100 15.04

77/25

tag are recorded and the canister is attached to a pressure gage

50/35

which will allow accurate measurement of the final canister

Carbon tetrachloride (Tetrachloromethane) 117/100 15.18

pressure. During analysis, water vapor may be reduced in the

119/97

1,2-Dichloropropane (Propylene dichloride) 63/100 15.83

gas stream by a Nafion dryer (if applicable), and the VOCs are

41/90

then concentrated by collection in a cryogenically-cooled trap.

D 5466

The cryogen is then removed and the temperature of the trap is over a specific time period (for example, 8 to 24 h), (2) remote

raised. The VOCs originally collected in the trap are revolatil- sampling and central laboratory analysis, (3) ease of storing

ized, separated on a GC column, then detected by a mass and shipping samples, (4) unattended sample collection, (5)

spectrometer. Com

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.