ASTM D4800-94(2015)

(Guide)Standard Guide for Classifying and Specifying Adhesives

Standard Guide for Classifying and Specifying Adhesives

SIGNIFICANCE AND USE

4.1 The purpose of this classification system is to provide a method of identifying adhesives in order to give industry a system that can be used universally for materials. It further provides a means for specifying these materials by the use of the standards that are developed using this guide.

4.2 This classification system was developed to permit the addition of future adhesives.

SCOPE

1.1 This guide provides a classification system for tabulating the properties of adhesives suitable for holding parts or assemblies together. The use of this guide also provides information necessary for the development of standard specifications for adhesives.

Note 1: This classification system may serve many of the needs of industries using adhesives. This guide is subject to revision as the need requires; therefore, the latest revision should always be used.

1.2 Limitations—This classification system is intended to be a means of identifying adhesives. It is not intended for the selection of materials. Material selection should be made by those having expertise in the adhesives field after careful consideration of the design and the performance required of the part, the environment to which it will be exposed, the attachment process to be employed, the inherent properties of the material not covered in this document, and the economic factors.

1.3 This classification system is based on the premise that adhesives can be arranged into broad generic families using basic properties to arrange the materials into groups, classes, and grades.

1.4 In all cases where the provisions of this classification system would conflict with the referenced ASTM specification for a particular material, the latter shall take precedence.

1.5 The values stated in SI units, as detailed in IEEE/ASTM SI 10, are to be regarded as the standard.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4800 − 94 (Reapproved 2015)

Standard Guide for

1

Classifying and Specifying Adhesives

This standard is issued under the fixed designation D4800; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1298 Test Method for Density, Relative Density, or API

Gravity of Crude Petroleum and Liquid Petroleum Prod-

1.1 This guide provides a classification system for tabulat-

ucts by Hydrometer Method

ing the properties of adhesives suitable for holding parts or

D1310 Test Method for Flash Point and Fire Point of Liquids

assemblies together. The use of this guide also provides

by Tag Open-Cup Apparatus

information necessary for the development of standard speci-

D2240 Test Method for Rubber Property—Durometer Hard-

fications for adhesives.

ness

NOTE 1—This classification system may serve many of the needs of

D2583 Test Method for Indentation Hardness of Rigid Plas-

industries using adhesives. This guide is subject to revision as the need

tics by Means of a Barcol Impressor

requires; therefore, the latest revision should always be used.

D2834 Test Method for Nonvolatile Matter (Total Solids) in

1.2 Limitations—This classification system is intended to be

Water-Emulsion Floor Polishes, Solvent-Based Floor

a means of identifying adhesives. It is not intended for the

Polishes, and Polymer-Emulsion Floor Polishes

selection of materials. Material selection should be made by

D3278 Test Methods for Flash Point of Liquids by Small

those having expertise in the adhesives field after careful

Scale Closed-Cup Apparatus

consideration of the design and the performance required of the

D4562 Test Method for Shear Strength of Adhesives Using

part, the environment to which it will be exposed, the attach-

Pin-and-Collar Specimen

ment process to be employed, the inherent properties of the

D5363 Specification for Anaerobic Single-Component Ad-

material not covered in this document, and the economic

hesives (AN)

factors.

IEEE/ASTM SI 10 Standard for Use of the International

1.3 This classification system is based on the premise that System of Units (SI): The Modern Metric System

adhesives can be arranged into broad generic families using

2.2 Military Standards:

basic properties to arrange the materials into groups, classes,

MIL-STD-105 Sampling Procedures and Tables for Inspec-

and grades. 3

tion by Attributes

MIL-A-46146 Adhesive, Silicone, RTV, Noncorrosive (for

1.4 In all cases where the provisions of this classification

3

system would conflict with the referenced ASTM specification Use with Sensitive Metals and Equipment)

for a particular material, the latter shall take precedence.

3. Terminology

1.5 The values stated in SI units, as detailed in IEEE/ASTM

3.1 The terms used in this guide are in accordance with

SI 10, are to be regarded as the standard.

Terminology D907.

2. Referenced Documents

2 4. Significance and Use

2.1 ASTM Standards:

D907 Terminology of Adhesives 4.1 The purpose of this classification system is to provide a

D1084 Test Methods for Viscosity of Adhesives method of identifying adhesives in order to give industry a

system that can be used universally for materials. It further

provides a means for specifying these materials by the use of

1 the standards that are developed using this guide.

This guide is under the jurisdiction of ASTM Committee D14 on Adhesives and

is the direct responsibility of Subcommittee D14.60 on Adhesive Material Classi-

4.2 This classification system was developed to permit the

fication System.

addition of future adhesives.

Current edition approved Sept. 1, 2015. Published September 2015. Originally

approved in 1987. Last previous edition approved in 2011 as D4800 – 94 (2011).

DOI: 10.1520/D4800-94R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. dodssp.daps.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4800 − 94 (2015)

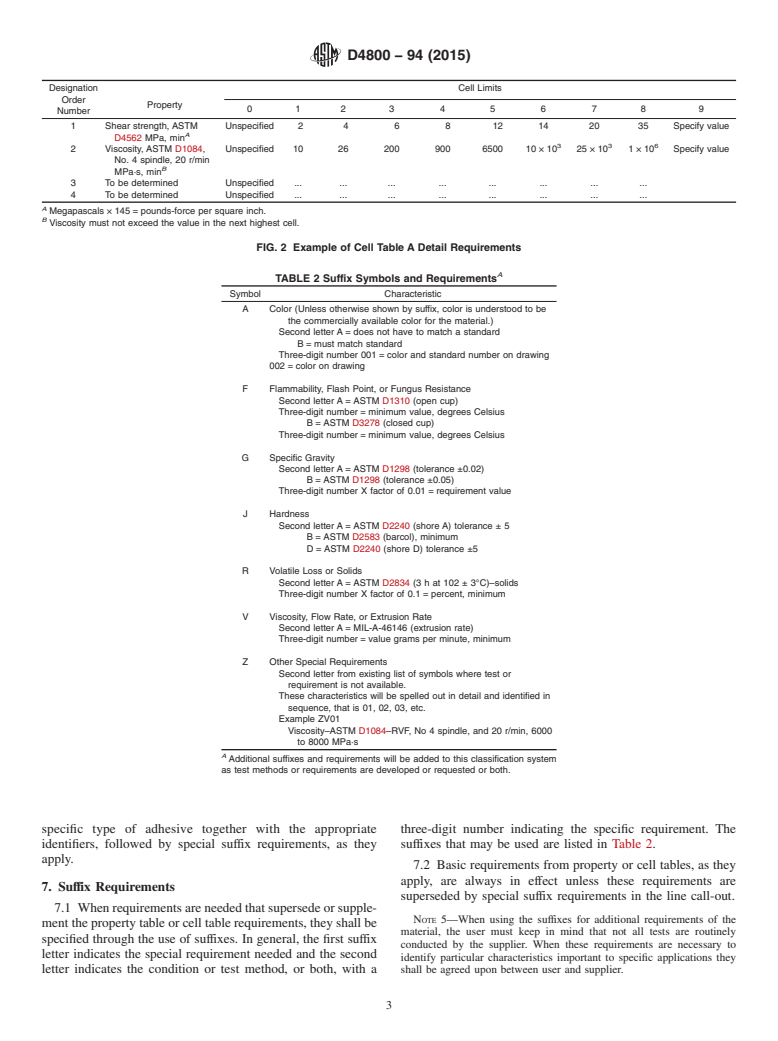

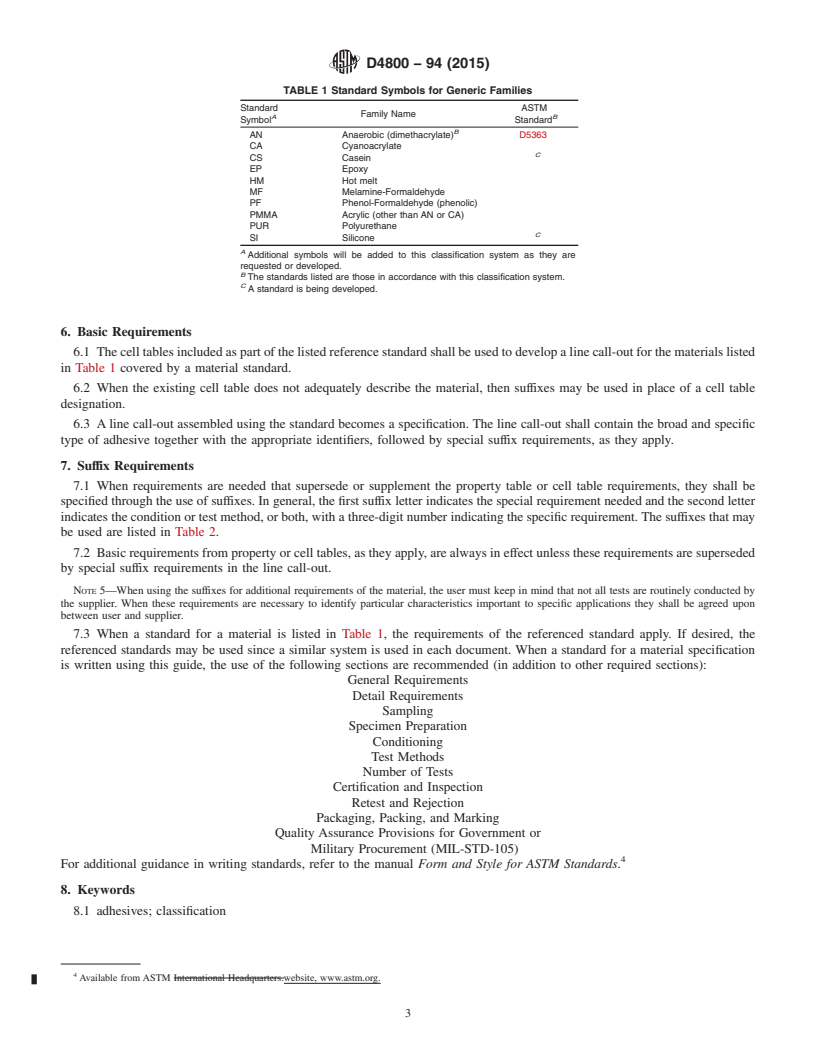

TABLE 1 Standard Symbols for Generic Families

5. Classification

Standard ASTM

5.1 Fig. 1 summarizes the classification system as detailed

Family Name

A B

Symbol Standard

in this guide.

B

AN Anaerobic (dimethacrylate) D5363

CA Cyanoacrylate

5.2 Adhesives shall be classified on the b

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4800 − 94 (Reapproved 2011) D4800 − 94 (Reapproved 2015)

Standard Guide for

1

Classifying and Specifying Adhesives

This standard is issued under the fixed designation D4800; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide provides a classification system for tabulating the properties of adhesives suitable for holding parts or assemblies

together. The use of this guide also provides information necessary for the development of standard specifications for adhesives.

NOTE 1—This classification system may serve many of the needs of industries using adhesives. This guide is subject to revision as the need requires;

therefore, the latest revision should always be used.

1.2 Limitations—This classification system is intended to be a means of identifying adhesives. It is not intended for the selection

of materials. Material selection should be made by those having expertise in the adhesives field after careful consideration of the

design and the performance required of the part, the environment to which it will be exposed, the attachment process to be

employed, the inherent properties of the material not covered in this document, and the economic factors.

1.3 This classification system is based on the premise that adhesives can be arranged into broad generic families using basic

properties to arrange the materials into groups, classes, and grades.

1.4 In all cases where the provisions of this classification system would conflict with the referenced ASTM specification for a

particular material, the latter shall take precedence.

1.5 The values stated in SI units, as detailed in IEEE/ASTM SI 10, are to be regarded as the standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D907 Terminology of Adhesives

D1084 Test Methods for Viscosity of Adhesives

D1298 Test Method for Density, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by

Hydrometer Method

D1310 Test Method for Flash Point and Fire Point of Liquids by Tag Open-Cup Apparatus

D2240 Test Method for Rubber Property—Durometer Hardness

D2583 Test Method for Indentation Hardness of Rigid Plastics by Means of a Barcol Impressor

D2834 Test Method for Nonvolatile Matter (Total Solids) in Water-Emulsion Floor Polishes, Solvent-Based Floor Polishes, and

Polymer-Emulsion Floor Polishes

D3278 Test Methods for Flash Point of Liquids by Small Scale Closed-Cup Apparatus

D4562 Test Method for Shear Strength of Adhesives Using Pin-and-Collar Specimen

D5363 Specification for Anaerobic Single-Component Adhesives (AN)

IEEE/ASTM SI 10 Standard for Use of the International System of Units (SI): The Modern Metric System

2.2 Military Standards:

3

MIL-STD-105 Sampling Procedures and Tables for Inspection by Attributes

3

MIL-A-46146 Adhesive, Silicone, RTV, Noncorrosive (for Use with Sensitive Metals and Equipment)

3. Terminology

3.1 The terms used in this guide are in accordance with Terminology D907.

1

This guide is under the jurisdiction of ASTM Committee D14 on Adhesives and is the direct responsibility of Subcommittee D14.60 on Adhesive Material Classification

System.

Current edition approved Dec. 1, 2011Sept. 1, 2015. Published December 2011September 2015. Originally approved in 1987. Last previous edition approved in 20052011

as D4800 – 94 (2005).(2011). DOI: 10.1520/D4800-94R11.10.1520/D4800-94R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://dodssp.daps.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4800 − 94 (2015)

4. Significance and Use

4.1 The purpose of this classification system is to provide a method of identifying adhesives in order to give industry a system

that can be used universally for materials. It further provides a means for specifying these materials by the use of the standards

that are developed using this guide.

4.2 This classification system

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.